How to Use Servo DM 15kg: Examples, Pinouts, and Specs

Design with Servo DM 15kg in Cirkit Designer

Design with Servo DM 15kg in Cirkit DesignerIntroduction

The Servo DM 15kg is a high-torque servo motor designed for applications requiring precise control of angular position. With a torque rating of up to 15 kg-cm, this servo is ideal for demanding tasks in robotics, automation, RC vehicles, and industrial machinery. Its robust design and high torque output make it suitable for moving heavy loads with accuracy and reliability.

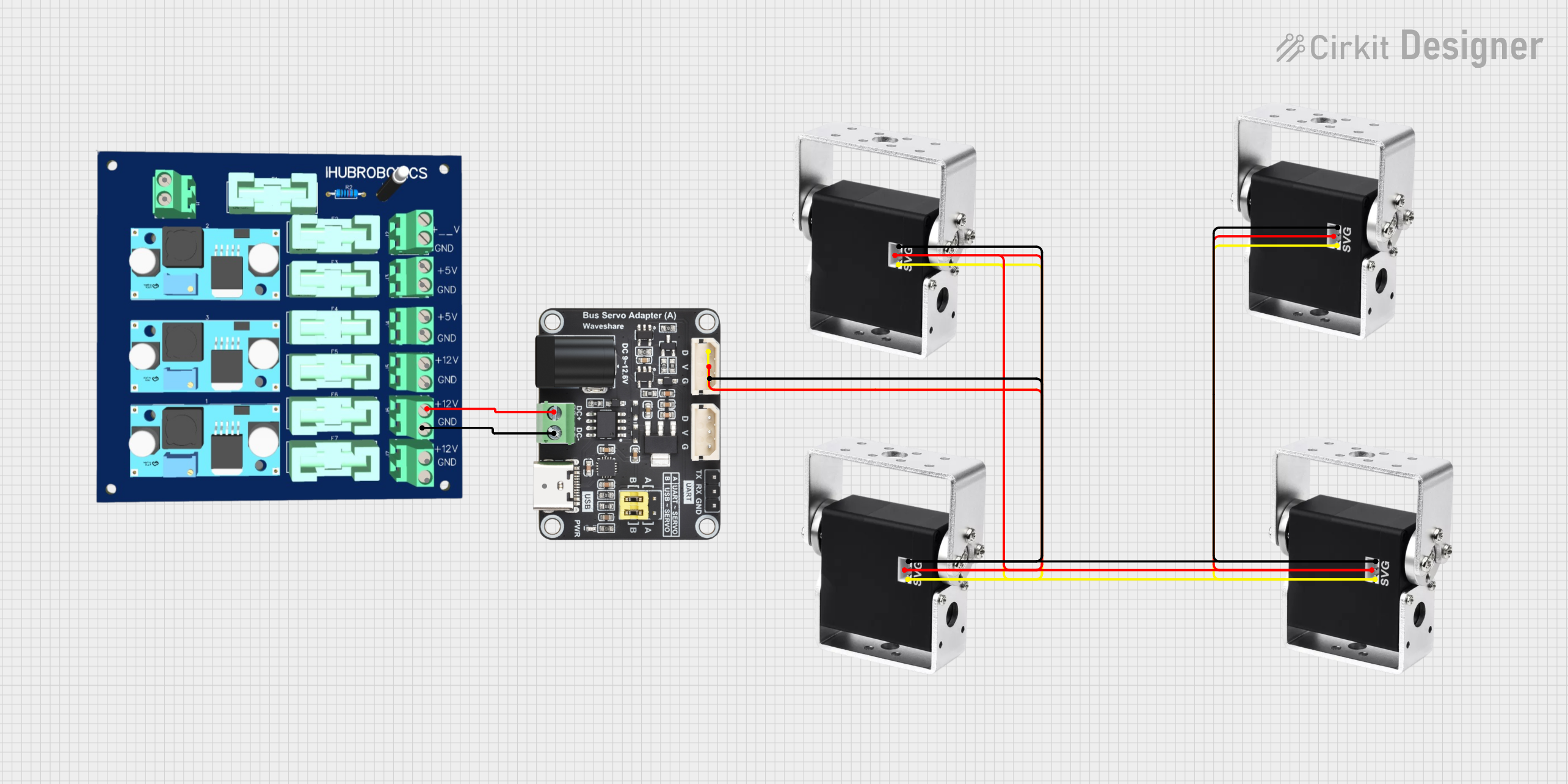

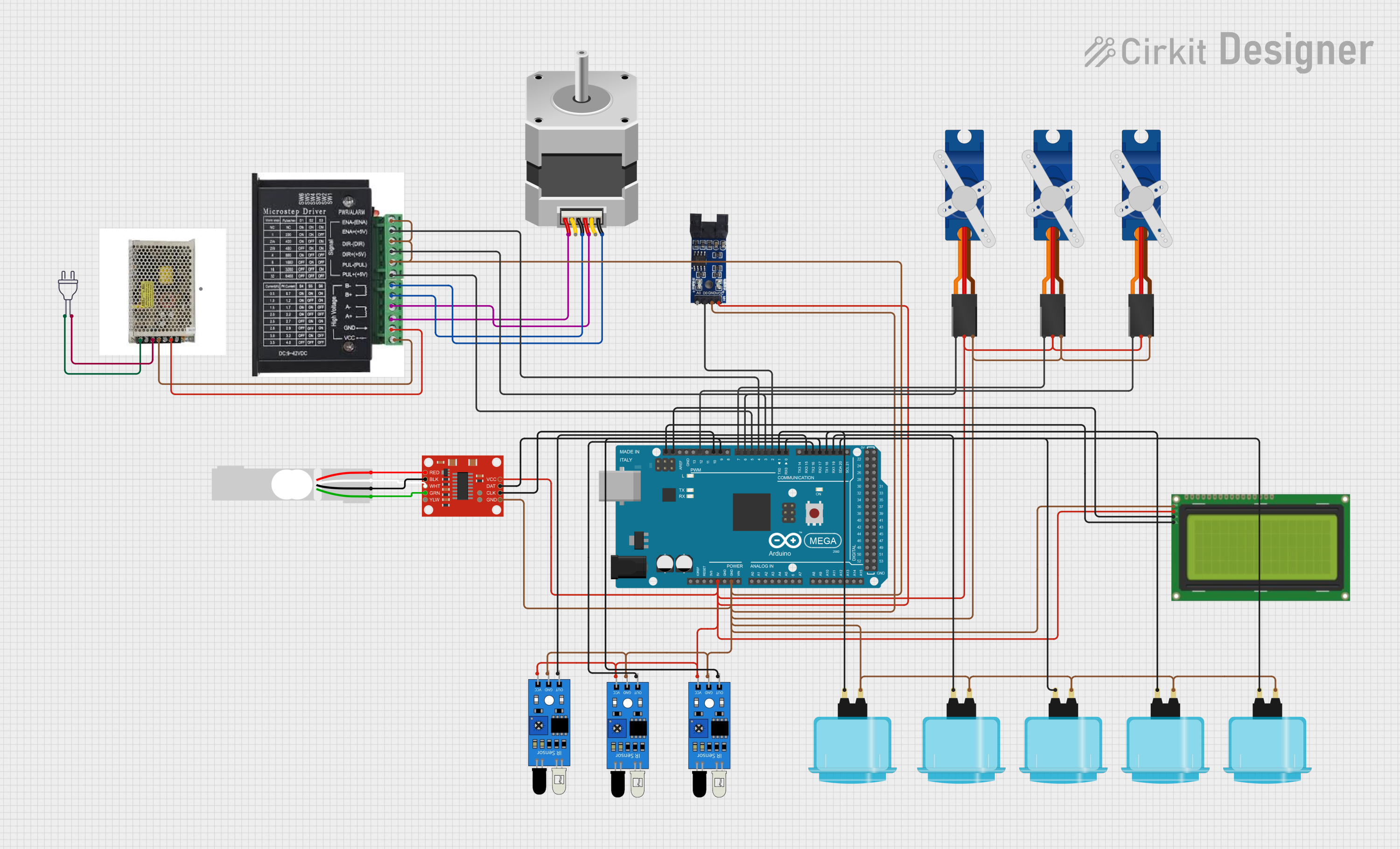

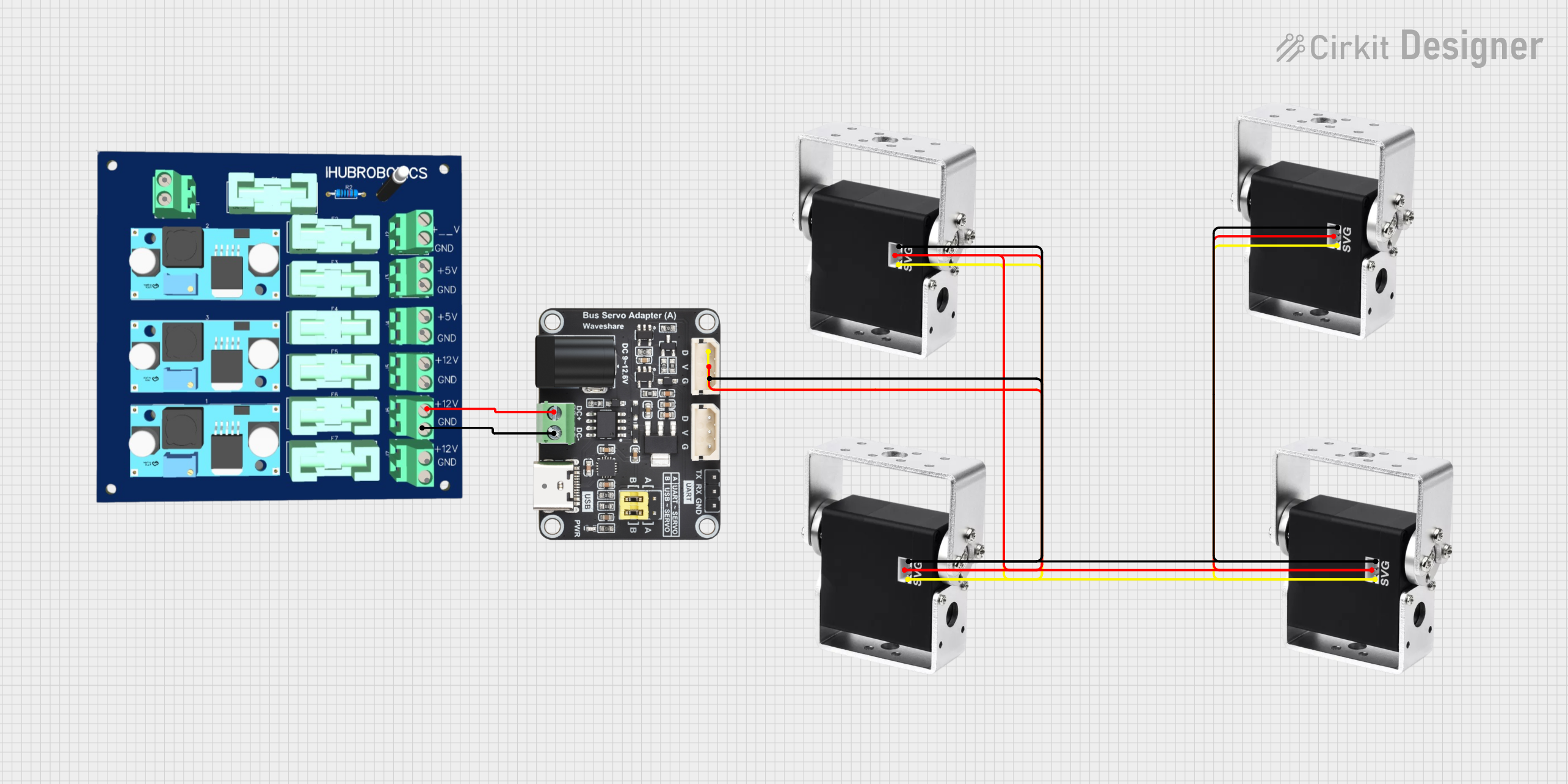

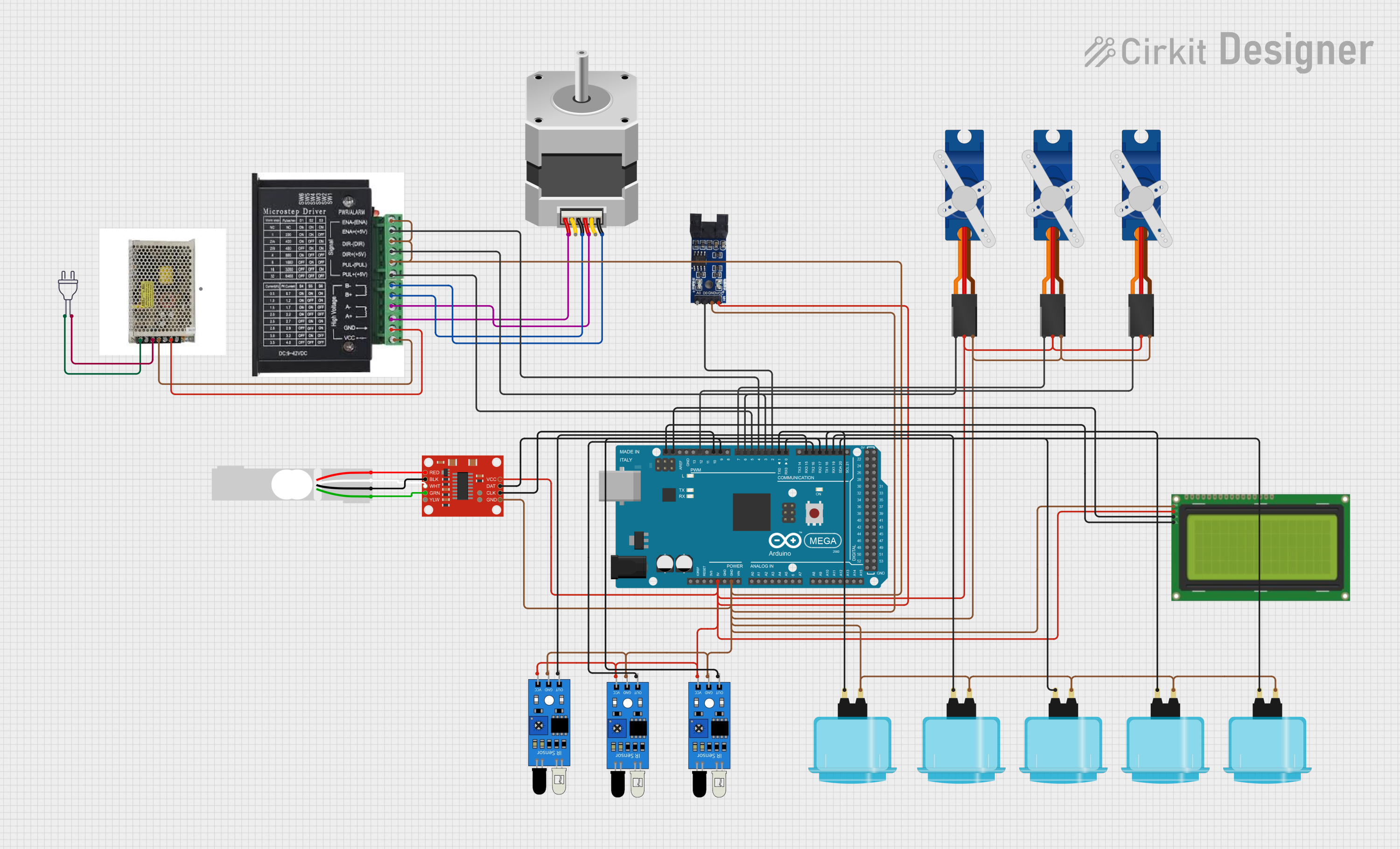

Explore Projects Built with Servo DM 15kg

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Servo DM 15kg

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotic arms and grippers

- RC cars, boats, and planes

- Automated machinery and conveyor systems

- Pan-tilt camera mounts

- Precision control systems in industrial automation

Technical Specifications

The Servo DM 15kg is built to deliver high performance while maintaining durability. Below are its key technical details:

| Parameter | Specification |

|---|---|

| Operating Voltage | 4.8V - 6.8V |

| Stall Torque | 15 kg-cm @ 6.8V |

| Operating Speed | 0.16 sec/60° @ 4.8V, 0.14 sec/60° @ 6.8V |

| Control Signal | PWM (Pulse Width Modulation) |

| PWM Range | 500 µs - 2500 µs |

| Angle Range | 0° - 180° |

| Gear Material | Metal |

| Motor Type | Coreless |

| Connector Type | 3-pin female header (Futaba/JR type) |

| Dimensions | 40.5mm x 20mm x 38mm |

| Weight | 60g |

Pin Configuration

The Servo DM 15kg has a standard 3-pin connector. Below is the pinout description:

| Pin | Wire Color | Function |

|---|---|---|

| 1 | Brown/Black | Ground (GND) |

| 2 | Red | Power (VCC) |

| 3 | Orange/White | Signal (PWM Input) |

Usage Instructions

How to Use the Servo DM 15kg in a Circuit

- Power Supply: Connect the red wire to a stable power source (4.8V to 6.8V). Ensure the power supply can provide sufficient current (at least 2A) to handle the servo's peak load.

- Ground Connection: Connect the brown/black wire to the ground of your circuit.

- Signal Input: Connect the orange/white wire to a PWM signal source, such as a microcontroller (e.g., Arduino UNO).

Important Considerations

- Power Requirements: Use a separate power supply for the servo if your microcontroller cannot provide sufficient current. This prevents voltage drops and potential damage to the microcontroller.

- PWM Signal: Ensure the PWM signal is within the range of 500 µs to 2500 µs. A pulse width of 1500 µs typically corresponds to the neutral position (90°).

- Mounting: Secure the servo using screws and rubber grommets to minimize vibrations and ensure stable operation.

- Overloading: Avoid exceeding the torque rating of 15 kg-cm to prevent damage to the servo motor.

Example: Controlling the Servo DM 15kg with Arduino UNO

Below is an example code to control the Servo DM 15kg using an Arduino UNO:

#include <Servo.h> // Include the Servo library

Servo myServo; // Create a Servo object to control the servo

void setup() {

myServo.attach(9); // Attach the servo to pin 9 on the Arduino

// The PWM signal will be sent from this pin

}

void loop() {

myServo.write(0); // Move the servo to 0 degrees

delay(1000); // Wait for 1 second

myServo.write(90); // Move the servo to 90 degrees (neutral position)

delay(1000); // Wait for 1 second

myServo.write(180); // Move the servo to 180 degrees

delay(1000); // Wait for 1 second

}

Notes on the Code

- The

Servolibrary simplifies the process of generating PWM signals for the servo. - The

myServo.write(angle)function accepts an angle between 0° and 180°. - Ensure the servo is properly powered before running the code to avoid erratic behavior.

Troubleshooting and FAQs

Common Issues and Solutions

Servo Not Moving

- Cause: Insufficient power supply.

- Solution: Use a power source capable of providing at least 2A of current.

Erratic Movements

- Cause: Noise or interference in the PWM signal.

- Solution: Use shorter wires for the signal connection and ensure proper grounding.

Overheating

- Cause: Prolonged operation under high torque or stalled conditions.

- Solution: Avoid stalling the servo and ensure it operates within its torque limits.

Limited Range of Motion

- Cause: Incorrect PWM signal range.

- Solution: Verify that the PWM signal is within the 500 µs to 2500 µs range.

FAQs

Q: Can I power the servo directly from the Arduino UNO?

A: It is not recommended, as the Arduino UNO cannot provide sufficient current for the servo. Use an external power supply.

Q: What happens if I exceed the torque rating?

A: Exceeding the torque rating can damage the servo's internal gears or motor. Always operate within the specified limits.

Q: Can I use the Servo DM 15kg for continuous rotation?

A: No, this servo is designed for positional control (0° to 180°). For continuous rotation, use a modified or dedicated continuous rotation servo.

Q: How do I calibrate the servo's neutral position?

A: Send a 1500 µs PWM signal (corresponding to 90°) and adjust the servo horn if necessary to align it with the desired neutral position.

By following this documentation, you can effectively integrate the Servo DM 15kg into your projects and achieve precise control for a variety of applications.