How to Use HiLink 12V to 5V: Examples, Pinouts, and Specs

Design with HiLink 12V to 5V in Cirkit Designer

Design with HiLink 12V to 5V in Cirkit DesignerIntroduction

The HiLink 12V to 5V is a compact DC-DC buck converter designed to step down a 12V input voltage to a stable 5V output. This component is widely used in applications requiring a reliable 5V power source, such as powering microcontrollers, sensors, and other low-voltage devices. Its small size and high efficiency make it an excellent choice for embedded systems, IoT devices, and portable electronics.

Explore Projects Built with HiLink 12V to 5V

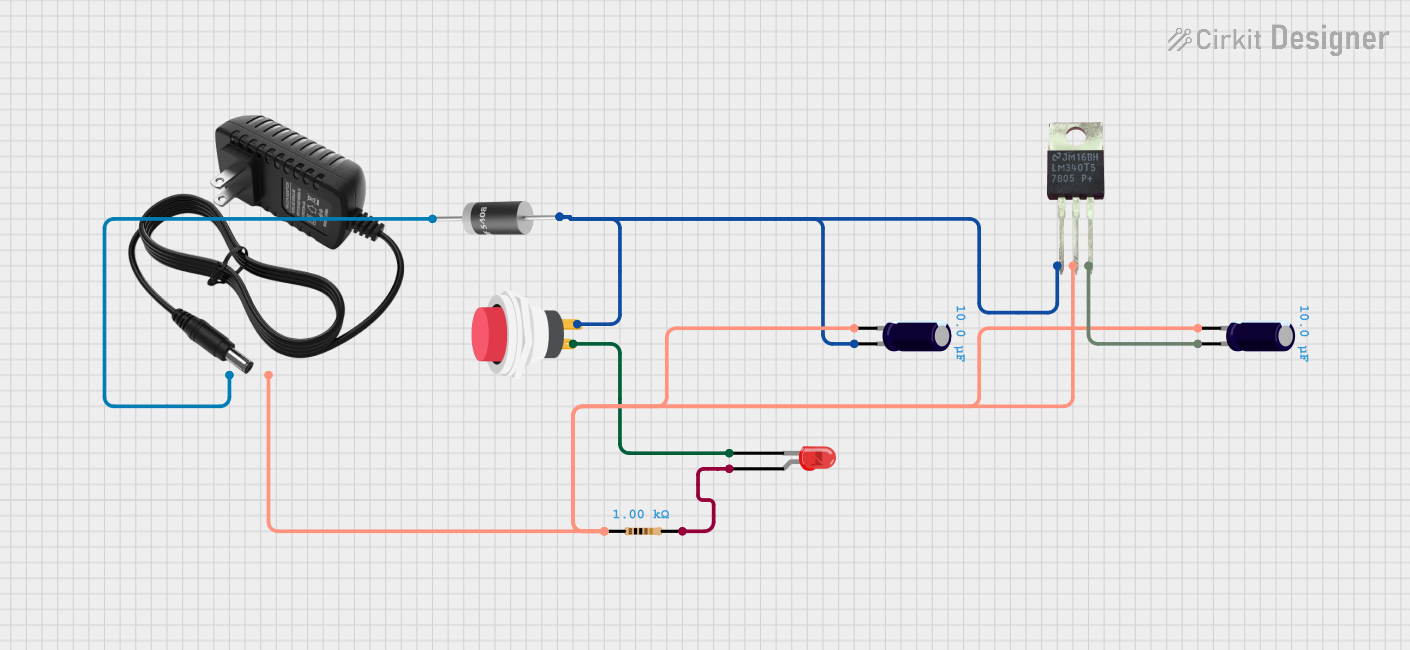

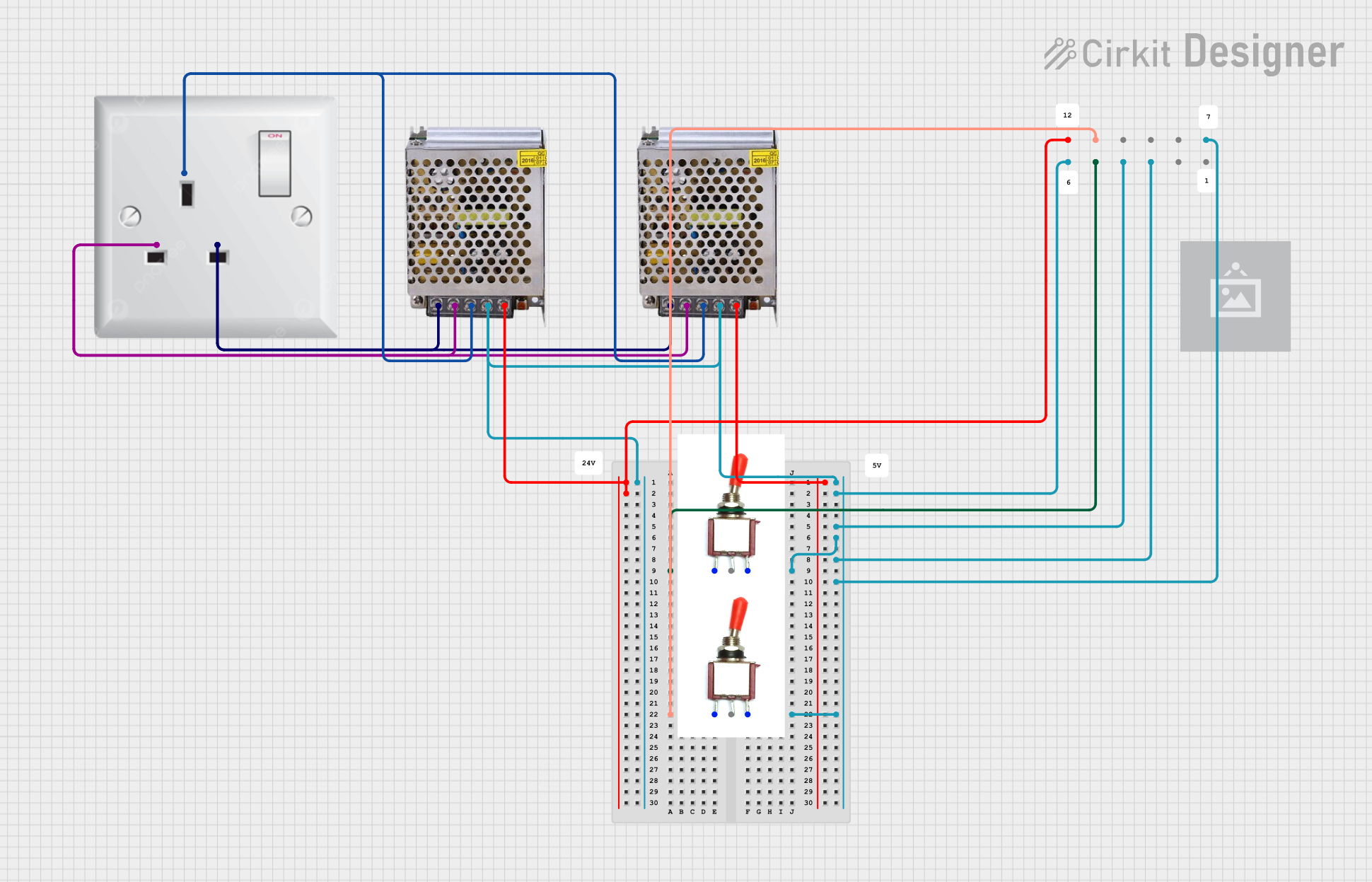

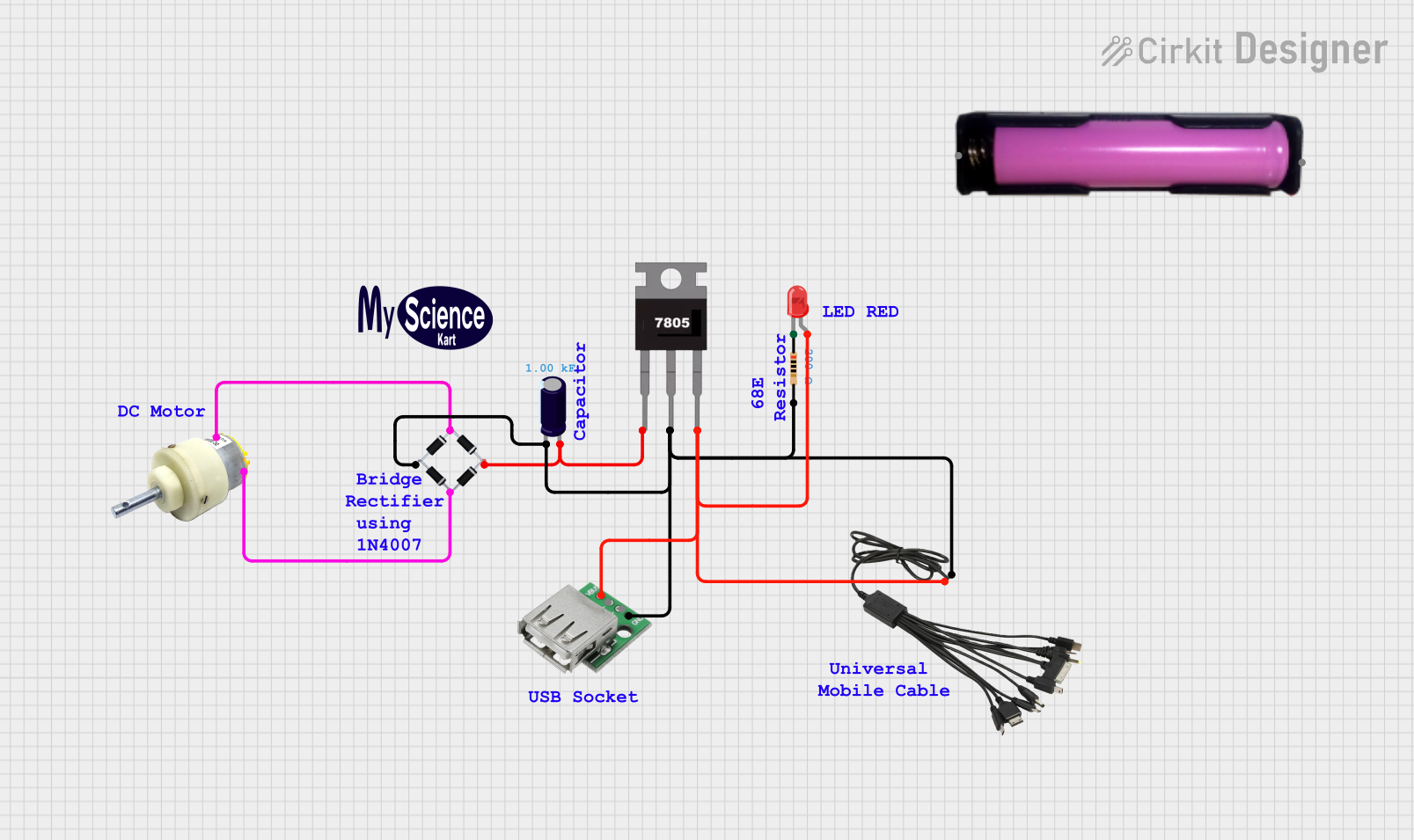

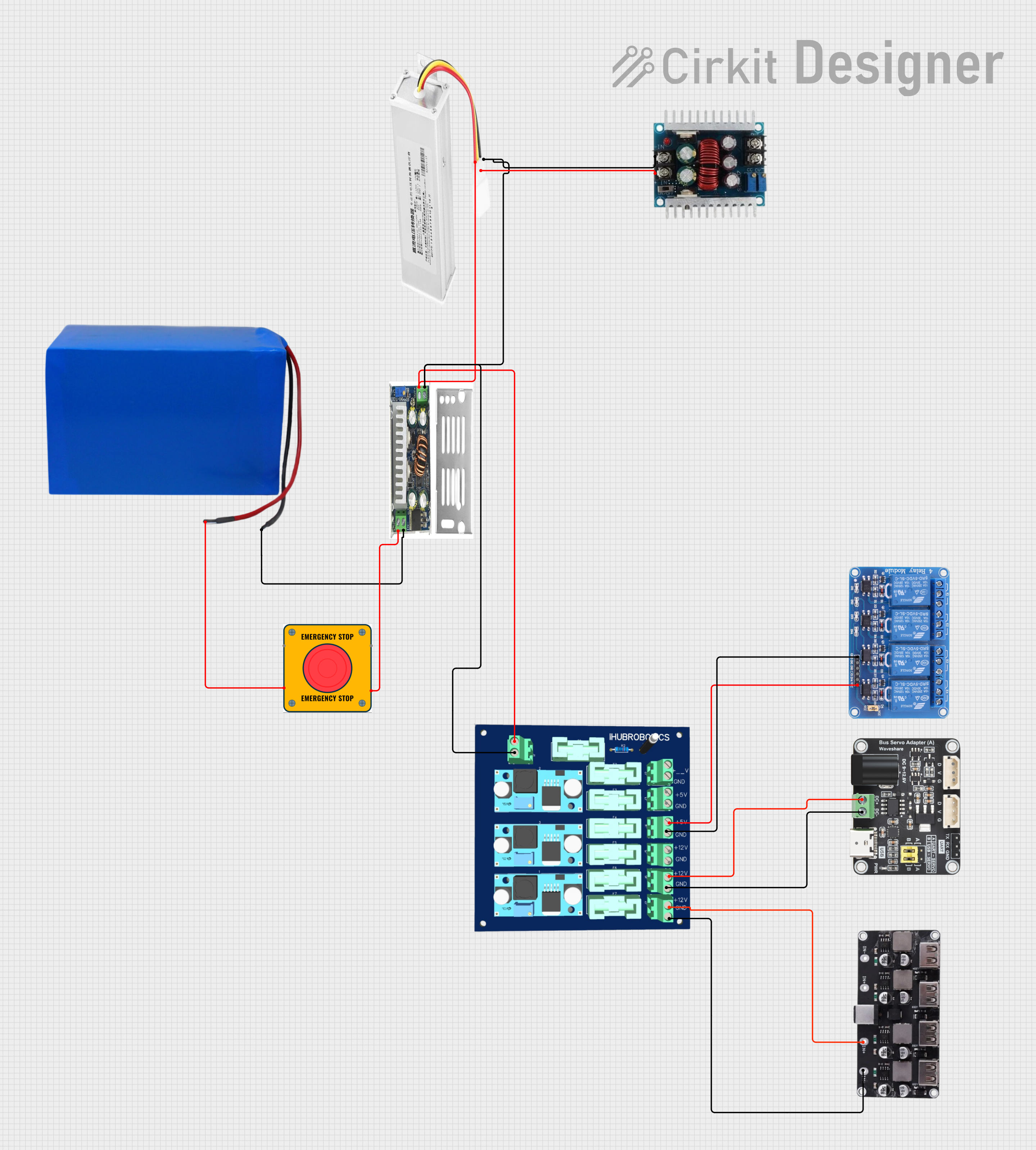

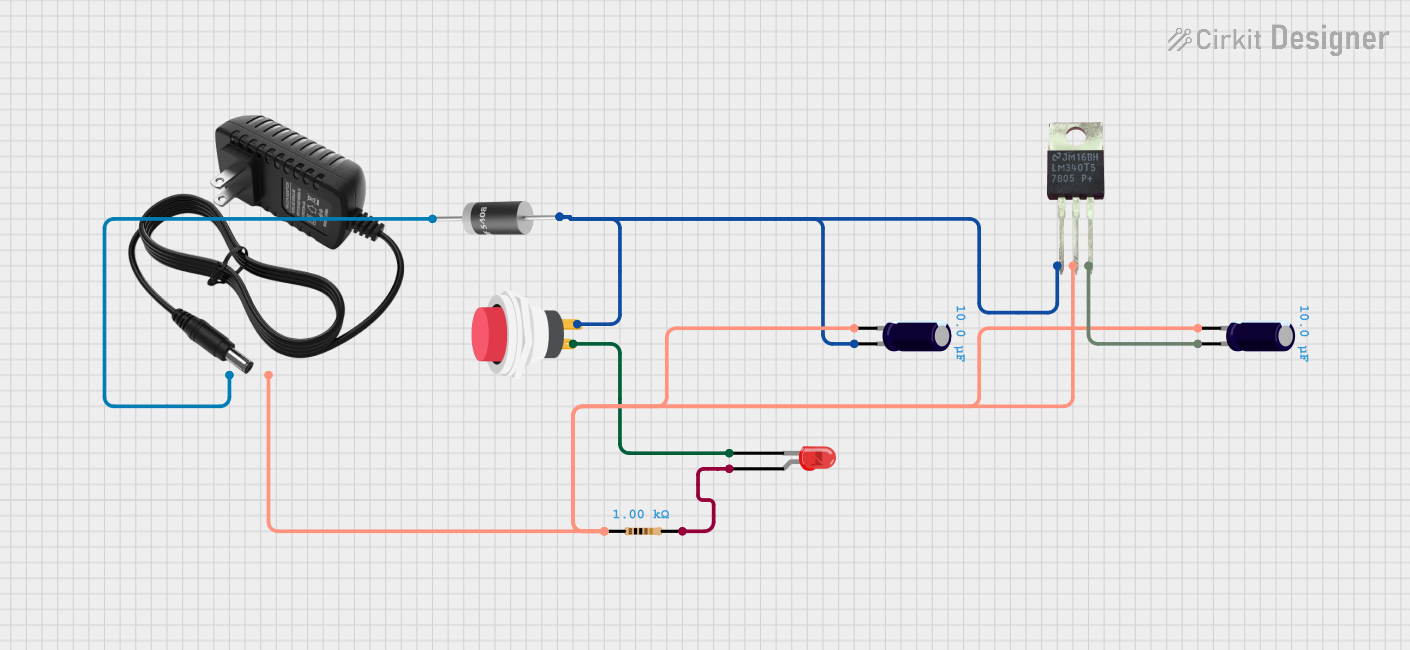

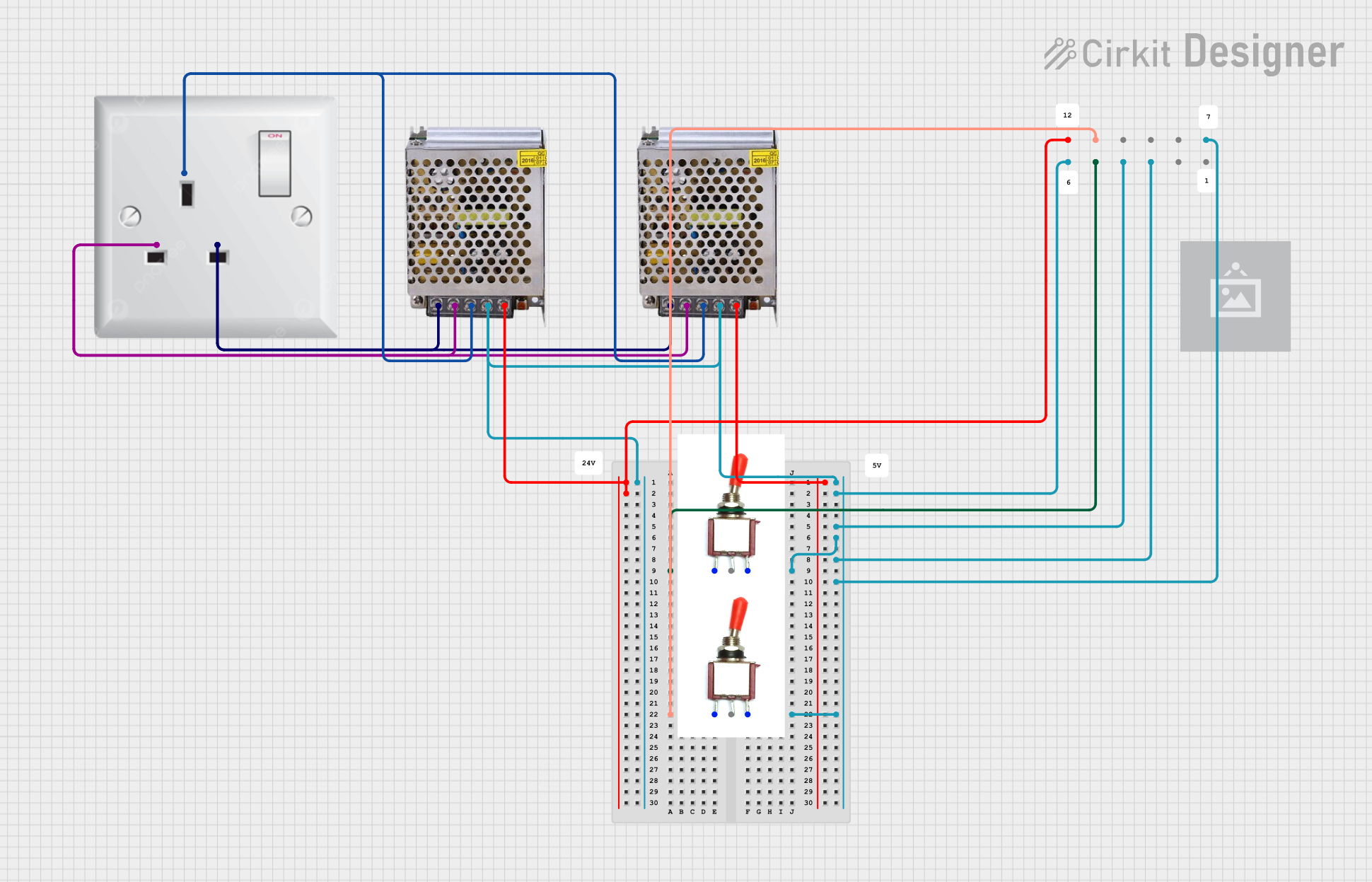

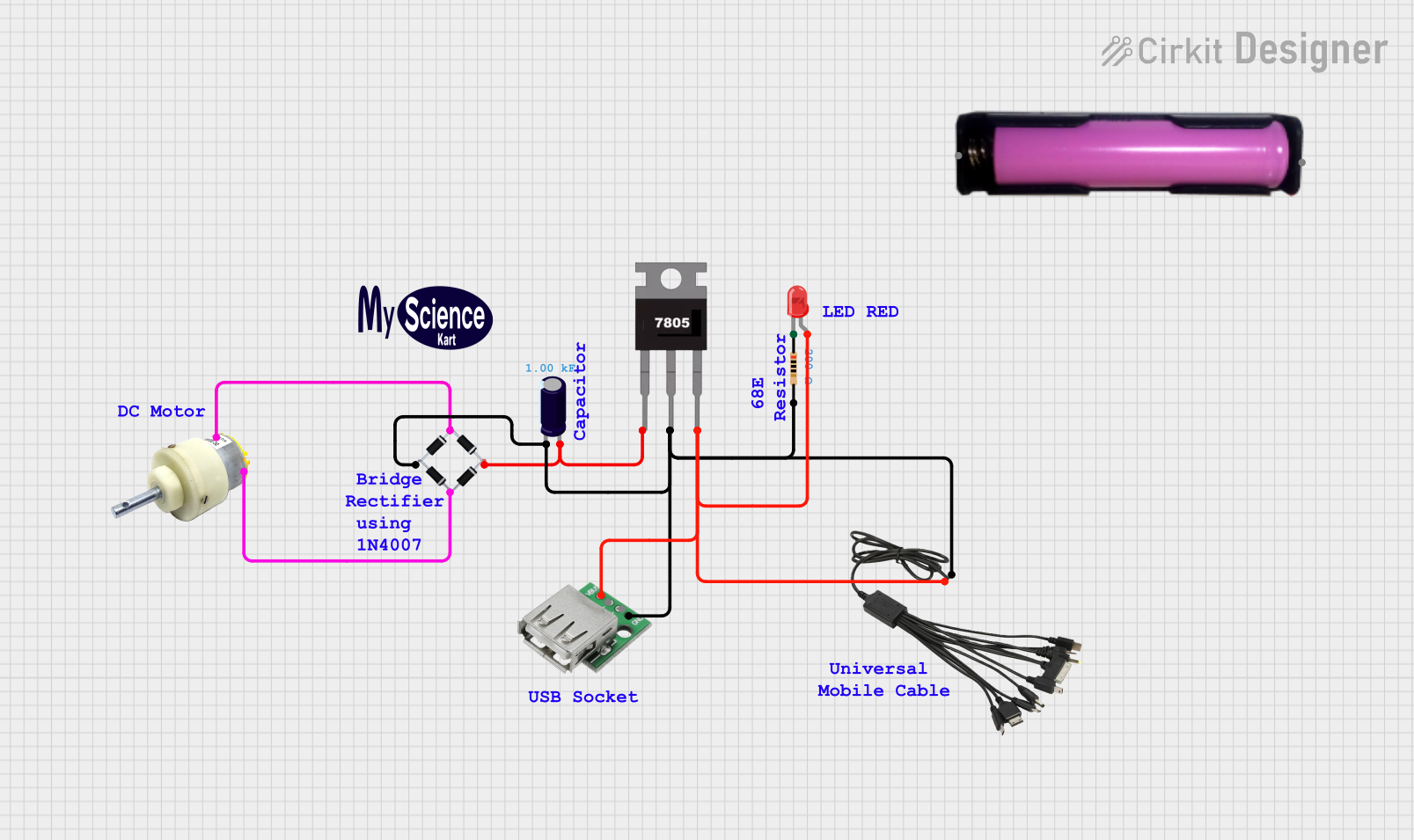

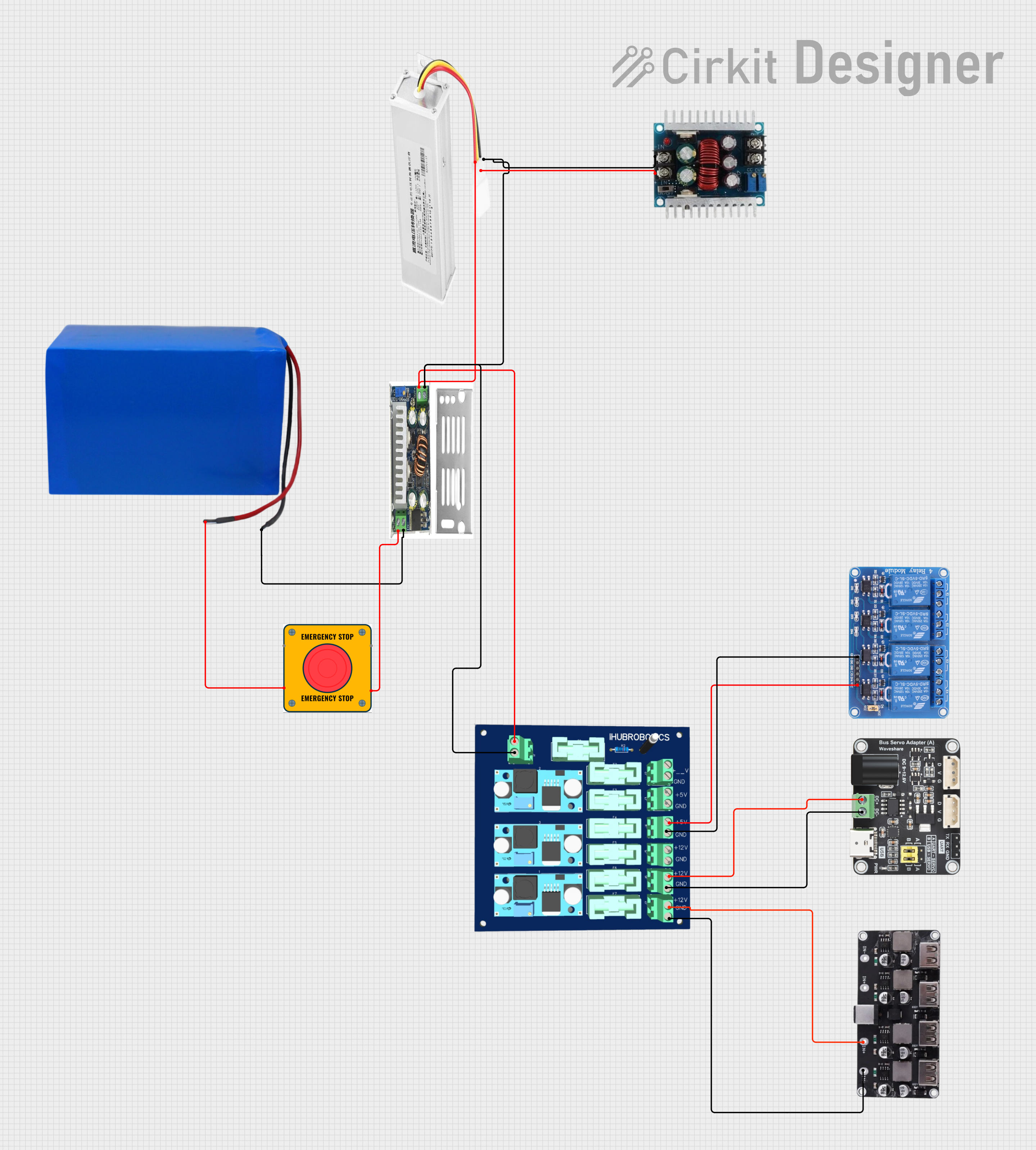

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with HiLink 12V to 5V

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Powering microcontrollers (e.g., Arduino, ESP32, Raspberry Pi)

- Supplying 5V to sensors, relays, and modules

- Battery-powered devices requiring voltage regulation

- Automotive electronics for stepping down 12V car battery voltage

Technical Specifications

Below are the key technical details of the HiLink 12V to 5V DC-DC buck converter:

| Parameter | Value |

|---|---|

| Input Voltage Range | 8V to 24V |

| Output Voltage | 5V ± 0.1V |

| Output Current | Up to 3A |

| Efficiency | Up to 96% |

| Ripple Voltage | ≤ 50mV |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 25mm x 15mm x 10mm |

| Weight | ~5g |

Pin Configuration and Descriptions

The HiLink 12V to 5V module typically has four pins or terminals. Their functions are described in the table below:

| Pin Name | Description |

|---|---|

| VIN+ | Positive input voltage terminal (8V to 24V) |

| VIN- | Negative input voltage terminal (ground) |

| VOUT+ | Positive output voltage terminal (5V) |

| VOUT- | Negative output voltage terminal (ground) |

Usage Instructions

How to Use the HiLink 12V to 5V in a Circuit

- Connect the Input Voltage:

- Attach the VIN+ pin to the positive terminal of your 12V power source.

- Connect the VIN- pin to the ground of your power source.

- Connect the Output Voltage:

- Attach the VOUT+ pin to the positive terminal of the device requiring 5V.

- Connect the VOUT- pin to the ground of the device.

- Verify Connections:

- Double-check all connections to ensure proper polarity and avoid short circuits.

- Power On:

- Turn on the 12V power source. The module will regulate the input voltage and provide a stable 5V output.

Important Considerations and Best Practices

- Heat Dissipation: Although the module is highly efficient, ensure adequate ventilation or heat sinking if operating near the maximum current (3A).

- Input Voltage Range: Do not exceed the specified input voltage range (8V to 24V) to avoid damaging the module.

- Load Requirements: Ensure the connected load does not exceed the maximum output current of 3A.

- Polarity Protection: Double-check the polarity of input and output connections to prevent damage to the module or connected devices.

Example: Using the HiLink 12V to 5V with an Arduino UNO

The HiLink 12V to 5V can be used to power an Arduino UNO from a 12V power source. Below is an example circuit and Arduino code to blink an LED:

Circuit Connections

- Connect the VIN+ pin of the HiLink module to the 12V power source's positive terminal.

- Connect the VIN- pin to the 12V power source's ground.

- Connect the VOUT+ pin to the Arduino UNO's 5V pin.

- Connect the VOUT- pin to the Arduino UNO's GND pin.

- Connect an LED to pin 13 of the Arduino UNO with a 220-ohm resistor in series.

Arduino Code

// Simple LED blink example for Arduino UNO

// This code assumes the HiLink 12V to 5V module is powering the Arduino

void setup() {

pinMode(13, OUTPUT); // Set pin 13 as an output for the LED

}

void loop() {

digitalWrite(13, HIGH); // Turn the LED on

delay(1000); // Wait for 1 second

digitalWrite(13, LOW); // Turn the LED off

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage:

- Cause: Incorrect input connections or insufficient input voltage.

- Solution: Verify that the VIN+ and VIN- pins are connected correctly and that the input voltage is within the 8V to 24V range.

Overheating:

- Cause: Excessive load current or poor ventilation.

- Solution: Reduce the load current or improve ventilation around the module.

Output Voltage Fluctuations:

- Cause: High ripple voltage due to insufficient filtering.

- Solution: Add a capacitor (e.g., 100µF) across the output terminals to reduce ripple.

Device Not Powering On:

- Cause: Polarity mismatch or damaged module.

- Solution: Check the polarity of all connections and replace the module if necessary.

FAQs

Q: Can I use the HiLink 12V to 5V with a 24V input?

A: Yes, the module supports input voltages up to 24V. However, ensure the load current does not exceed 3A.Q: Is the module protected against reverse polarity?

A: No, the module does not have built-in reverse polarity protection. Always double-check connections before powering on.Q: Can I use this module to power a Raspberry Pi?

A: Yes, the module can power a Raspberry Pi, but ensure the total current draw (including peripherals) does not exceed 3A.Q: How do I reduce noise in the output voltage?

A: Adding a capacitor (e.g., 100µF to 470µF) across the output terminals can help reduce noise and ripple.

This concludes the documentation for the HiLink 12V to 5V DC-DC buck converter.