How to Use MRB Planetary gearbox motor: Examples, Pinouts, and Specs

Design with MRB Planetary gearbox motor in Cirkit Designer

Design with MRB Planetary gearbox motor in Cirkit DesignerIntroduction

The MRB Planetary Gearbox Motor is a high-performance motor integrated with a planetary gearbox. This design provides a compact and efficient solution for applications requiring high torque, precise speed control, and accurate positioning. The planetary gearbox ensures uniform load distribution, high power density, and reduced backlash, making it ideal for demanding tasks.

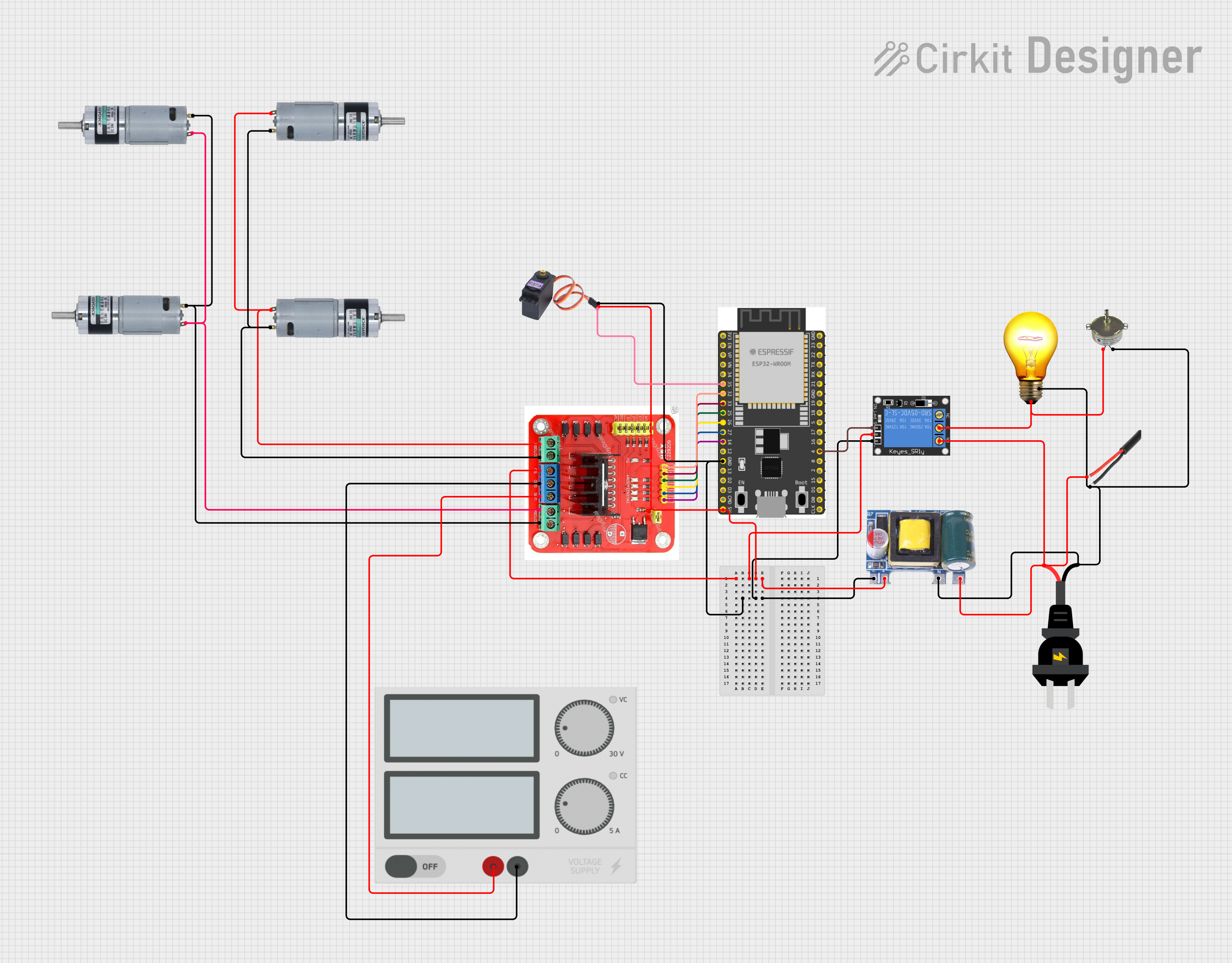

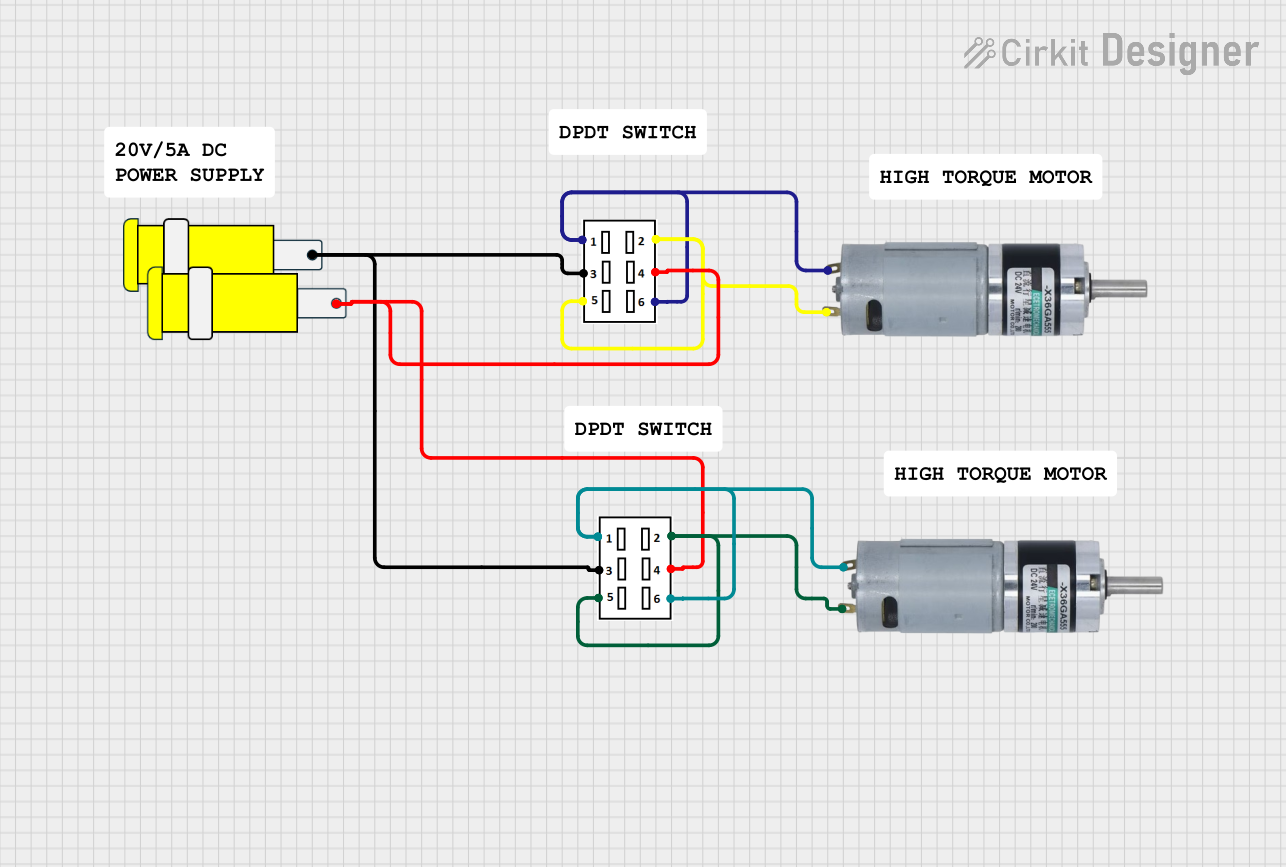

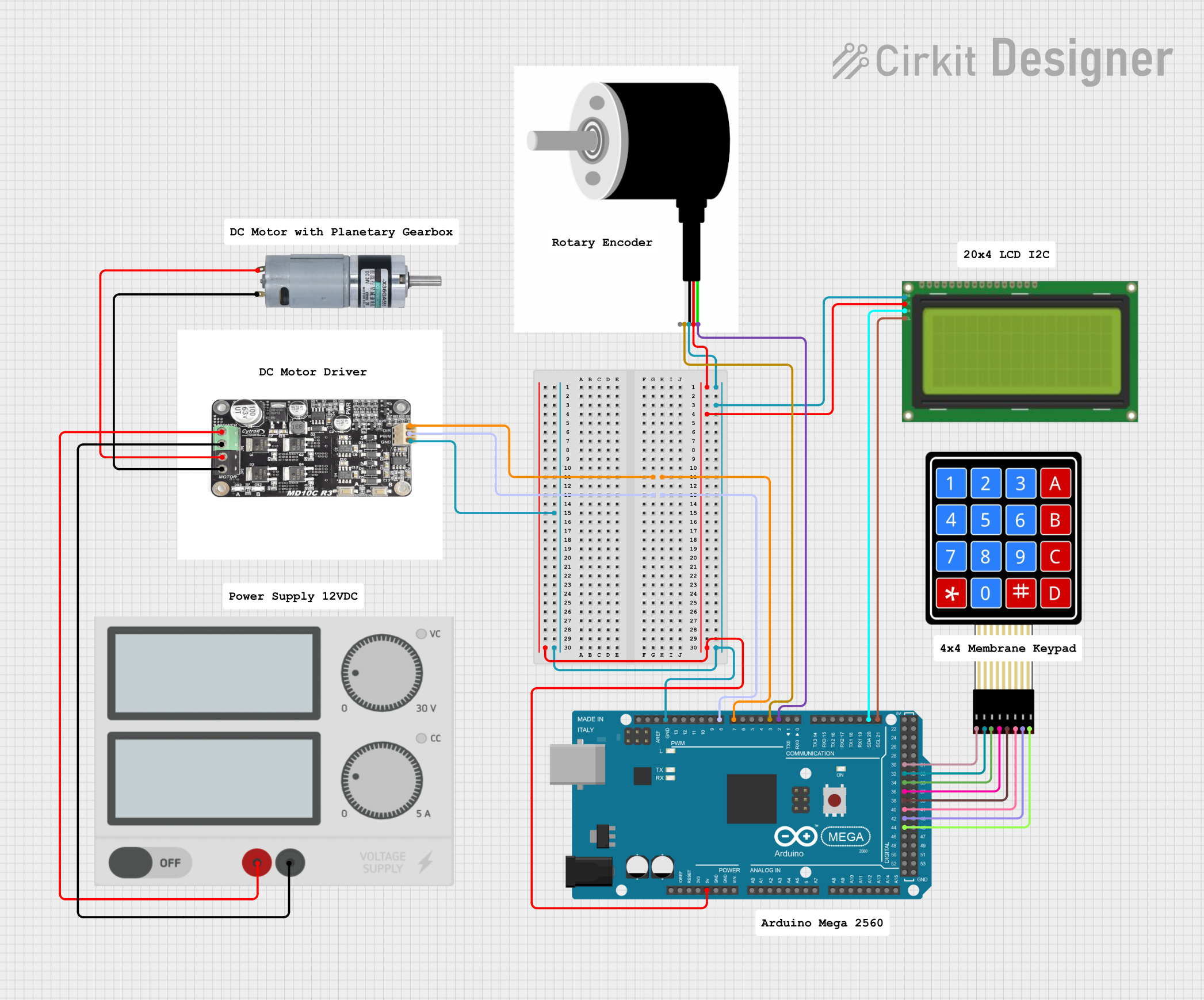

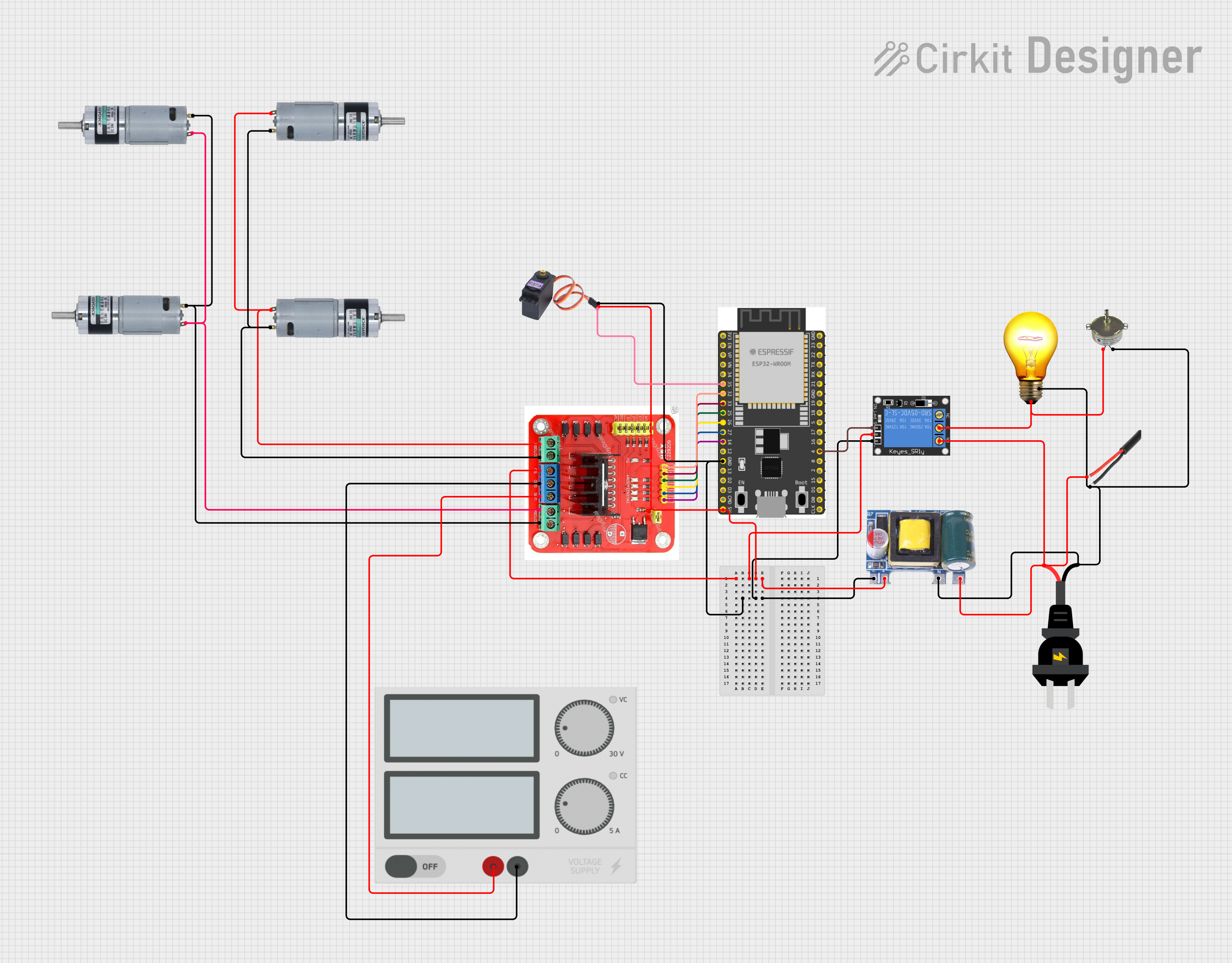

Explore Projects Built with MRB Planetary gearbox motor

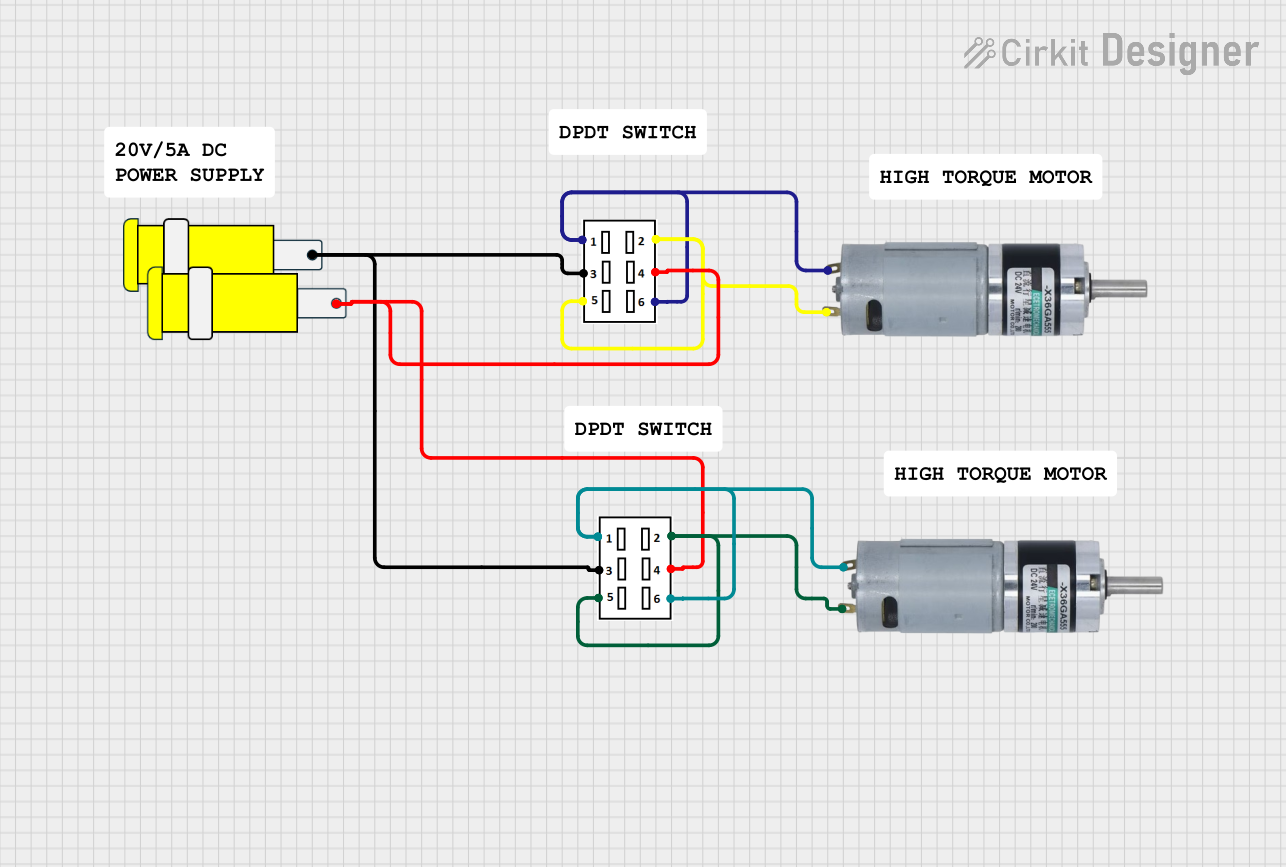

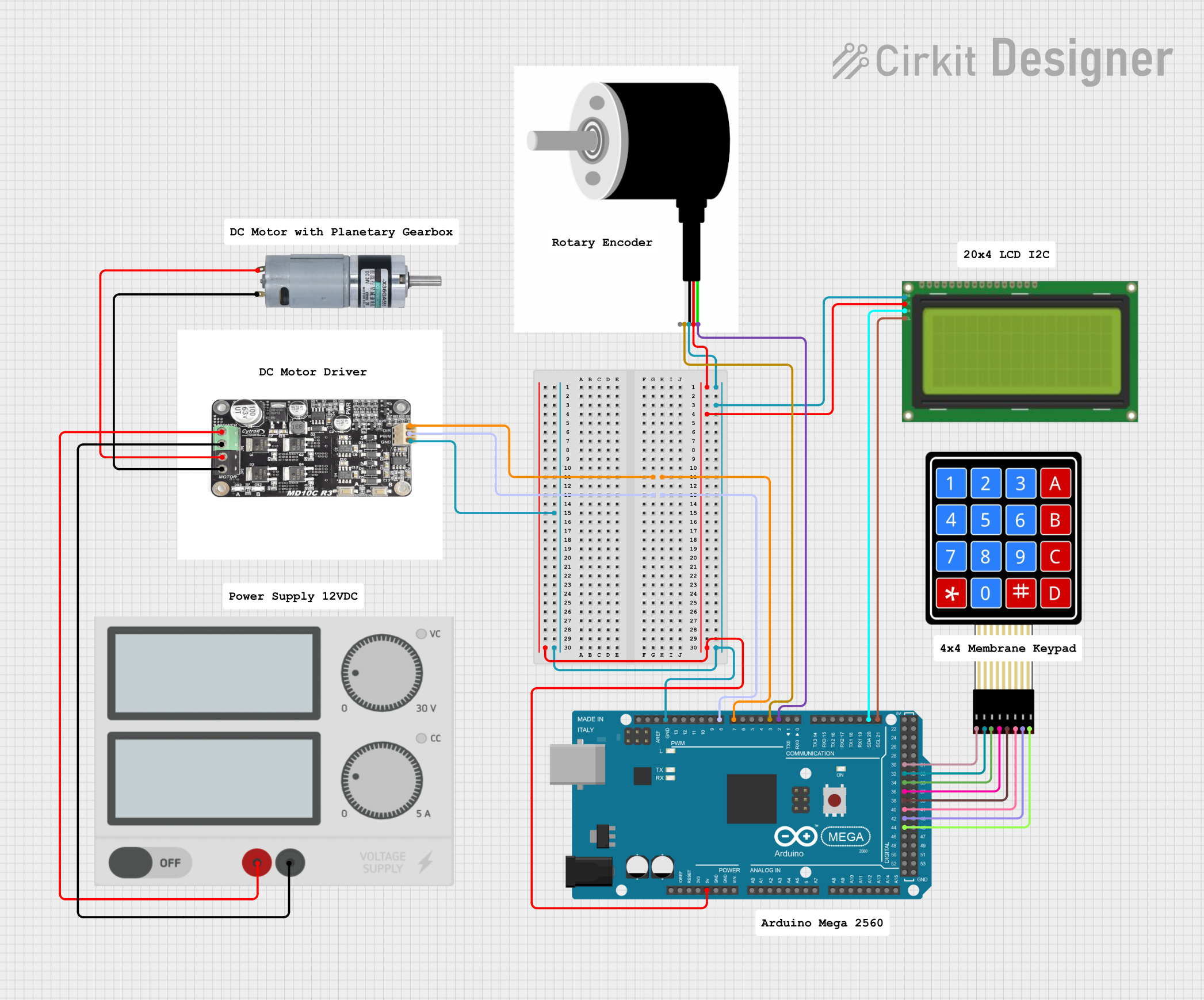

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with MRB Planetary gearbox motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics and automation systems

- CNC machines and 3D printers

- Electric vehicles and mobility devices

- Industrial machinery requiring precise motion control

- Actuators in aerospace and defense applications

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Motor Type | DC motor with planetary gearbox |

| Gearbox Type | Planetary |

| Input Voltage Range | 6V to 24V |

| Rated Torque | Up to 50 Nm (varies by model) |

| Gear Ratio Options | 4:1, 16:1, 64:1, etc. |

| No-Load Speed | 50 to 500 RPM (varies by model) |

| Efficiency | Up to 90% |

| Backlash | < 1° |

| Operating Temperature | -20°C to 60°C |

| Shaft Diameter | 6 mm to 12 mm (varies by model) |

| Mounting Configuration | Flange-mounted |

Pin Configuration and Descriptions

The MRB Planetary Gearbox Motor typically has two or three wires for electrical connections. Below is a general description of the pin configuration:

| Pin/Wire Color | Function | Description |

|---|---|---|

| Red | Power (V+) | Connect to the positive terminal of the power supply. |

| Black | Ground (GND) | Connect to the negative terminal of the power supply. |

| Yellow (optional) | Encoder Signal A (if applicable) | Provides feedback for speed and position control. |

| Green (optional) | Encoder Signal B (if applicable) | Secondary feedback signal for direction sensing. |

Note: The exact pin configuration may vary depending on the specific model. Refer to the datasheet for your motor.

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Ensure the power supply voltage matches the motor's input voltage range (6V to 24V). Use a regulated DC power source for optimal performance.

- Connections:

- Connect the red wire to the positive terminal of the power supply.

- Connect the black wire to the ground terminal.

- If the motor includes an encoder, connect the encoder wires (yellow and green) to the appropriate microcontroller pins for feedback.

- Motor Driver: Use a motor driver or H-bridge circuit to control the motor's speed and direction. Ensure the driver can handle the motor's current and voltage requirements.

- Control: For precise control, use a microcontroller (e.g., Arduino UNO) to send PWM signals to the motor driver.

Important Considerations and Best Practices

- Gear Ratio Selection: Choose a gear ratio that balances speed and torque for your application.

- Load Limits: Avoid exceeding the motor's rated torque to prevent damage.

- Heat Management: Ensure proper ventilation or cooling if the motor operates continuously under high load.

- Encoder Feedback: If using an encoder, calibrate it for accurate speed and position control.

- Mounting: Securely mount the motor to prevent misalignment or vibration during operation.

Example: Connecting to an Arduino UNO

Below is an example of controlling the MRB Planetary Gearbox Motor using an Arduino UNO and an L298N motor driver.

// Example: Controlling MRB Planetary Gearbox Motor with Arduino UNO

// Ensure the motor driver is connected to the motor and power supply correctly.

#define ENA 9 // PWM pin for motor speed control

#define IN1 8 // Motor direction pin 1

#define IN2 7 // Motor direction pin 2

void setup() {

pinMode(ENA, OUTPUT); // Set ENA as output

pinMode(IN1, OUTPUT); // Set IN1 as output

pinMode(IN2, OUTPUT); // Set IN2 as output

}

void loop() {

// Rotate motor forward

digitalWrite(IN1, HIGH); // Set IN1 high

digitalWrite(IN2, LOW); // Set IN2 low

analogWrite(ENA, 150); // Set speed (0-255)

delay(2000); // Run motor for 2 seconds

// Rotate motor backward

digitalWrite(IN1, LOW); // Set IN1 low

digitalWrite(IN2, HIGH); // Set IN2 high

analogWrite(ENA, 150); // Set speed (0-255)

delay(2000); // Run motor for 2 seconds

// Stop motor

digitalWrite(IN1, LOW); // Set IN1 low

digitalWrite(IN2, LOW); // Set IN2 low

analogWrite(ENA, 0); // Set speed to 0

delay(2000); // Wait for 2 seconds before repeating

}

Note: Adjust the

analogWritevalue to control the motor speed. Ensure the motor driver can handle the motor's current requirements.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Start:

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Double-check all connections and ensure the power supply meets the motor's voltage and current requirements.

Motor Overheats:

- Cause: Excessive load or prolonged operation at high torque.

- Solution: Reduce the load or provide adequate cooling.

Inconsistent Speed or Position:

- Cause: Encoder feedback not properly connected or calibrated.

- Solution: Verify encoder connections and recalibrate the system.

Excessive Noise or Vibration:

- Cause: Misalignment or loose mounting.

- Solution: Securely mount the motor and check for proper alignment.

FAQs

Q: Can the motor run on a 12V battery?

- A: Yes, as long as the battery can supply sufficient current for the motor's operation.

Q: How do I select the right gear ratio?

- A: Consider the required speed and torque for your application. Higher gear ratios provide more torque but reduce speed.

Q: Is the motor compatible with other microcontrollers?

- A: Yes, the motor can be controlled by any microcontroller capable of generating PWM signals, such as Raspberry Pi or ESP32.

Q: Can I use the motor without an encoder?

- A: Yes, but you will lose precise speed and position control. An encoder is recommended for applications requiring feedback.

This concludes the documentation for the MRB Planetary Gearbox Motor. For further assistance, refer to the manufacturer's datasheet or contact technical support.