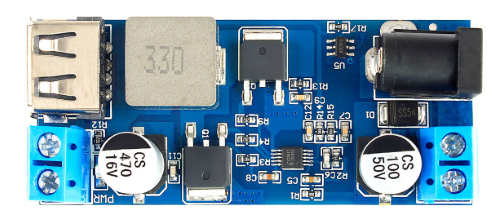

How to Use STEP DOWN XY 3606: Examples, Pinouts, and Specs

Design with STEP DOWN XY 3606 in Cirkit Designer

Design with STEP DOWN XY 3606 in Cirkit DesignerIntroduction

The STEP DOWN XY 3606 is a high-efficiency DC-DC buck converter module designed to step down voltage from a higher level to a lower level. This versatile component is widely used in various applications where voltage regulation is crucial. It is particularly useful in battery-powered devices, power supply units, and embedded systems.

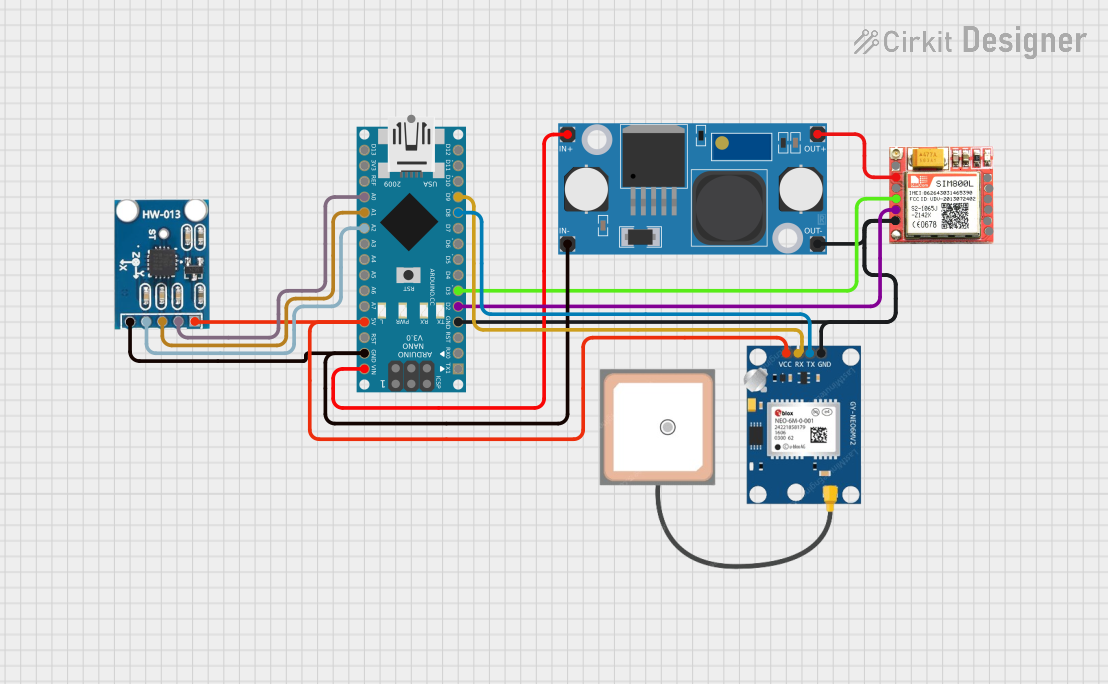

Explore Projects Built with STEP DOWN XY 3606

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with STEP DOWN XY 3606

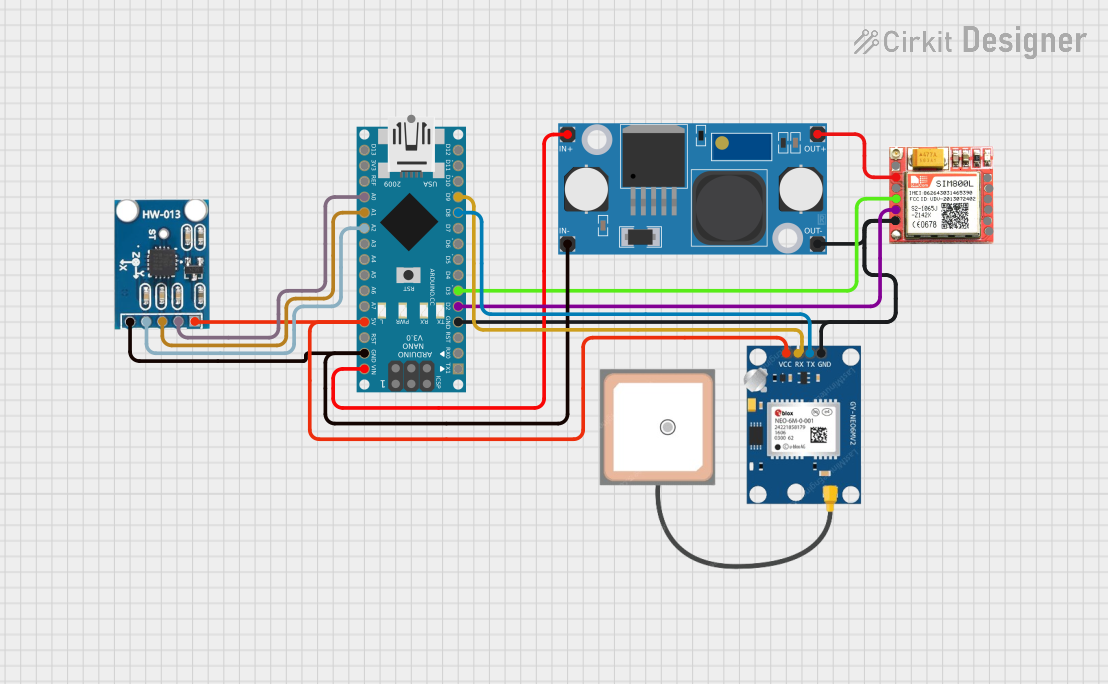

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Battery-Powered Devices: Efficiently step down voltage to prolong battery life.

- Power Supply Units: Provide stable voltage to sensitive electronic components.

- Embedded Systems: Regulate voltage for microcontrollers and other digital circuits.

- LED Drivers: Supply constant voltage to LED arrays.

- Arduino Projects: Commonly used to power Arduino boards and peripherals.

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Input Voltage | 4.0V to 38V |

| Output Voltage | 1.25V to 36V |

| Output Current | Up to 5A (with heat sink) |

| Efficiency | Up to 96% |

| Switching Frequency | 150 kHz |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 45mm x 20mm x 14mm |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VIN | Input voltage (4.0V to 38V) |

| 2 | GND | Ground |

| 3 | VOUT | Output voltage (1.25V to 36V) |

| 4 | EN | Enable pin (active high, connect to VIN to enable) |

Usage Instructions

How to Use the Component in a Circuit

Connect the Input Voltage:

- Connect the positive terminal of your power source to the

VINpin. - Connect the negative terminal of your power source to the

GNDpin.

- Connect the positive terminal of your power source to the

Connect the Output Voltage:

- Connect the

VOUTpin to the load that requires the stepped-down voltage. - Ensure the

GNDpin is also connected to the ground of the load.

- Connect the

Enable the Module:

- To enable the module, connect the

ENpin to theVINpin. - If you wish to control the enable function, you can connect the

ENpin to a microcontroller or a switch.

- To enable the module, connect the

Adjust the Output Voltage:

- Use the onboard potentiometer to adjust the output voltage to the desired level.

- Measure the output voltage with a multimeter while adjusting.

Important Considerations and Best Practices

- Heat Dissipation: For high current applications, ensure proper heat dissipation by attaching a heat sink to the module.

- Input Voltage: Always ensure the input voltage is within the specified range (4.0V to 38V).

- Polarity: Double-check the polarity of the connections to avoid damaging the module.

- Load Requirements: Ensure the load does not exceed the maximum output current of 5A.

Example: Using XY 3606 with Arduino UNO

To power an Arduino UNO using the XY 3606, follow these steps:

Connect the Input Voltage:

- Connect a 12V power source to the

VINandGNDpins of the XY 3606.

- Connect a 12V power source to the

Connect the Output Voltage:

- Adjust the output voltage to 5V using the potentiometer.

- Connect the

VOUTpin to the5Vpin of the Arduino UNO. - Connect the

GNDpin to theGNDpin of the Arduino UNO.

Enable the Module:

- Connect the

ENpin to theVINpin to enable the module.

- Connect the

Troubleshooting and FAQs

Common Issues Users Might Face

No Output Voltage:

- Solution: Check the input voltage and ensure it is within the specified range. Verify that the

ENpin is connected toVIN.

- Solution: Check the input voltage and ensure it is within the specified range. Verify that the

Overheating:

- Solution: Ensure proper heat dissipation by attaching a heat sink. Reduce the load current if necessary.

Output Voltage Not Stable:

- Solution: Check the connections and ensure they are secure. Verify that the input voltage is stable and within the specified range.

FAQs

Q1: Can I use the XY 3606 to power my Raspberry Pi?

- A1: Yes, you can use the XY 3606 to step down the voltage to 5V and power your Raspberry Pi. Ensure the output current is sufficient for your Raspberry Pi model.

Q2: How do I adjust the output voltage?

- A2: Use the onboard potentiometer to adjust the output voltage. Measure the voltage with a multimeter while adjusting.

Q3: What is the maximum input voltage for the XY 3606?

- A3: The maximum input voltage is 38V. Ensure the input voltage does not exceed this limit to avoid damaging the module.

Q4: Can I use the XY 3606 in automotive applications?

- A4: Yes, the XY 3606 can be used in automotive applications, provided the input voltage is within the specified range and proper heat dissipation is ensured.

By following this documentation, users can effectively utilize the STEP DOWN XY 3606 DC-DC buck converter module in their projects, ensuring efficient and reliable voltage regulation.