How to Use Motor driver: Examples, Pinouts, and Specs

Design with Motor driver in Cirkit Designer

Design with Motor driver in Cirkit DesignerIntroduction

A motor driver is an electronic circuit designed to control the operation of a motor by providing the necessary voltage and current. It acts as an interface between a microcontroller or control system and the motor, enabling precise control of motor speed, direction, and torque. Motor drivers are essential in applications where motors are used, such as robotics, automation systems, electric vehicles, and industrial machinery.

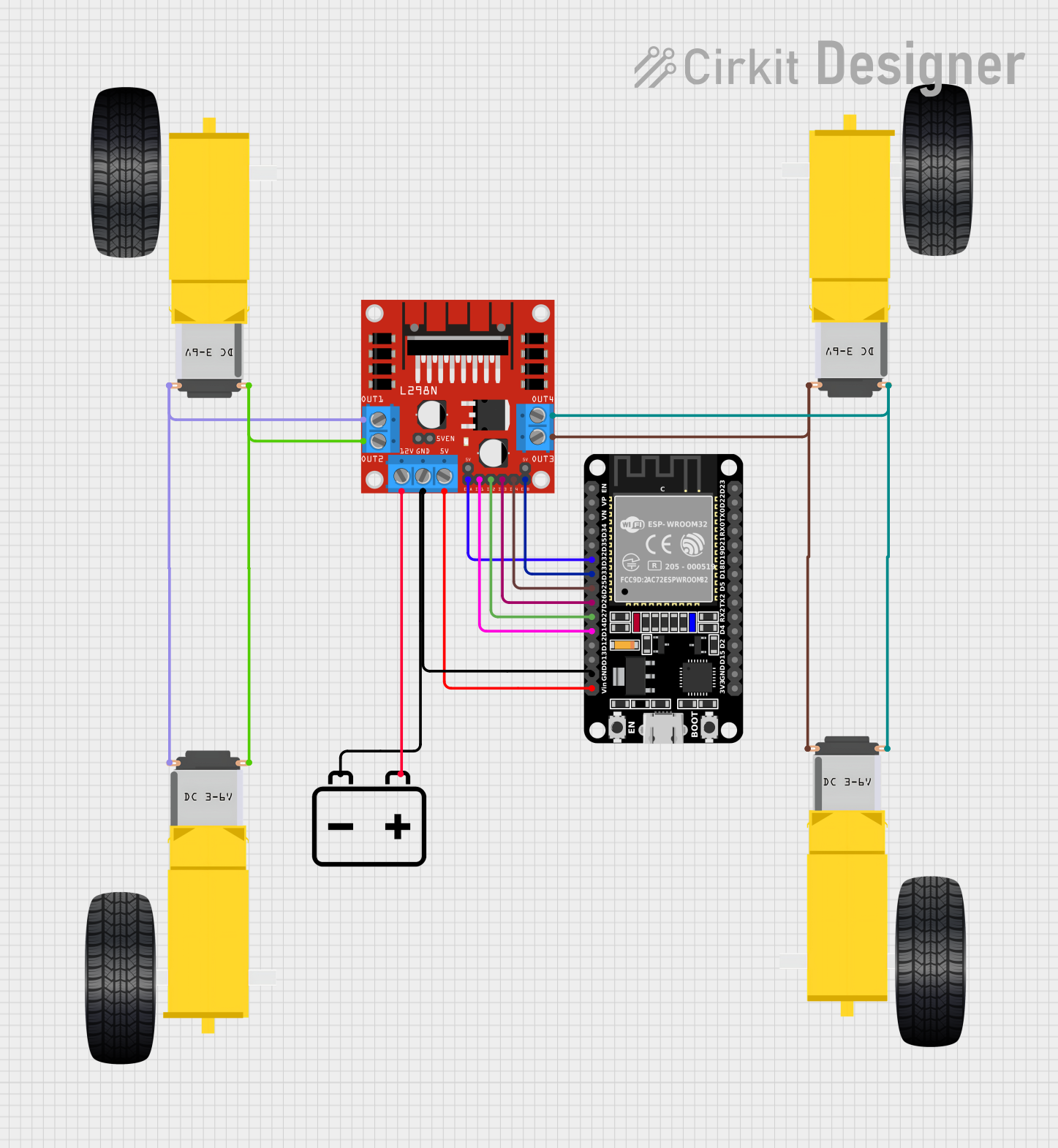

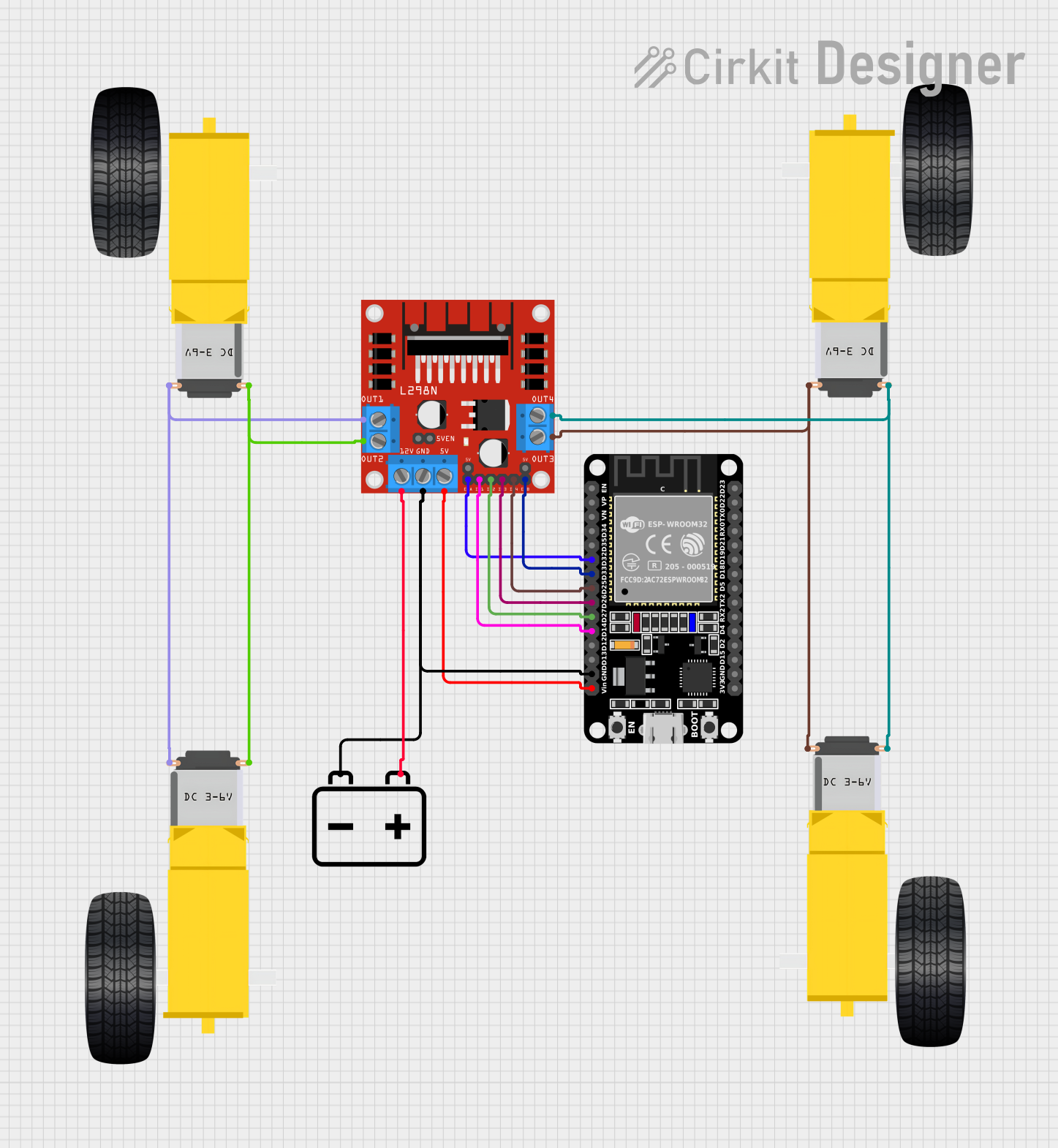

Explore Projects Built with Motor driver

Open Project in Cirkit Designer

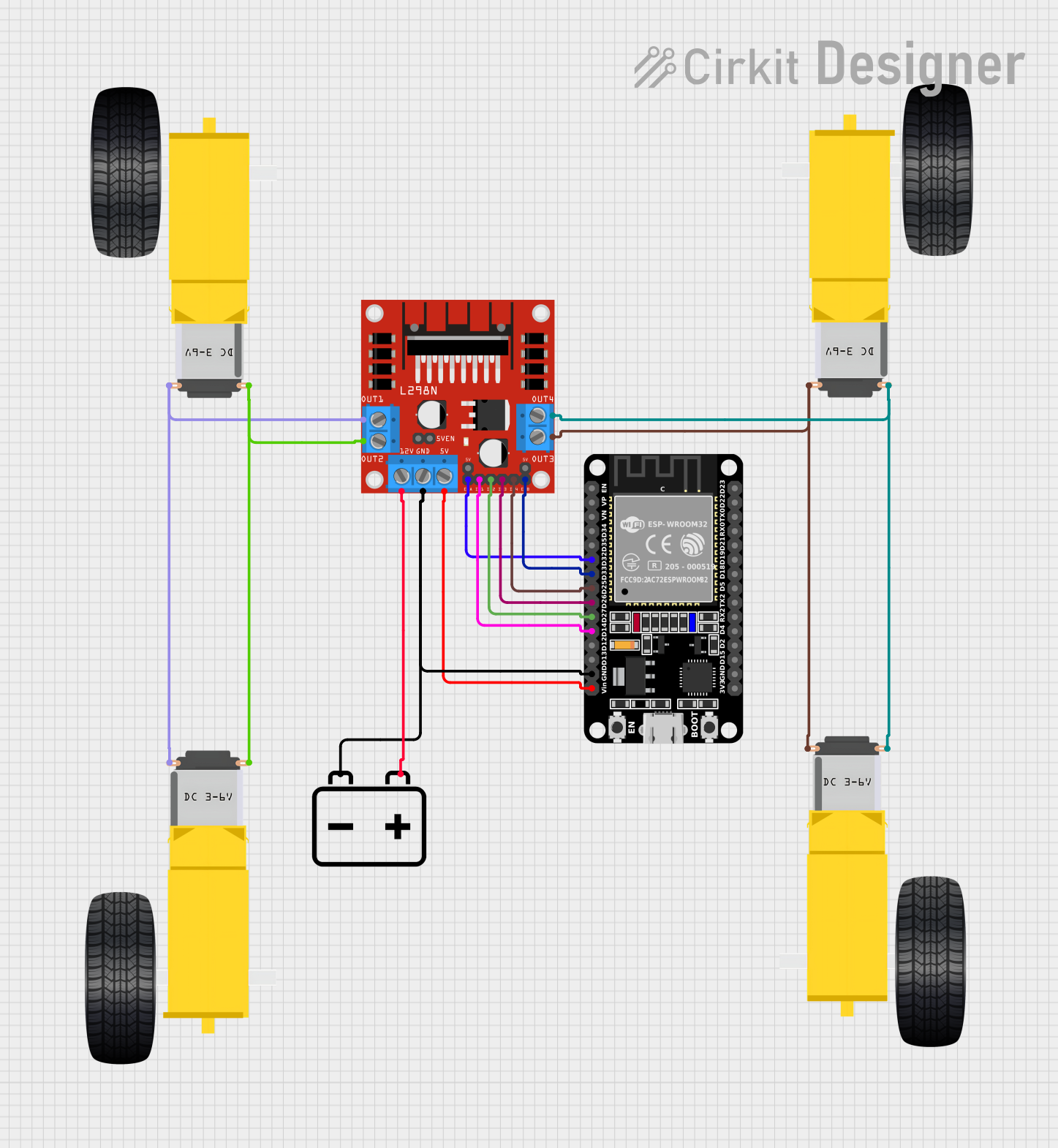

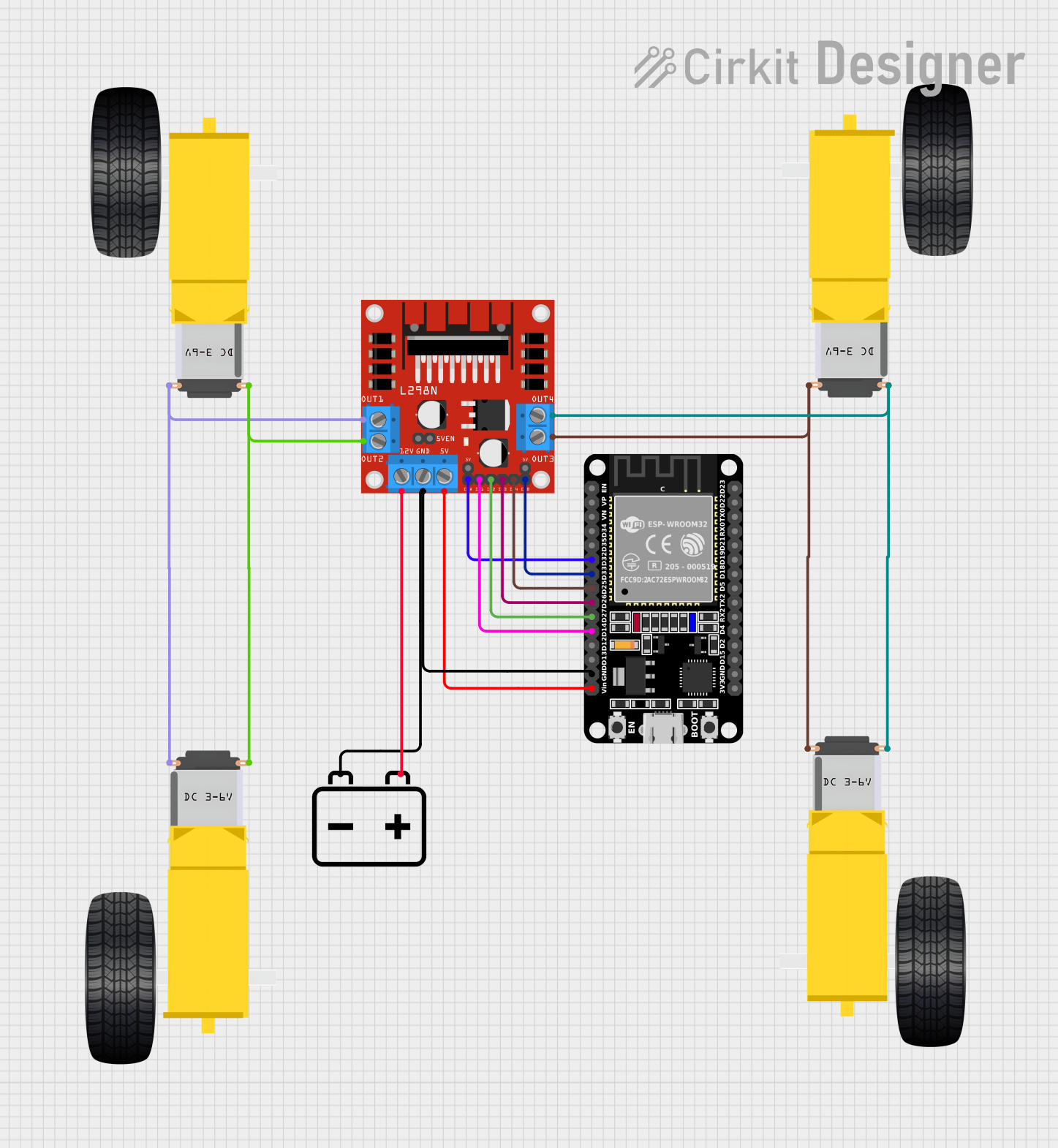

Open Project in Cirkit Designer

Open Project in Cirkit Designer

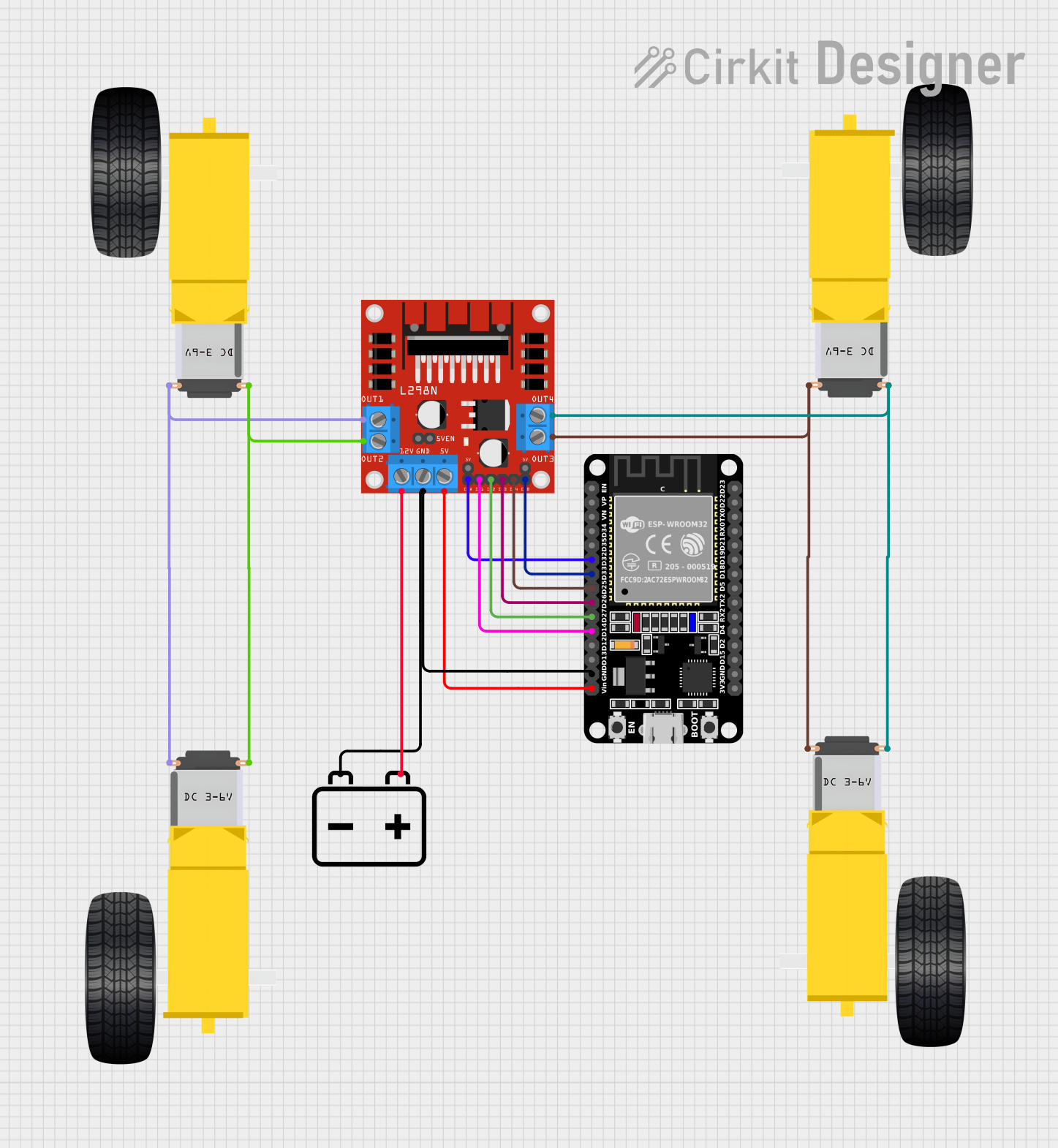

Open Project in Cirkit Designer

Open Project in Cirkit Designer

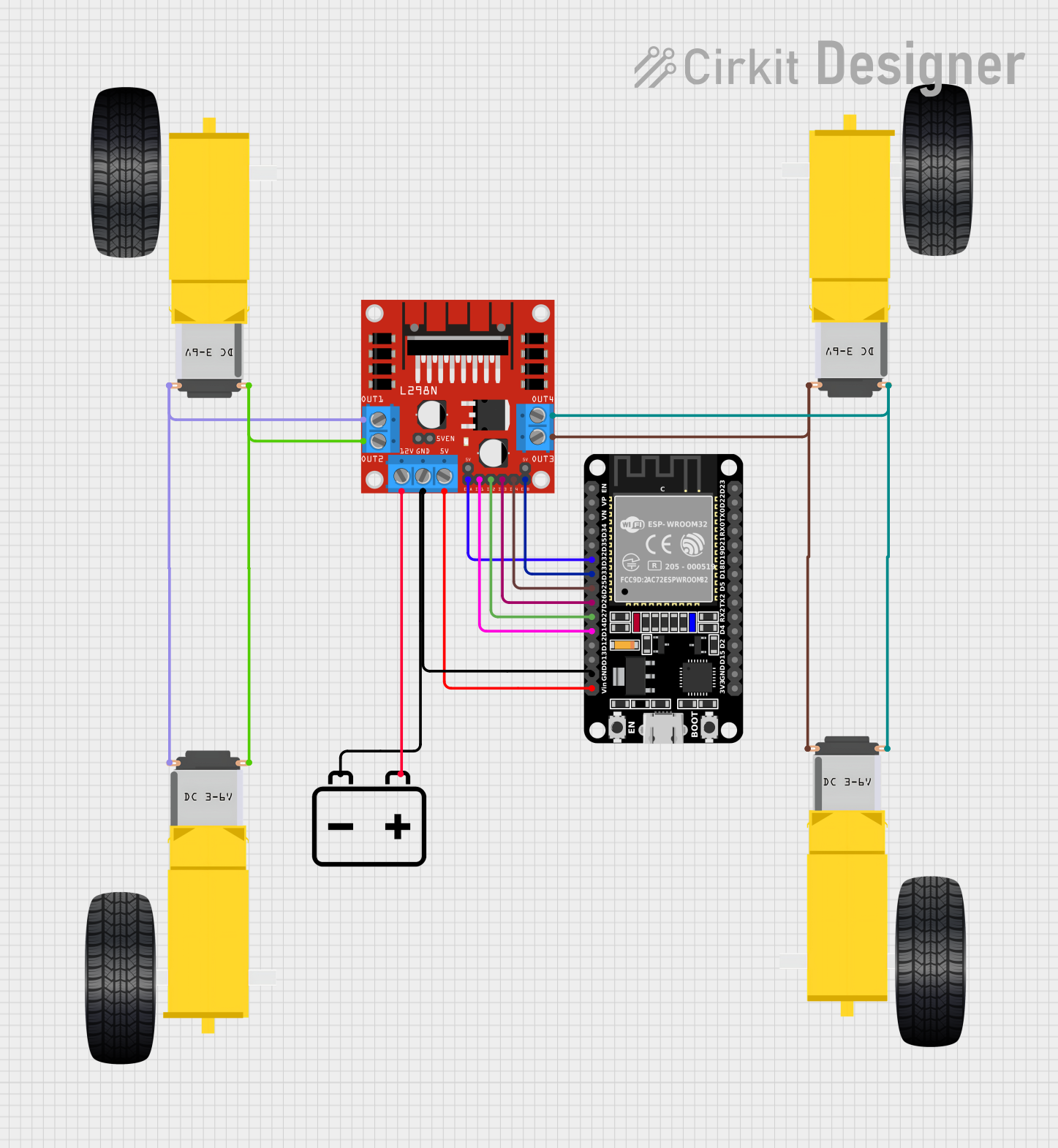

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Motor driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Controlling the movement of robotic arms, wheels, or actuators.

- Automation Systems: Driving conveyor belts, pumps, or other automated machinery.

- Electric Vehicles: Managing the operation of DC or stepper motors in electric vehicles.

- Home Appliances: Used in devices like fans, washing machines, and air conditioners.

- Prototyping and DIY Projects: Widely used in hobbyist projects involving Arduino or Raspberry Pi.

Technical Specifications

Below are the general technical specifications for a typical motor driver (e.g., L298N Dual H-Bridge Motor Driver):

Key Technical Details

- Operating Voltage: 5V to 46V

- Output Current: Up to 2A per channel (continuous), 3A peak

- Number of Channels: Dual (can control two motors independently)

- Control Logic Voltage: 3.3V or 5V (compatible with most microcontrollers)

- Power Dissipation: Up to 25W (with proper heat sinking)

- Built-in Protection: Thermal shutdown and overcurrent protection

- PWM Frequency: Up to 25 kHz

Pin Configuration and Descriptions

The following table describes the pinout for a typical L298N motor driver module:

| Pin Name | Type | Description |

|---|---|---|

IN1 |

Input | Control input for Motor A (logic HIGH or LOW to set direction). |

IN2 |

Input | Control input for Motor A (logic HIGH or LOW to set direction). |

IN3 |

Input | Control input for Motor B (logic HIGH or LOW to set direction). |

IN4 |

Input | Control input for Motor B (logic HIGH or LOW to set direction). |

ENA |

Input (PWM) | Enable pin for Motor A (connect to PWM signal for speed control). |

ENB |

Input (PWM) | Enable pin for Motor B (connect to PWM signal for speed control). |

OUT1 |

Output | Output terminal for Motor A. |

OUT2 |

Output | Output terminal for Motor A. |

OUT3 |

Output | Output terminal for Motor B. |

OUT4 |

Output | Output terminal for Motor B. |

VCC |

Power Supply | Motor power supply (5V to 46V). |

GND |

Ground | Common ground for the circuit. |

5V |

Power Output | Regulated 5V output (can power the microcontroller if needed). |

Usage Instructions

How to Use the Motor Driver in a Circuit

Connect Power Supply:

- Connect the motor power supply to the

VCCpin and ground to theGNDpin. - Ensure the power supply voltage matches the motor's operating voltage.

- Connect the motor power supply to the

Connect Motors:

- Connect the motor terminals to the

OUT1andOUT2pins for Motor A, andOUT3andOUT4pins for Motor B.

- Connect the motor terminals to the

Connect Control Pins:

- Connect the

IN1,IN2,IN3, andIN4pins to the microcontroller's GPIO pins. - Use the

ENAandENBpins for speed control by providing a PWM signal.

- Connect the

Logic Voltage:

- If the motor driver has a

5Vpin, it can be used to power the microcontroller. Otherwise, ensure the control logic voltage matches the microcontroller's requirements.

- If the motor driver has a

Programming:

- Write code to control the motor's speed and direction using the microcontroller.

Important Considerations and Best Practices

- Heat Management: Use a heat sink or cooling fan if the motor driver operates at high currents.

- Power Supply: Ensure the power supply can provide sufficient current for the motors.

- Protection: Use diodes or capacitors to suppress voltage spikes caused by motor back-EMF.

- Testing: Test the circuit with a low-power motor before connecting high-power motors.

Example Code for Arduino UNO

Below is an example code to control a DC motor using an L298N motor driver and Arduino UNO:

// Define motor control pins

const int IN1 = 9; // Motor A direction control pin 1

const int IN2 = 8; // Motor A direction control pin 2

const int ENA = 10; // Motor A speed control (PWM) pin

void setup() {

// Set motor control pins as outputs

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(ENA, OUTPUT);

}

void loop() {

// Rotate motor in one direction

digitalWrite(IN1, HIGH); // Set IN1 HIGH

digitalWrite(IN2, LOW); // Set IN2 LOW

analogWrite(ENA, 128); // Set speed to 50% (PWM value: 128 out of 255)

delay(2000); // Run for 2 seconds

// Stop the motor

analogWrite(ENA, 0); // Set speed to 0

delay(1000); // Wait for 1 second

// Rotate motor in the opposite direction

digitalWrite(IN1, LOW); // Set IN1 LOW

digitalWrite(IN2, HIGH); // Set IN2 HIGH

analogWrite(ENA, 200); // Set speed to ~78% (PWM value: 200 out of 255)

delay(2000); // Run for 2 seconds

// Stop the motor

analogWrite(ENA, 0); // Set speed to 0

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Running:

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Double-check all connections and ensure the power supply meets the motor's requirements.

Motor Running in the Wrong Direction:

- Cause: Control pins (

IN1,IN2, etc.) are not set correctly. - Solution: Swap the logic levels of the control pins to reverse the motor direction.

- Cause: Control pins (

Overheating:

- Cause: Excessive current draw or inadequate heat dissipation.

- Solution: Use a heat sink or cooling fan, and ensure the motor driver is not overloaded.

PWM Signal Not Working:

- Cause: Incorrect PWM pin configuration or incompatible frequency.

- Solution: Verify the PWM pin and frequency settings in the microcontroller code.

FAQs

Can I use the motor driver with a stepper motor? Yes, the L298N motor driver can control stepper motors by energizing the coils in the correct sequence.

What is the maximum motor voltage I can use? The maximum motor voltage depends on the motor driver's specifications. For the L298N, it is typically 46V.

Can I control more than two motors with one driver? No, the L298N is designed to control up to two motors. For more motors, additional drivers are required.