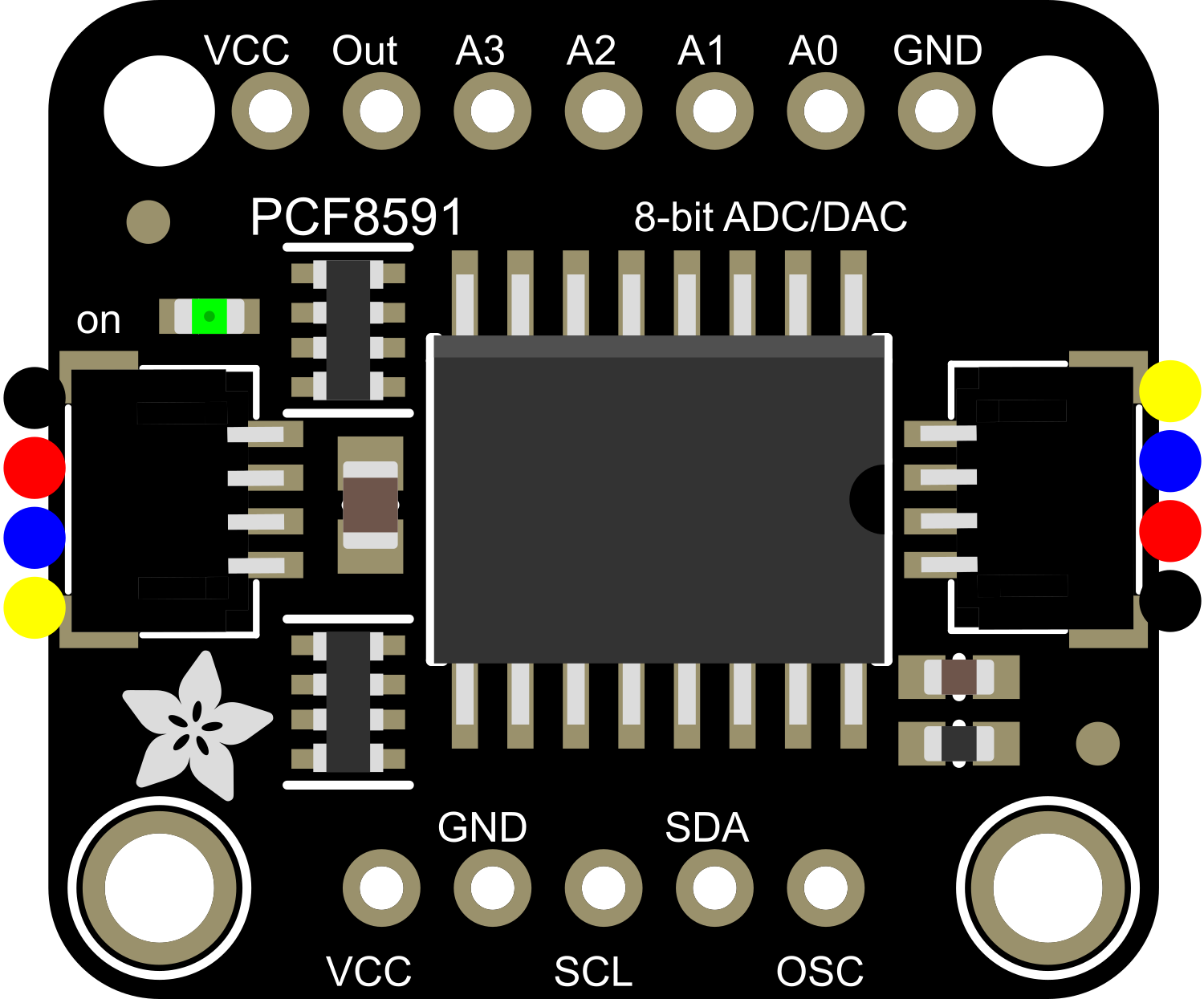

How to Use Adafruit PCF8591: Examples, Pinouts, and Specs

Design with Adafruit PCF8591 in Cirkit Designer

Design with Adafruit PCF8591 in Cirkit DesignerIntroduction

The Adafruit PCF8591 is a versatile breakout board featuring the PCF8591 IC, which is a single-chip, single-supply low-power 8-bit CMOS data acquisition device with four analog inputs, one analog output, and a serial I²C-bus interface. This component is commonly used in applications requiring analog-to-digital conversion (ADC) and digital-to-analog conversion (DAC), such as sensor data reading, light intensity measurement, and simple feedback control systems.

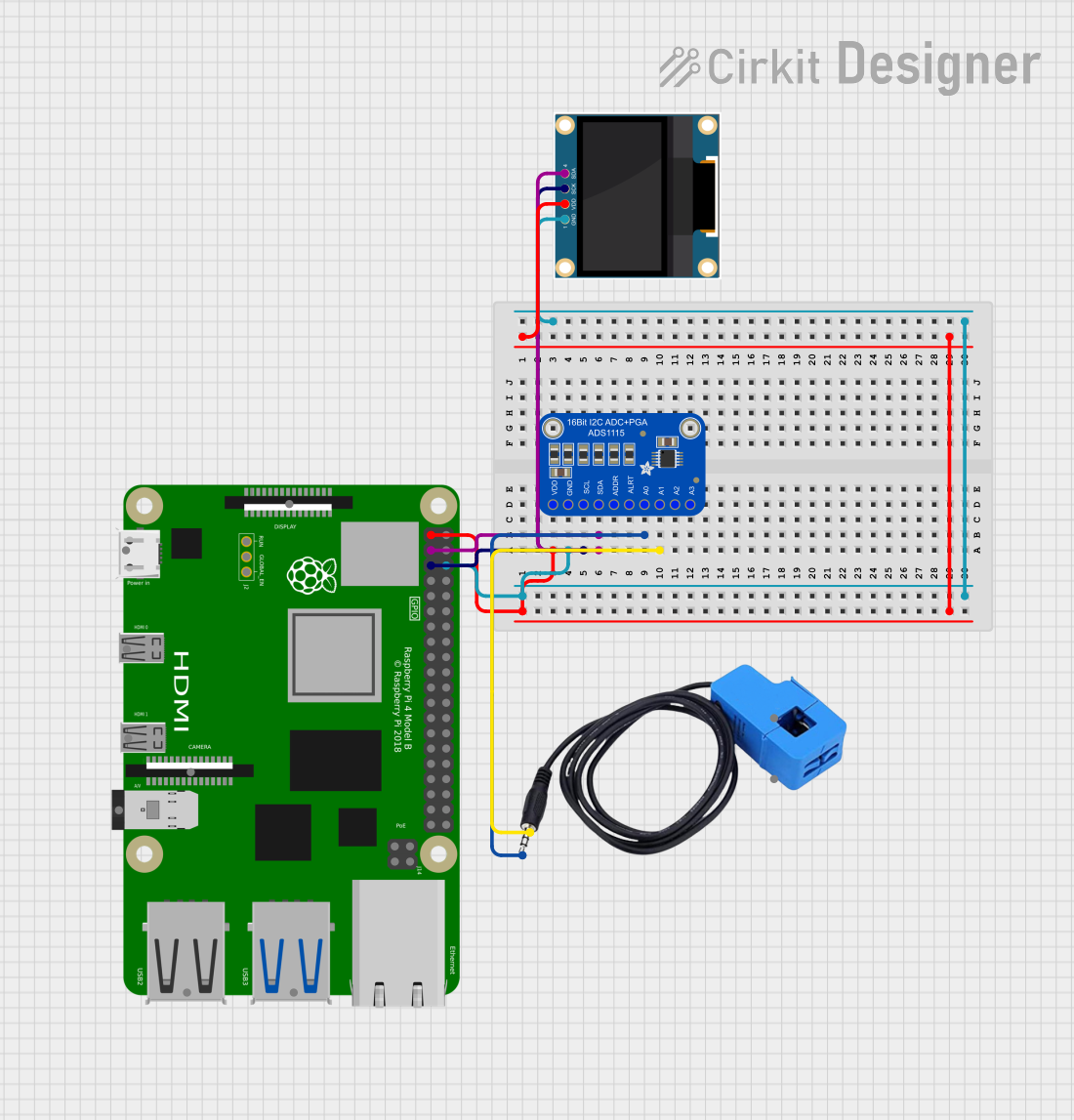

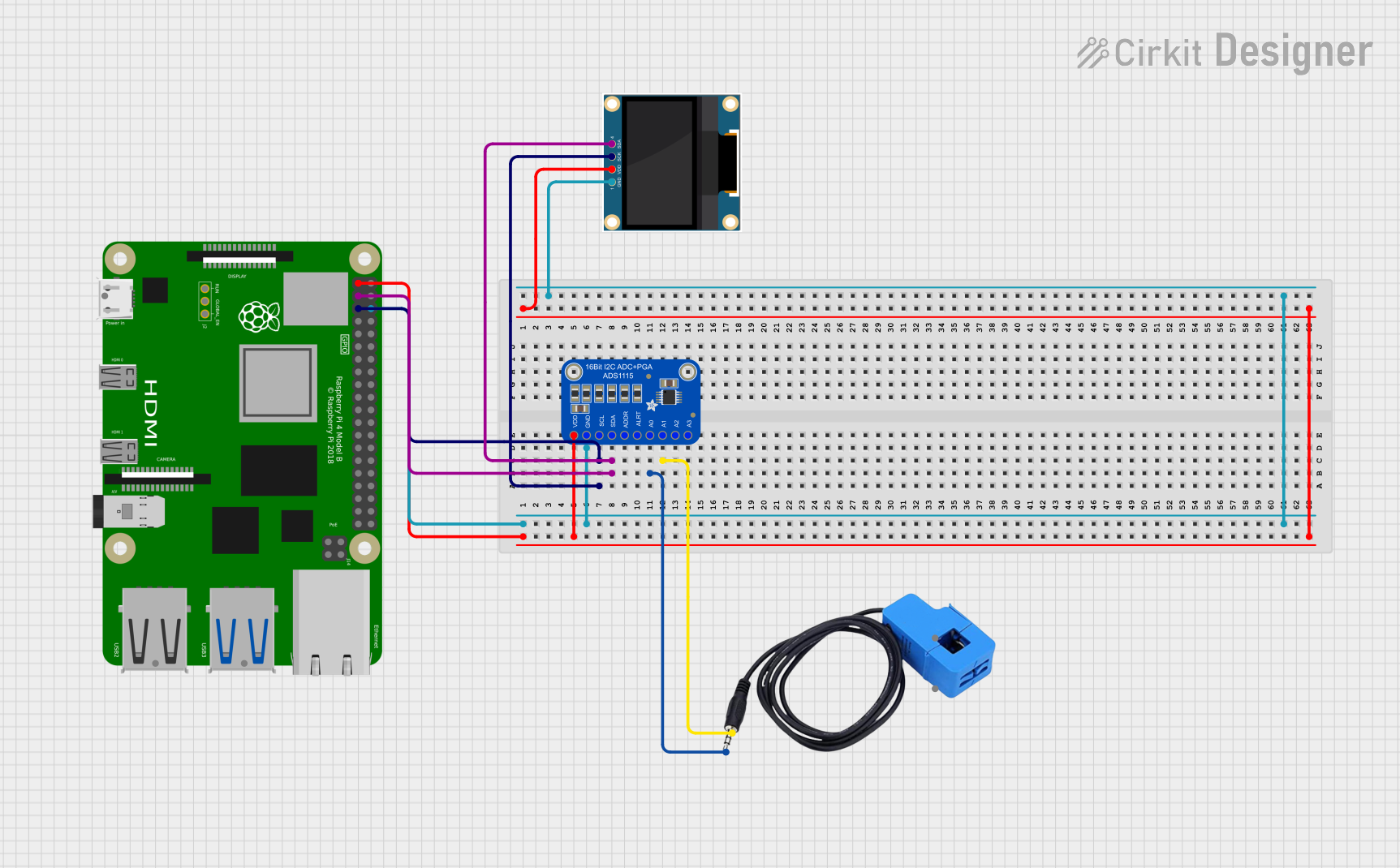

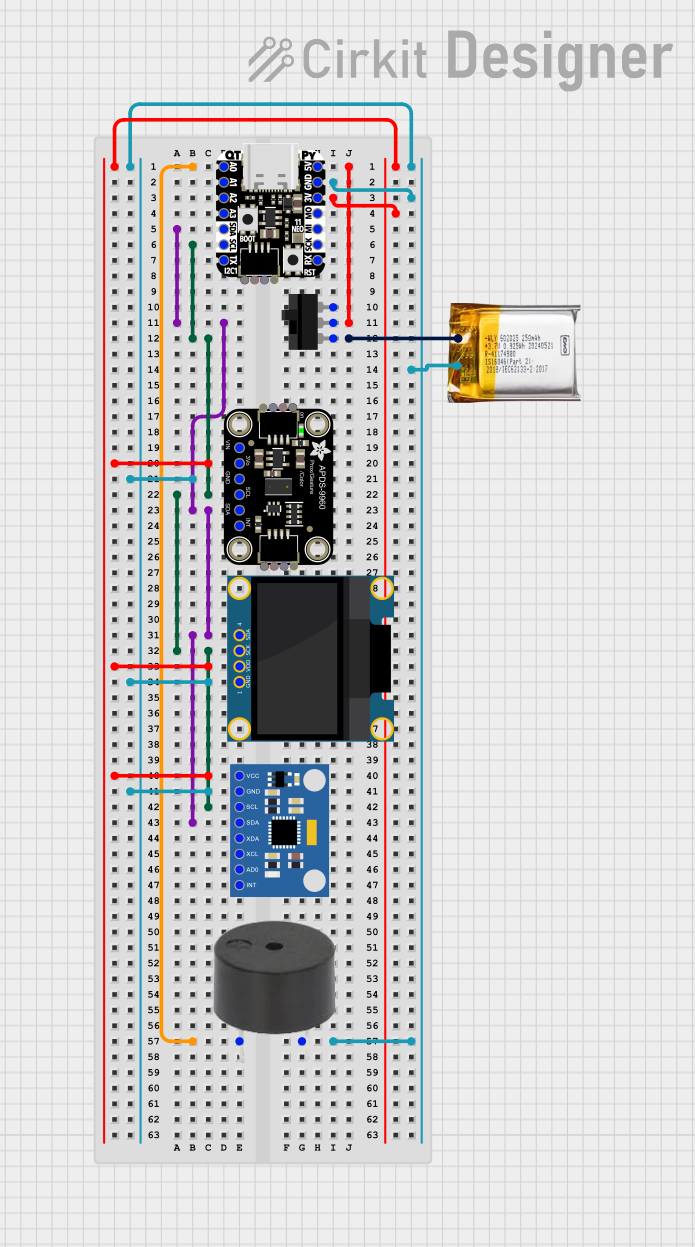

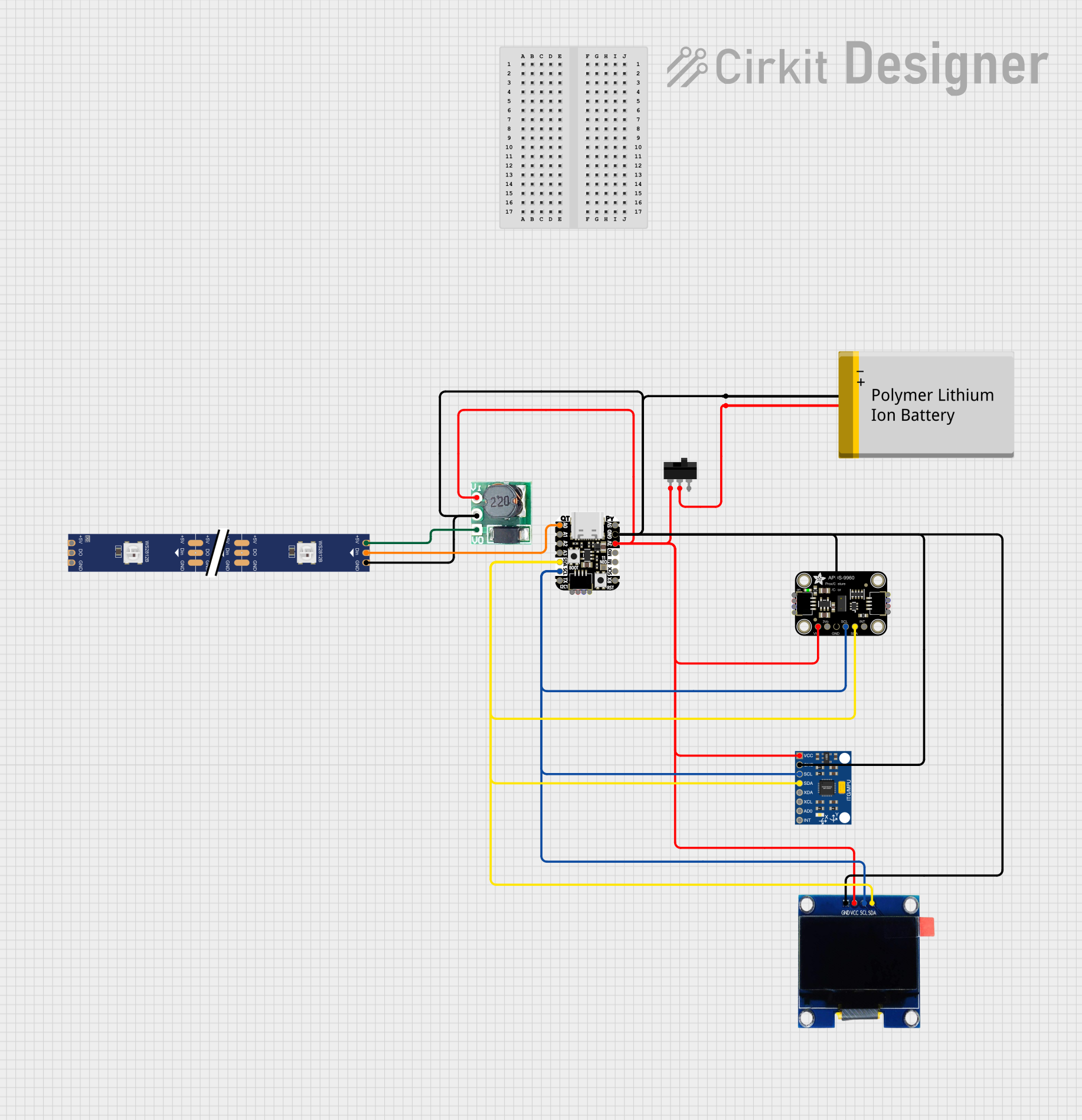

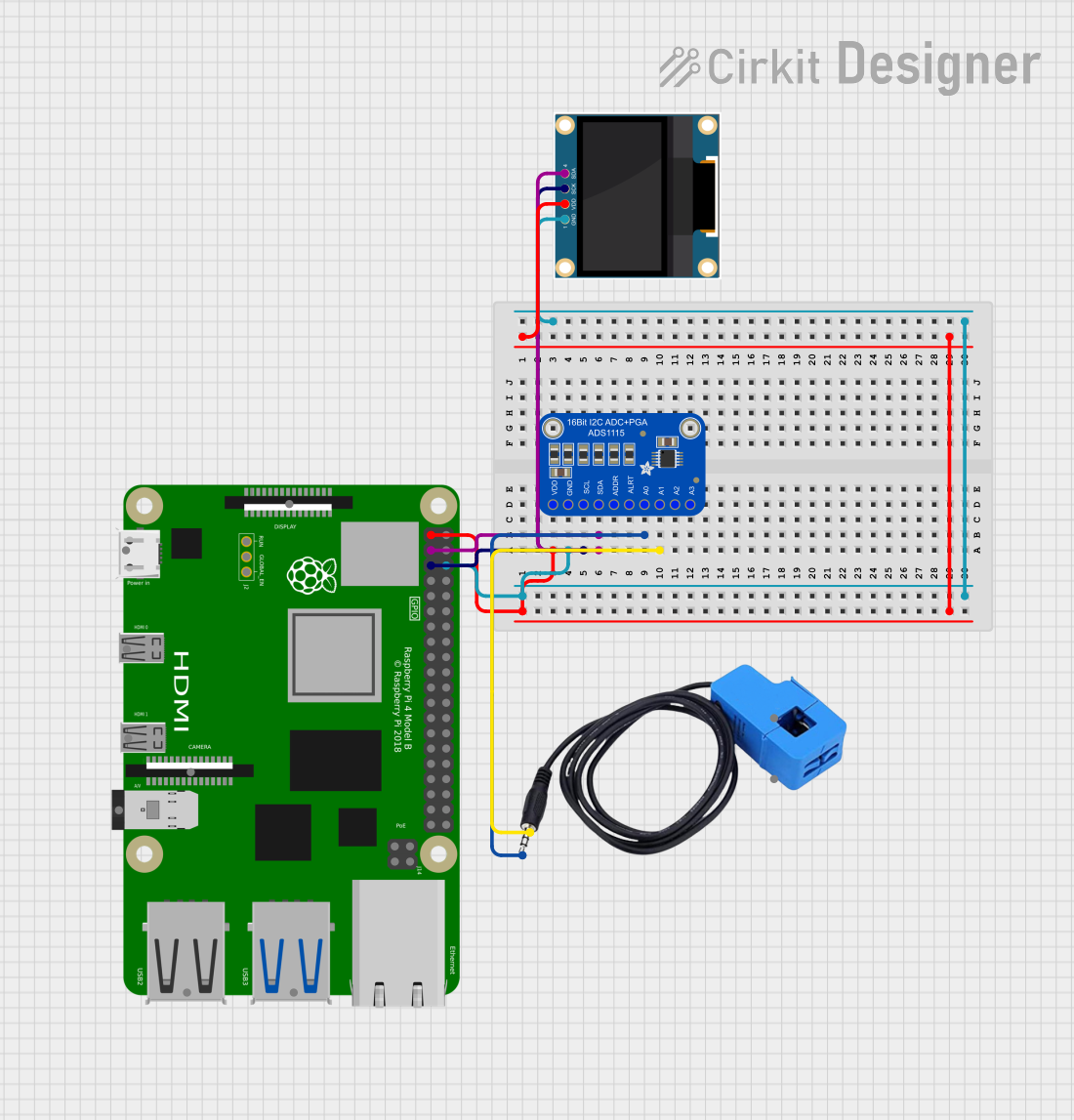

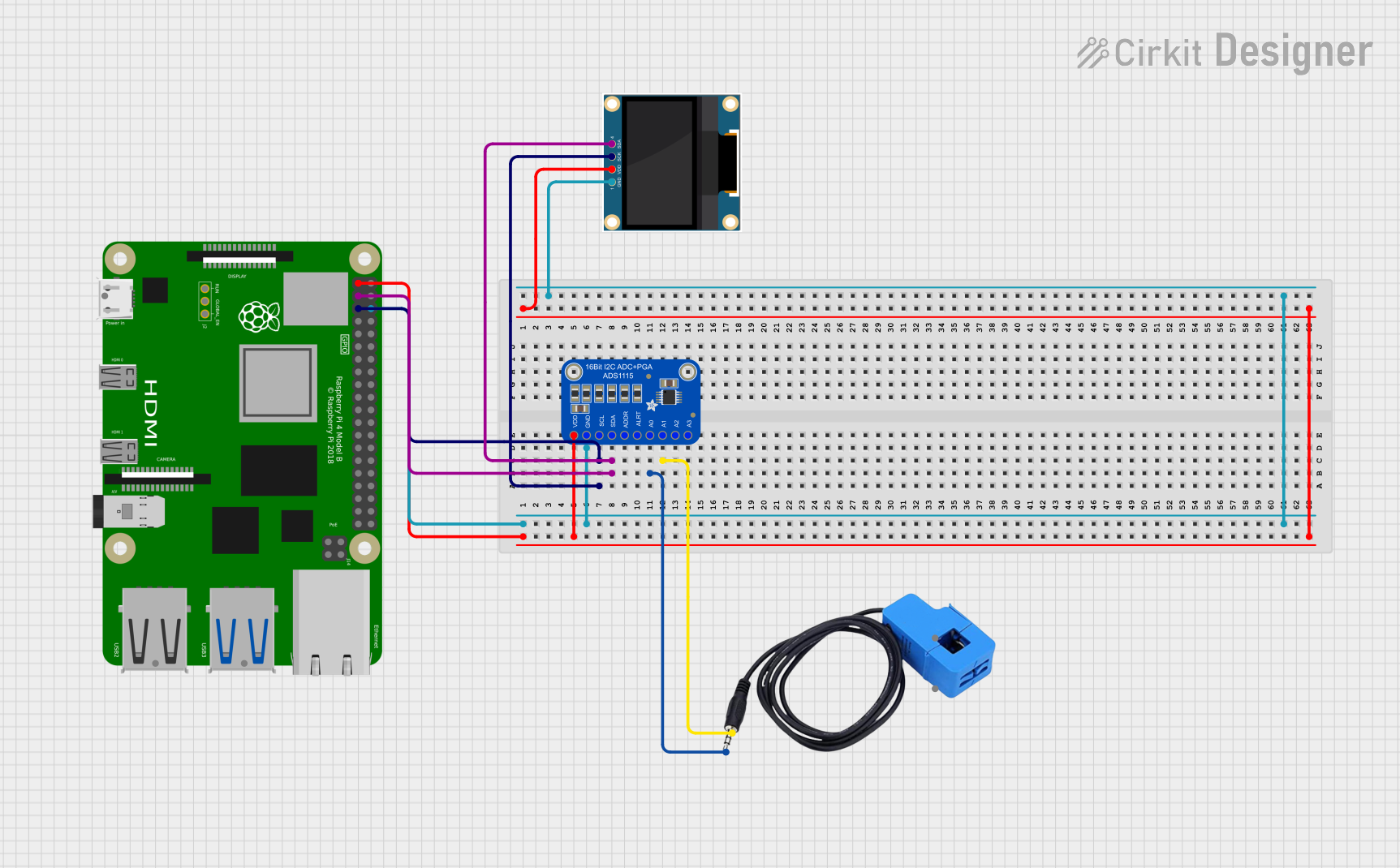

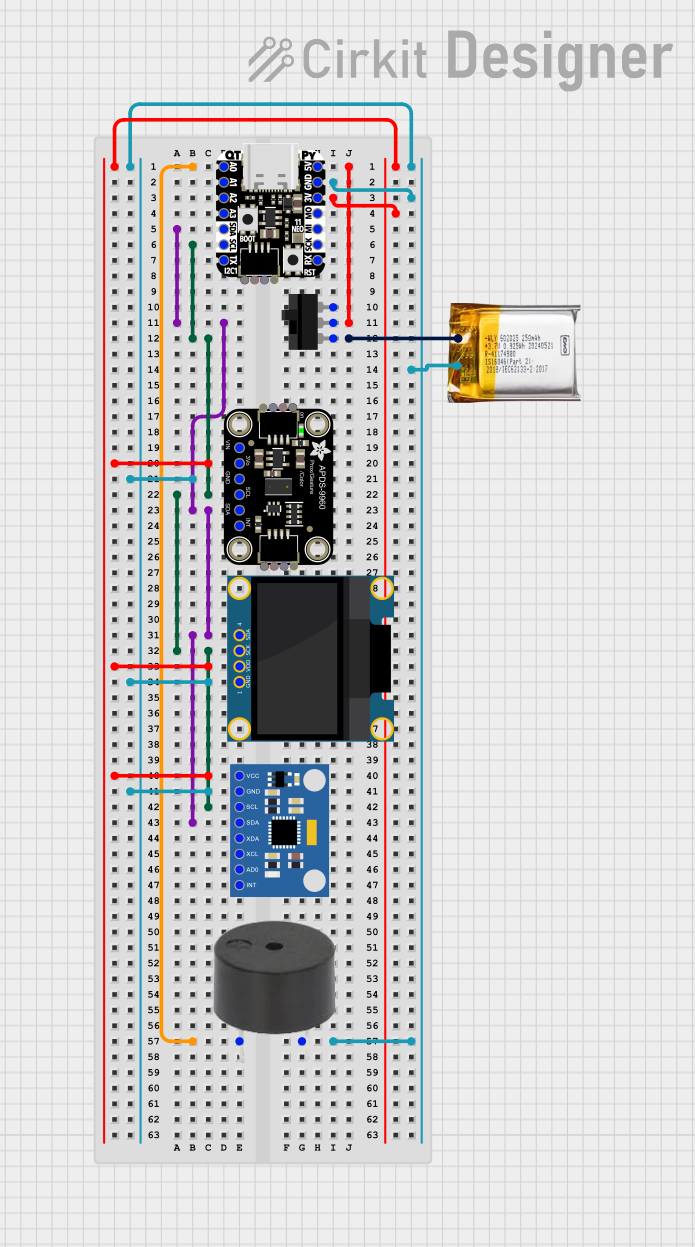

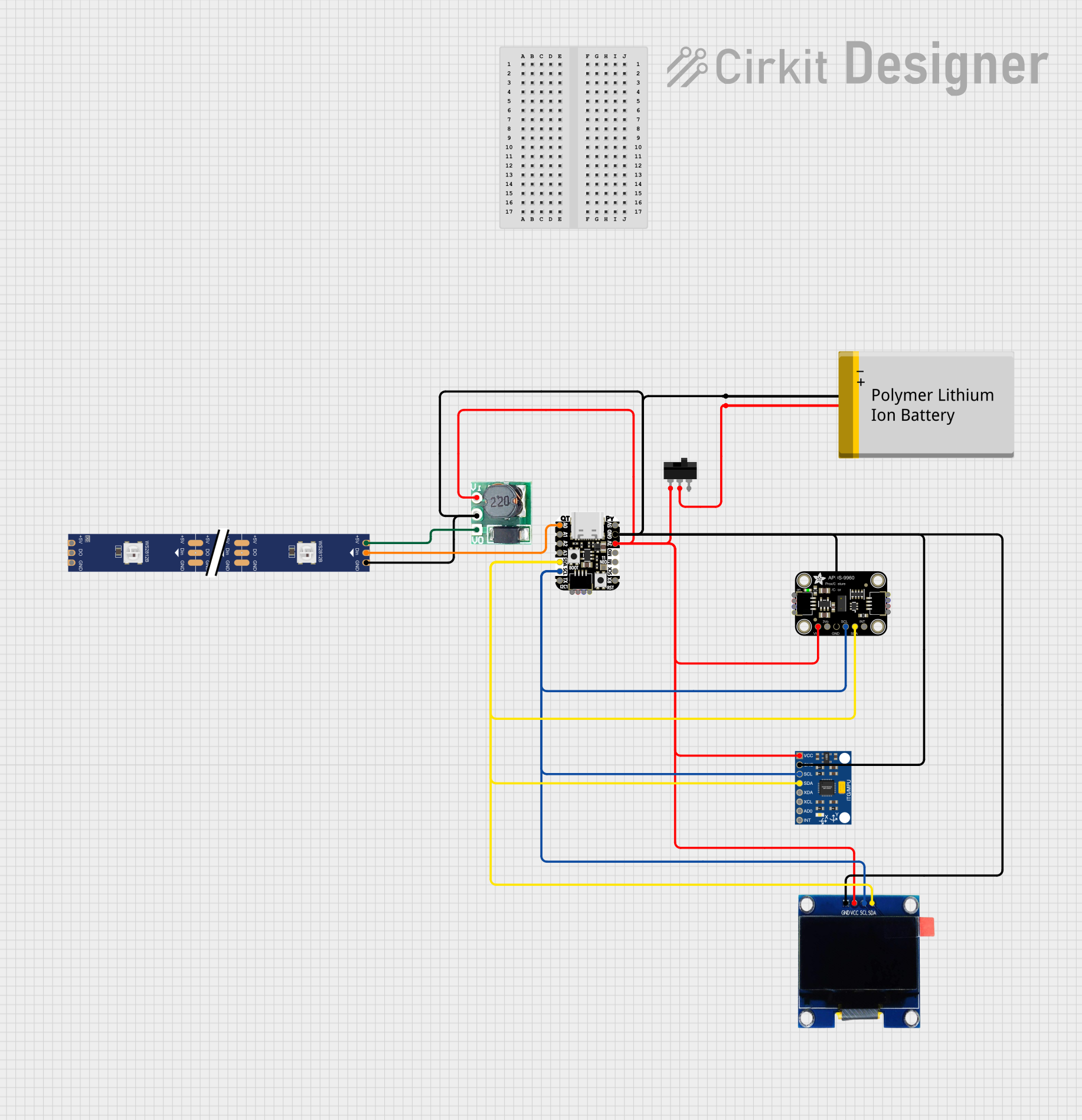

Explore Projects Built with Adafruit PCF8591

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Adafruit PCF8591

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Supply Voltage (VCC): 2.5V to 6V

- Input/Output Voltage (VI/O): 0V to VCC

- Analog Inputs: 4-channel, single-ended or 3-channel differential

- Analog Output: 1-channel, 8-bit resolution

- Resolution: 8-bit for both ADC and DAC

- I²C Address: Selectable via jumpers (0x48 to 0x4F)

- Operating Temperature: -40°C to +85°C

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | AIN0 | Analog input channel 0 |

| 2 | AIN1 | Analog input channel 1 |

| 3 | AIN2 | Analog input channel 2 |

| 4 | AIN3 | Analog input channel 3 |

| 5 | AOUT | Analog output |

| 6 | AGND | Analog ground |

| 7 | VREF | Reference voltage for ADC and DAC |

| 8 | VSS | Power supply ground |

| 9 | SCL | Serial clock line for I²C |

| 10 | SDA | Serial data line for I²C |

| 11 | VDD | Positive power supply |

| 12 | OS | Output enable for the DAC, active low |

Usage Instructions

Integration with a Circuit

- Power Supply: Connect VDD to a 2.5V to 6V power source and VSS to ground.

- I²C Communication: Connect SDA and SCL to your microcontroller's I²C data and clock lines.

- Analog Inputs: Connect your analog signals to AIN0 through AIN3 as needed.

- Analog Output: AOUT provides the DAC output, which can be used to control analog devices.

- Reference Voltage: VREF should be connected to the desired reference voltage for ADC/DAC operations.

Important Considerations and Best Practices

- Ensure that the input voltage does not exceed the VCC voltage to prevent damage.

- Use pull-up resistors on the SDA and SCL lines if your microcontroller does not have built-in pull-ups.

- To minimize noise, keep analog signal paths as short as possible and away from high-current traces.

- Configure the I²C address using the onboard jumpers if multiple I²C devices are used on the same bus.

Example Code for Arduino UNO

#include <Wire.h>

// PCF8591 default I2C address

const int PCF8591 = 0x48;

void setup() {

Wire.begin(); // Join I2C bus

Serial.begin(9600); // Start serial communication at 9600 baud

}

void loop() {

Wire.beginTransmission(PCF8591); // Start transmission to device

Wire.write(0x04); // Control byte - enable DAC, enable ADC0

Wire.endTransmission(); // End transmission

Wire.requestFrom(PCF8591, 2); // Request 2 bytes from the PCF8591

Wire.read(); // Read first byte (dummy read)

int analogValue = Wire.read(); // Read second byte (ADC0 value)

Serial.println(analogValue); // Print the value to the serial monitor

delay(1000); // Wait for 1 second

}

This example initializes the I²C communication and reads the analog value from channel AIN0 every second, then prints it to the serial monitor.

Troubleshooting and FAQs

Common Issues

- No response from the device: Check the wiring, especially the I²C connections, and ensure that the correct I²C address is used.

- Inaccurate readings: Verify that VREF is correctly set and that there is no noise in the analog signal path.

- Unable to write to DAC: Ensure that the OS pin is pulled low to enable the output.

Solutions and Tips for Troubleshooting

- Use a multimeter to check for proper voltage levels at VDD and VREF.

- If using long wires for I²C, consider using a lower pull-up resistor value to maintain signal integrity.

- Check for solder bridges or cold solder joints that might be causing shorts or open circuits.

FAQs

Q: Can I use this board with a 5V Arduino? A: Yes, the PCF8591 can operate at 5V and is compatible with 5V Arduino boards.

Q: How do I change the I²C address? A: The I²C address can be changed by adjusting the jumpers on the board to one of the eight possible addresses (0x48 to 0x4F).

Q: Can I use differential inputs with this board? A: Yes, the PCF8591 allows for three differential input measurements. Refer to the datasheet for configuring differential inputs.

Q: What is the maximum sampling rate of the ADC? A: The maximum sampling rate depends on the I²C clock frequency but typically is around 100 samples per second.

Remember to always consult the PCF8591 datasheet for detailed information and specifications.