How to Use TMC2226 Stepper Driver: Examples, Pinouts, and Specs

Design with TMC2226 Stepper Driver in Cirkit Designer

Design with TMC2226 Stepper Driver in Cirkit DesignerIntroduction

The TMC2226 is a high-performance stepper motor driver manufactured by Trinamic (TMC). It is designed for precise and efficient control of stepper motors, offering advanced features such as microstepping, current control, and low-noise operation. The TMC2226 is particularly well-suited for applications requiring smooth and quiet motor operation, such as 3D printers, CNC machines, and robotics.

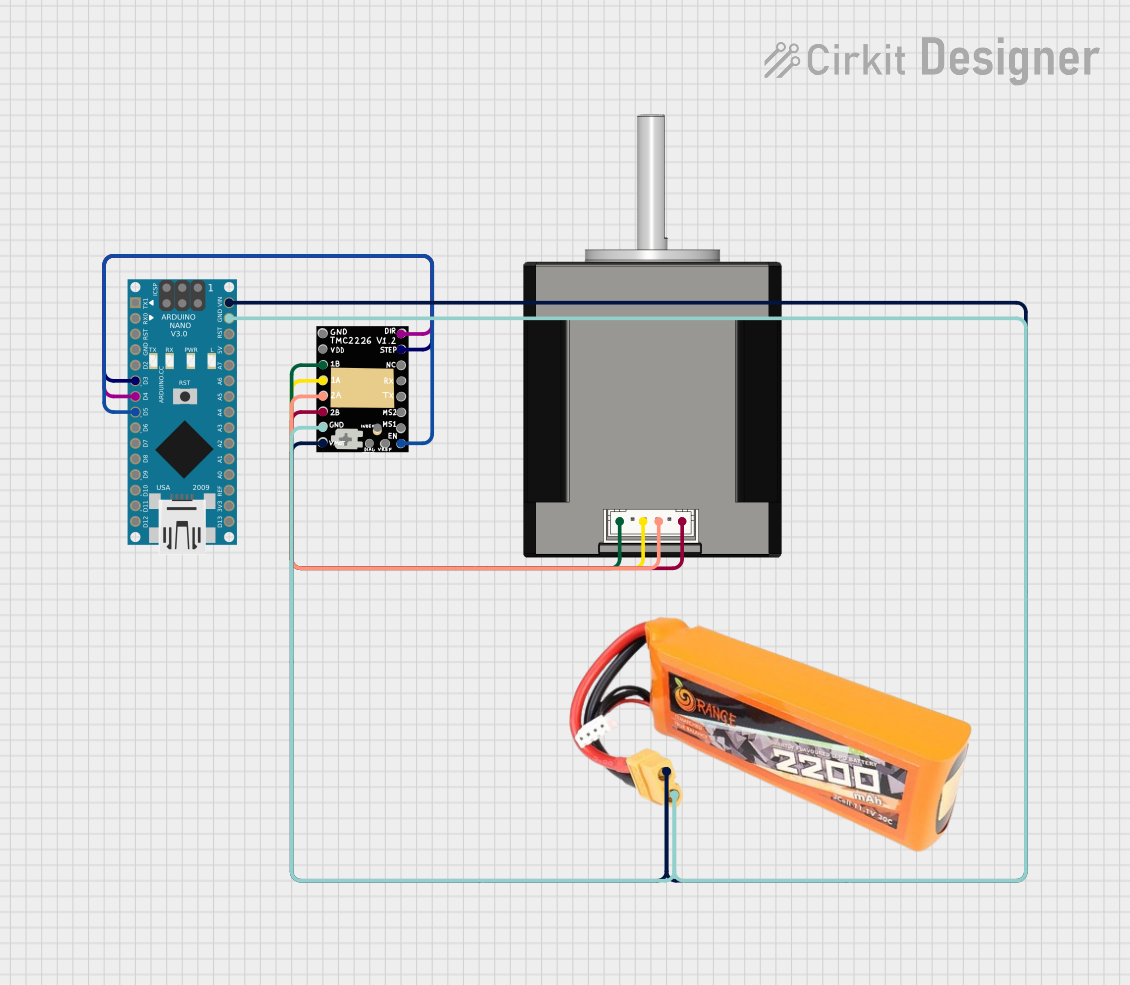

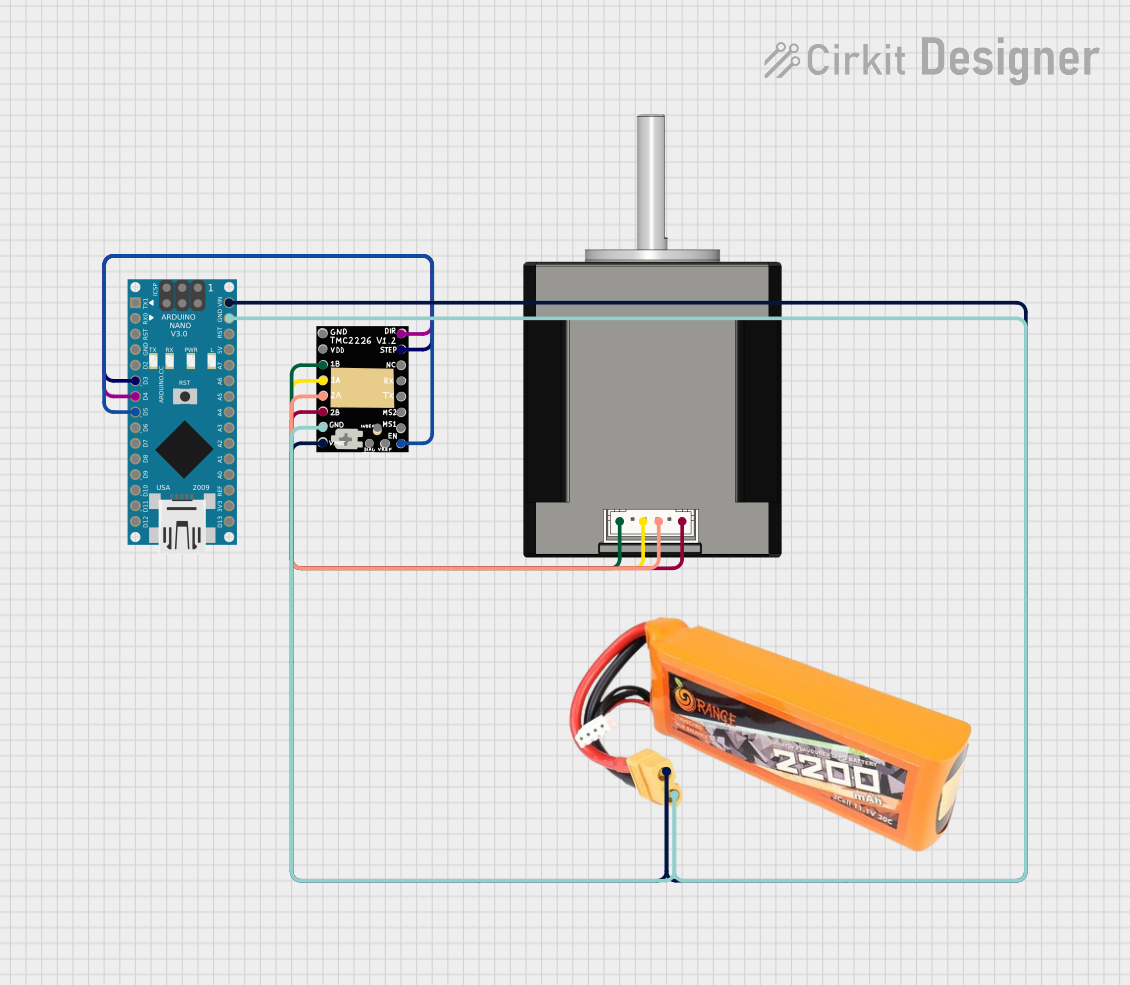

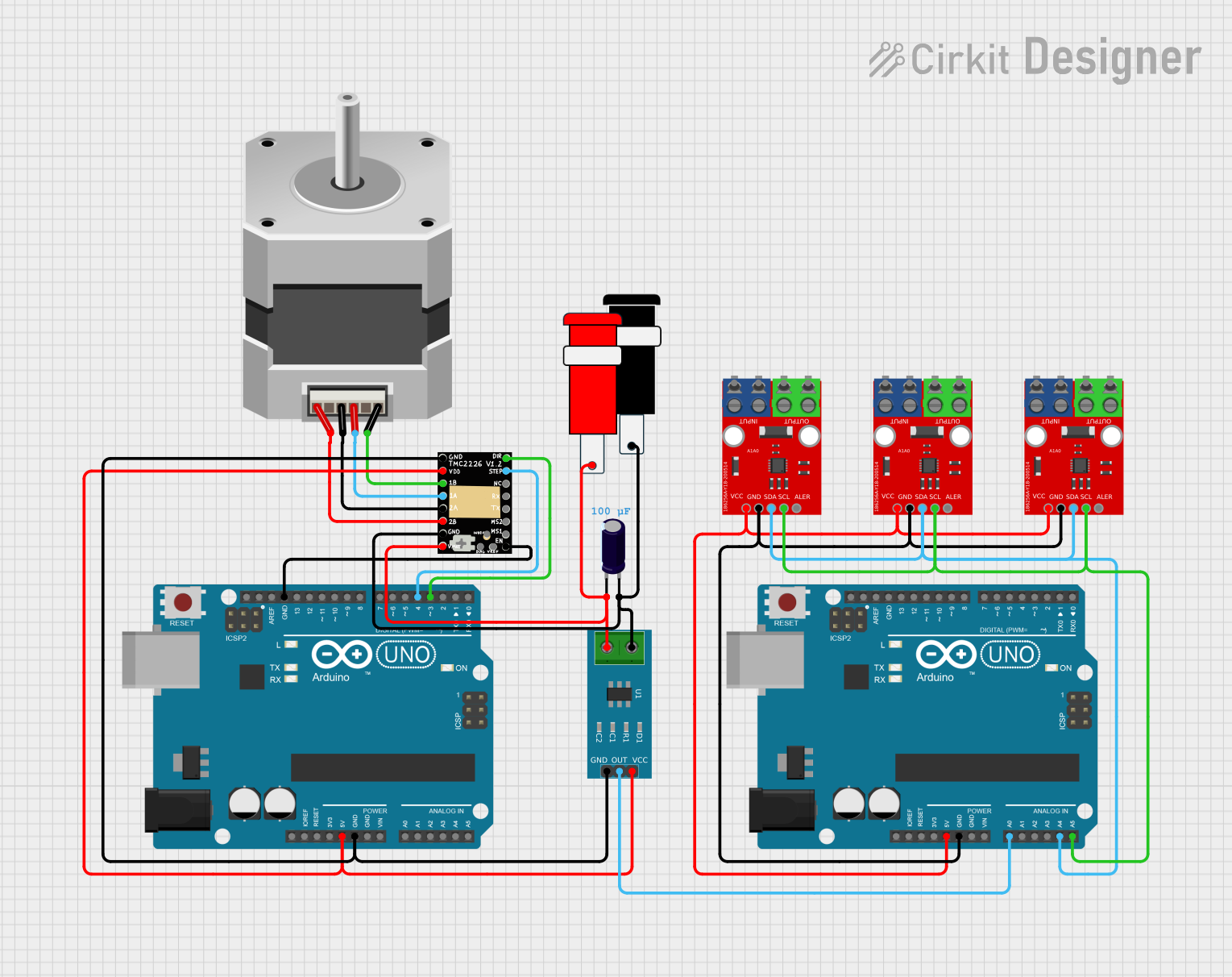

Explore Projects Built with TMC2226 Stepper Driver

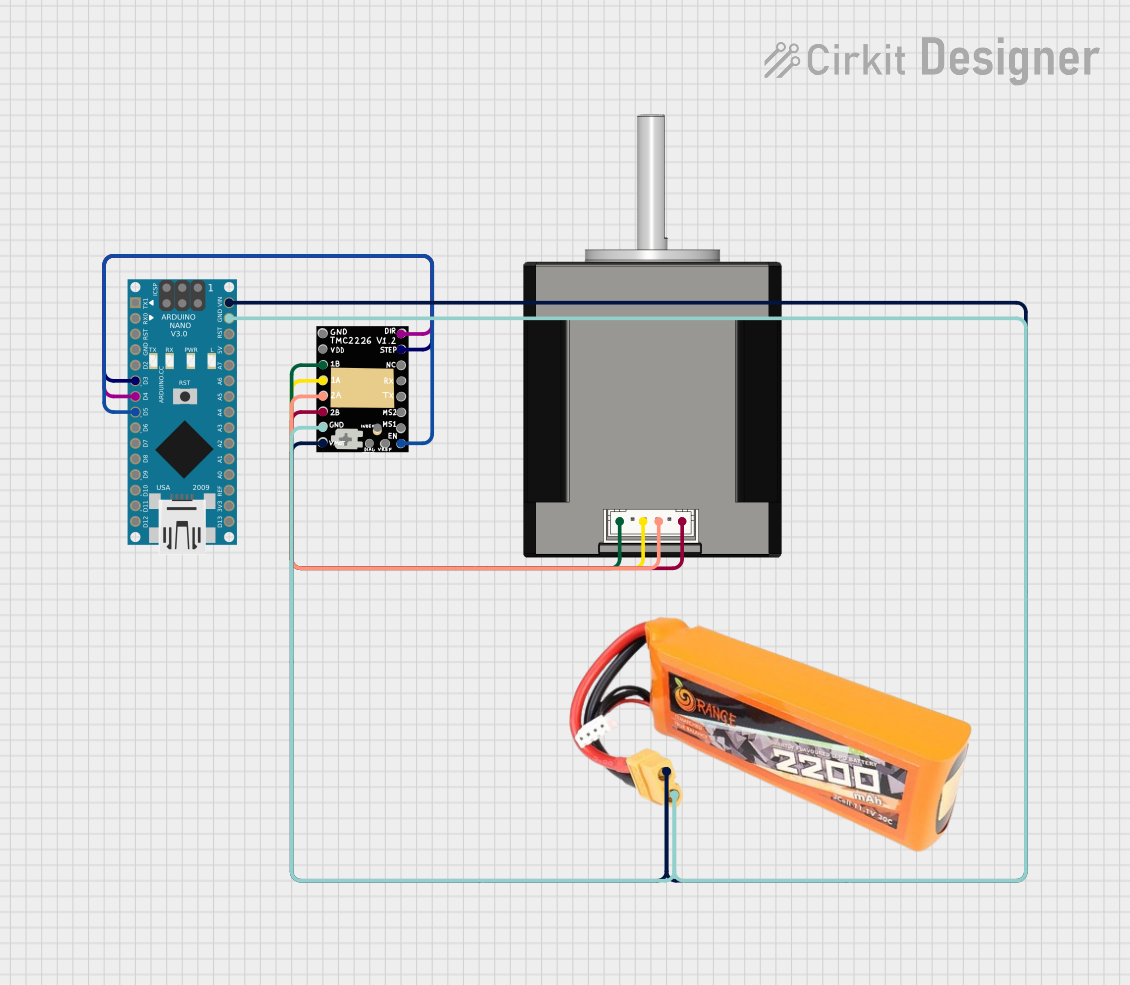

Open Project in Cirkit Designer

Open Project in Cirkit Designer

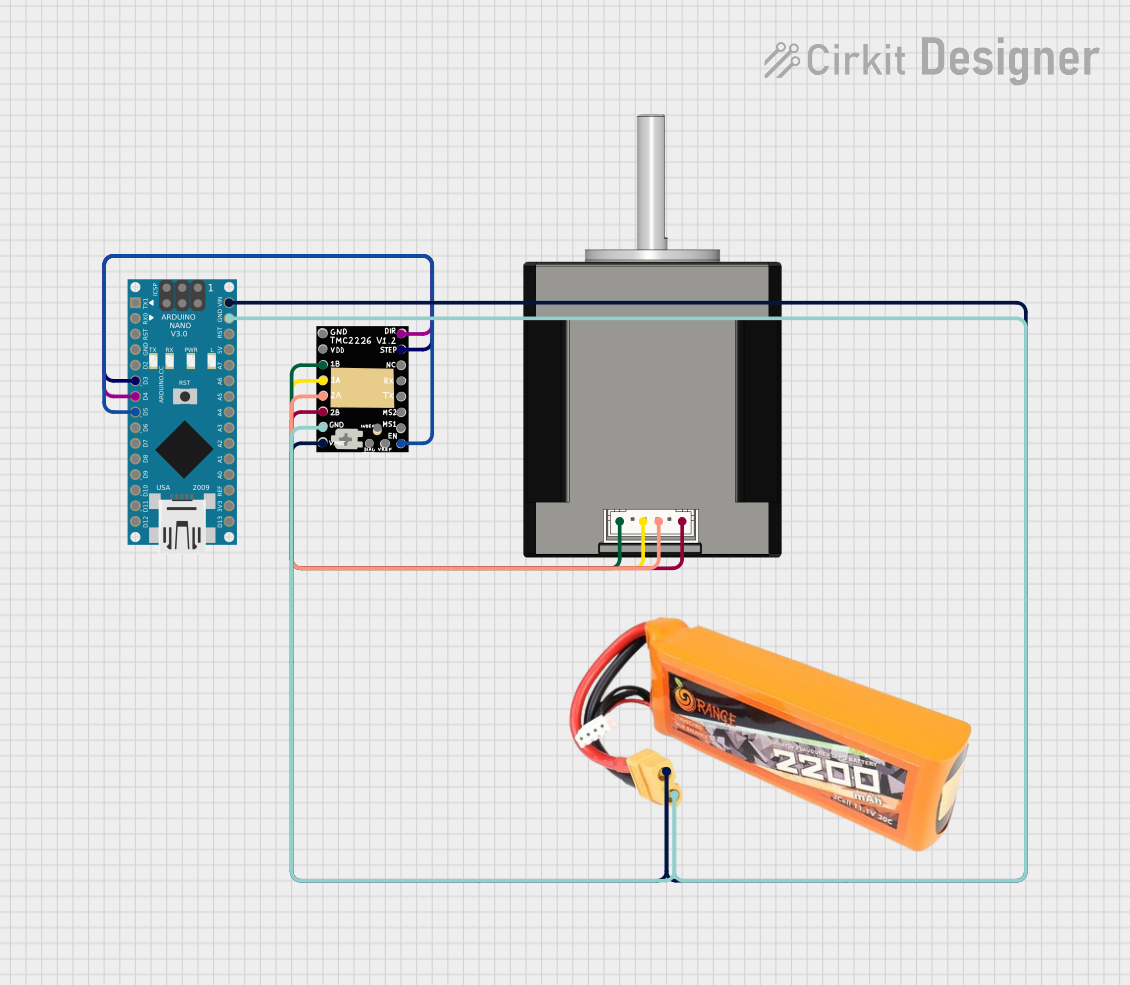

Open Project in Cirkit Designer

Open Project in Cirkit Designer

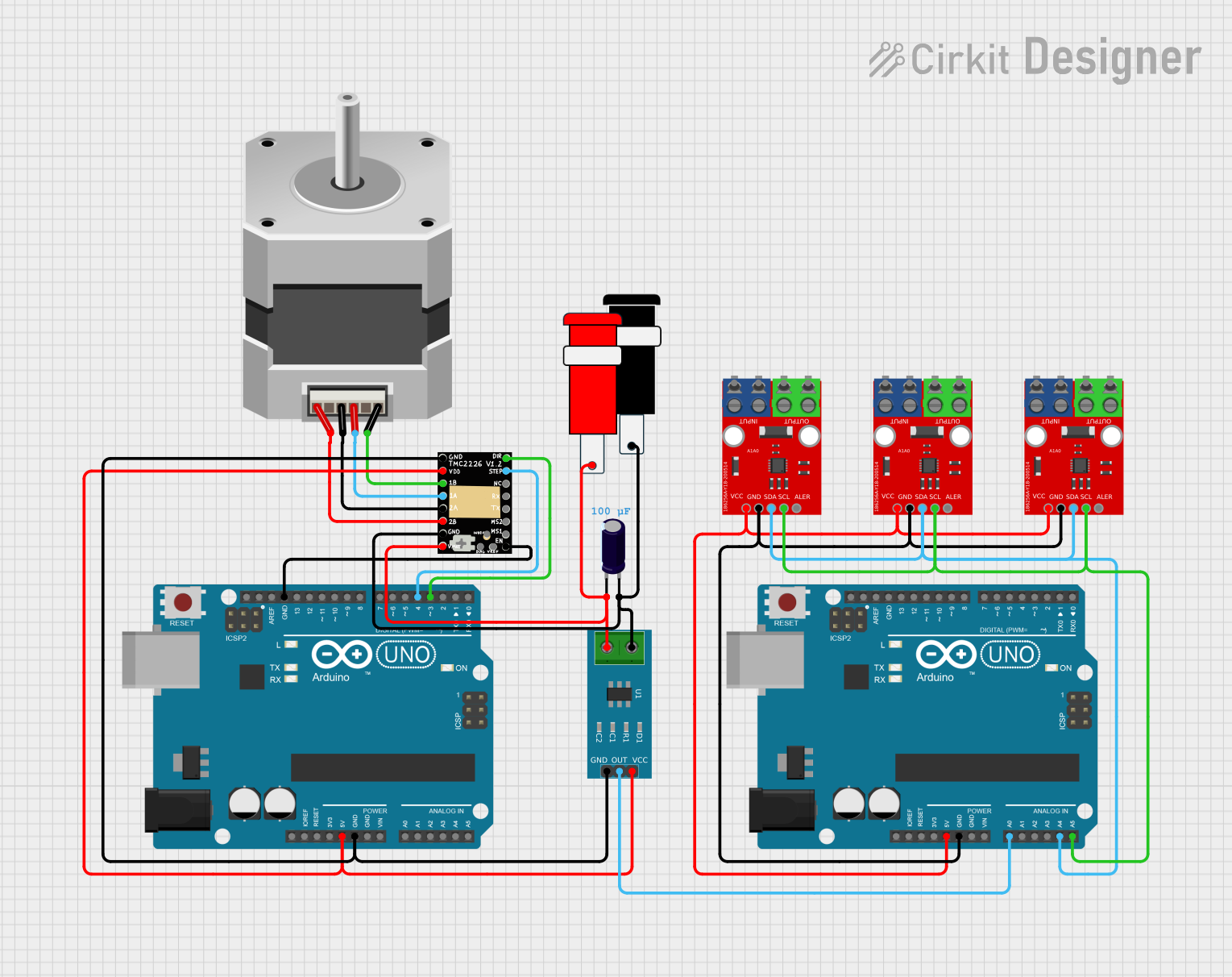

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with TMC2226 Stepper Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- 3D printers for precise and quiet motor control

- CNC machines for accurate positioning

- Robotics for smooth and efficient motion

- Automated systems requiring low-noise stepper motor operation

Technical Specifications

The TMC2226 is a versatile and feature-rich stepper driver. Below are its key technical specifications:

| Parameter | Value |

|---|---|

| Supply Voltage (V_M) | 4.75V to 29V |

| Logic Voltage (V_IO) | 3.3V or 5V |

| Maximum Motor Current | Up to 2.8A (peak) per phase |

| Microstepping Resolution | Up to 1/256 steps |

| Communication Interface | UART |

| Standby Current | Ultra-low standby current |

| Operating Temperature | -40°C to +125°C |

| Features | StealthChop2™, SpreadCycle™, CoolStep™, StallGuard4™ |

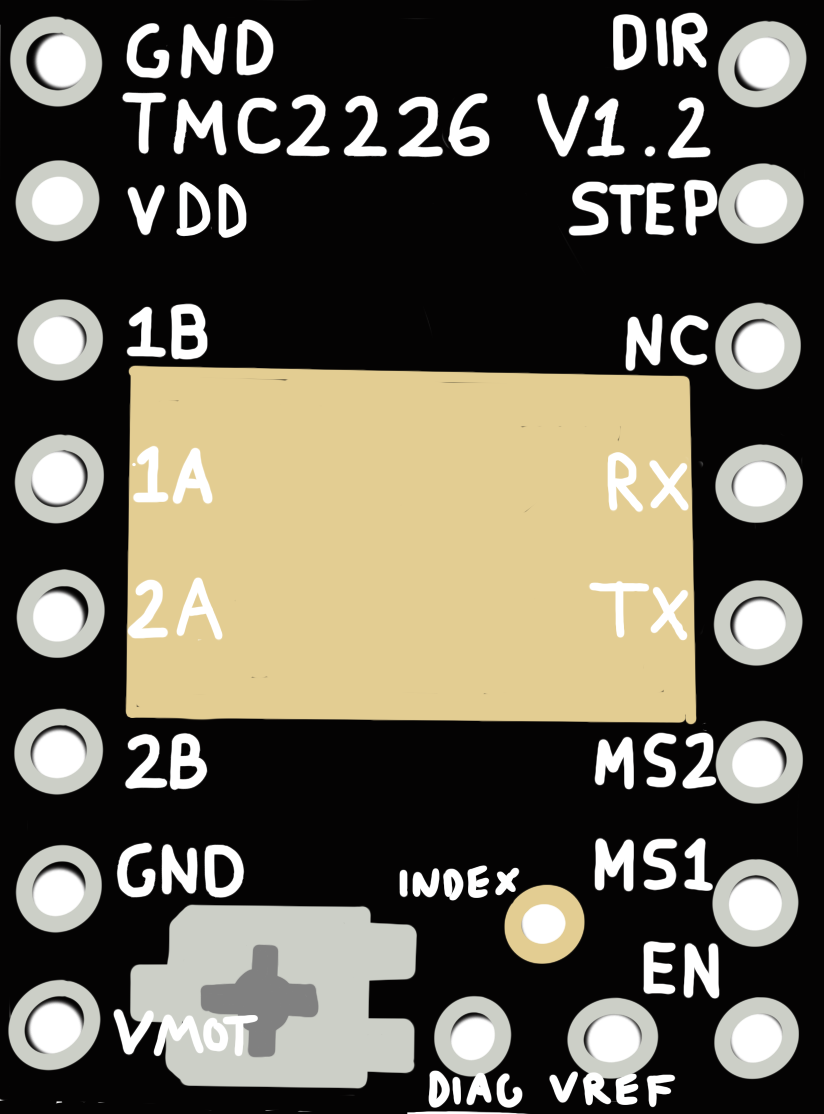

Pin Configuration and Descriptions

The TMC2226 comes in a 28-pin HTSSOP package. Below is the pin configuration and description:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | V_M | Motor power supply (4.75V to 29V) |

| 2 | GND | Ground connection |

| 3 | ENN | Enable input (active low) |

| 4 | DIR | Direction input for motor rotation |

| 5 | STEP | Step pulse input |

| 6 | UART | UART data input/output for configuration and diagnostics |

| 7 | V_IO | Logic voltage supply (3.3V or 5V) |

| 8 | MS1 | Microstep resolution selection input 1 |

| 9 | MS2 | Microstep resolution selection input 2 |

| 10 | DIAG | Diagnostic output (e.g., stall detection) |

| 11-28 | Various | Motor phase outputs, additional configuration, and power connections |

Refer to the TMC2226 datasheet for a complete pinout and detailed descriptions.

Usage Instructions

How to Use the TMC2226 in a Circuit

- Power Supply: Connect the motor power supply (V_M) to a voltage source between 4.75V and 29V. Ensure the logic voltage (V_IO) matches your microcontroller's logic level (3.3V or 5V).

- Motor Connections: Connect the stepper motor's two coils to the appropriate motor phase output pins.

- Control Signals: Use the STEP and DIR pins to control the motor's movement and direction. Optionally, configure microstepping using the MS1 and MS2 pins.

- UART Configuration: For advanced features like StealthChop2™ or StallGuard4™, connect the UART pin to your microcontroller for communication.

- Enable Pin: Pull the ENN pin low to enable the driver.

Important Considerations and Best Practices

- Heat Dissipation: The TMC2226 can generate heat during operation. Use a heatsink or ensure proper ventilation to prevent overheating.

- Microstepping: For smoother motor operation, configure the driver for higher microstepping resolutions (e.g., 1/16 or 1/256 steps).

- Current Limiting: Set the motor current limit appropriately to avoid damaging the motor or driver.

- Noise Reduction: Enable StealthChop2™ mode for ultra-quiet operation, especially in noise-sensitive applications.

Example: Using the TMC2226 with an Arduino UNO

Below is an example of how to control a stepper motor using the TMC2226 and an Arduino UNO:

// Include necessary libraries

#include <TMCStepper.h>

// Define TMC2226 pins

#define EN_PIN 8 // Enable pin

#define DIR_PIN 5 // Direction pin

#define STEP_PIN 6 // Step pin

#define SERIAL_PORT Serial // UART communication port

// Define motor current (in milliamps)

#define R_SENSE 0.11 // Sense resistor value

TMC2226Stepper driver(&SERIAL_PORT, R_SENSE); // Initialize driver

void setup() {

pinMode(EN_PIN, OUTPUT);

pinMode(DIR_PIN, OUTPUT);

pinMode(STEP_PIN, OUTPUT);

digitalWrite(EN_PIN, LOW); // Enable the driver

SERIAL_PORT.begin(115200); // Initialize UART communication

driver.begin(); // Initialize TMC2226

driver.toff(5); // Enable driver

driver.rms_current(800); // Set motor current to 800mA

driver.microsteps(16); // Set microstepping to 1/16

}

void loop() {

digitalWrite(DIR_PIN, HIGH); // Set direction

for (int i = 0; i < 200; i++) {

digitalWrite(STEP_PIN, HIGH);

delayMicroseconds(1000); // Step delay

digitalWrite(STEP_PIN, LOW);

delayMicroseconds(1000);

}

delay(1000); // Wait before changing direction

digitalWrite(DIR_PIN, LOW); // Reverse direction

for (int i = 0; i < 200; i++) {

digitalWrite(STEP_PIN, HIGH);

delayMicroseconds(1000);

digitalWrite(STEP_PIN, LOW);

delayMicroseconds(1000);

}

delay(1000);

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Ensure the ENN pin is pulled low to enable the driver.

- Verify the STEP and DIR signals are being sent correctly.

- Check the motor connections and ensure the power supply is adequate.

Overheating:

- Use a heatsink or improve ventilation around the driver.

- Reduce the motor current limit using the UART interface or configuration pins.

Noisy Operation:

- Enable StealthChop2™ mode for quieter operation.

- Check for loose connections or mechanical issues with the motor.

Stall Detection Not Working:

- Ensure StallGuard4™ is enabled and properly configured via UART.

- Verify the motor current and load conditions are within the recommended range.

FAQs

Q: Can the TMC2226 operate without UART?

A: Yes, the TMC2226 can operate in standalone mode using the STEP, DIR, and microstepping pins. However, UART is required for advanced features like StealthChop2™ and StallGuard4™.

Q: What is the maximum microstepping resolution?

A: The TMC2226 supports up to 1/256 microstepping for ultra-smooth motor operation.

Q: How do I set the motor current limit?

A: The motor current limit can be set via UART or by adjusting the sense resistor value (R_SENSE).

Q: Is the TMC2226 compatible with 5V logic?

A: Yes, the TMC2226 supports both 3.3V and 5V logic levels for compatibility with a wide range of microcontrollers.