Cirkit Designer

Your all-in-one circuit design IDE

Home /

Component Documentation

How to Use L298N DC motor driver: Examples, Pinouts, and Specs

Design with L298N DC motor driver in Cirkit Designer

Design with L298N DC motor driver in Cirkit DesignerIntroduction

The L298N DC Motor Driver Module, manufactured by STM32 with part ID Uno, is a versatile and robust dual H-bridge motor driver. It allows for the control of the speed and direction of two DC motors independently. With a current handling capacity of up to 2A per channel, it is widely used in robotics, automation projects, and other applications requiring precise motor control.

Explore Projects Built with L298N DC motor driver

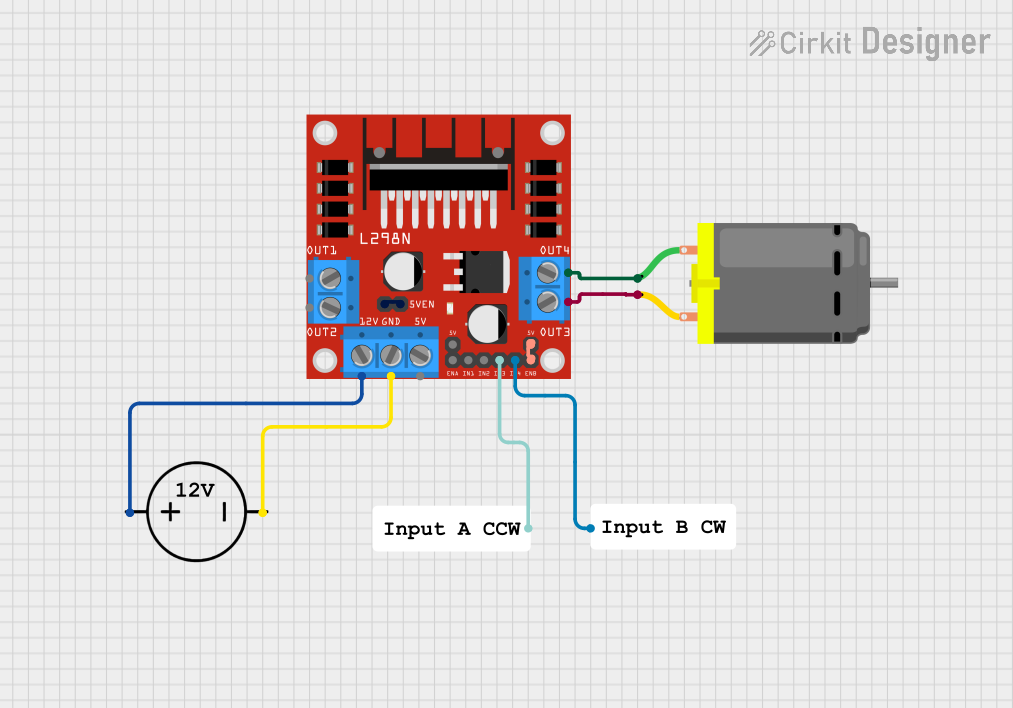

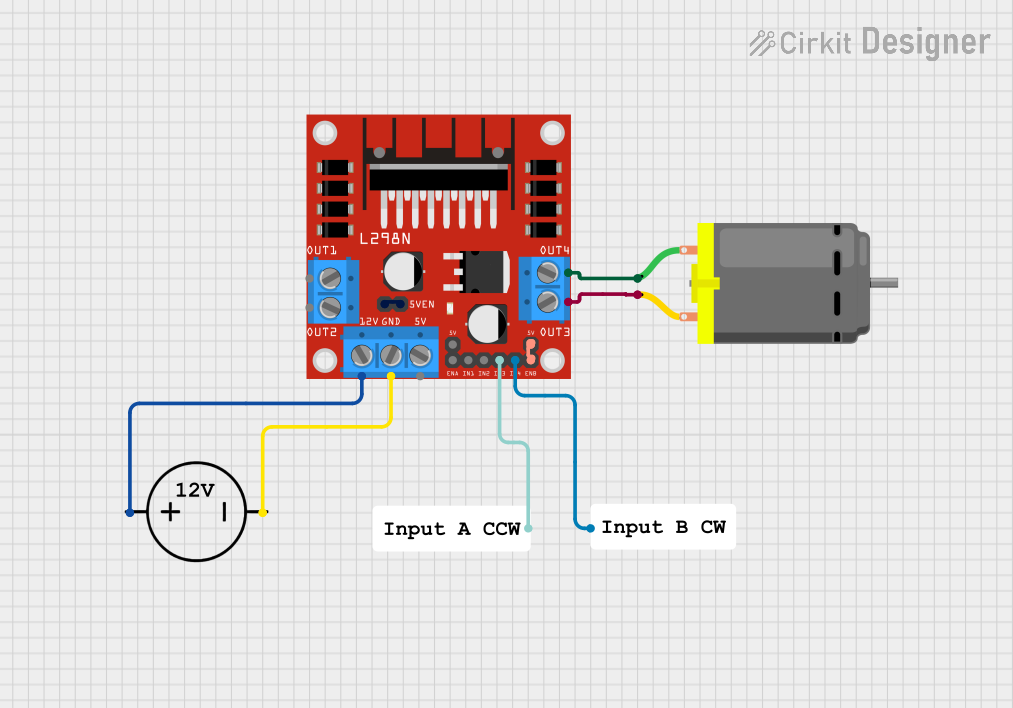

L298N DC Motor Driver Controlled DC Motor System

This circuit is designed to control a DC motor using an L298N motor driver module. The motor driver is powered by a DC power source and interfaces with the motor through its output pins, while resistors are used to manage the input signals to the driver.

Open Project in Cirkit Designer

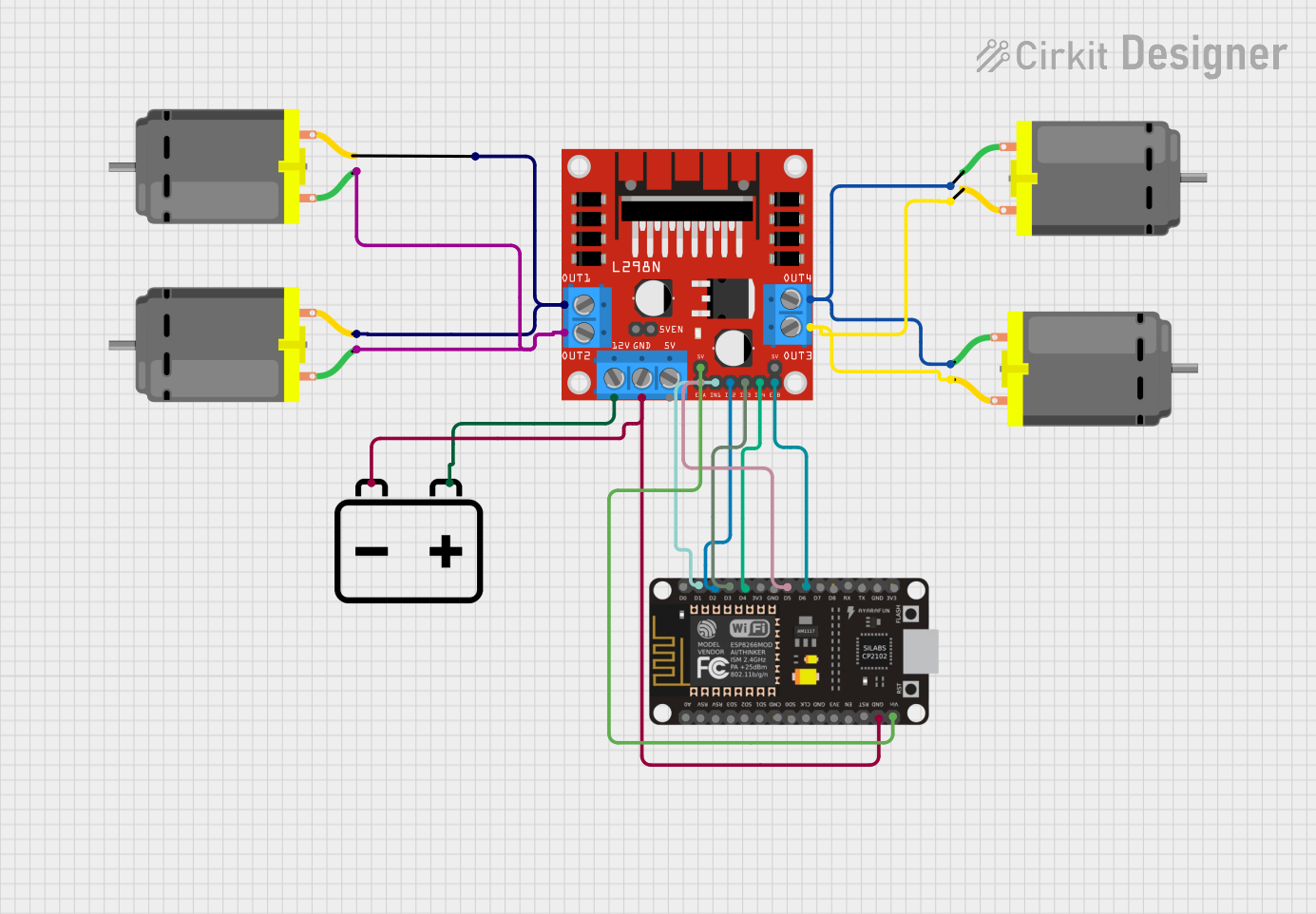

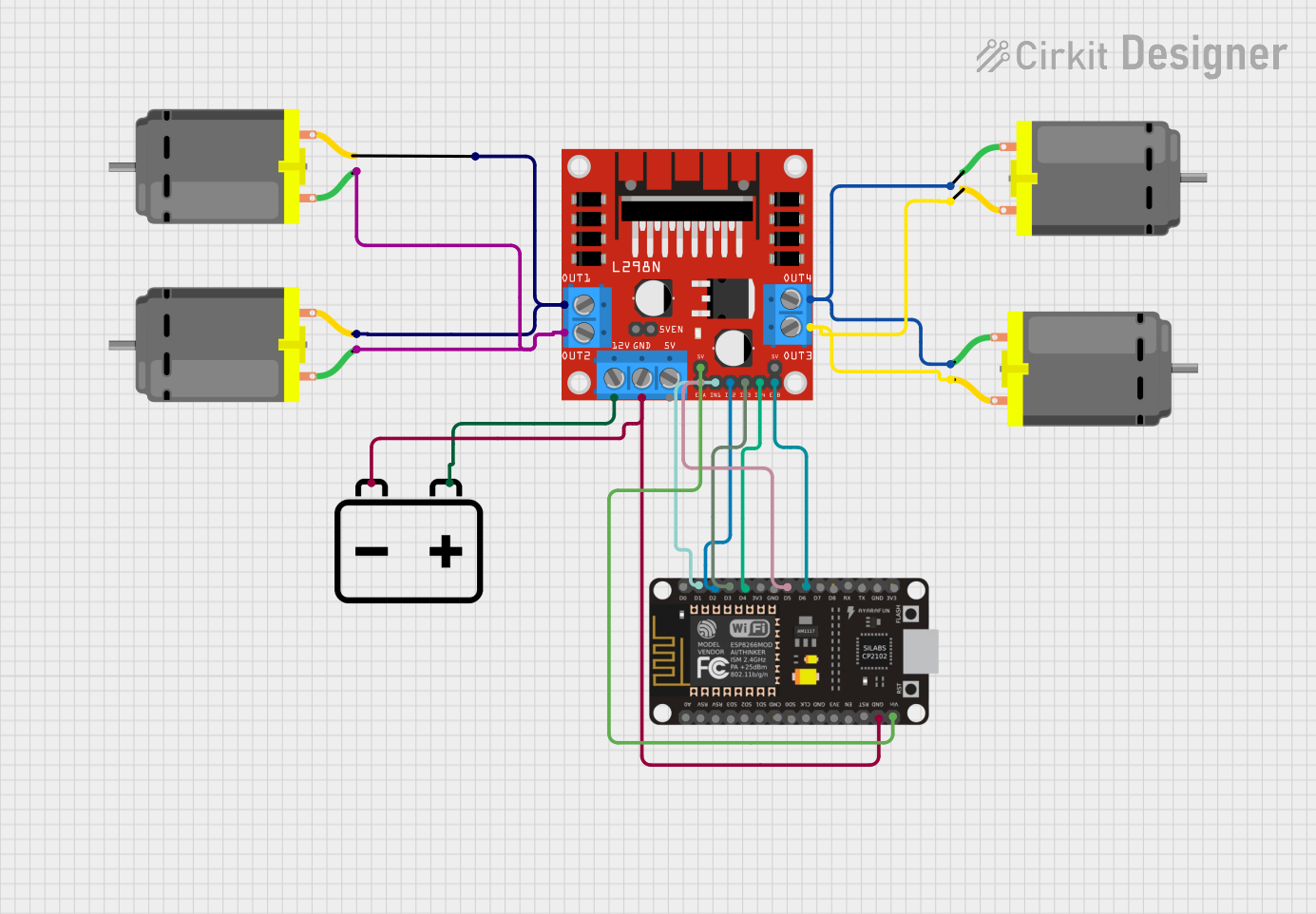

Open Project in Cirkit DesignerWi-Fi Controlled Quad DC Motor Driver System

This circuit is designed to control four DC motors using an L298N motor driver module, which is interfaced with an ESP8266 NodeMCU microcontroller. The NodeMCU's digital pins (D1-D6) are connected to the input pins of the L298N to control the speed and direction of the motors. A 12V battery provides power to the motors through the motor driver, and also powers the NodeMCU through a voltage regulator on the L298N.

Open Project in Cirkit Designer

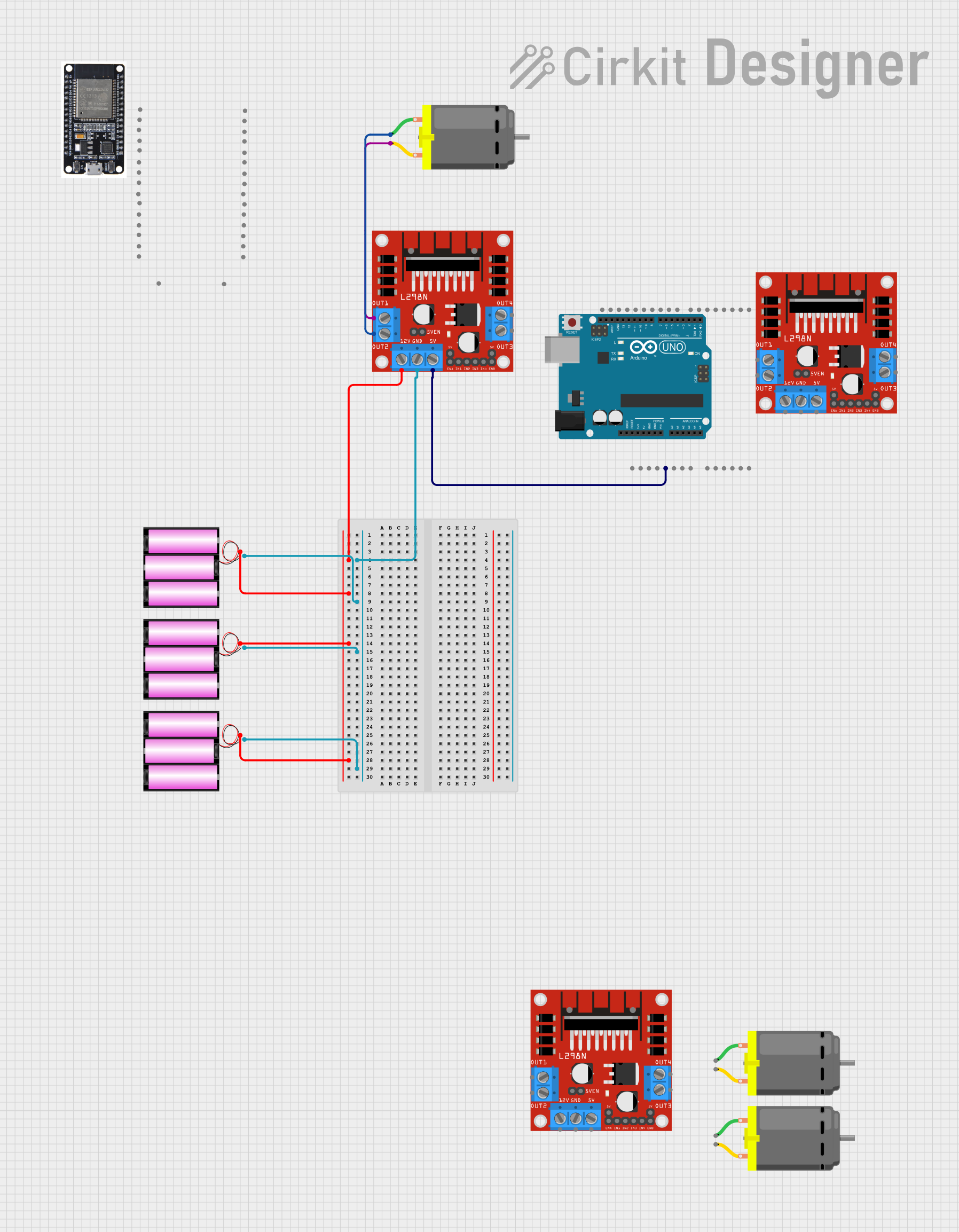

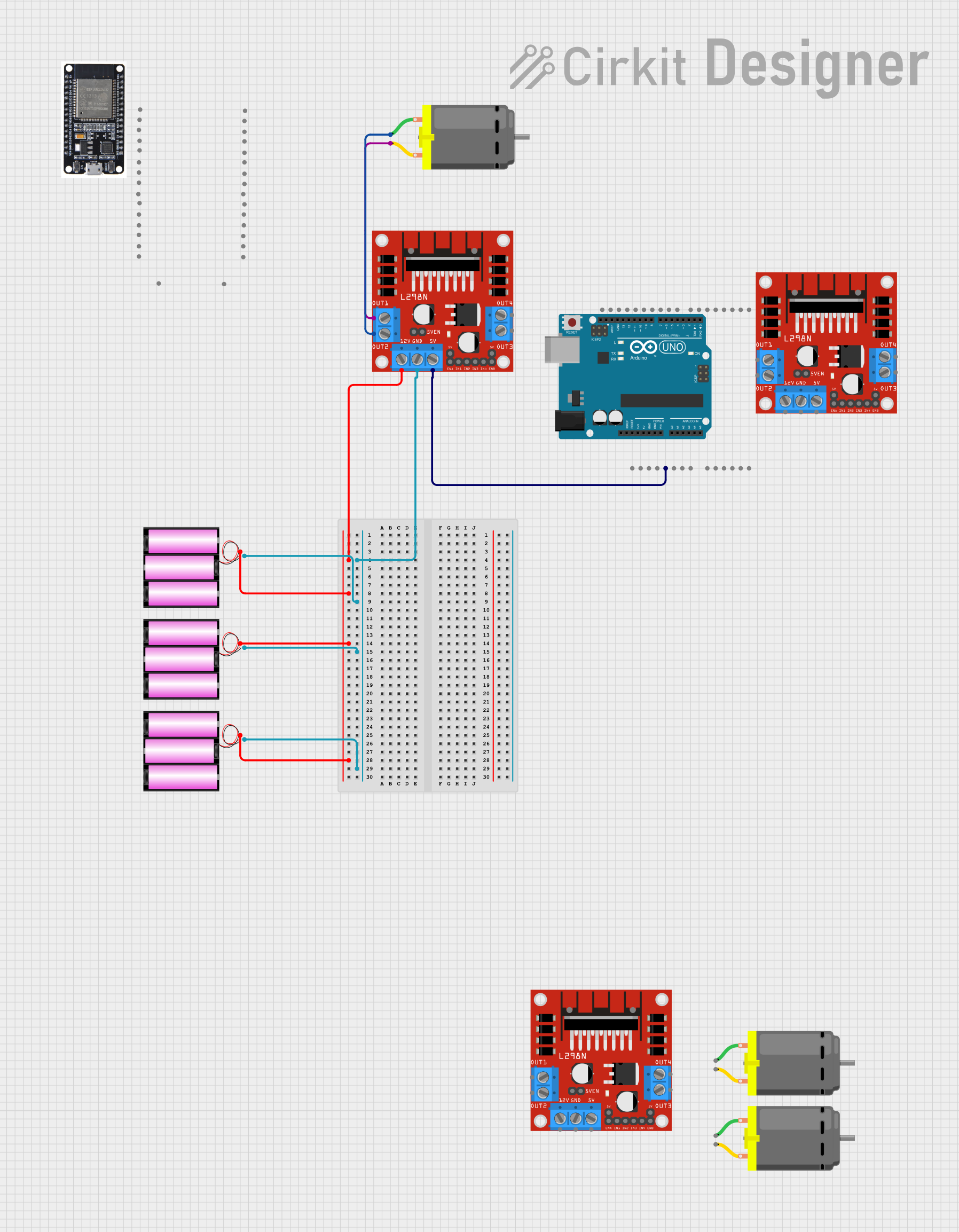

Open Project in Cirkit DesignerArduino and L298N Motor Driver Controlled DC Motor System

This circuit controls a DC motor using an L298N motor driver module, powered by three 12V batteries. An Arduino UNO is used to provide 5V power to the motor driver and can be programmed to control the motor's operation.

Open Project in Cirkit Designer

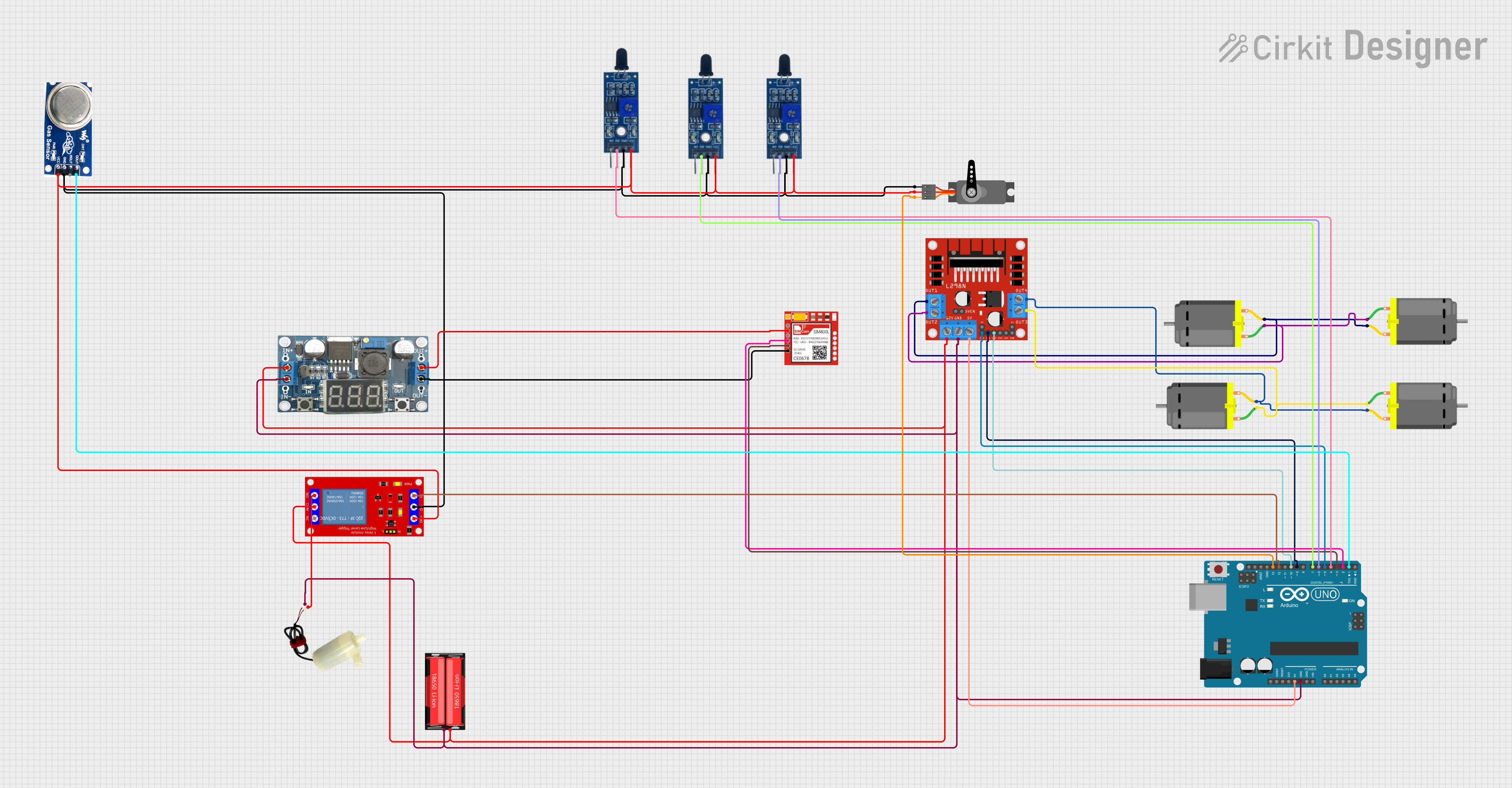

Open Project in Cirkit DesignerArduino-Controlled Fire Detection and GSM Notification System

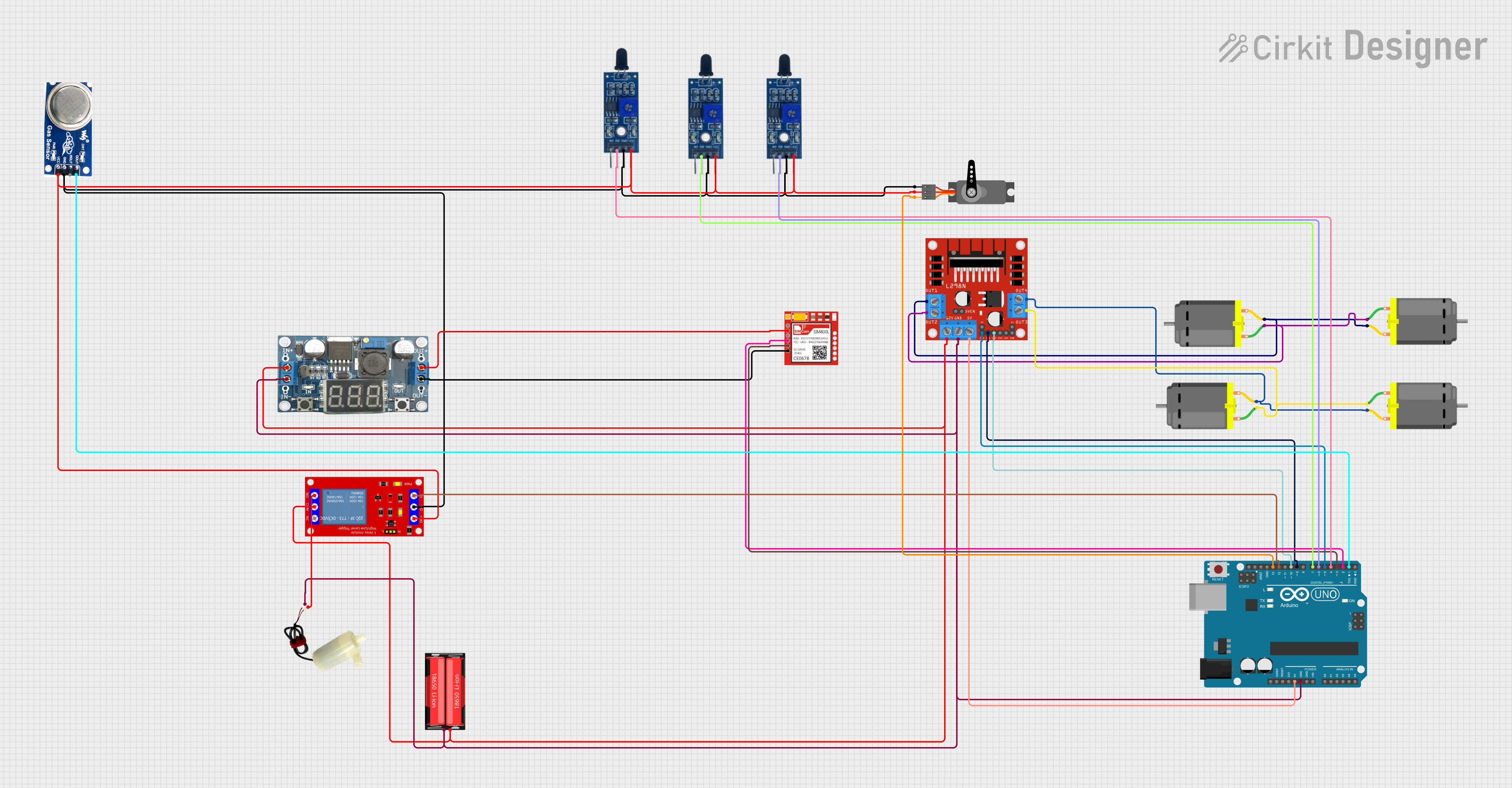

This circuit is designed to control multiple DC motors using an L298N motor driver, which is interfaced with an Arduino UNO microcontroller. The Arduino controls the direction and speed of the motors, as well as a servo motor, and can activate a water pump via a relay module. Additionally, the circuit includes flame and smoke sensors for safety monitoring, and a SIM800L module for potential communication capabilities.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with L298N DC motor driver

L298N DC Motor Driver Controlled DC Motor System

This circuit is designed to control a DC motor using an L298N motor driver module. The motor driver is powered by a DC power source and interfaces with the motor through its output pins, while resistors are used to manage the input signals to the driver.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Wi-Fi Controlled Quad DC Motor Driver System

This circuit is designed to control four DC motors using an L298N motor driver module, which is interfaced with an ESP8266 NodeMCU microcontroller. The NodeMCU's digital pins (D1-D6) are connected to the input pins of the L298N to control the speed and direction of the motors. A 12V battery provides power to the motors through the motor driver, and also powers the NodeMCU through a voltage regulator on the L298N.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Arduino and L298N Motor Driver Controlled DC Motor System

This circuit controls a DC motor using an L298N motor driver module, powered by three 12V batteries. An Arduino UNO is used to provide 5V power to the motor driver and can be programmed to control the motor's operation.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Arduino-Controlled Fire Detection and GSM Notification System

This circuit is designed to control multiple DC motors using an L298N motor driver, which is interfaced with an Arduino UNO microcontroller. The Arduino controls the direction and speed of the motors, as well as a servo motor, and can activate a water pump via a relay module. Additionally, the circuit includes flame and smoke sensors for safety monitoring, and a SIM800L module for potential communication capabilities.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Manufacturer | STM32 |

| Part ID | Uno |

| Motor Channels | 2 |

| Maximum Current | 2A per channel |

| Operating Voltage | 5V to 35V |

| Logic Voltage | 5V |

| Control Interface | TTL logic |

| Dimensions | 43mm x 43mm x 27mm |

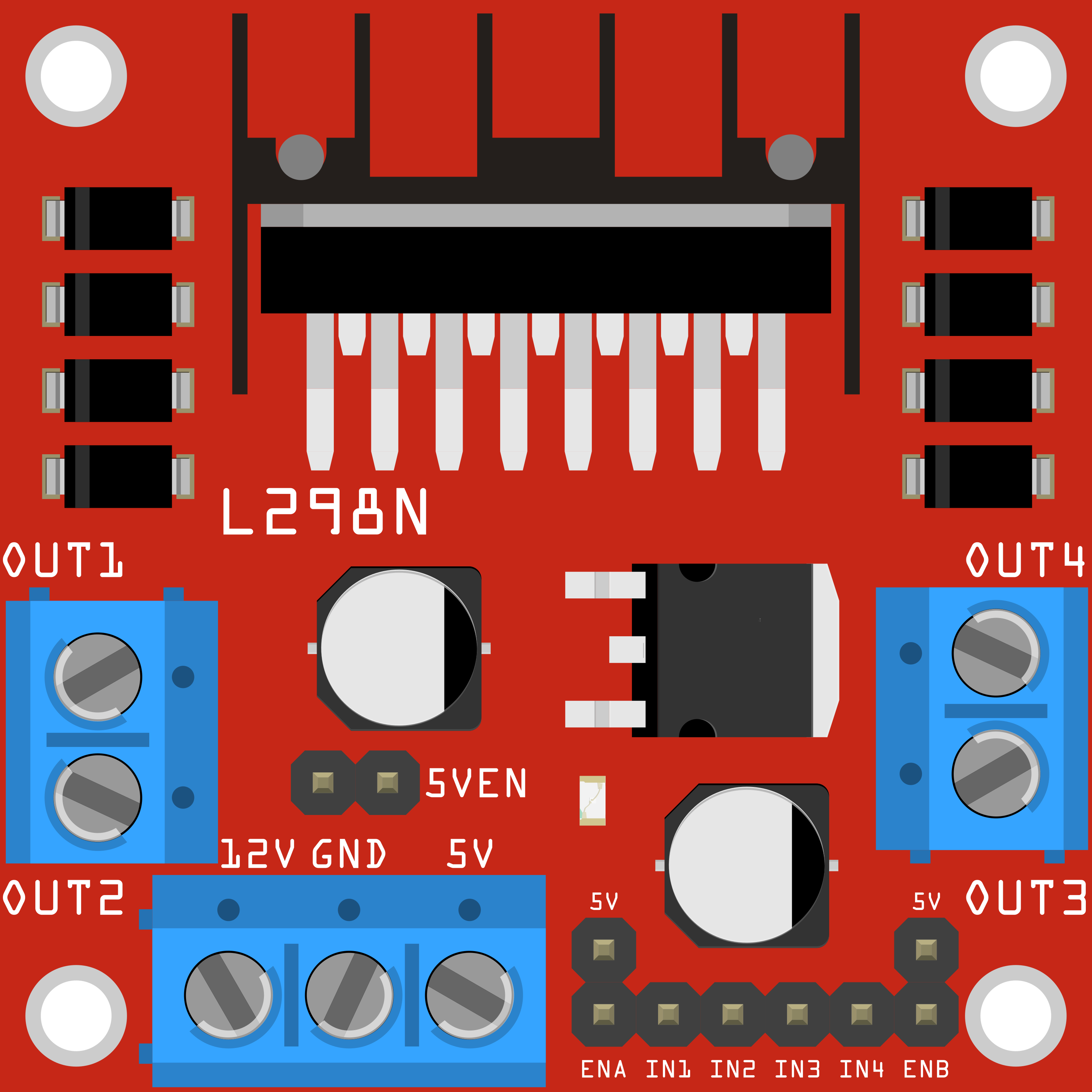

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | ENA | Enable pin for Motor A (High to enable) |

| 2 | IN1 | Input 1 for Motor A (controls direction) |

| 3 | IN2 | Input 2 for Motor A (controls direction) |

| 4 | OUT1 | Output 1 for Motor A |

| 5 | OUT2 | Output 2 for Motor A |

| 6 | GND | Ground |

| 7 | VCC | Supply voltage for motors (5V to 35V) |

| 8 | 5V | 5V logic supply |

| 9 | ENB | Enable pin for Motor B (High to enable) |

| 10 | IN3 | Input 1 for Motor B (controls direction) |

| 11 | IN4 | Input 2 for Motor B (controls direction) |

| 12 | OUT3 | Output 1 for Motor B |

| 13 | OUT4 | Output 2 for Motor B |

Usage Instructions

How to Use the Component in a Circuit

Power Connections:

- Connect the

VCCpin to the power supply for the motors (5V to 35V). - Connect the

GNDpin to the ground of the power supply. - Connect the

5Vpin to the 5V logic supply (e.g., from an Arduino).

- Connect the

Motor Connections:

- Connect the motor terminals to

OUT1andOUT2for Motor A. - Connect the motor terminals to

OUT3andOUT4for Motor B.

- Connect the motor terminals to

Control Connections:

- Connect

ENAto a PWM-capable pin on the microcontroller to control the speed of Motor A. - Connect

IN1andIN2to digital pins on the microcontroller to control the direction of Motor A. - Connect

ENBto a PWM-capable pin on the microcontroller to control the speed of Motor B. - Connect

IN3andIN4to digital pins on the microcontroller to control the direction of Motor B.

- Connect

Important Considerations and Best Practices

- Ensure that the power supply voltage matches the motor's voltage rating.

- Use appropriate heat sinks if the module is expected to handle high currents for extended periods.

- Avoid sudden changes in direction at high speeds to prevent damage to the motors and the driver module.

- Use proper decoupling capacitors to minimize noise and voltage spikes.

Example Code for Arduino UNO

// Define motor control pins

const int ENA = 9; // PWM pin for Motor A speed control

const int IN1 = 8; // Direction control pin for Motor A

const int IN2 = 7; // Direction control pin for Motor A

const int ENB = 10; // PWM pin for Motor B speed control

const int IN3 = 6; // Direction control pin for Motor B

const int IN4 = 5; // Direction control pin for Motor B

void setup() {

// Set all the motor control pins as outputs

pinMode(ENA, OUTPUT);

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(ENB, OUTPUT);

pinMode(IN3, OUTPUT);

pinMode(IN4, OUTPUT);

}

void loop() {

// Example: Rotate Motor A forward at half speed

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

analogWrite(ENA, 128); // 50% duty cycle

// Example: Rotate Motor B backward at full speed

digitalWrite(IN3, LOW);

digitalWrite(IN4, HIGH);

analogWrite(ENB, 255); // 100% duty cycle

delay(2000); // Run motors for 2 seconds

// Stop both motors

analogWrite(ENA, 0);

analogWrite(ENB, 0);

delay(2000); // Wait for 2 seconds before repeating

}

Troubleshooting and FAQs

Common Issues Users Might Face

Motors Not Running:

- Check power connections and ensure the power supply is adequate.

- Verify that the enable pins (

ENAandENB) are set high or receiving a PWM signal.

Motors Running in the Wrong Direction:

- Swap the connections of

IN1andIN2(orIN3andIN4) to change the direction.

- Swap the connections of

Overheating:

- Ensure proper heat dissipation with heat sinks or cooling fans.

- Check for excessive current draw and reduce the load if necessary.

Solutions and Tips for Troubleshooting

- Check Connections: Ensure all connections are secure and correctly placed.

- Measure Voltages: Use a multimeter to check the voltage levels at various points in the circuit.

- Use Serial Monitor: Implement serial debugging in your code to monitor the status of control signals.

- Consult Datasheets: Refer to the L298N datasheet for detailed electrical characteristics and limitations.

By following this documentation, users can effectively utilize the L298N DC Motor Driver Module in their projects, ensuring reliable and efficient motor control.