How to Use x9c104: Examples, Pinouts, and Specs

Design with x9c104 in Cirkit Designer

Design with x9c104 in Cirkit DesignerIntroduction

The X9C104 is a digital potentiometer manufactured in China, designed to provide variable resistance control through a digital interface. With a resistance range of 100kΩ, it is a versatile component suitable for a variety of applications. The X9C104 allows precise adjustment of resistance values, making it ideal for use in volume control, signal conditioning, sensor calibration, and other applications requiring fine-tuned resistance settings.

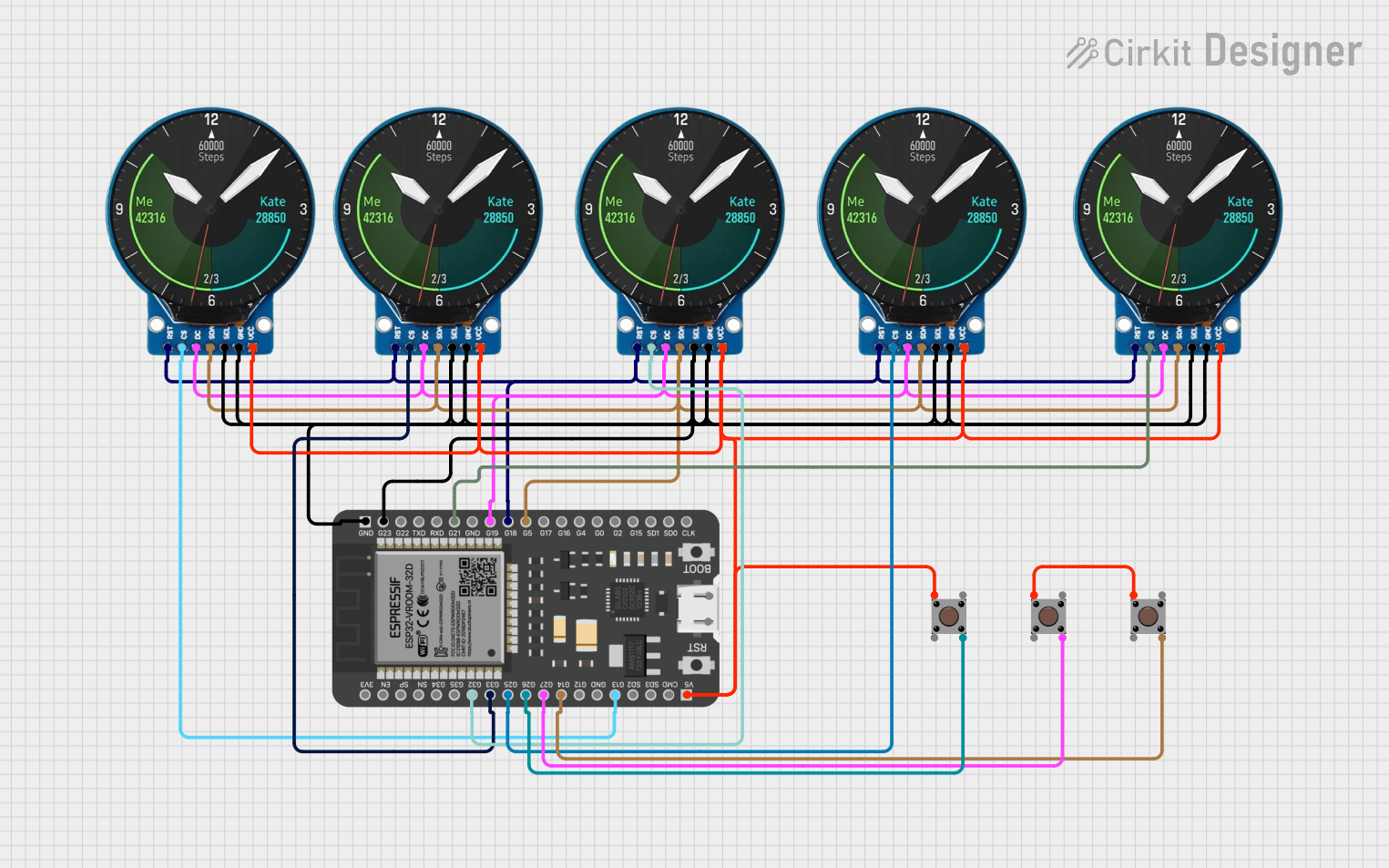

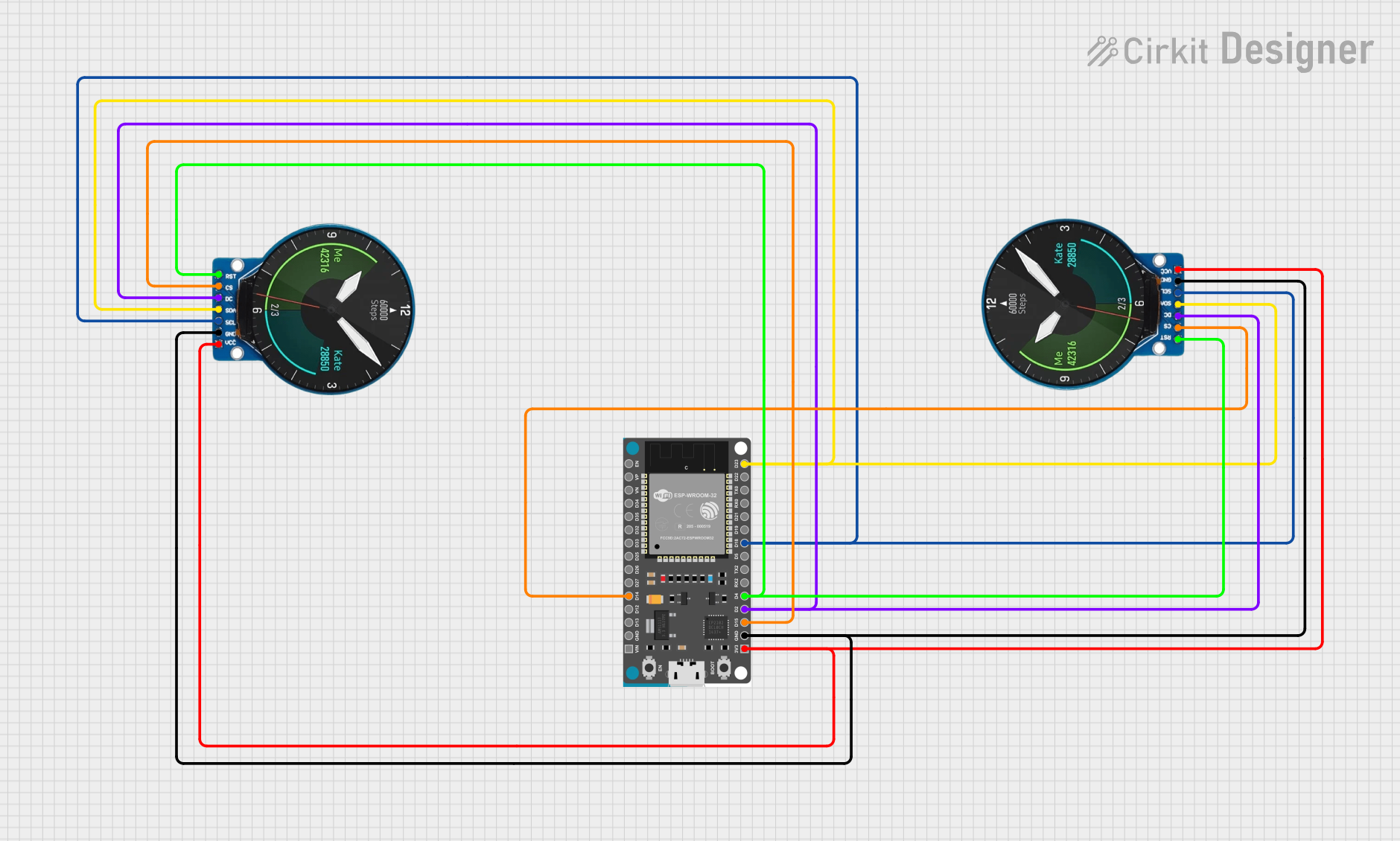

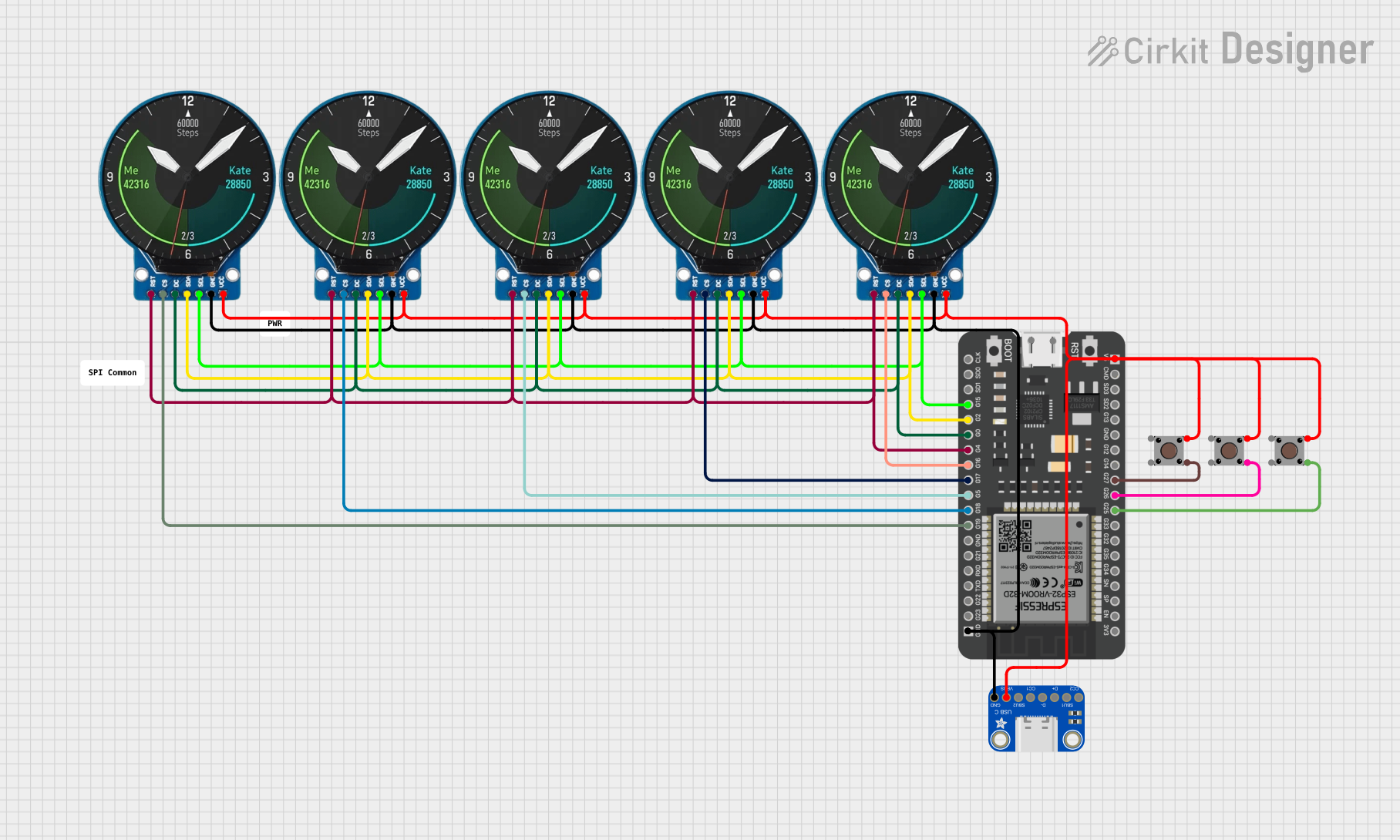

Explore Projects Built with x9c104

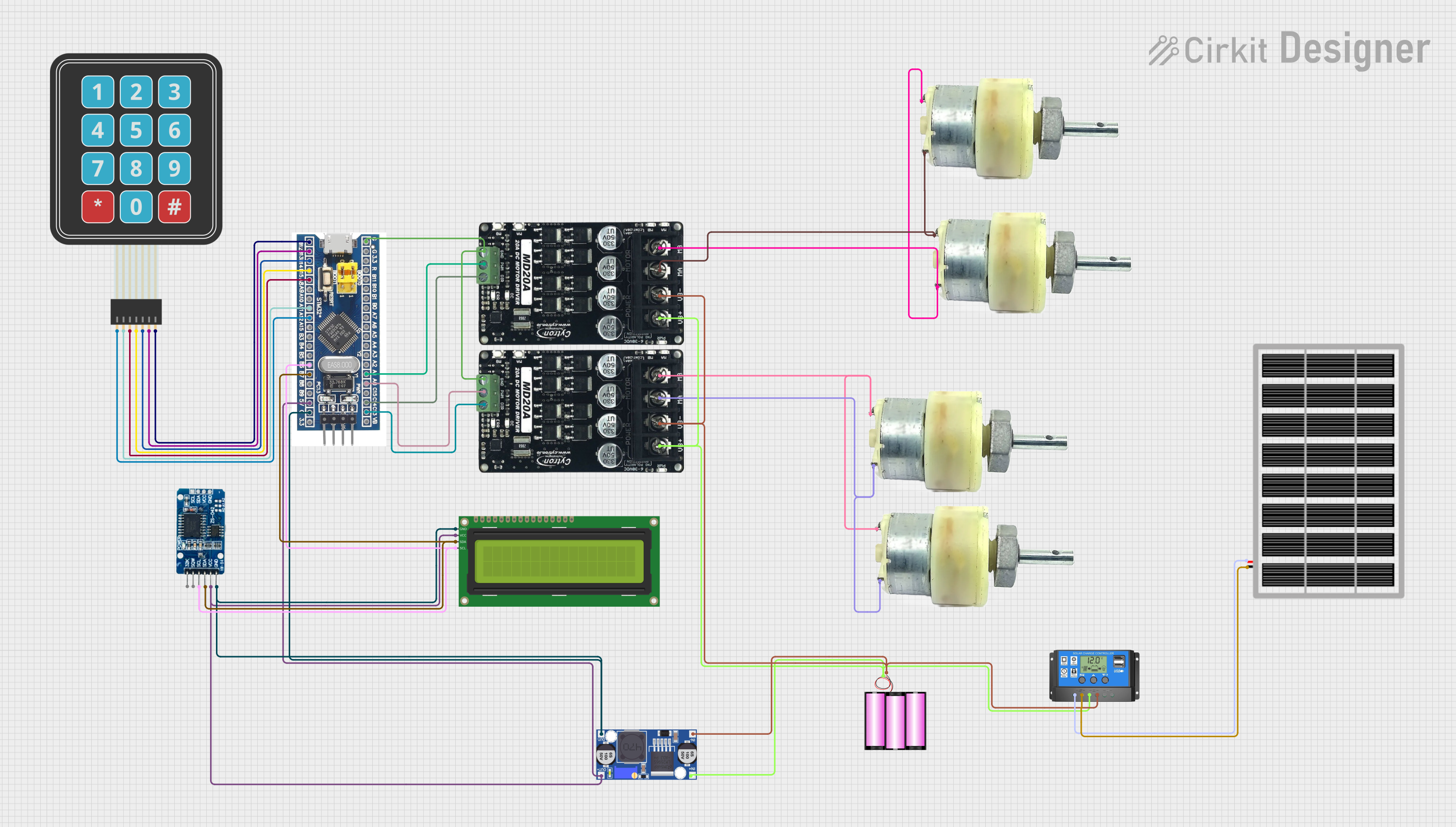

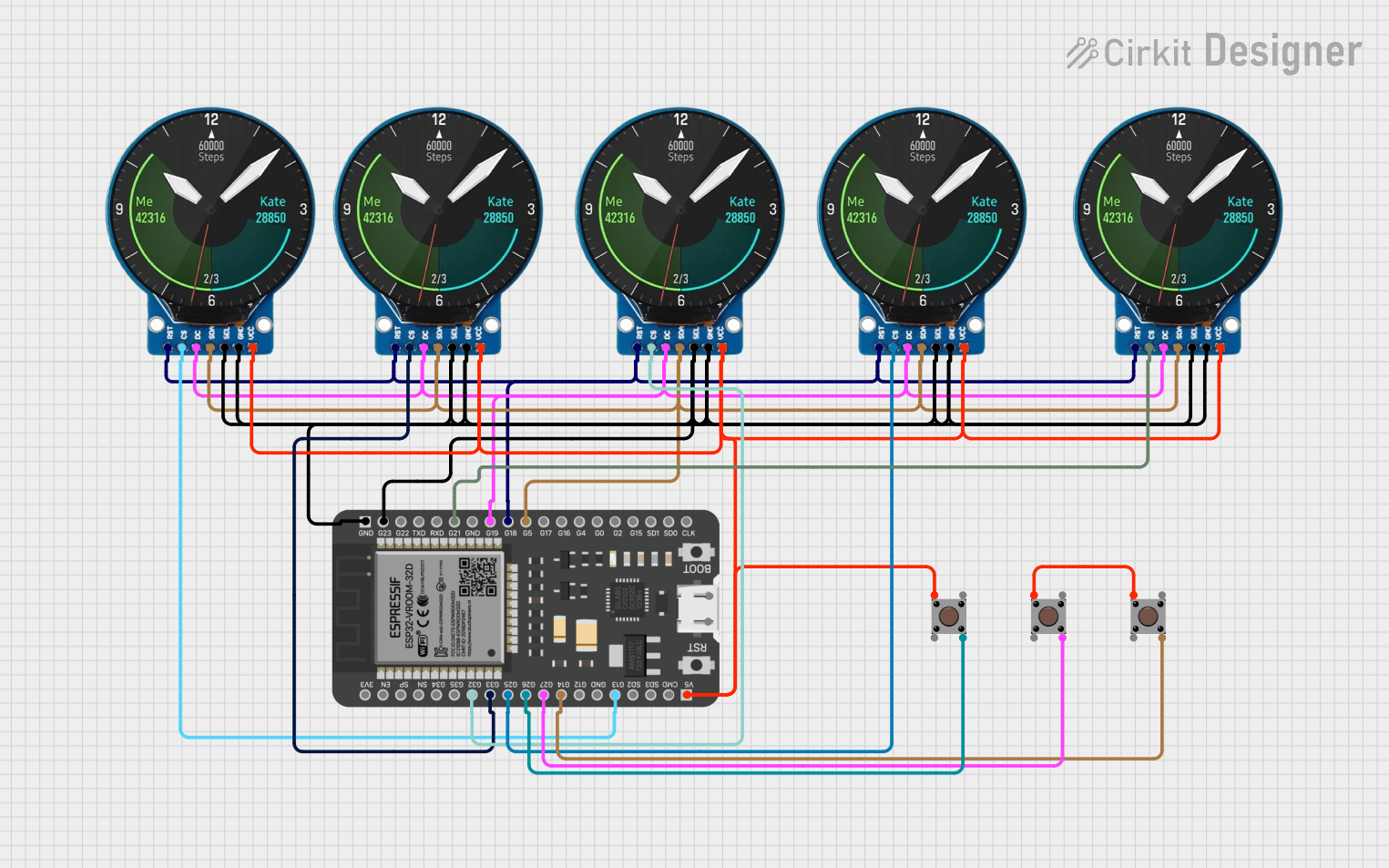

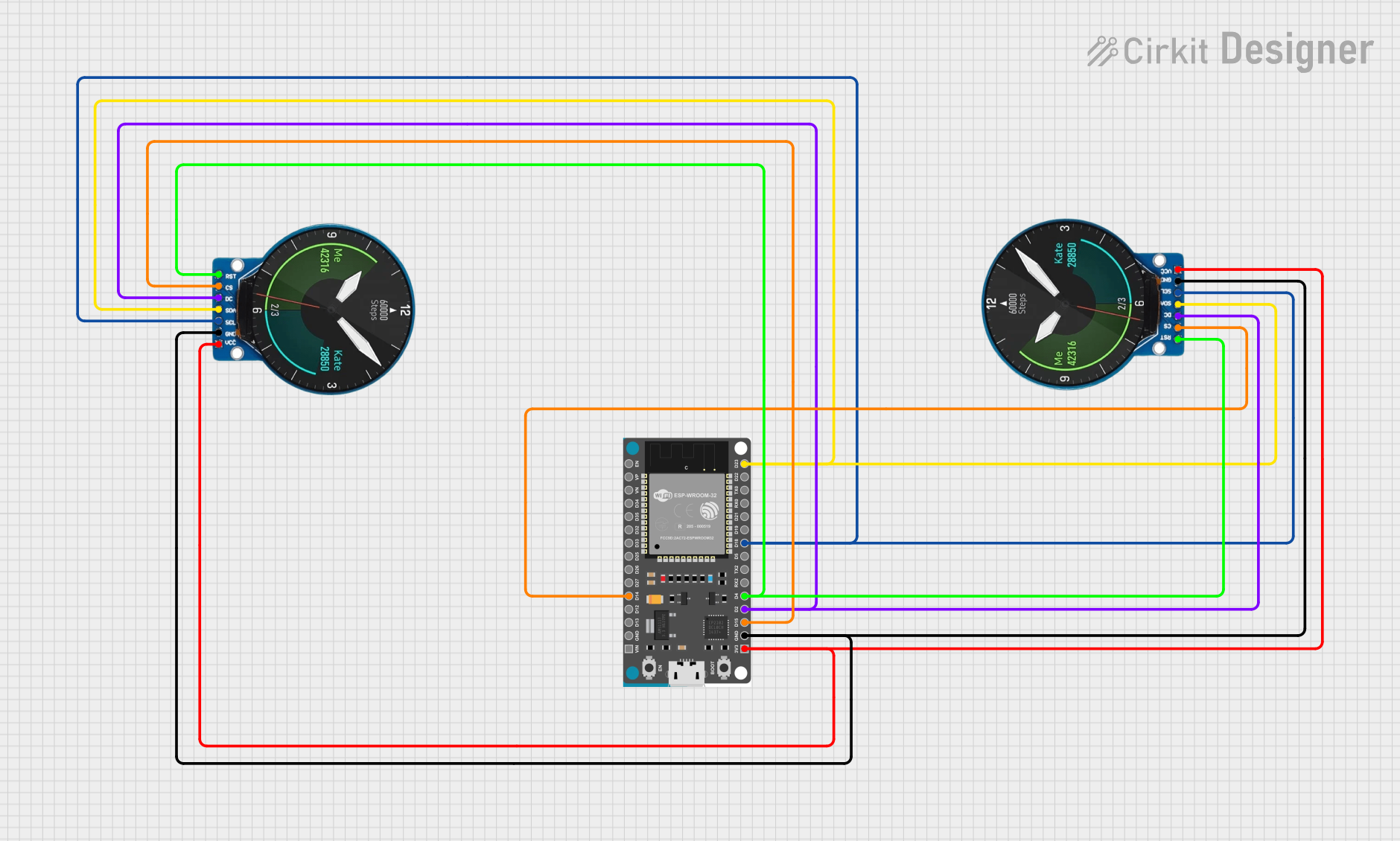

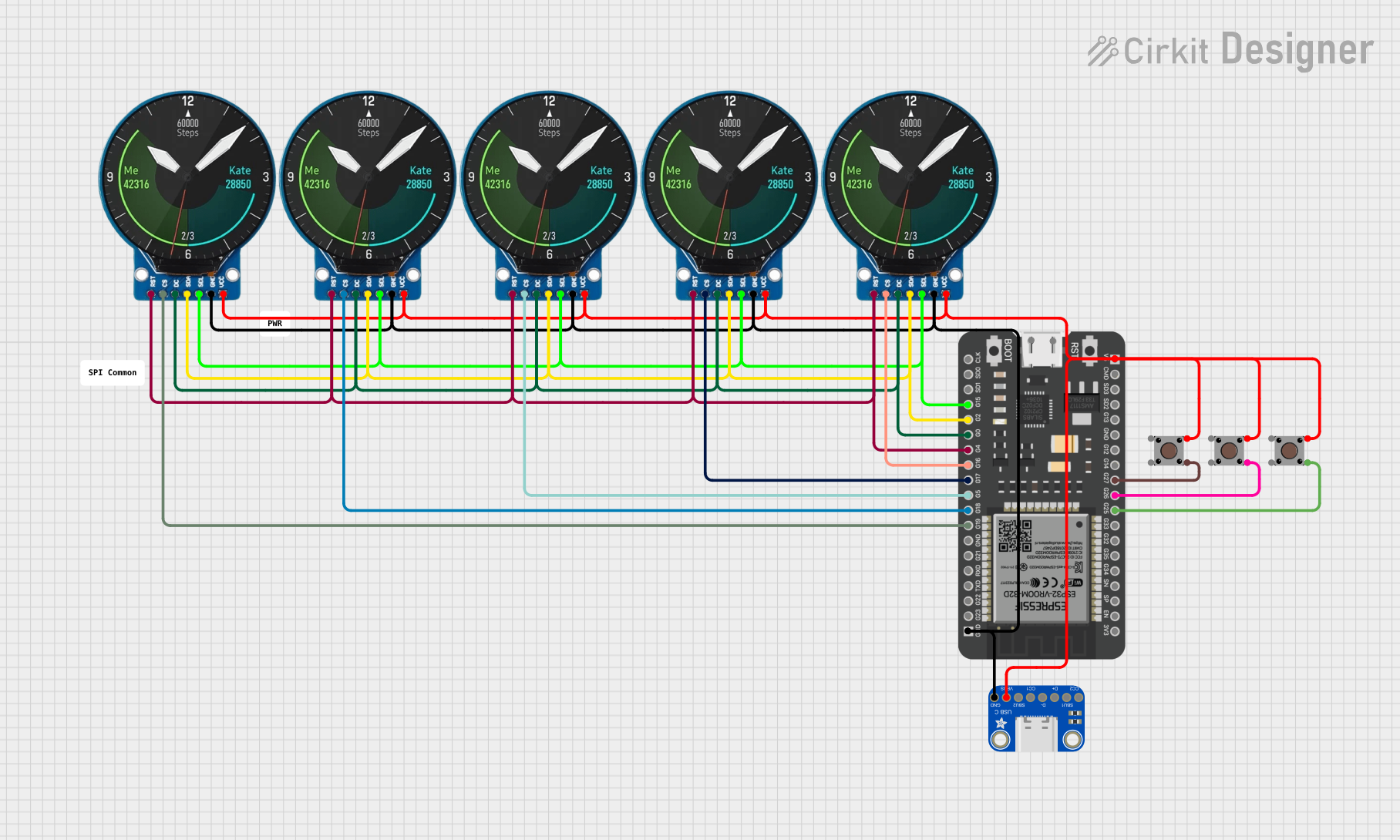

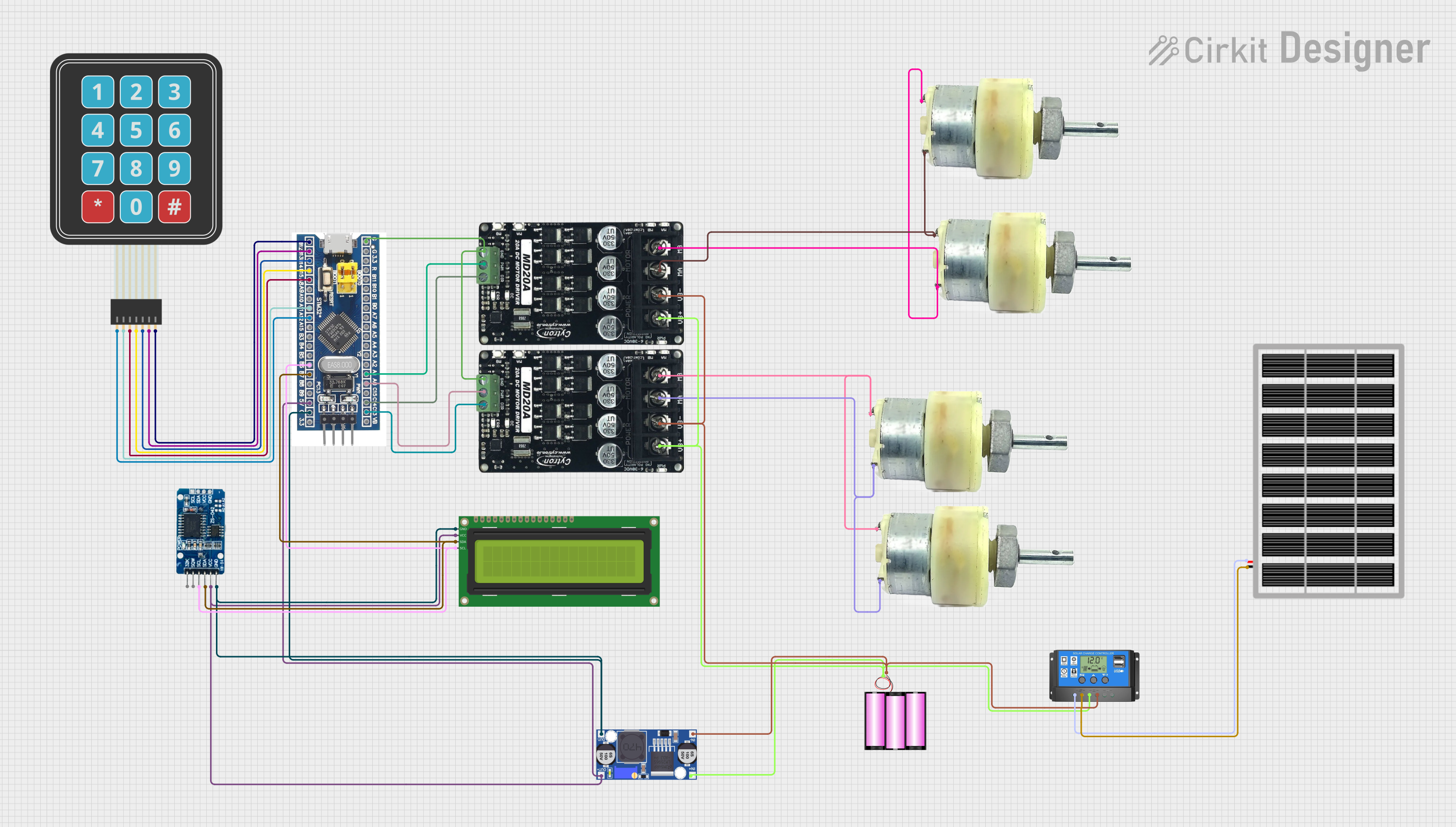

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with x9c104

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Audio volume control

- Signal conditioning in analog circuits

- Sensor calibration and tuning

- Adjustable gain in amplifiers

- Programmable resistor networks

Technical Specifications

The X9C104 is a 100kΩ digital potentiometer with 100 wiper positions, allowing for fine-grained resistance adjustments. It operates via a simple digital interface, making it easy to integrate into microcontroller-based systems.

Key Specifications

| Parameter | Value |

|---|---|

| Resistance Range | 100kΩ |

| Number of Wiper Steps | 100 |

| Wiper Resistance | 40Ω (typical) |

| Supply Voltage (Vcc) | 2.7V to 5.5V |

| Operating Current | 3mA (typical) |

| Standby Current | 1µA (typical) |

| Interface | Up/Down control with CS pin |

| Operating Temperature | -40°C to +85°C |

| Package Type | 8-pin DIP/SOIC |

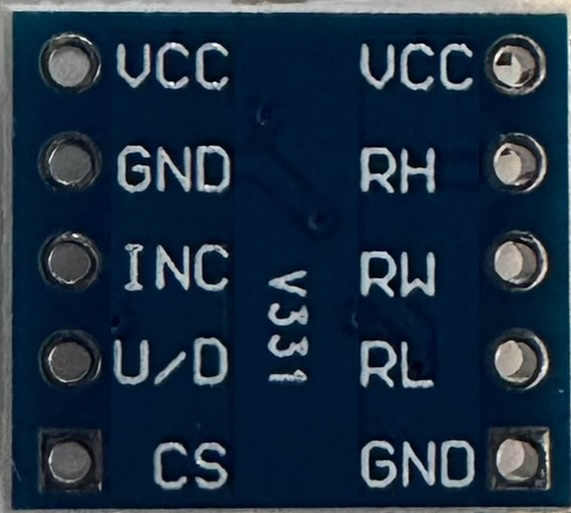

Pin Configuration and Descriptions

The X9C104 is an 8-pin device. The table below describes each pin:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | CS | Chip Select: Activates the device when pulled low. |

| 2 | INC | Increment: Adjusts the wiper position when toggled. |

| 3 | U/D | Up/Down: Determines the direction of wiper movement (high = up, low = down). |

| 4 | Vss | Ground: Connect to system ground. |

| 5 | Vw | Wiper Terminal: Connect to the adjustable output. |

| 6 | Vl | Low Terminal: Connect to the lower end of the resistor. |

| 7 | Vh | High Terminal: Connect to the upper end of the resistor. |

| 8 | Vcc | Power Supply: Connect to a 2.7V to 5.5V power source. |

Usage Instructions

The X9C104 is straightforward to use in a circuit. It requires a digital control signal to adjust the resistance between its terminals. Below are the steps and considerations for using the X9C104:

Basic Circuit Connection

- Power Supply: Connect the Vcc pin to a 2.7V to 5.5V power source and the Vss pin to ground.

- Resistor Terminals: Connect Vh to the high end of the resistor network, Vl to the low end, and Vw to the adjustable wiper output.

- Control Pins:

- Connect the CS pin to a digital output pin of a microcontroller.

- Connect the INC pin to another digital output pin for toggling the wiper position.

- Connect the U/D pin to a digital output pin to set the direction of wiper movement.

Important Considerations

- The CS pin must be pulled low to enable the device. When CS is high, the device is inactive.

- The INC pin must be toggled (high to low) to adjust the wiper position. The U/D pin determines whether the wiper moves up or down.

- The wiper position is non-volatile, meaning it retains its position even after power is removed.

Example: Using X9C104 with Arduino UNO

Below is an example of how to control the X9C104 using an Arduino UNO:

// Define pin connections for the X9C104

const int CS_PIN = 10; // Chip Select pin

const int INC_PIN = 9; // Increment pin

const int UD_PIN = 8; // Up/Down pin

void setup() {

// Set pin modes

pinMode(CS_PIN, OUTPUT);

pinMode(INC_PIN, OUTPUT);

pinMode(UD_PIN, OUTPUT);

// Initialize pins

digitalWrite(CS_PIN, HIGH); // Disable the device initially

digitalWrite(INC_PIN, HIGH); // Set INC to high

digitalWrite(UD_PIN, LOW); // Set direction to down

}

void loop() {

// Example: Increase resistance by 10 steps

digitalWrite(CS_PIN, LOW); // Enable the device

digitalWrite(UD_PIN, HIGH); // Set direction to up

for (int i = 0; i < 10; i++) {

digitalWrite(INC_PIN, LOW); // Toggle INC pin

delay(1); // Short delay

digitalWrite(INC_PIN, HIGH); // Complete the toggle

delay(1); // Short delay

}

digitalWrite(CS_PIN, HIGH); // Disable the device

delay(1000); // Wait for 1 second

// Example: Decrease resistance by 5 steps

digitalWrite(CS_PIN, LOW); // Enable the device

digitalWrite(UD_PIN, LOW); // Set direction to down

for (int i = 0; i < 5; i++) {

digitalWrite(INC_PIN, LOW); // Toggle INC pin

delay(1); // Short delay

digitalWrite(INC_PIN, HIGH); // Complete the toggle

delay(1); // Short delay

}

digitalWrite(CS_PIN, HIGH); // Disable the device

delay(1000); // Wait for 1 second

}

Best Practices

- Use decoupling capacitors (e.g., 0.1µF) near the Vcc pin to stabilize the power supply.

- Avoid toggling the INC pin too quickly; ensure a minimum pulse width of 1µs.

- Ensure the CS pin is high when not adjusting the wiper to prevent unintended changes.

Troubleshooting and FAQs

Common Issues

Wiper Position Not Changing:

- Ensure the CS pin is pulled low during adjustments.

- Verify that the INC pin is toggled correctly with sufficient delay.

Incorrect Resistance Output:

- Check the connections to Vh, Vl, and Vw.

- Ensure the U/D pin is set to the correct direction.

Device Not Responding:

- Verify the power supply voltage is within the specified range (2.7V to 5.5V).

- Check for loose or incorrect connections.

FAQs

Q: Can the X9C104 retain its wiper position after power is removed?

A: Yes, the X9C104 has non-volatile memory and retains its wiper position even after power is disconnected.

Q: What is the maximum current the wiper can handle?

A: The wiper can handle a maximum current of 1mA. Exceeding this limit may damage the device.

Q: Can I use the X9C104 with a 3.3V microcontroller?

A: Yes, the X9C104 operates within a supply voltage range of 2.7V to 5.5V, making it compatible with 3.3V systems.

Q: How precise is the resistance adjustment?

A: The X9C104 provides 100 discrete wiper positions, allowing for fine-grained resistance adjustments.