How to Use L9110: Examples, Pinouts, and Specs

Design with L9110 in Cirkit Designer

Design with L9110 in Cirkit DesignerIntroduction

The L9110 is an integrated circuit designed to control the direction and speed of DC motors. It consists of two H-bridge drivers that can independently control two small to medium-sized DC motors. The L9110 is widely used in robotics, automation projects, and various DIY applications due to its simplicity and efficiency.

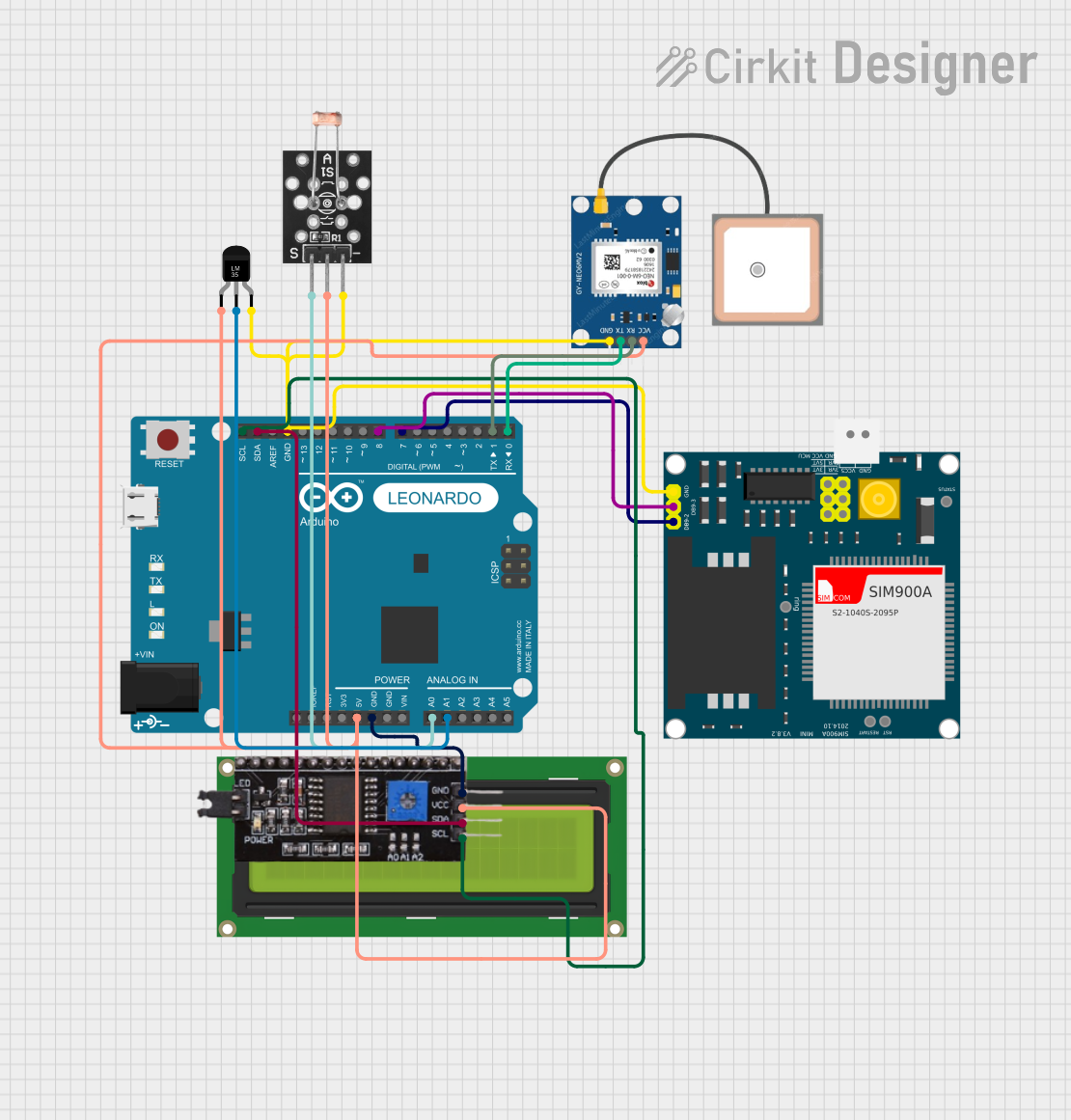

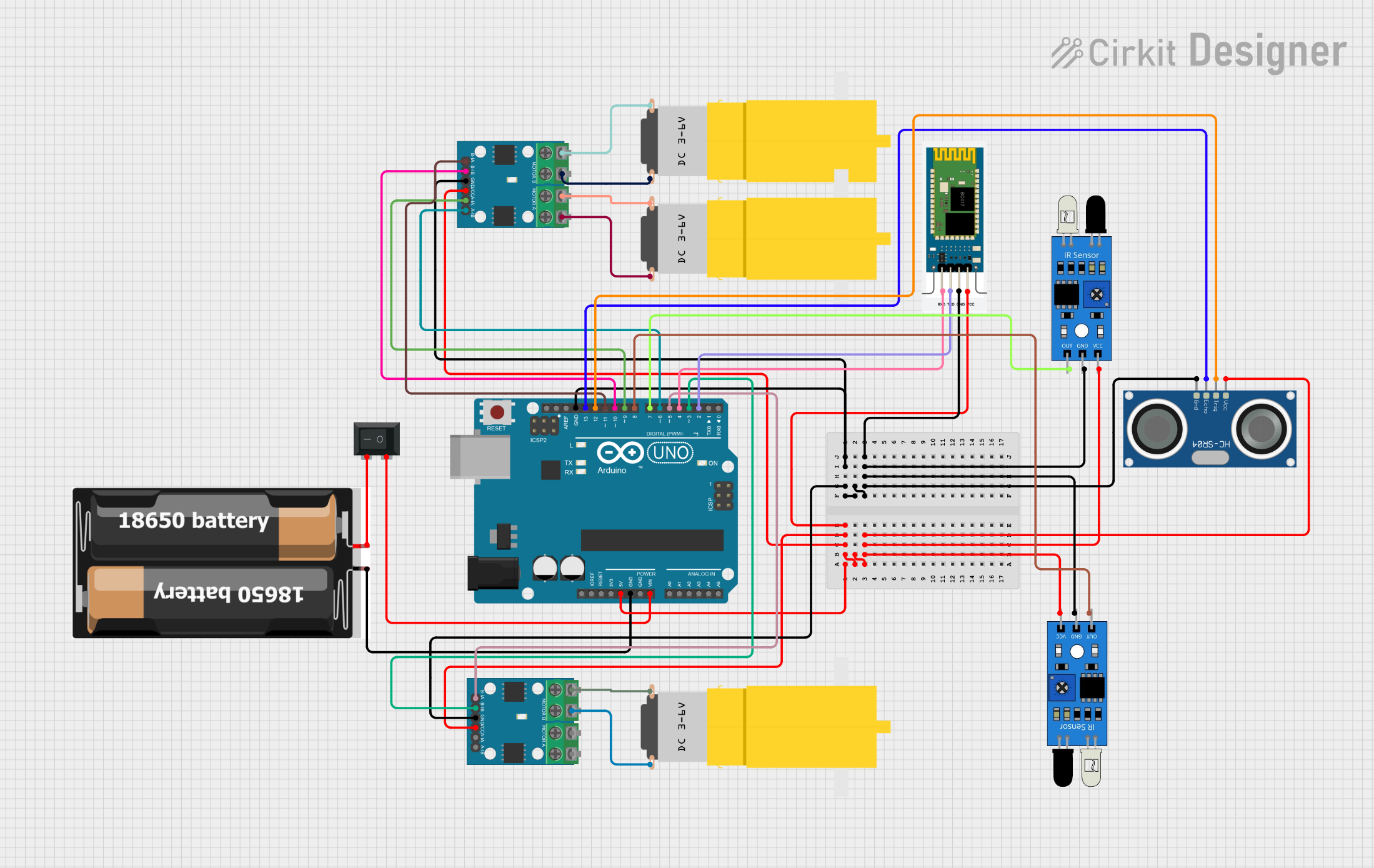

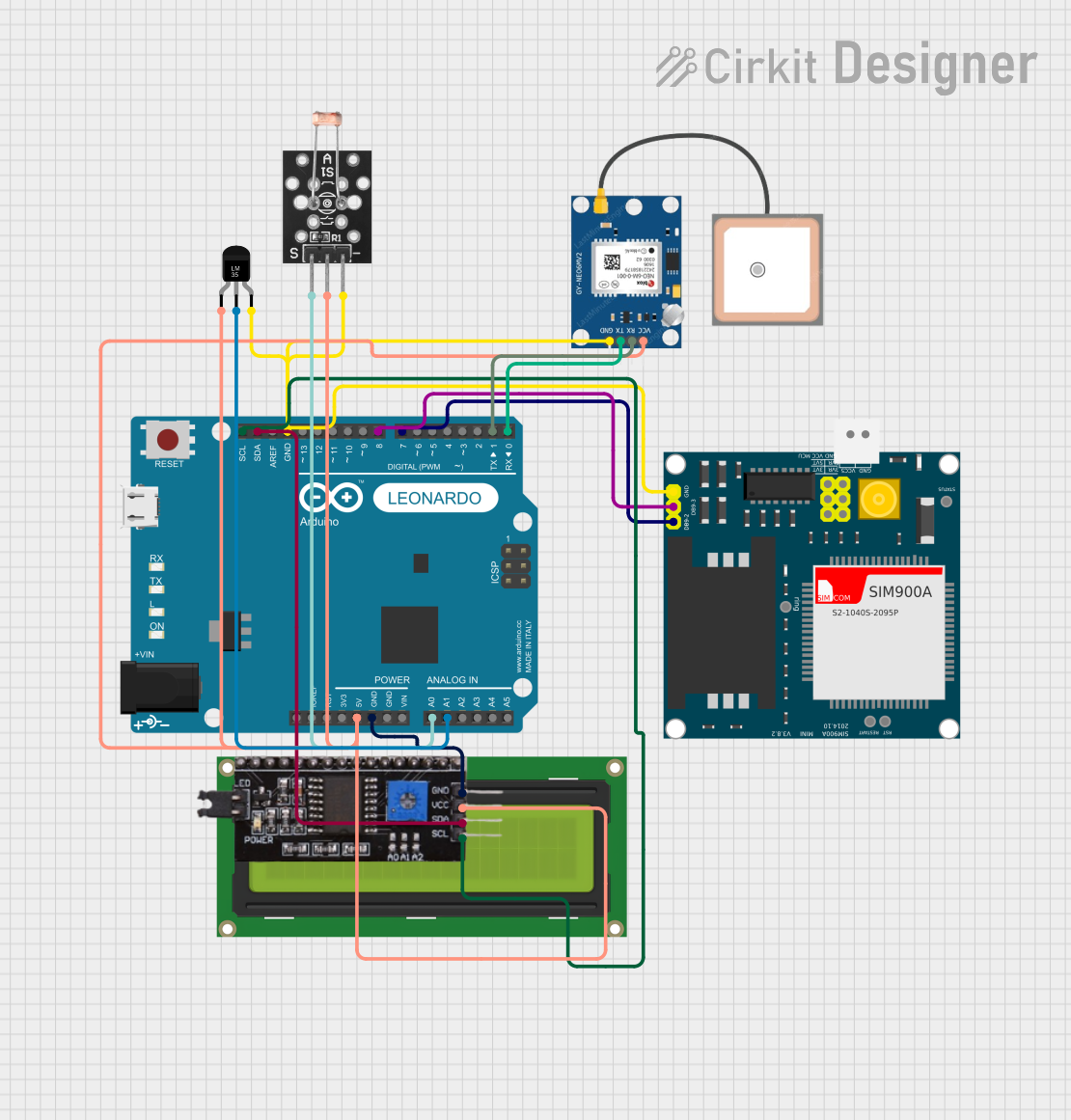

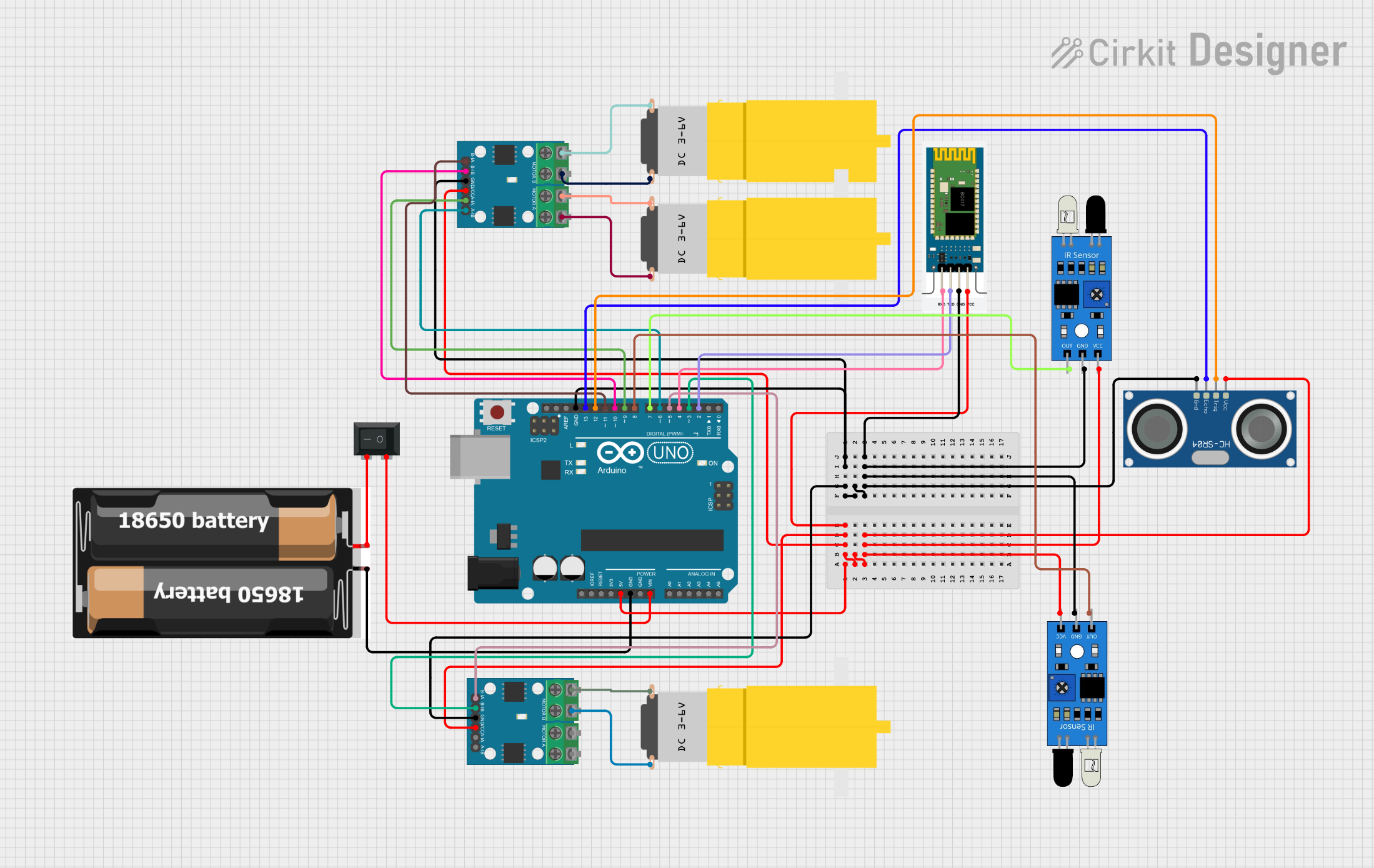

Explore Projects Built with L9110

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with L9110

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Driving wheels or tracks.

- Automation: Controlling actuators and mechanical systems.

- Hobby Projects: RC cars, drones, and other motorized gadgets.

Technical Specifications

Key Technical Details

- Operating Voltage: 2.5V to 12V

- Output Current: Up to 800mA per channel

- Peak Output Current: 1.5A (for a short duration)

- Standby Control to Save Power

- Input Logic Voltage: 2.5V to 12V

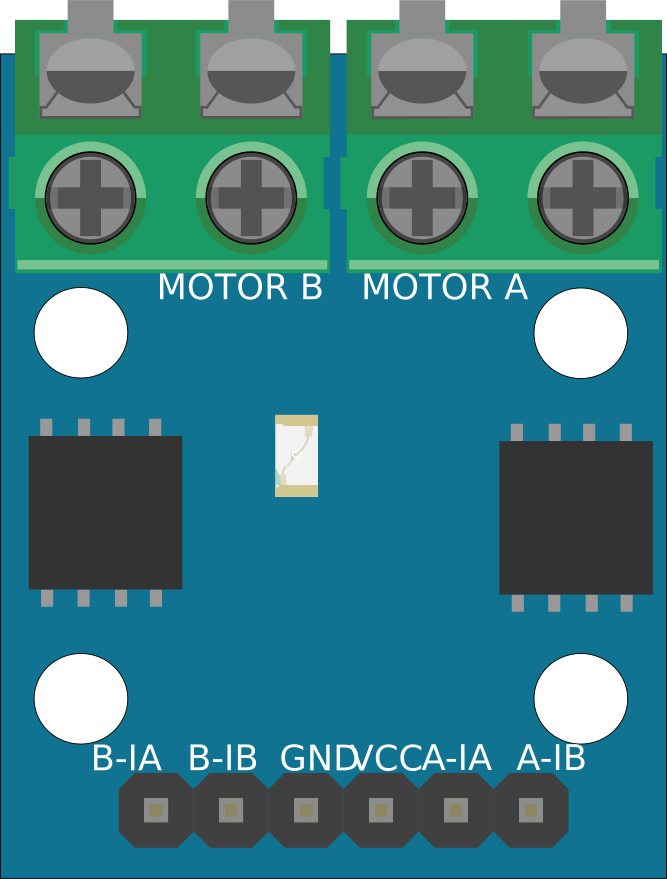

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | Vcc | Motor power supply (2.5V to 12V) |

| 2 | GND | Ground |

| 3 | B-IA | Input A for motor B, logic level |

| 4 | B-IB | Input B for motor B, logic level |

| 5 | A-IA | Input A for motor A, logic level |

| 6 | A-IB | Input B for motor A, logic level |

| 7 | A-O1 | Output 1 for motor A |

| 8 | A-O2 | Output 2 for motor A |

| 9 | B-O1 | Output 1 for motor B |

| 10 | B-O2 | Output 2 for motor B |

Usage Instructions

How to Use the Component in a Circuit

- Connect the motor power supply to the Vcc and GND pins.

- Connect the motors to the output pins A-O1/A-O2 and B-O1/B-O2.

- Apply logic signals to the input pins A-IA/A-IB and B-IA/B-IB to control the motors.

Important Considerations and Best Practices

- Ensure the power supply voltage and motor current do not exceed the IC's ratings.

- Use a proper heat sink if operating near the maximum current rating.

- Avoid shorting the output pins as it may damage the IC.

- Use flyback diodes across the motors to protect the IC from voltage spikes.

Example Code for Arduino UNO

// Define the L9110 control pins connected to the Arduino

const int motorA_IA = 2;

const int motorA_IB = 3;

const int motorB_IA = 4;

const int motorB_IB = 5;

void setup() {

// Set the motor control pins as outputs

pinMode(motorA_IA, OUTPUT);

pinMode(motorA_IB, OUTPUT);

pinMode(motorB_IA, OUTPUT);

pinMode(motorB_IB, OUTPUT);

}

void loop() {

// Rotate Motor A clockwise

digitalWrite(motorA_IA, HIGH);

digitalWrite(motorA_IB, LOW);

delay(1000); // Run for 1 second

// Rotate Motor A counterclockwise

digitalWrite(motorA_IA, LOW);

digitalWrite(motorA_IB, HIGH);

delay(1000); // Run for 1 second

// Stop Motor A

digitalWrite(motorA_IA, LOW);

digitalWrite(motorA_IB, LOW);

delay(1000); // Stop for 1 second

// The same logic can be applied to control Motor B using motorB_IA and motorB_IB

}

Troubleshooting and FAQs

Common Issues Users Might Face

- Motor not running: Check power supply and connections.

- Overheating: Ensure current is within limits and use a heat sink.

- Inconsistent motor speed: Verify the input logic levels and power supply stability.

Solutions and Tips for Troubleshooting

- Double-check wiring against the pin configuration.

- Measure the voltage at the motor terminals to ensure proper operation.

- Use a multimeter to check for shorts or open circuits in the connections.

FAQs

Q: Can the L9110 drive stepper motors? A: No, the L9110 is designed for DC motors and does not have the necessary control for stepper motors.

Q: What is the maximum frequency for PWM control? A: The L9110 can typically handle PWM frequencies up to 100kHz, but for most applications, a frequency of around 1kHz to 25kHz is sufficient.

Q: Can I use the L9110 without a microcontroller? A: Yes, you can use manual switches or logic gates to control the inputs, but a microcontroller like an Arduino provides more flexibility and control options.