How to Use 3v 3a Dc Pump: Examples, Pinouts, and Specs

Design with 3v 3a Dc Pump in Cirkit Designer

Design with 3v 3a Dc Pump in Cirkit DesignerIntroduction

The 3V 3A DC Pump (Manufacturer: ZyrexRobotics, Part ID: DC Pump) is a compact and efficient electric pump designed to operate on a 3-volt direct current (DC) supply. With a maximum current rating of 3 amps, this pump is ideal for applications requiring the movement of liquids in small-scale systems. Its versatility and reliability make it a popular choice for projects such as aquariums, water cooling systems, and micro-irrigation setups.

Explore Projects Built with 3v 3a Dc Pump

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 3v 3a Dc Pump

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Aquariums: Circulating and aerating water for aquatic life.

- Cooling Systems: Pumping coolant in small electronic or mechanical systems.

- Irrigation: Delivering water in small-scale gardening or hydroponic systems.

- DIY Projects: Custom liquid-handling solutions for hobbyists and makers.

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Operating Voltage | 3V DC |

| Maximum Current | 3A |

| Flow Rate | ~1.5–2.5 liters per minute (varies by load) |

| Maximum Lift Height | ~1.5 meters |

| Inlet/Outlet Diameter | ~5 mm |

| Operating Temperature | 0°C to 50°C |

| Dimensions | ~40 mm x 30 mm x 25 mm |

| Weight | ~50 grams |

Pin Configuration and Descriptions

The 3V 3A DC Pump has two wires for electrical connection:

| Wire Color | Function | Description |

|---|---|---|

| Red | Positive (+) | Connect to the positive terminal of the power supply. |

| Black | Negative (-) | Connect to the negative terminal of the power supply. |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Ensure you have a stable 3V DC power source capable of supplying up to 3A. A battery pack or a DC power adapter is recommended.

- Connections:

- Connect the red wire of the pump to the positive terminal of the power supply.

- Connect the black wire of the pump to the negative terminal of the power supply.

- Liquid Handling:

- Attach tubing to the inlet and outlet ports of the pump. Ensure the tubing is securely fastened to prevent leaks.

- Submerge the pump in the liquid (if it is submersible) or ensure the inlet is properly primed for non-submersible models.

- Operation:

- Turn on the power supply to activate the pump. The pump will begin moving liquid through the tubing.

Important Considerations and Best Practices

- Power Supply: Avoid exceeding the rated voltage (3V DC) to prevent damage to the pump.

- Current Limitation: Ensure the power source can deliver up to 3A without significant voltage drops.

- Polarity: Double-check the wire connections to avoid reversing polarity, which can damage the pump.

- Dry Run: Do not operate the pump without liquid, as this can cause overheating and damage.

- Maintenance: Periodically clean the pump and tubing to prevent clogs or buildup of debris.

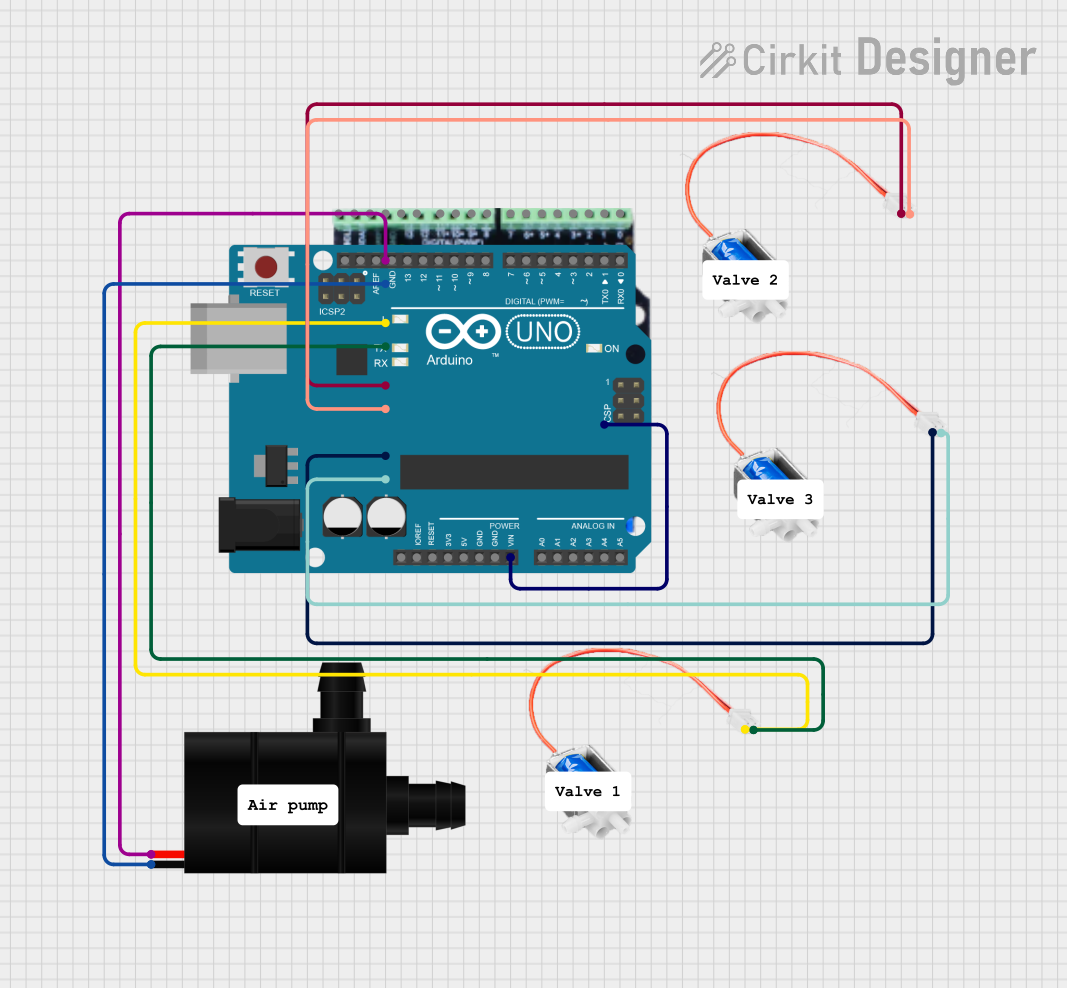

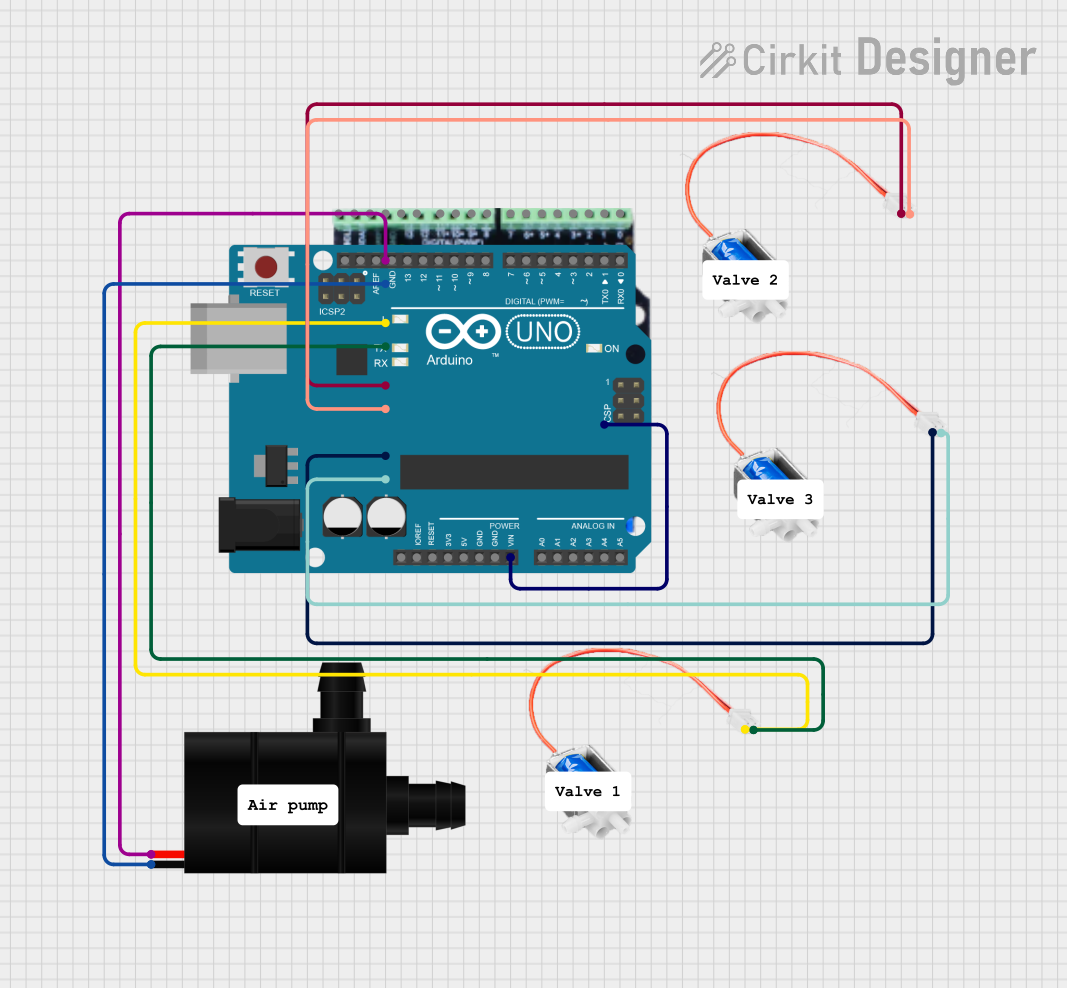

Example: Using the Pump with an Arduino UNO

The 3V 3A DC Pump can be controlled using an Arduino UNO and a transistor or relay module. Below is an example circuit and code to control the pump using a relay module.

Circuit Setup

- Connect the pump's red wire to the relay module's NO (Normally Open) terminal.

- Connect the pump's black wire to the relay module's COM (Common) terminal.

- Connect the relay module's VCC, GND, and IN pins to the Arduino's 5V, GND, and a digital pin (e.g., D7), respectively.

- Use an external 3V DC power supply to power the pump.

Arduino Code

// Arduino code to control a 3V 3A DC pump using a relay module

const int relayPin = 7; // Pin connected to the relay module's IN pin

void setup() {

pinMode(relayPin, OUTPUT); // Set the relay pin as an output

digitalWrite(relayPin, LOW); // Ensure the pump is off at startup

}

void loop() {

// Turn the pump ON

digitalWrite(relayPin, HIGH);

delay(5000); // Keep the pump on for 5 seconds

// Turn the pump OFF

digitalWrite(relayPin, LOW);

delay(5000); // Keep the pump off for 5 seconds

}

Troubleshooting and FAQs

Common Issues and Solutions

Pump Does Not Start:

- Cause: Insufficient power supply or incorrect wiring.

- Solution: Verify the power supply voltage and current ratings. Check the wire connections for proper polarity.

Low Flow Rate:

- Cause: Clogged tubing or pump inlet.

- Solution: Inspect and clean the tubing and pump inlet to remove any blockages.

Pump Overheats:

- Cause: Operating the pump without liquid or exceeding the rated voltage.

- Solution: Ensure the pump is submerged or primed with liquid. Use a regulated 3V DC power supply.

Noise or Vibration:

- Cause: Loose mounting or air trapped in the pump.

- Solution: Securely mount the pump and ensure proper priming to remove air bubbles.

FAQs

Q: Can the pump handle hot liquids?

- A: The pump is designed for liquids within the operating temperature range of 0°C to 50°C. Avoid using it with hot liquids above this range.

Q: Is the pump waterproof?

- A: Check the product specifications from ZyrexRobotics. If it is a submersible model, it can be fully submerged; otherwise, ensure only the inlet is in contact with liquid.

Q: Can I control the pump speed?

- A: The pump does not have built-in speed control. You can use a PWM (Pulse Width Modulation) controller or a variable power supply to adjust the speed.

Q: What type of tubing should I use?

- A: Use tubing with an inner diameter of approximately 5 mm to ensure a secure fit with the pump's inlet and outlet ports.

This concludes the documentation for the 3V 3A DC Pump by ZyrexRobotics. For further assistance, refer to the manufacturer's support resources.