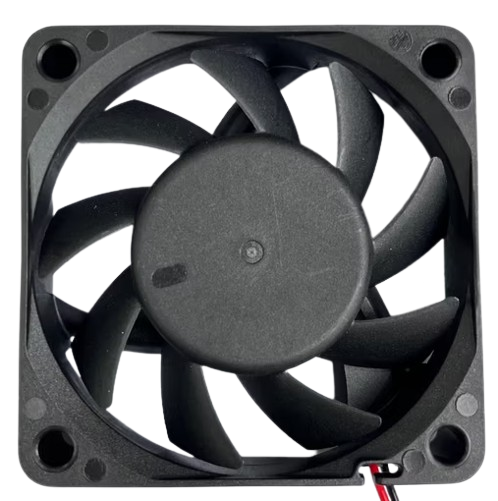

How to Use 60x60x20 Fan 24V: Examples, Pinouts, and Specs

Design with 60x60x20 Fan 24V in Cirkit Designer

Design with 60x60x20 Fan 24V in Cirkit DesignerIntroduction

The 60x60x20 Fan 24V is a compact axial fan designed for efficient cooling in electronic and industrial applications. With dimensions of 60mm x 60mm x 20mm and a 24V operating voltage, this fan is ideal for dissipating heat and maintaining optimal operating temperatures in devices such as power supplies, 3D printers, computer systems, and other heat-sensitive equipment. Its small size and reliable performance make it a popular choice for thermal management in confined spaces.

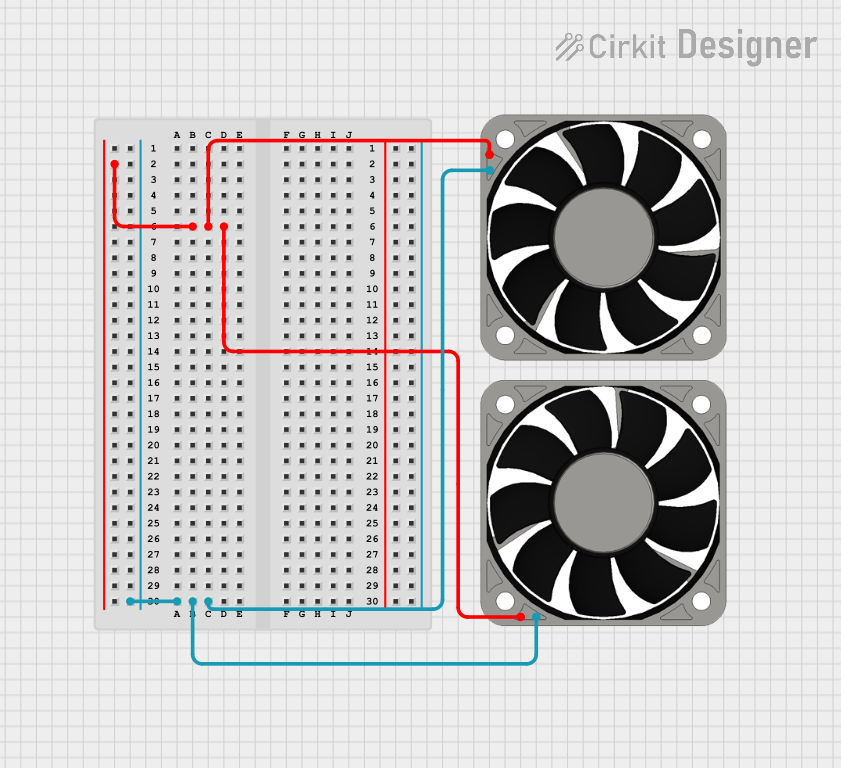

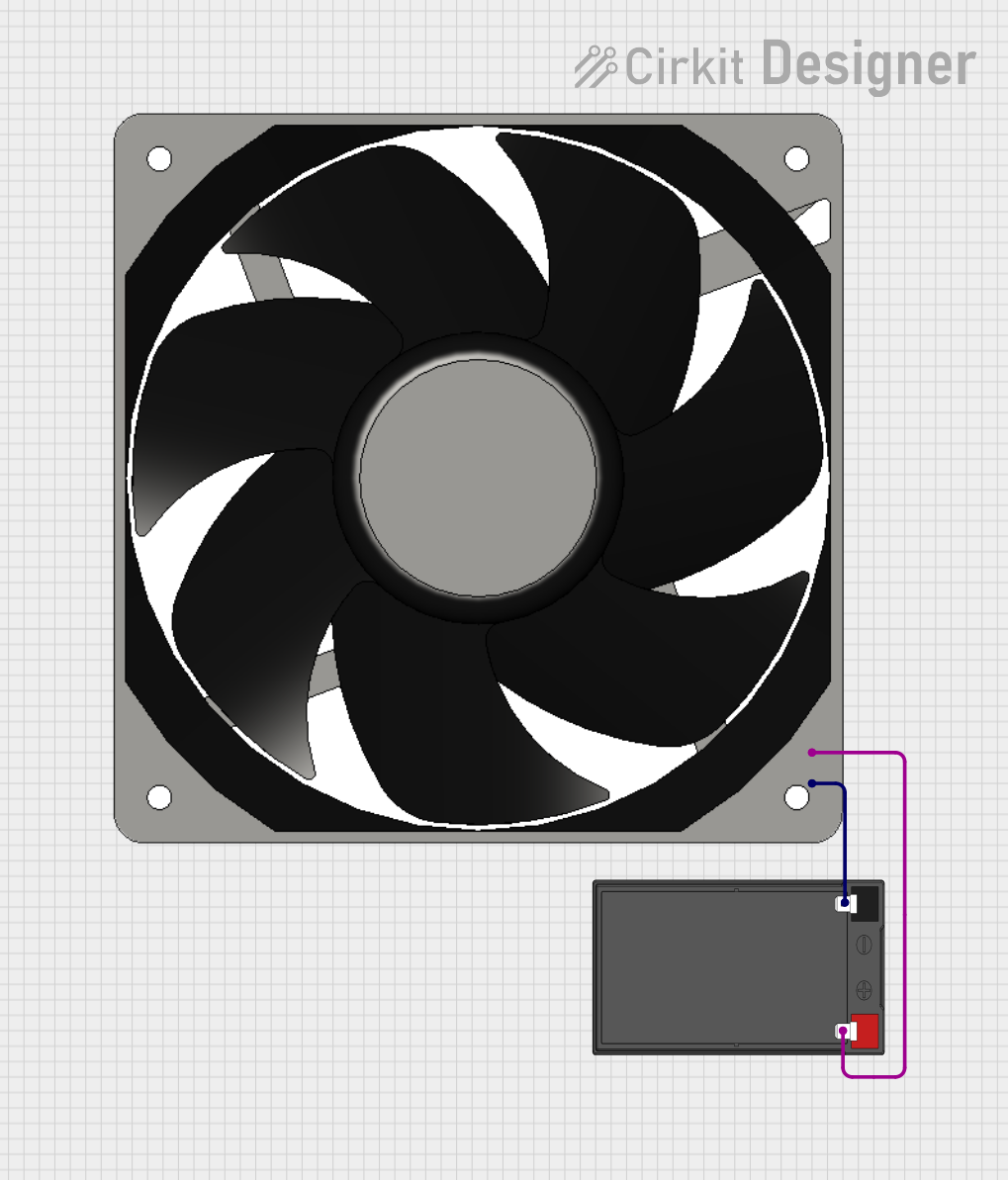

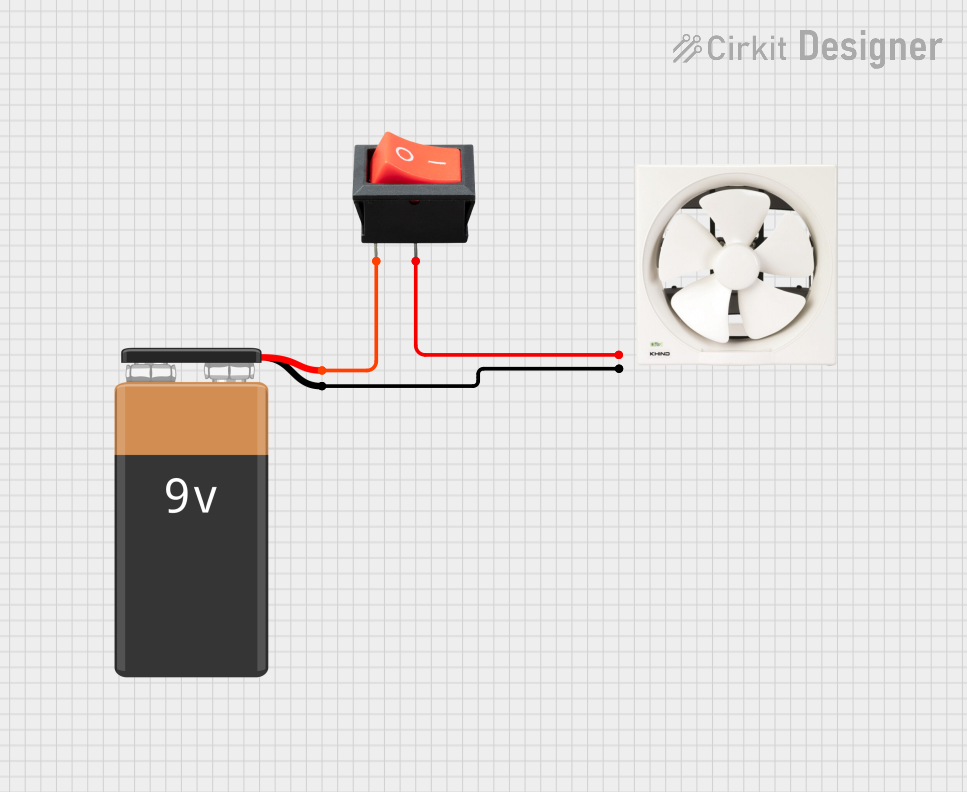

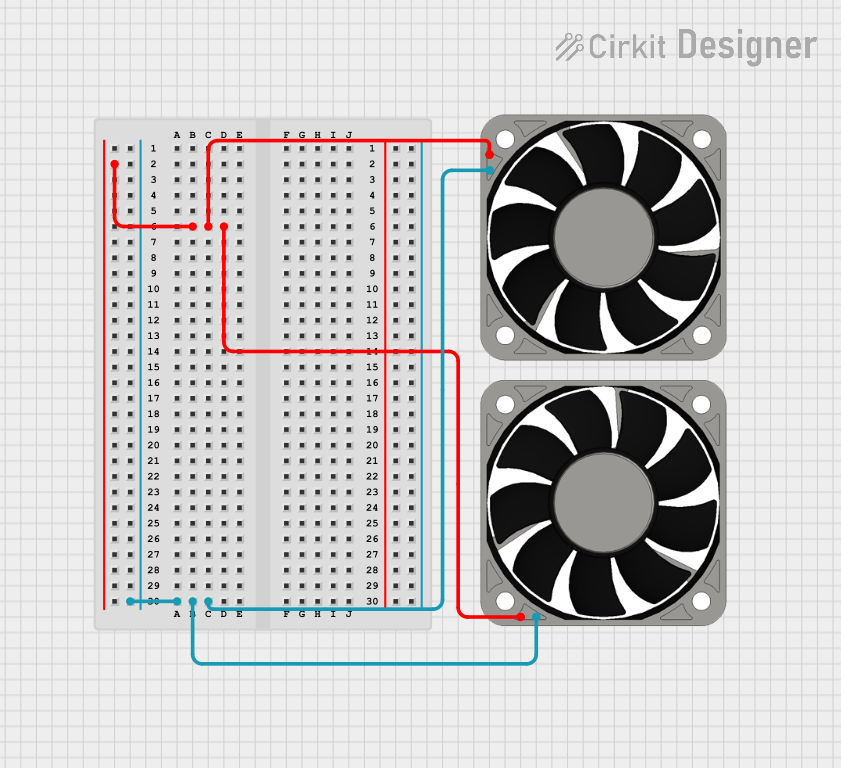

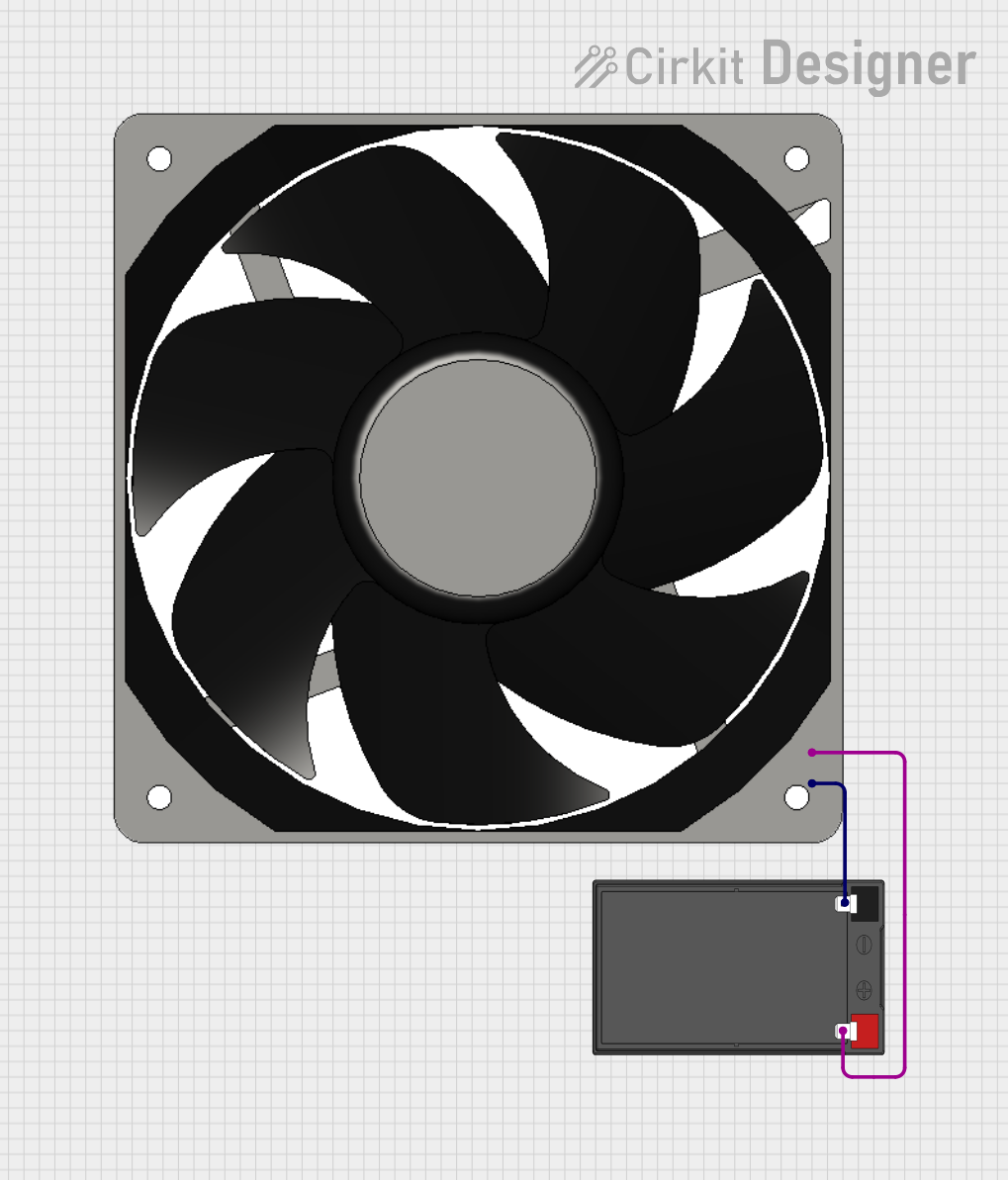

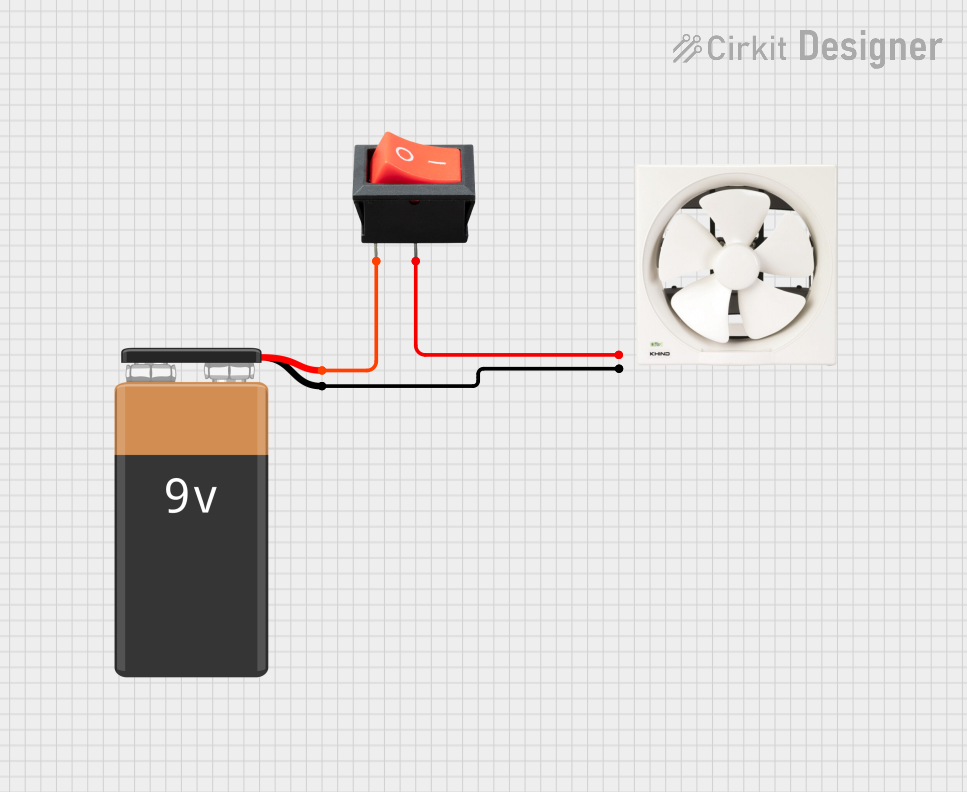

Explore Projects Built with 60x60x20 Fan 24V

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 60x60x20 Fan 24V

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Cooling electronic components in power supplies and enclosures

- Thermal management in 3D printers and CNC machines

- Heat dissipation in computer systems and servers

- Ventilation in small appliances and industrial control panels

Technical Specifications

The following table outlines the key technical specifications of the 60x60x20 Fan 24V:

| Parameter | Specification |

|---|---|

| Dimensions | 60mm x 60mm x 20mm |

| Operating Voltage | 24V DC |

| Current Consumption | ~0.1A (varies by model) |

| Power Consumption | ~2.4W |

| Airflow | ~20-25 CFM (Cubic Feet per Minute) |

| Noise Level | ~25-30 dBA |

| Bearing Type | Sleeve or Ball Bearing (varies) |

| Connector Type | 2-pin or 3-pin (depending on model) |

| Operating Temperature | -10°C to +70°C |

| Lifespan | ~30,000 to 50,000 hours |

Pin Configuration and Descriptions

The fan typically comes with a 2-pin or 3-pin connector. The pin configuration is as follows:

2-Pin Connector

| Pin Number | Wire Color | Description |

|---|---|---|

| 1 | Red | Positive (+24V DC) |

| 2 | Black | Ground (GND) |

3-Pin Connector

| Pin Number | Wire Color | Description |

|---|---|---|

| 1 | Red | Positive (+24V DC) |

| 2 | Black | Ground (GND) |

| 3 | Yellow | Tachometer Signal (optional) |

Usage Instructions

How to Use the 60x60x20 Fan 24V in a Circuit

- Power Supply: Ensure you have a 24V DC power source capable of supplying at least 0.1A of current.

- Wiring:

- For a 2-pin fan, connect the red wire to the positive terminal of the power supply and the black wire to the ground terminal.

- For a 3-pin fan, connect the red and black wires as above. The yellow wire can be connected to a microcontroller or monitoring circuit to read the fan's speed (tachometer signal).

- Mounting: Secure the fan using screws or adhesive mounts. Ensure proper airflow direction by checking the arrow markings on the fan housing.

- Testing: Power on the circuit and verify that the fan spins smoothly and provides adequate airflow.

Important Considerations and Best Practices

- Voltage Compatibility: Do not exceed the rated 24V DC input to avoid damaging the fan.

- Airflow Direction: The fan's airflow direction is typically indicated by arrows on the housing. Ensure the fan is oriented correctly for optimal cooling.

- Noise Reduction: Use rubber mounts or grommets to minimize vibration and noise.

- Maintenance: Periodically clean the fan blades to remove dust and debris, which can reduce efficiency and lifespan.

- Tachometer Signal: If using the 3-pin version, connect the yellow wire to a microcontroller (e.g., Arduino) to monitor the fan's speed.

Example: Connecting to an Arduino UNO

If you are using the 3-pin version of the fan and want to monitor its speed, you can connect the tachometer signal to an Arduino UNO. Below is an example code snippet:

// Example code to read the tachometer signal from a 60x60x20 Fan 24V

// Connect the fan's yellow wire to Arduino pin 2 (interrupt pin)

const int tachPin = 2; // Tachometer signal pin

volatile int fanRPM = 0; // Variable to store fan speed in RPM

volatile int pulseCount = 0; // Count of tachometer pulses

void setup() {

pinMode(tachPin, INPUT_PULLUP); // Set tachometer pin as input

attachInterrupt(digitalPinToInterrupt(tachPin), countPulses, FALLING);

Serial.begin(9600); // Initialize serial communication

}

void loop() {

delay(1000); // Wait for 1 second

noInterrupts(); // Disable interrupts to calculate RPM

fanRPM = (pulseCount * 60) / 2; // Calculate RPM (2 pulses per revolution)

pulseCount = 0; // Reset pulse count

interrupts(); // Re-enable interrupts

Serial.print("Fan Speed: ");

Serial.print(fanRPM);

Serial.println(" RPM");

}

void countPulses() {

pulseCount++; // Increment pulse count on each falling edge

}

Troubleshooting and FAQs

Common Issues and Solutions

Fan Not Spinning:

- Cause: Insufficient voltage or incorrect wiring.

- Solution: Verify the power supply provides 24V DC and check the wiring connections.

Excessive Noise:

- Cause: Dust buildup, loose mounting, or worn bearings.

- Solution: Clean the fan blades, tighten mounting screws, or replace the fan if bearings are worn.

Low Airflow:

- Cause: Obstructions or incorrect orientation.

- Solution: Remove any obstructions and ensure the fan is mounted with the correct airflow direction.

Tachometer Signal Not Working:

- Cause: Incorrect connection or incompatible microcontroller.

- Solution: Verify the yellow wire is connected to a digital input pin and ensure the microcontroller supports interrupt-based signal reading.

FAQs

Q1: Can I use this fan with a 12V power supply?

A1: No, the fan is designed for 24V DC operation. Using a lower voltage may result in reduced performance or failure to start.

Q2: How do I determine the airflow direction?

A2: The airflow direction is indicated by arrows on the fan housing. One arrow shows the airflow direction, and the other shows the blade rotation direction.

Q3: Can I control the fan speed?

A3: This fan does not have built-in PWM control. However, you can use an external PWM controller or a transistor circuit to modulate the voltage and control the speed.

Q4: What is the lifespan of this fan?

A4: The fan typically has a lifespan of 30,000 to 50,000 hours, depending on operating conditions and maintenance.