How to Use Resettable Fuse PTC: Examples, Pinouts, and Specs

Design with Resettable Fuse PTC in Cirkit Designer

Design with Resettable Fuse PTC in Cirkit DesignerIntroduction

A Resettable Fuse, also known as a Polymeric Positive Temperature Coefficient (PTC) device, is a passive electronic component used to protect circuits from excessive current conditions. Unlike traditional fuses, which must be replaced after a single use, PTCs can reset themselves once the overcurrent condition is removed and the device cools down. This makes them ideal for applications where overcurrent conditions are expected to occur occasionally, such as in battery packs, power supplies, and consumer electronics.

Explore Projects Built with Resettable Fuse PTC

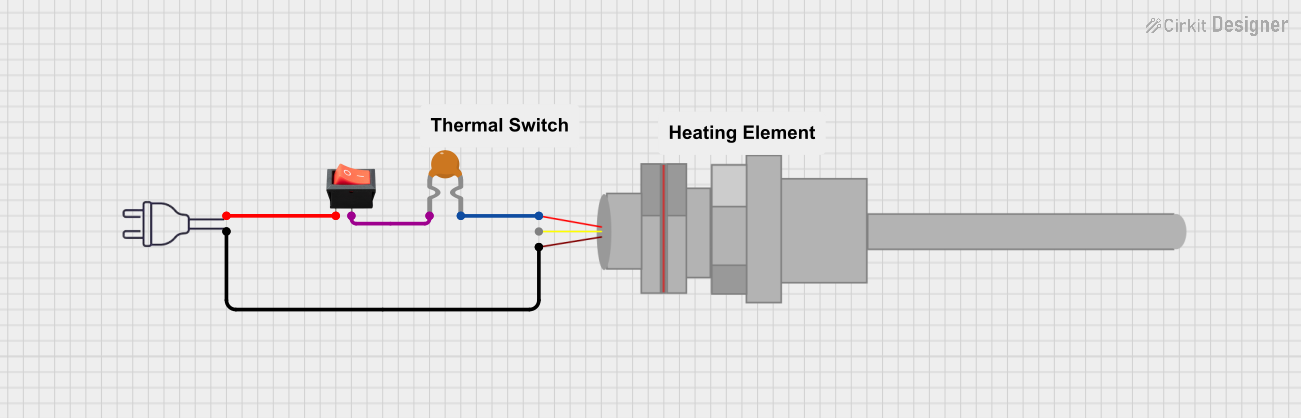

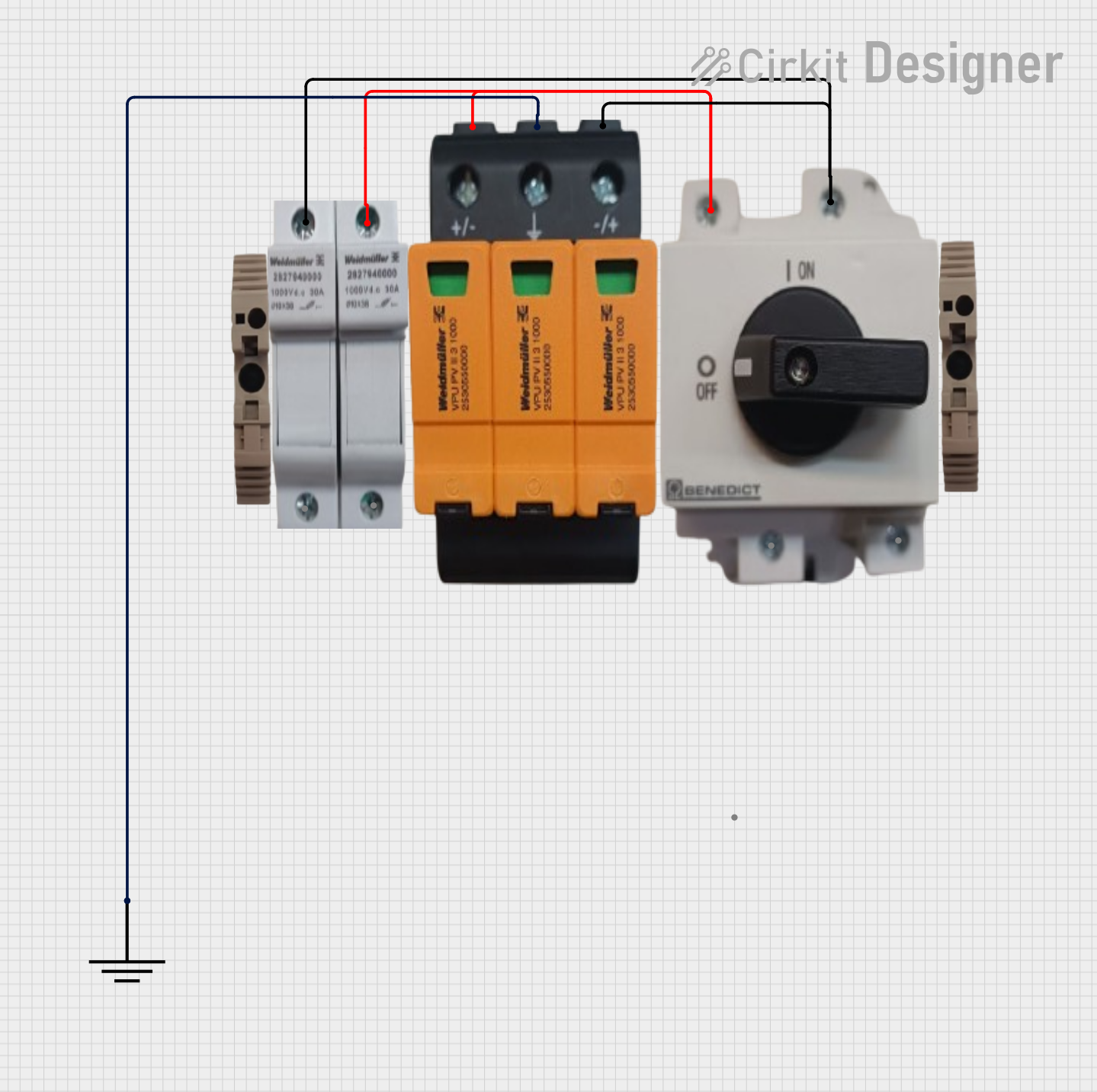

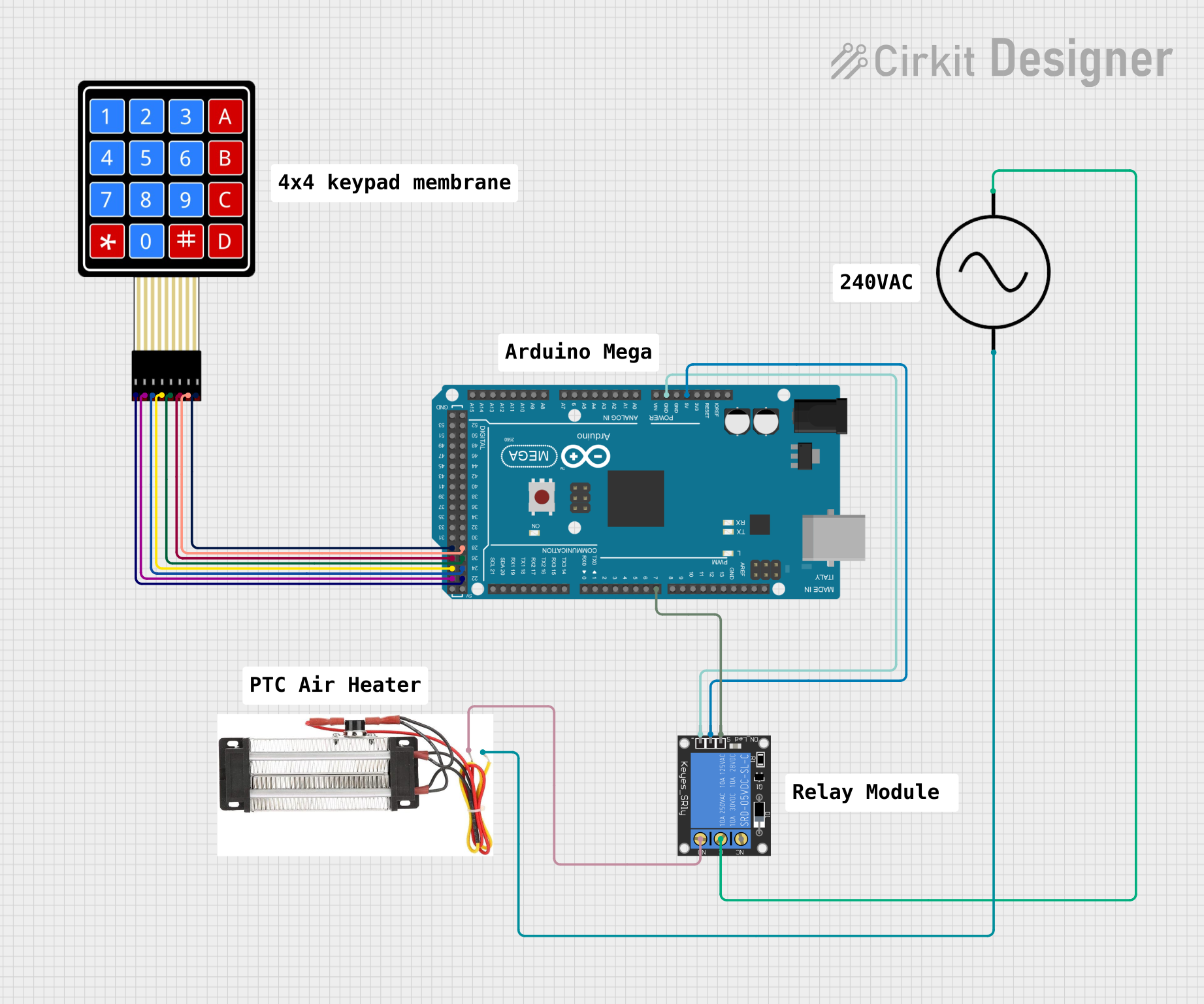

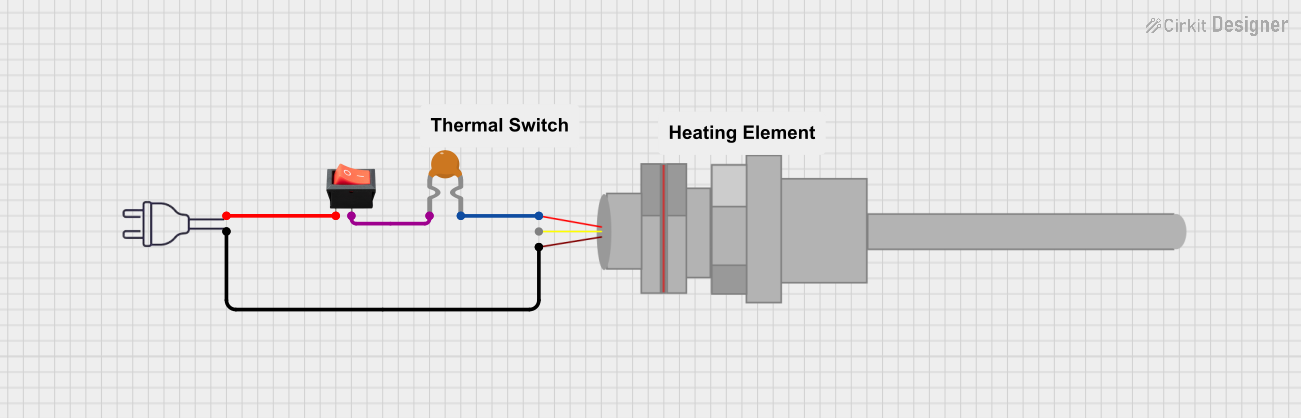

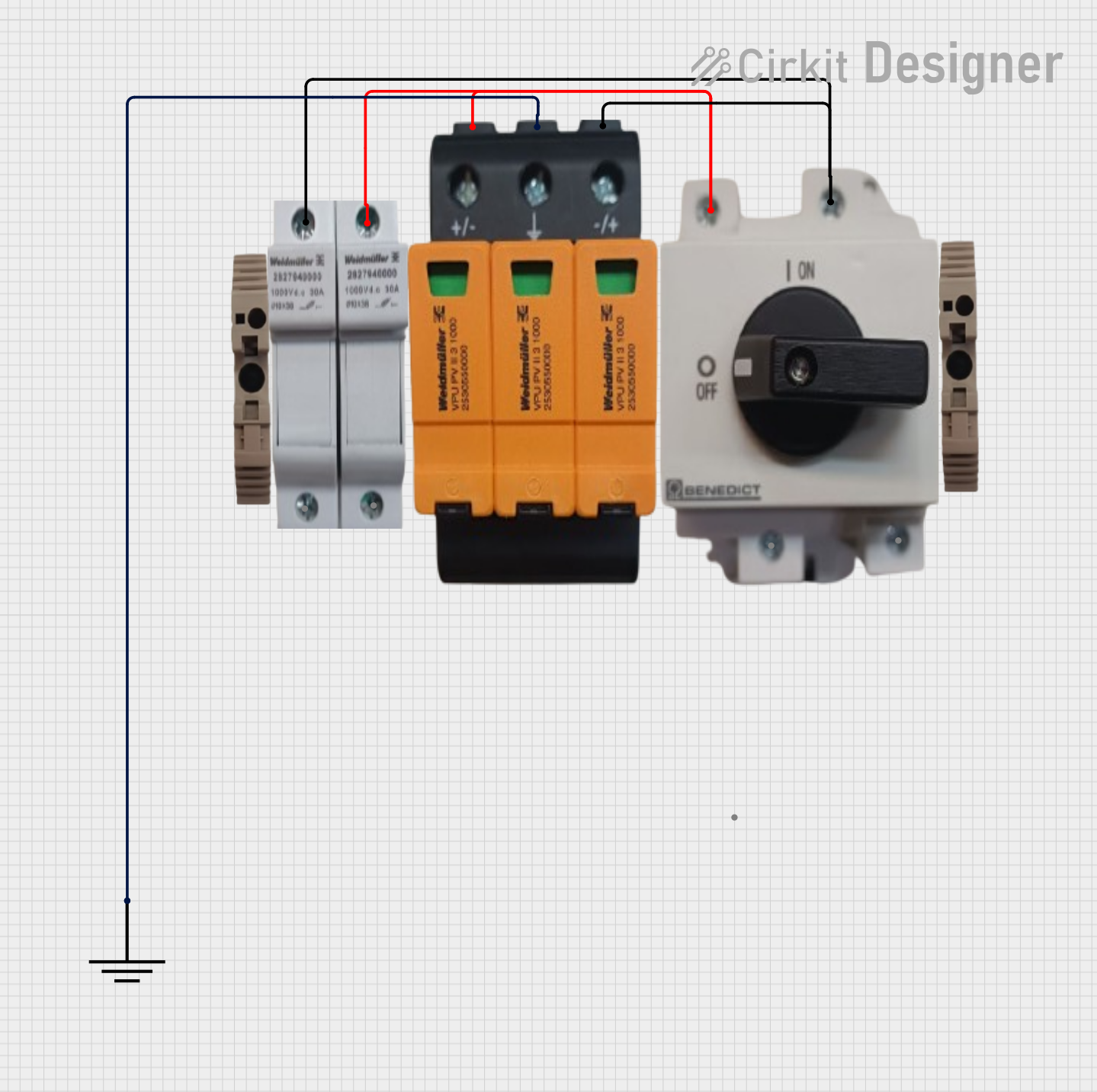

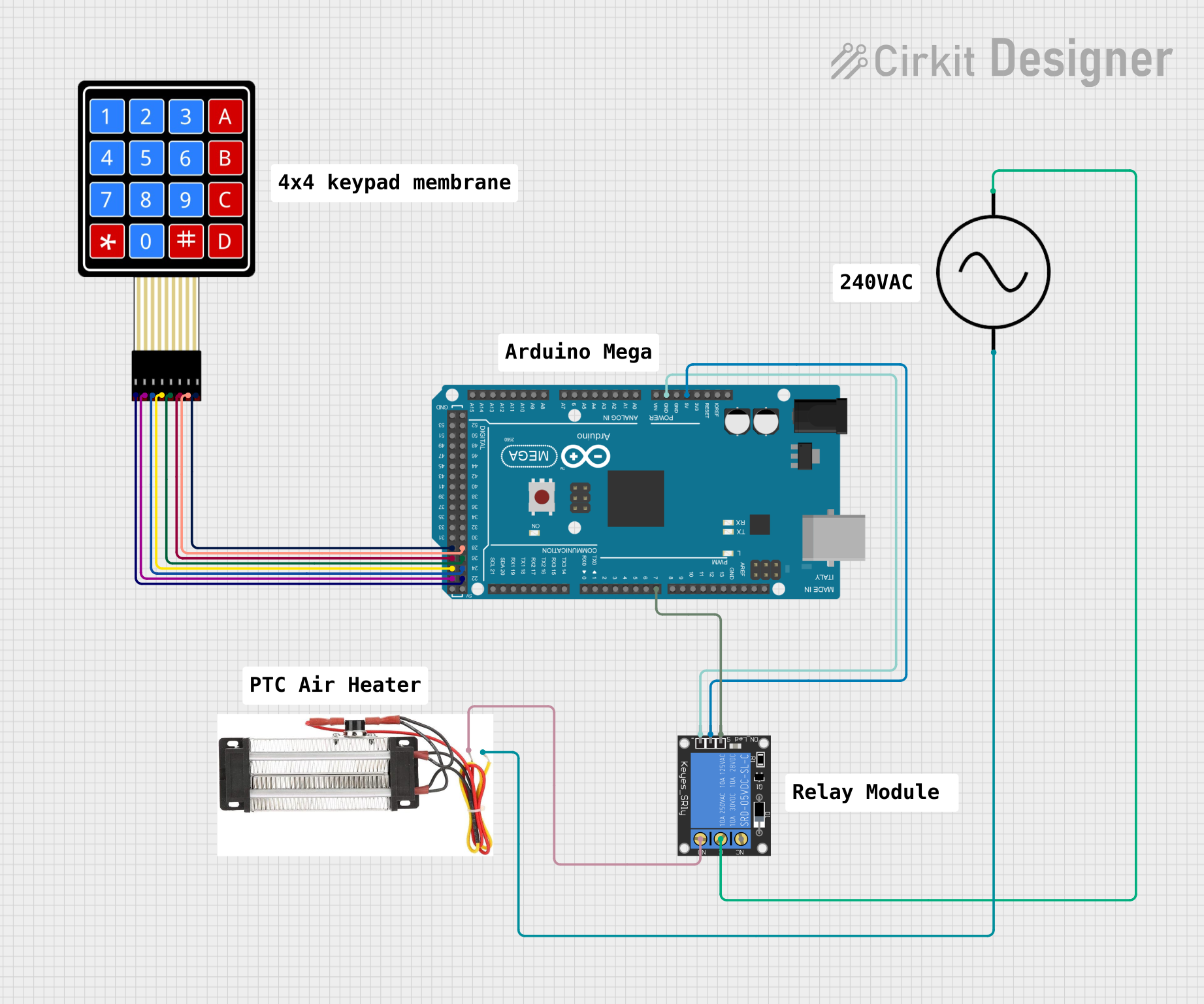

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Resettable Fuse PTC

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Voltage Rating: The maximum voltage the PTC can withstand without damage.

- Current Rating: The operating current range before the PTC trips.

- Trip Current: The current at which the PTC will transition to a high-resistance state.

- Time to Trip: The time it takes for the PTC to trip at a specified current.

- Resistance: The resistance of the PTC in its normal (low-resistance) and tripped (high-resistance) states.

- Power Rating: The maximum power the PTC can dissipate without damage.

Pin Configuration and Descriptions

| Pin Number | Description |

|---|---|

| 1 | Current Input |

| 2 | Current Output |

Note: PTCs are typically two-terminal devices and can be connected in any orientation.

Usage Instructions

How to Use the PTC in a Circuit

Identify the Correct PTC: Choose a PTC with a voltage rating above the maximum operating voltage of your circuit and a current rating that matches the normal operating current.

Circuit Placement: Connect the PTC in series with the load that needs protection. Ensure that the PTC is placed close to the power source to protect the entire circuit.

Testing: After installation, test the circuit at normal operating conditions to ensure that the PTC does not trip during regular use.

Important Considerations and Best Practices

- Orientation: PTCs are non-polarized, so they can be installed in either direction.

- Environment: Avoid placing PTCs in high-temperature environments, as this can cause them to trip prematurely.

- Recovery Time: Allow time for the PTC to cool down and reset after a trip event.

- Ventilation: Ensure proper ventilation around the PTC to facilitate cooling.

Troubleshooting and FAQs

Common Issues

- PTC Does Not Reset: If the PTC does not reset after a trip, check if the overcurrent condition still exists or if the ambient temperature is too high.

- Nuisance Tripping: If the PTC trips during normal operation, it may be undersized for the application. Verify the current rating and trip current specifications.

Solutions and Tips

- Resetting the PTC: Remove the power source and wait for the PTC to cool down. Once cooled, it should reset automatically.

- Selecting the Right PTC: Ensure the PTC's specifications match the circuit requirements to prevent nuisance tripping.

FAQs

Q: Can a PTC be used multiple times? A: Yes, PTCs are designed to reset themselves after an overcurrent condition is cleared.

Q: How quickly does a PTC reset? A: The reset time can vary based on the PTC design and the ambient temperature. It can range from a few seconds to several minutes.

Q: Is there any polarity to be considered when installing a PTC? A: No, PTCs are non-polarized components and can be installed in any orientation.

Q: Can I use a PTC for AC applications? A: Yes, there are PTCs designed for AC applications. Ensure the PTC's voltage rating is suitable for the AC voltage level.

Example Code for Arduino UNO

If you're using a PTC with an Arduino UNO to protect against overcurrent in an external circuit, no specific code is required for the PTC itself. However, you can monitor the state of the PTC by measuring the voltage across it with an analog input. Here's an example of how you might do that:

const int ptcPin = A0; // Analog pin connected to the PTC

void setup() {

Serial.begin(9600);

}

void loop() {

int ptcValue = analogRead(ptcPin); // Read the voltage across the PTC

float voltage = ptcValue * (5.0 / 1023.0); // Convert to voltage

Serial.print("PTC Voltage: ");

Serial.println(voltage);

// Check if the PTC has tripped (assuming a known resistance in the low state)

if (voltage < someThreshold) {

Serial.println("PTC may have tripped.");

}

delay(1000); // Wait for 1 second before reading again

}

Note: Replace someThreshold with the appropriate voltage threshold that indicates a tripped state, based on your specific PTC's resistance and the expected voltage drop.