How to Use FAN: Examples, Pinouts, and Specs

Design with FAN in Cirkit Designer

Design with FAN in Cirkit DesignerIntroduction

A fan is an electromechanical device designed to create airflow, primarily used for cooling or ventilation purposes. It is a critical component in electronic systems, where it helps dissipate heat generated by components such as processors, power supplies, and other heat-sensitive devices. By maintaining optimal operating temperatures, fans ensure the reliability and longevity of electronic equipment.

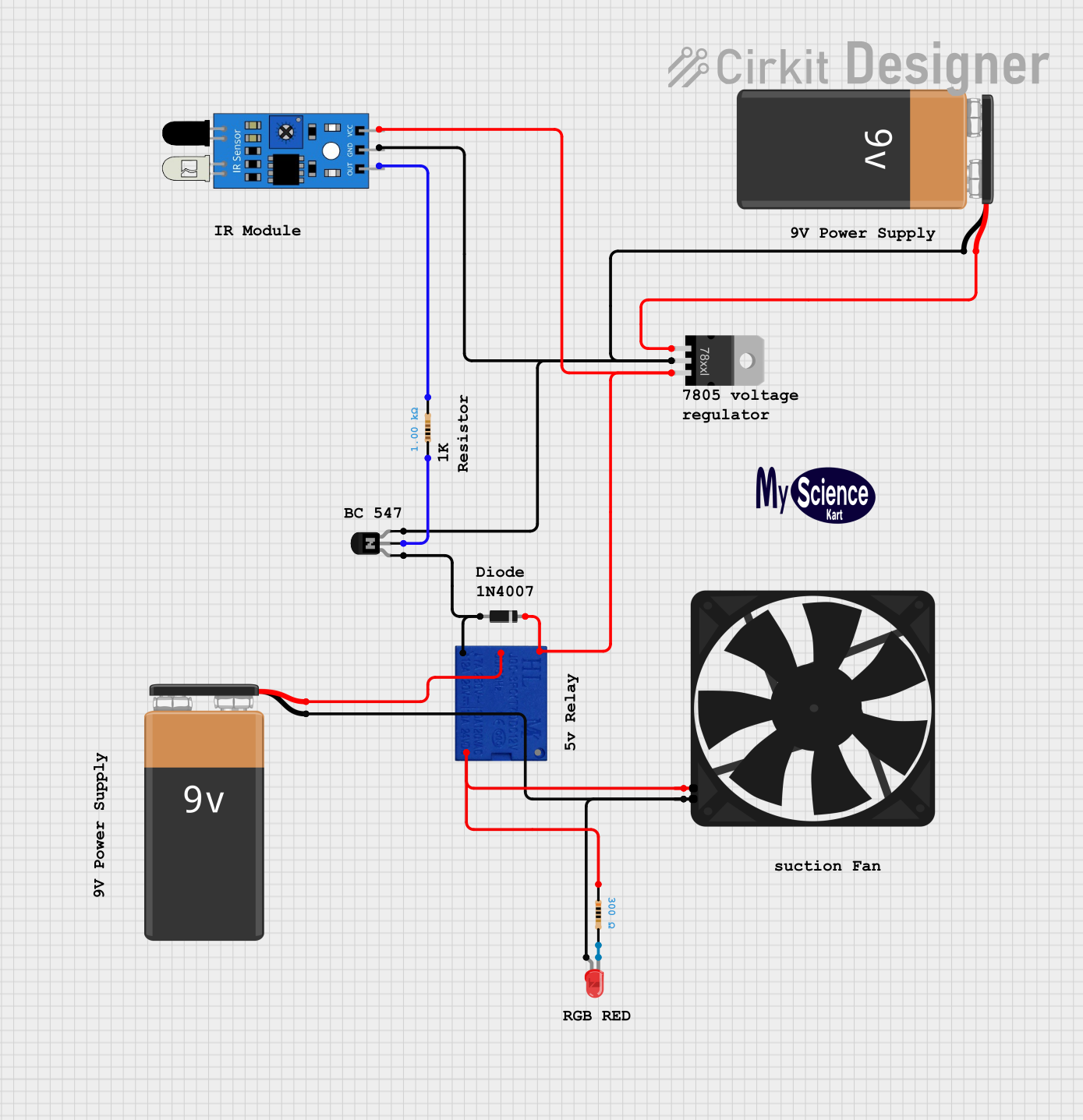

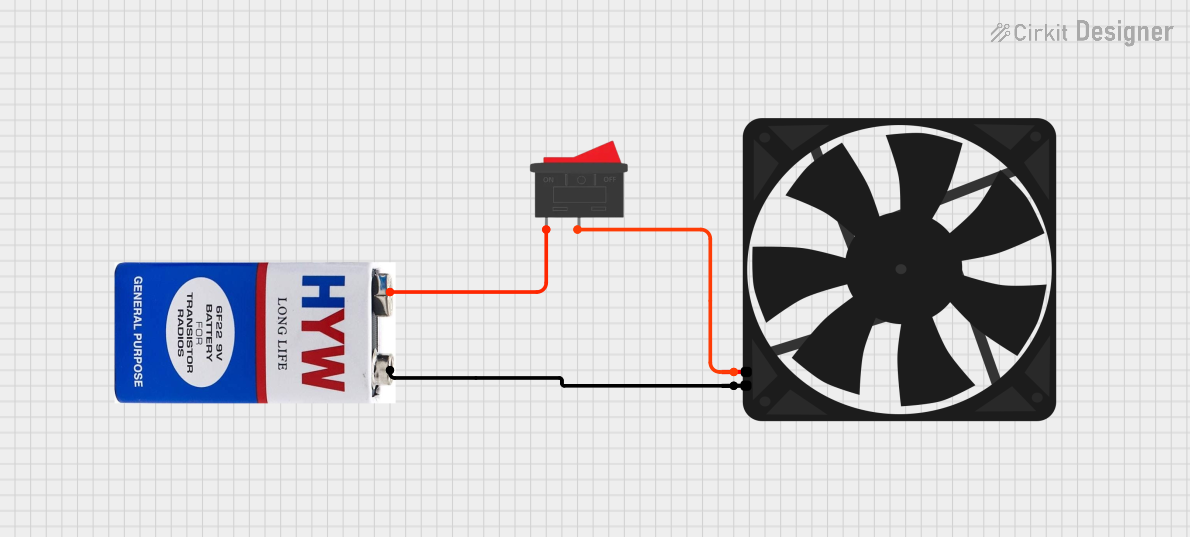

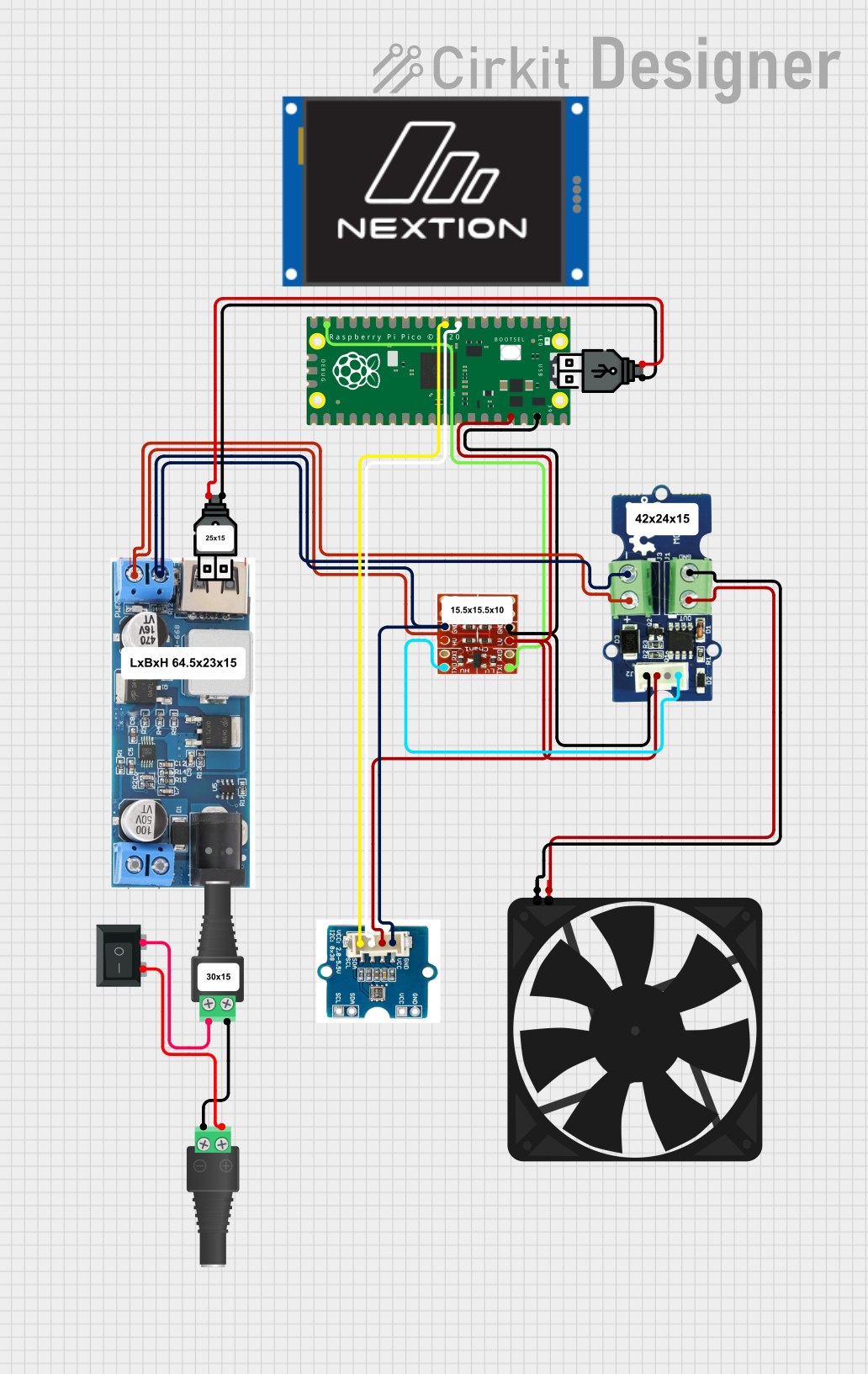

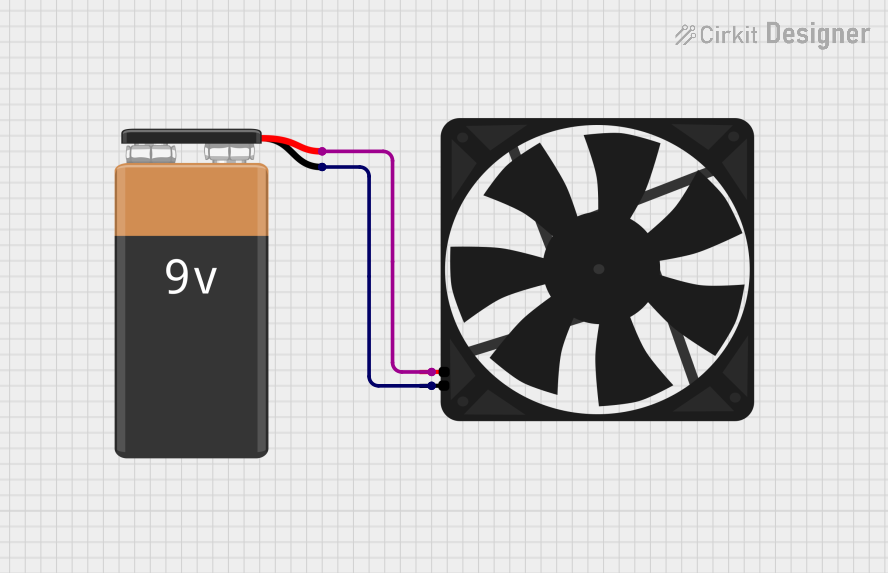

Explore Projects Built with FAN

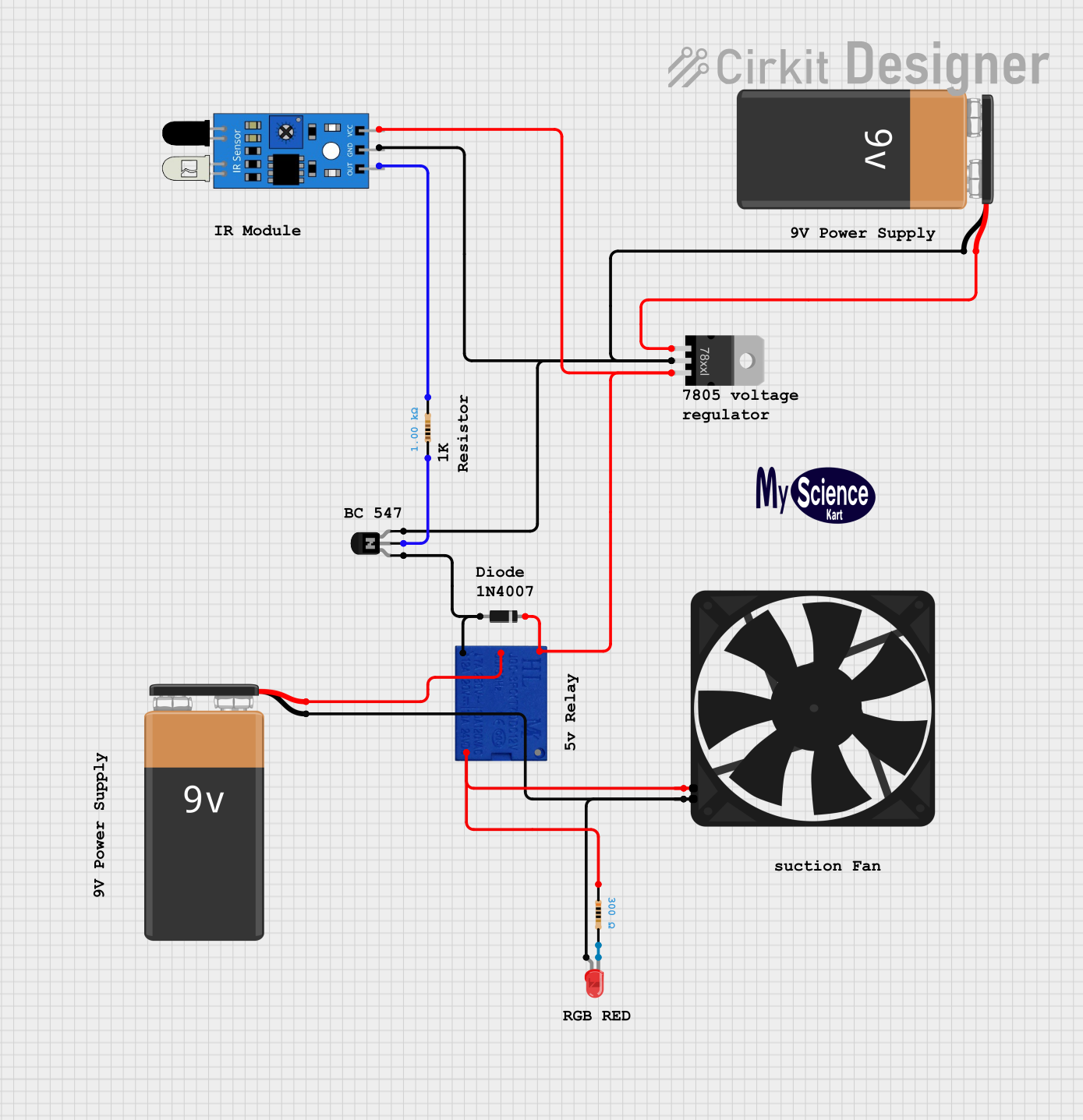

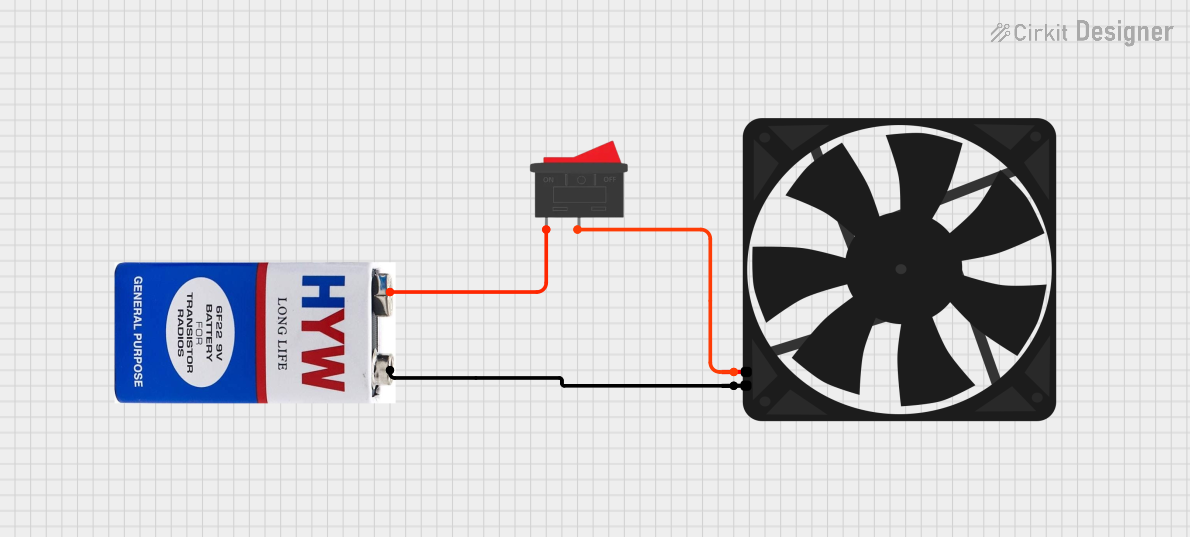

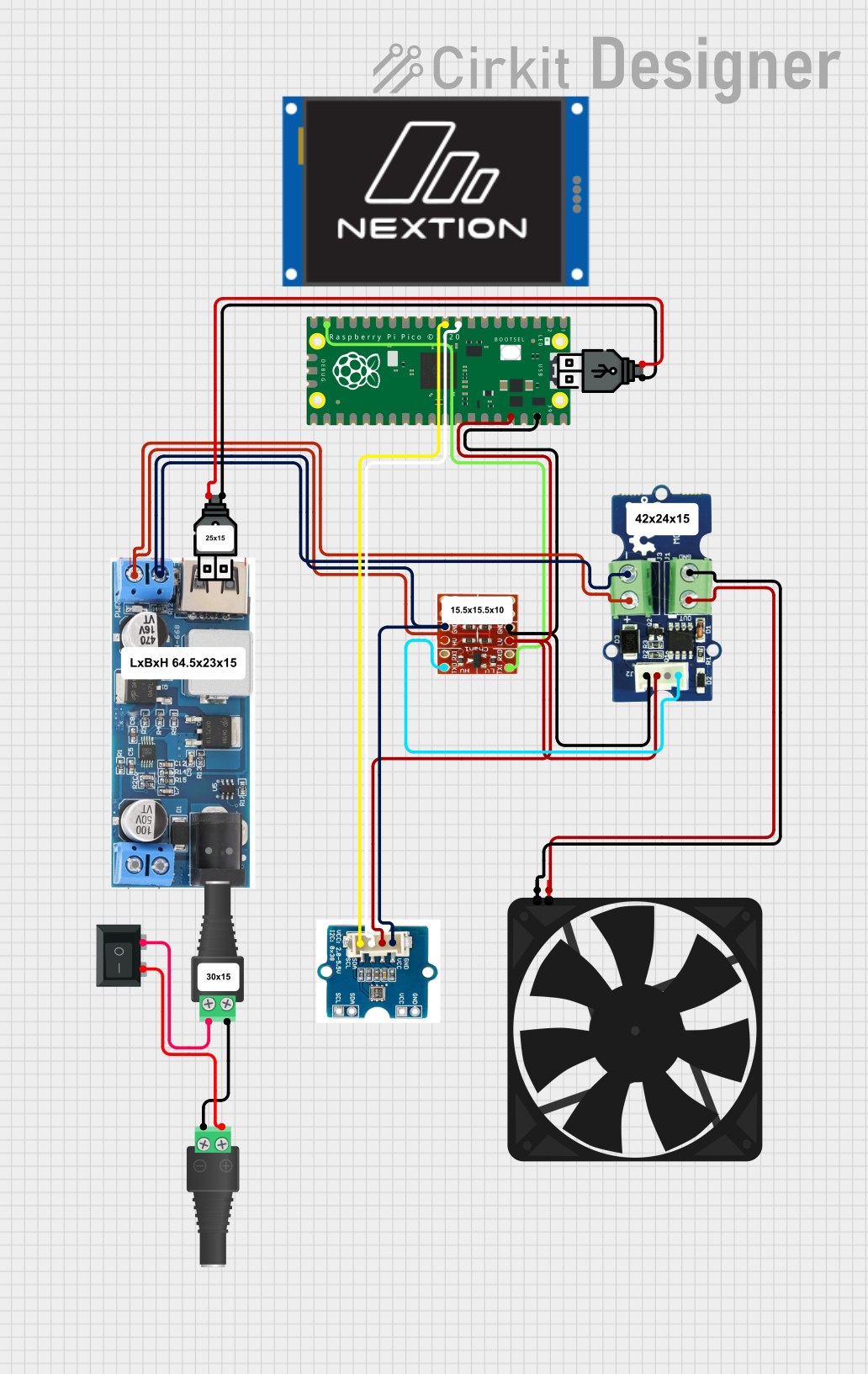

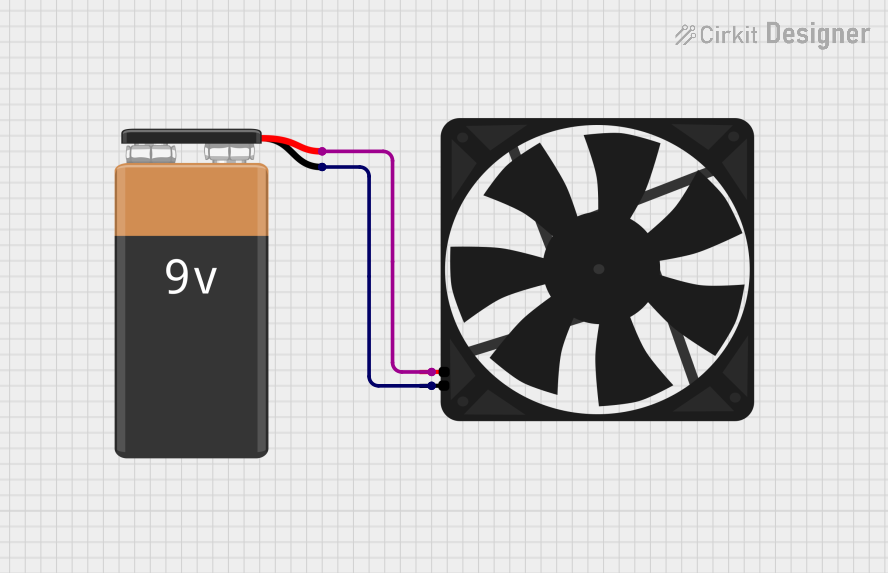

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with FAN

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Cooling computer processors, graphics cards, and power supplies.

- Ventilating enclosures for industrial or consumer electronics.

- Heat dissipation in power amplifiers and other high-power devices.

- Air circulation in HVAC systems and small appliances.

- Used in robotics and DIY projects for thermal management.

Technical Specifications

Below are the general technical specifications for a standard DC fan manufactured in China. Specifications may vary depending on the specific model.

Key Technical Details

- Operating Voltage: 5V, 12V, or 24V DC (depending on the model)

- Current Rating: 0.1A to 0.5A

- Power Consumption: Typically 0.5W to 6W

- Speed: 2000 to 5000 RPM (Revolutions Per Minute)

- Airflow: 10 to 100 CFM (Cubic Feet per Minute)

- Noise Level: 20 to 40 dBA

- Bearing Type: Sleeve or Ball Bearing

- Connector Type: 2-pin, 3-pin, or 4-pin (PWM control)

Pin Configuration and Descriptions

The pin configuration for a 3-pin and 4-pin fan is detailed below:

3-Pin Fan Connector

| Pin Number | Name | Description |

|---|---|---|

| 1 | GND | Ground connection |

| 2 | VCC | Power supply (e.g., 12V DC) |

| 3 | Tachometer | Outputs a signal for speed monitoring |

4-Pin Fan Connector

| Pin Number | Name | Description |

|---|---|---|

| 1 | GND | Ground connection |

| 2 | VCC | Power supply (e.g., 12V DC) |

| 3 | Tachometer | Outputs a signal for speed monitoring |

| 4 | PWM | Pulse Width Modulation for speed control |

Usage Instructions

How to Use the Fan in a Circuit

- Power Connection:

- Connect the VCC pin to the appropriate voltage source (e.g., 12V DC).

- Connect the GND pin to the ground of the power supply.

- Speed Monitoring (Optional):

- For 3-pin and 4-pin fans, connect the Tachometer pin to a microcontroller or monitoring circuit to measure the fan's speed.

- Speed Control (4-Pin Fans Only):

- Use the PWM pin to control the fan speed. A PWM signal (typically 25 kHz) can be generated using a microcontroller like an Arduino.

Important Considerations and Best Practices

- Voltage Compatibility: Ensure the fan's operating voltage matches the power supply to avoid damage.

- Current Rating: Verify that the power supply can provide sufficient current for the fan.

- Orientation: Install the fan in the correct orientation to ensure proper airflow direction.

- Noise Reduction: Use rubber mounts or grommets to minimize vibration and noise.

- Dust Management: Periodically clean the fan to prevent dust buildup, which can reduce efficiency.

Example: Connecting a 4-Pin Fan to an Arduino UNO

Below is an example of how to control a 4-pin fan using an Arduino UNO and PWM.

// Example: Controlling a 4-pin fan with Arduino UNO

// Connect the fan's PWM pin to Arduino pin 9

// Ensure the fan's VCC and GND are connected to a 12V power source

const int fanPWM = 9; // PWM pin connected to the fan's PWM input

void setup() {

pinMode(fanPWM, OUTPUT); // Set the PWM pin as an output

}

void loop() {

// Set fan speed to 50% duty cycle (128 out of 255)

analogWrite(fanPWM, 128);

// Run at 50% speed for 5 seconds

delay(5000);

// Set fan speed to 100% duty cycle (255 out of 255)

analogWrite(fanPWM, 255);

// Run at full speed for 5 seconds

delay(5000);

}

Troubleshooting and FAQs

Common Issues and Solutions

Fan Does Not Spin:

- Cause: Incorrect power supply voltage or loose connections.

- Solution: Verify the voltage and ensure all connections are secure.

Fan Spins Slowly:

- Cause: Insufficient power supply current or high PWM duty cycle.

- Solution: Check the power supply's current rating and adjust the PWM signal.

Excessive Noise:

- Cause: Dust buildup or worn-out bearings.

- Solution: Clean the fan and consider replacing it if the bearings are damaged.

No Speed Signal from Tachometer:

- Cause: Tachometer pin not connected or incompatible monitoring circuit.

- Solution: Ensure the tachometer pin is properly connected and the monitoring circuit is compatible.

FAQs

Q: Can I use a 3-pin fan with PWM control?

A: No, 3-pin fans do not have a dedicated PWM pin. However, you can control their speed by varying the supply voltage using a DC motor driver or similar circuit.

Q: How do I determine the airflow direction of the fan?

A: Most fans have an arrow on the housing indicating the airflow direction. If not, airflow typically moves from the open side to the side with the fan's frame supports.

Q: Can I power a 12V fan with a 5V supply?

A: While the fan may spin at a reduced speed, it is not recommended as it may not operate reliably or provide sufficient airflow.

Q: How often should I clean the fan?

A: Clean the fan every 3 to 6 months, or more frequently in dusty environments, to maintain optimal performance.