How to Use CNC Shield V3: Examples, Pinouts, and Specs

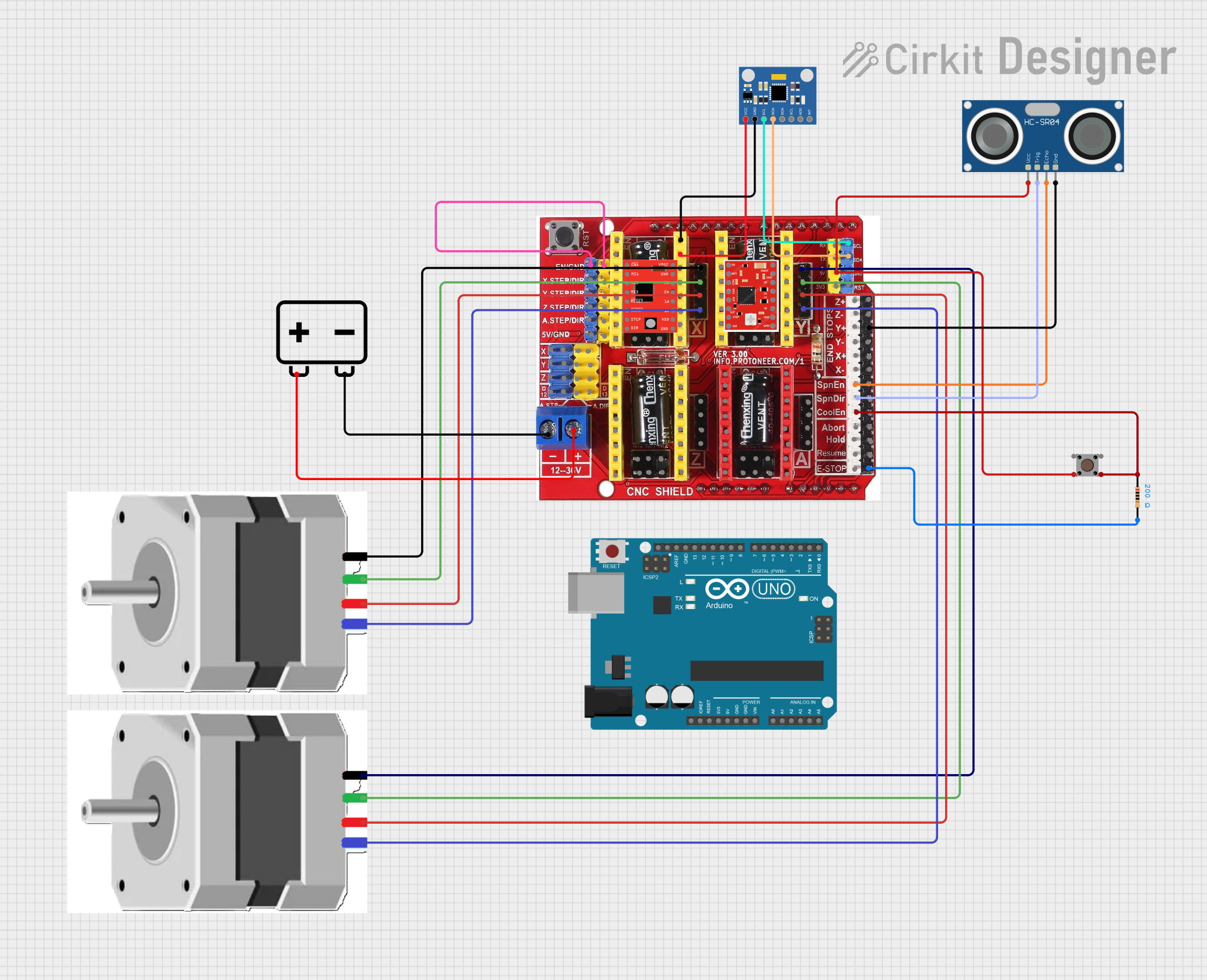

Design with CNC Shield V3 in Cirkit Designer

Design with CNC Shield V3 in Cirkit DesignerIntroduction

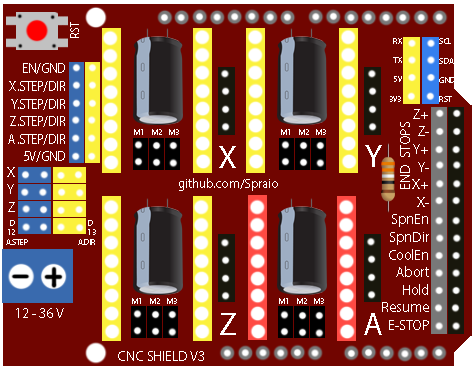

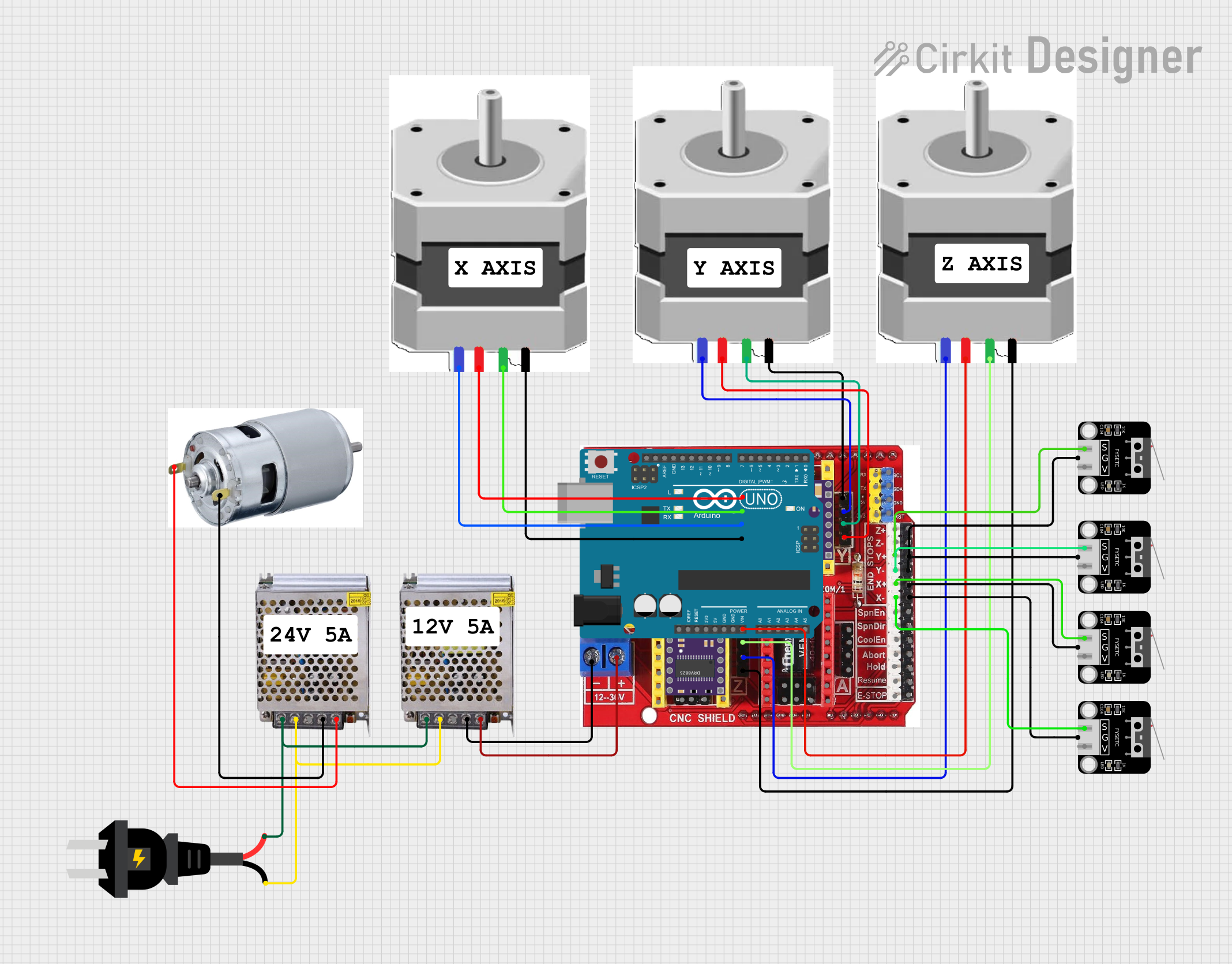

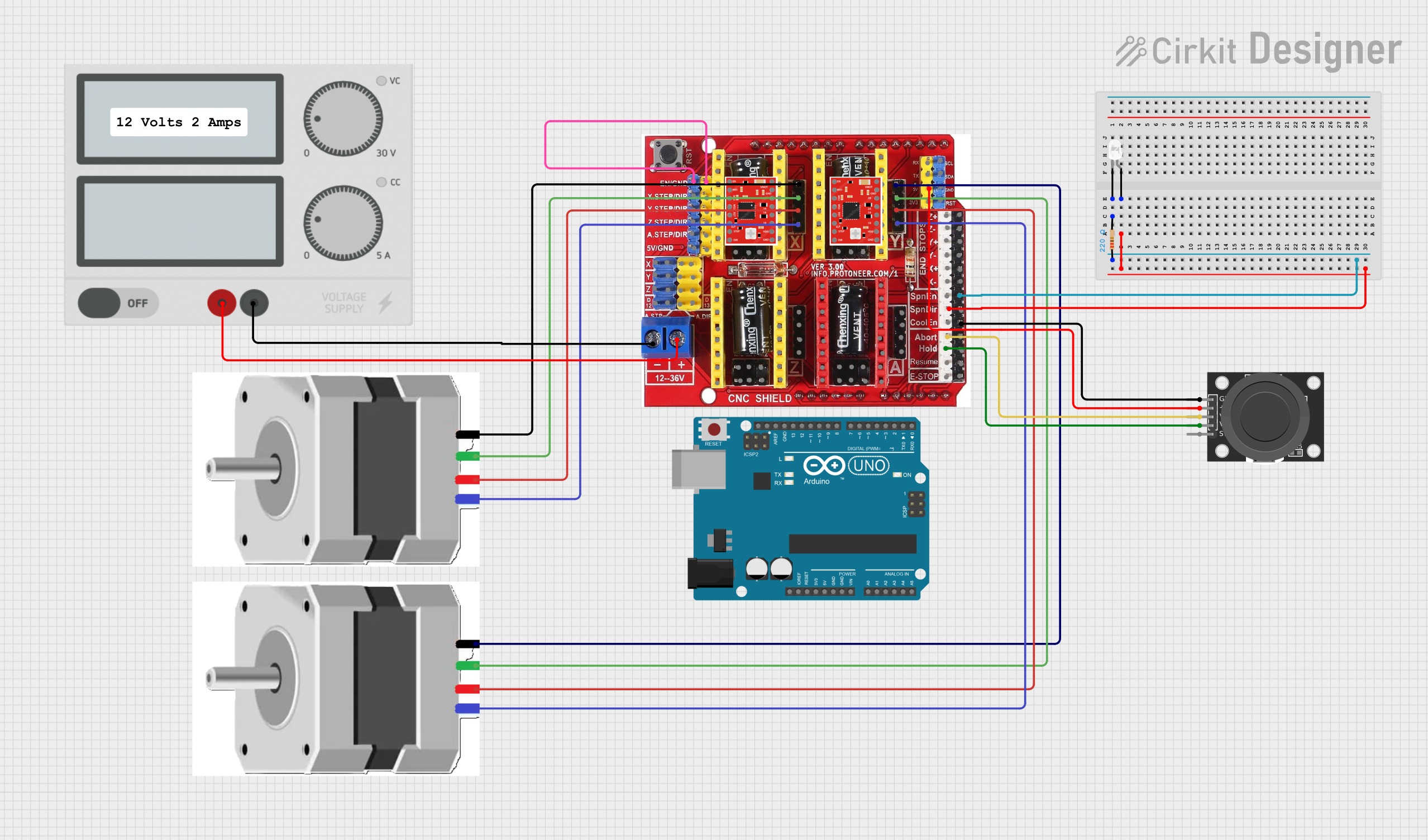

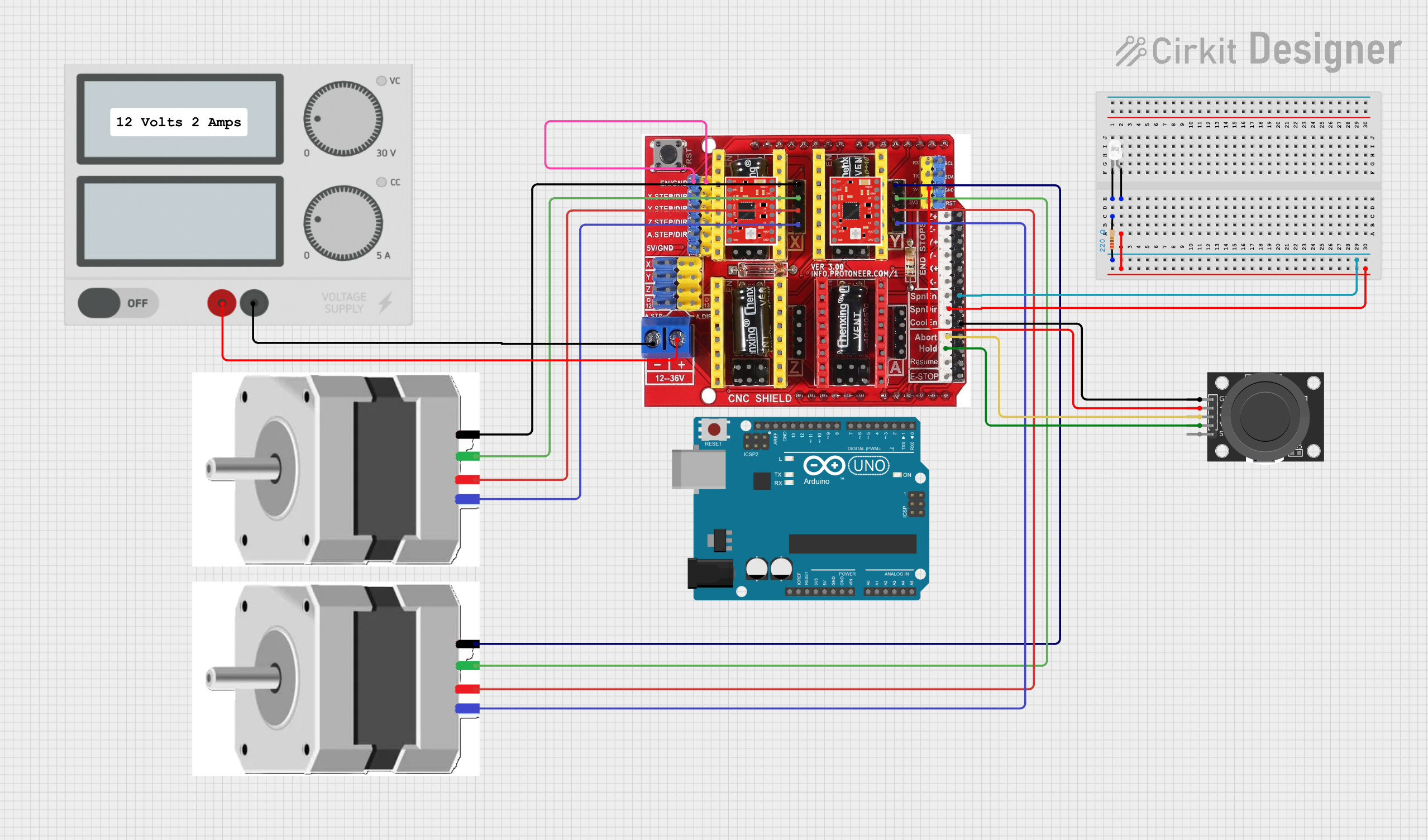

The CNC Shield V3, manufactured by Protoneer (Part ID: CNC Shield), is an expansion board designed for Arduino. It facilitates the control of stepper motors and other components in CNC (Computer Numerical Control) machines. This shield provides slots for stepper motor drivers and includes connections for limit switches and other peripherals, making it an essential component for DIY CNC projects and automation systems.

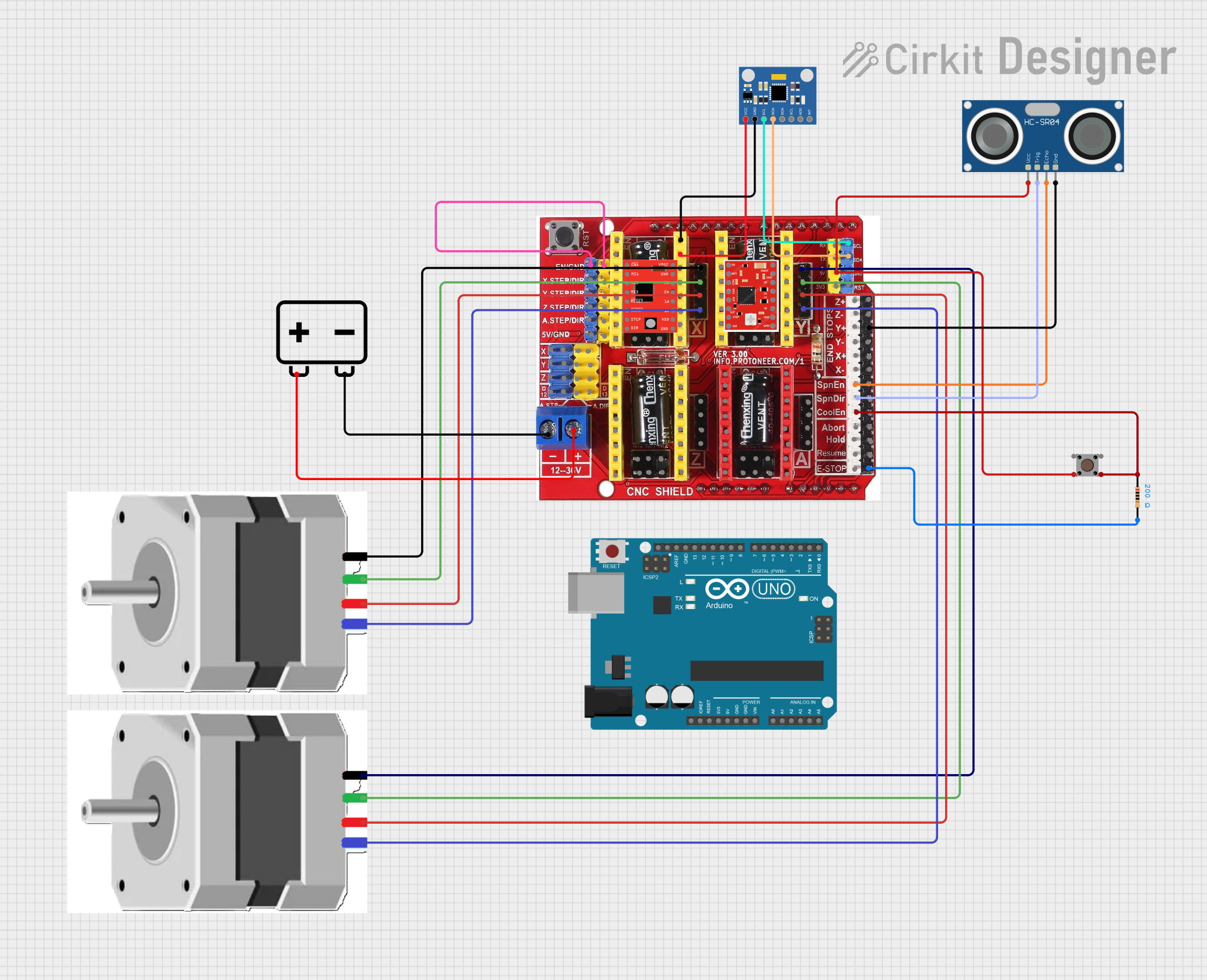

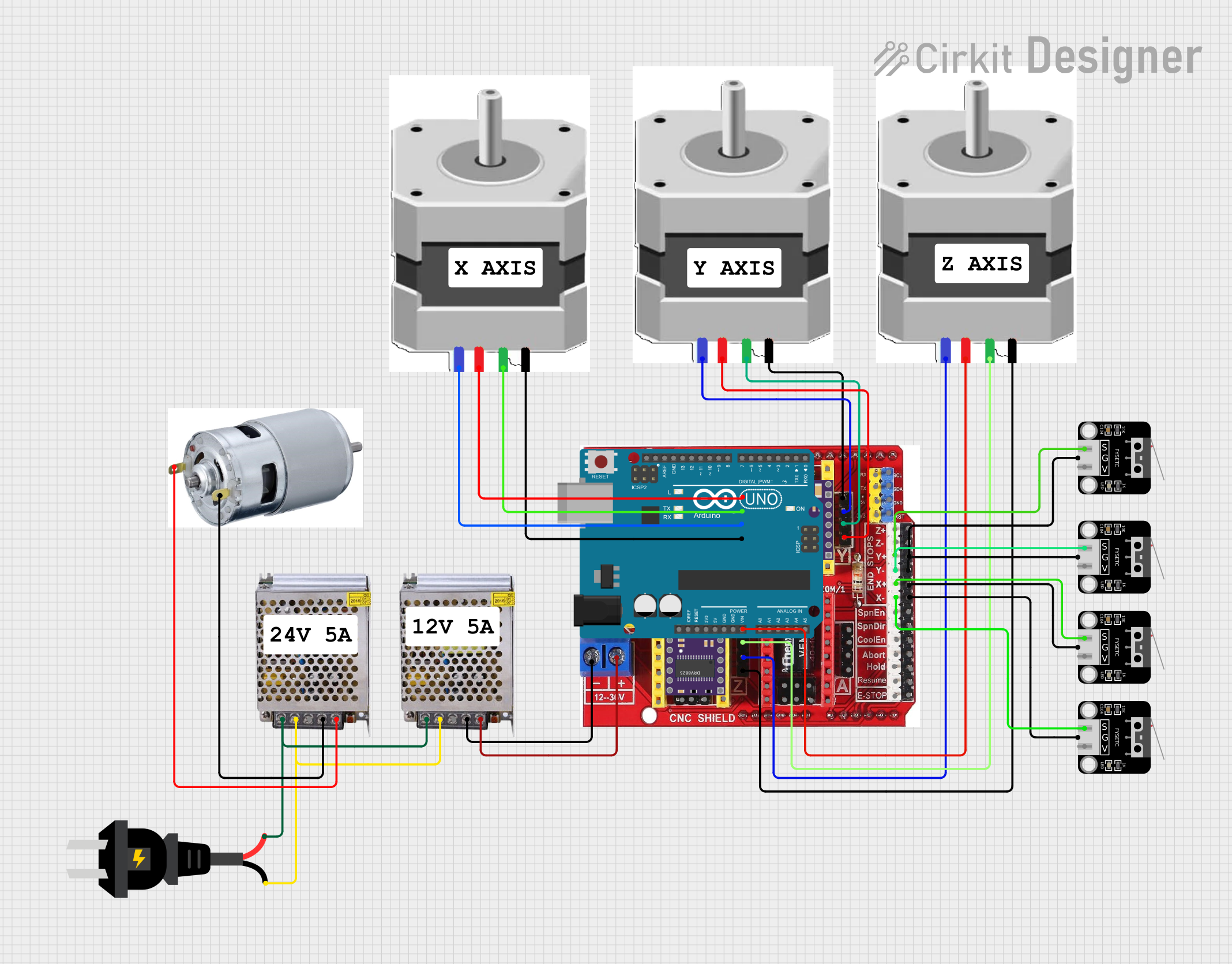

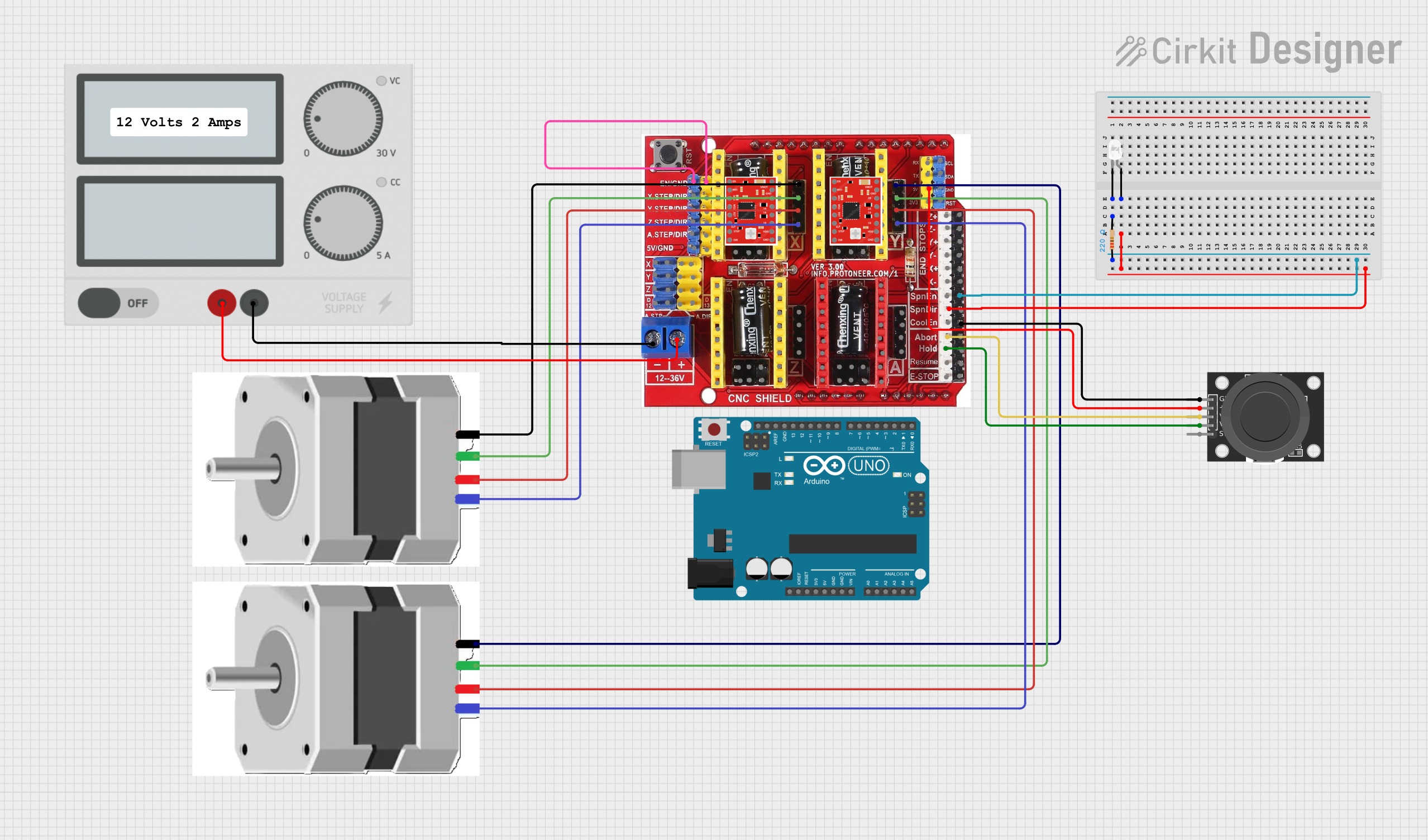

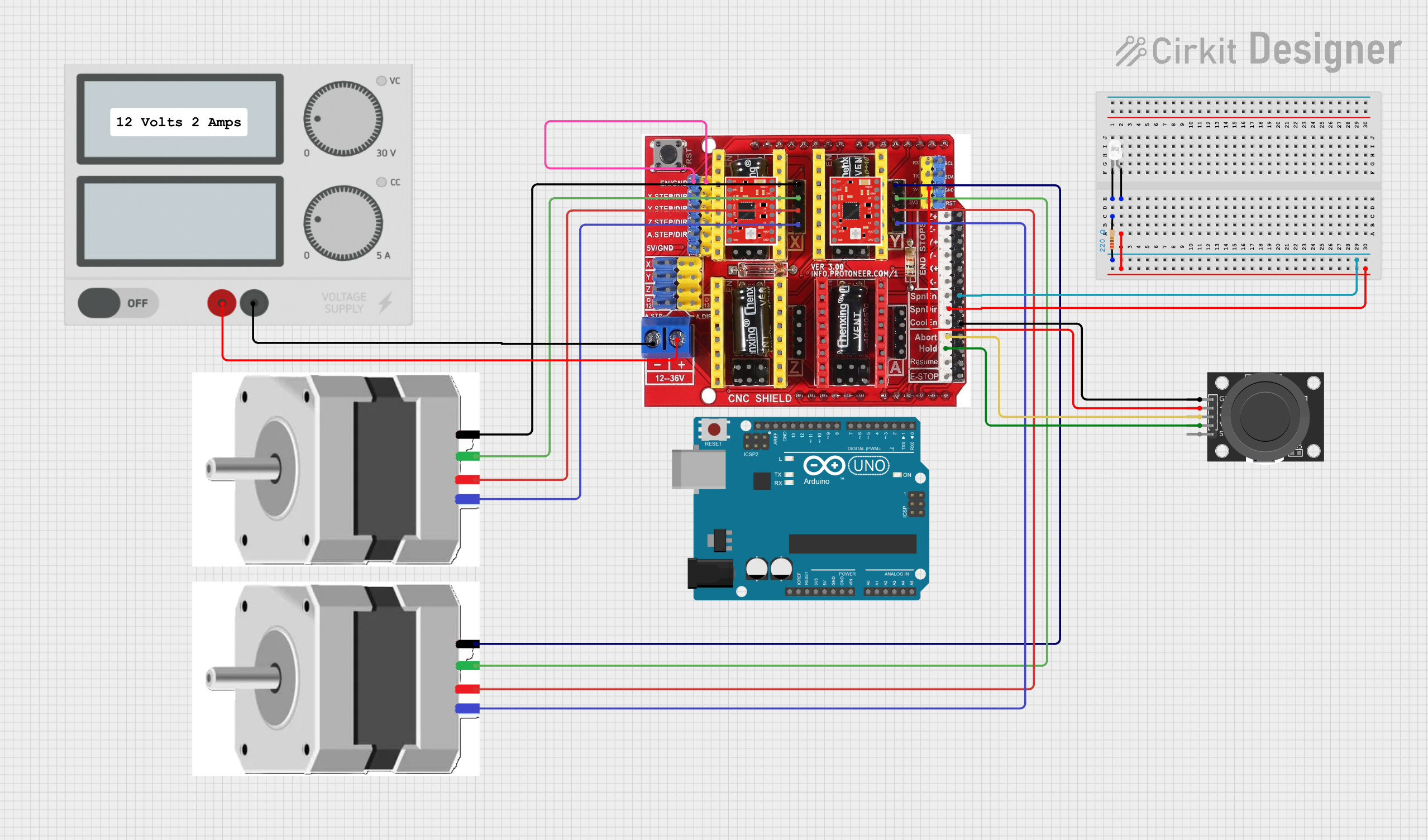

Explore Projects Built with CNC Shield V3

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with CNC Shield V3

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- CNC Machines: Used in DIY CNC routers, mills, and lathes.

- 3D Printers: Controls stepper motors for precise movement.

- Robotics: Manages multiple stepper motors in robotic arms and other devices.

- Automation Systems: Integrates with various sensors and actuators for automated processes.

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Operating Voltage | 12V - 36V |

| Stepper Motor Drivers | Compatible with A4988, DRV8825, and others |

| Number of Axes | 4 (X, Y, Z, and A) |

| Limit Switches | 6 (2 per axis) |

| Microstepping | Configurable via jumpers |

| Communication | I2C, SPI, UART |

Pin Configuration and Descriptions

CNC Shield V3 Pinout

| Pin Name | Description |

|---|---|

| X-EN | Enable pin for X-axis stepper driver |

| X-STEP | Step pin for X-axis stepper driver |

| X-DIR | Direction pin for X-axis stepper driver |

| Y-EN | Enable pin for Y-axis stepper driver |

| Y-STEP | Step pin for Y-axis stepper driver |

| Y-DIR | Direction pin for Y-axis stepper driver |

| Z-EN | Enable pin for Z-axis stepper driver |

| Z-STEP | Step pin for Z-axis stepper driver |

| Z-DIR | Direction pin for Z-axis stepper driver |

| A-EN | Enable pin for A-axis stepper driver |

| A-STEP | Step pin for A-axis stepper driver |

| A-DIR | Direction pin for A-axis stepper driver |

| END-STOP | Limit switch connections (X, Y, Z) |

| SPINDLE | Spindle control |

| I2C | I2C communication pins |

| SPI | SPI communication pins |

| UART | UART communication pins |

Usage Instructions

How to Use the CNC Shield V3 in a Circuit

Mount the CNC Shield V3 on an Arduino UNO:

- Align the pins of the CNC Shield V3 with the corresponding headers on the Arduino UNO.

- Press down gently to ensure a secure connection.

Install Stepper Motor Drivers:

- Insert the stepper motor drivers (e.g., A4988, DRV8825) into the designated slots on the CNC Shield V3.

- Ensure correct orientation as per the manufacturer's instructions.

Connect Stepper Motors:

- Connect the stepper motors to the corresponding motor outputs (X, Y, Z, A) on the CNC Shield V3.

Connect Limit Switches:

- Attach limit switches to the END-STOP pins for each axis (X, Y, Z).

Power the Shield:

- Connect a suitable power supply (12V - 36V) to the power input terminals on the CNC Shield V3.

Upload Control Code:

- Use the Arduino IDE to upload the control code to the Arduino UNO.

Important Considerations and Best Practices

- Cooling: Ensure proper cooling for stepper motor drivers to prevent overheating.

- Power Supply: Use a stable and adequate power supply to avoid voltage drops.

- Microstepping Configuration: Set the microstepping jumpers according to your requirements.

- Limit Switches: Properly configure and test limit switches to avoid mechanical crashes.

Sample Arduino Code

// Sample code to control a stepper motor using CNC Shield V3

#include <Arduino.h>

// Define pin connections

#define X_STEP_PIN 2

#define X_DIR_PIN 5

#define X_ENABLE_PIN 8

void setup() {

// Set pin modes

pinMode(X_STEP_PIN, OUTPUT);

pinMode(X_DIR_PIN, OUTPUT);

pinMode(X_ENABLE_PIN, OUTPUT);

// Enable the stepper driver

digitalWrite(X_ENABLE_PIN, LOW);

}

void loop() {

// Set direction

digitalWrite(X_DIR_PIN, HIGH);

// Move stepper motor

for (int i = 0; i < 200; i++) {

digitalWrite(X_STEP_PIN, HIGH);

delayMicroseconds(1000);

digitalWrite(X_STEP_PIN, LOW);

delayMicroseconds(1000);

}

// Pause before changing direction

delay(1000);

// Change direction

digitalWrite(X_DIR_PIN, LOW);

// Move stepper motor in opposite direction

for (int i = 0; i < 200; i++) {

digitalWrite(X_STEP_PIN, HIGH);

delayMicroseconds(1000);

digitalWrite(X_STEP_PIN, LOW);

delayMicroseconds(1000);

}

// Pause before next loop

delay(1000);

}

Troubleshooting and FAQs

Common Issues Users Might Face

Stepper Motor Not Moving:

- Solution: Check the power supply and ensure it is connected properly. Verify the stepper motor driver orientation and connections.

Overheating Drivers:

- Solution: Ensure proper cooling and ventilation. Consider adding heatsinks or a cooling fan.

Limit Switches Not Working:

- Solution: Verify the wiring and connections of the limit switches. Check the configuration in the control code.

Inconsistent Motor Movement:

- Solution: Check for loose connections and ensure the power supply is stable. Verify the microstepping settings.

Solutions and Tips for Troubleshooting

- Check Connections: Ensure all connections are secure and correctly oriented.

- Use a Multimeter: Measure voltages and continuity to diagnose electrical issues.

- Consult Datasheets: Refer to the datasheets of the stepper motor drivers and other components for detailed information.

- Update Firmware: Ensure the latest firmware is uploaded to the Arduino UNO.

By following this documentation, users can effectively utilize the CNC Shield V3 in their CNC and automation projects, ensuring smooth and precise control of stepper motors and other peripherals.