How to Use Silent Step Click: Examples, Pinouts, and Specs

Design with Silent Step Click in Cirkit Designer

Design with Silent Step Click in Cirkit DesignerIntroduction

The Silent Step Click (Manufacturer Part ID: MIKROE-3714) is a specialized electronic module designed by Mikroelectronica. It is a stepper motor driver that provides ultra-quiet operation with minimal audible feedback, making it ideal for applications requiring silent and precise motor control. This module is based on advanced stepper motor driver ICs, ensuring smooth motion and high efficiency.

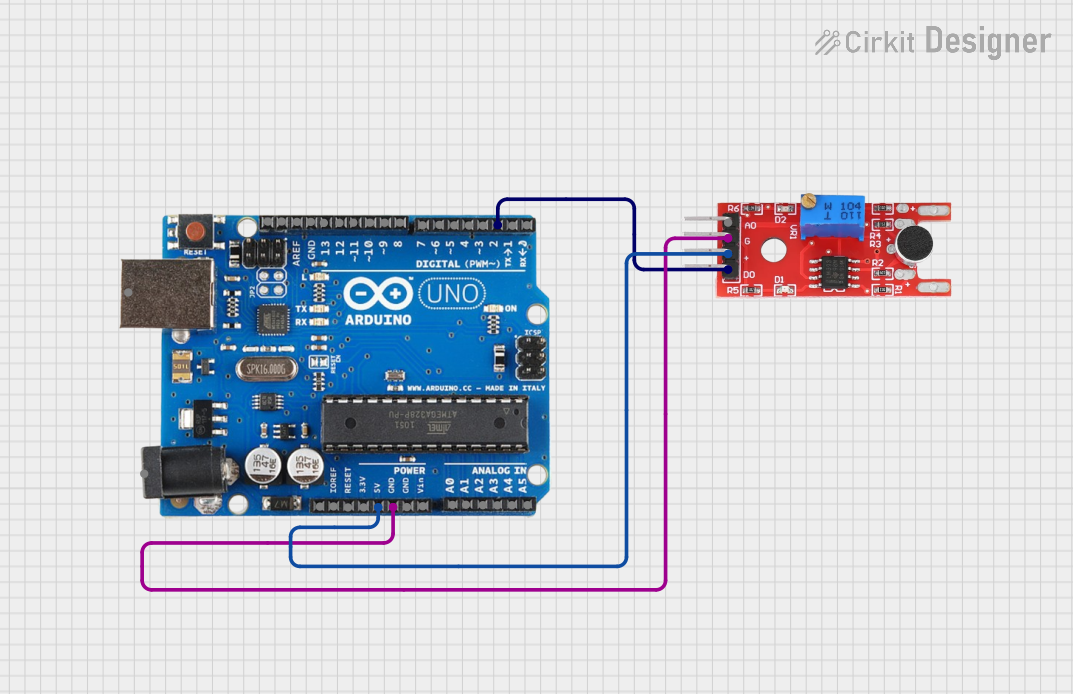

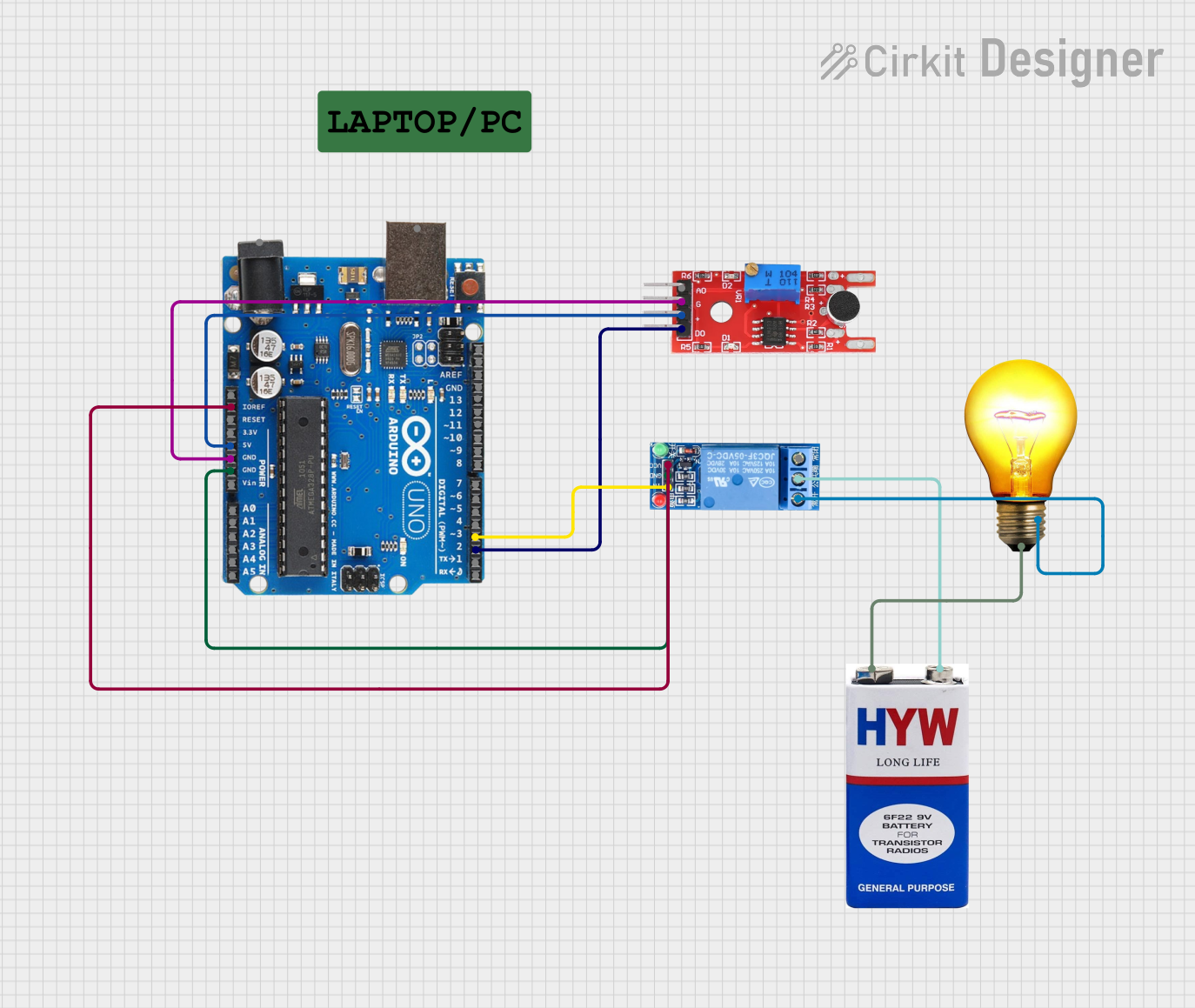

Explore Projects Built with Silent Step Click

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Silent Step Click

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- 3D printers for quiet and precise motor control

- Robotics and automation systems

- CNC machines

- Camera gimbals and stabilizers

- Any application requiring silent stepper motor operation

Technical Specifications

Key Technical Details

- Input Voltage: 3.3V or 5V (selectable via onboard jumper)

- Motor Voltage Range: 4.5V to 45V

- Maximum Motor Current: Up to 1.2A RMS per phase

- Microstepping Resolution: Up to 1/256 steps

- Communication Interface: GPIO (Step/Dir control)

- Driver IC: TMC2130 SilentStepStick

- Protection Features: Overcurrent, overtemperature, and undervoltage protection

- Dimensions: Standard Click board size (28.6mm x 25.4mm)

Pin Configuration and Descriptions

The Silent Step Click uses the standard MikroBUS™ socket, which includes the following pins:

| Pin | Name | Type | Description |

|---|---|---|---|

| 1 | AN | Analog Input | Not used (reserved for future use) |

| 2 | RST | Digital Input | Reset pin for the driver IC |

| 3 | CS | Digital Input | Chip Select for SPI communication |

| 4 | SCK | Digital Input | SPI Clock |

| 5 | MISO | Digital Output | SPI Master-In-Slave-Out |

| 6 | MOSI | Digital Input | SPI Master-Out-Slave-In |

| 7 | PWM | Digital Input | Step signal for motor control |

| 8 | INT | Digital Output | Interrupt signal (fault detection) |

| 9 | TX | Digital Output | Not used (reserved for future use) |

| 10 | RX | Digital Input | Not used (reserved for future use) |

| 11 | SCL | Digital Input | Not used (reserved for future use) |

| 12 | SDA | Digital Input | Not used (reserved for future use) |

| 13 | 3.3V | Power | 3.3V power supply |

| 14 | 5V | Power | 5V power supply |

| 15 | GND | Ground | Ground connection |

Usage Instructions

How to Use the Silent Step Click in a Circuit

- Power Supply: Connect the Silent Step Click to a 3.3V or 5V power source, depending on your system's requirements. Use the onboard jumper to select the appropriate voltage.

- Motor Connection: Connect the stepper motor to the onboard screw terminals. Ensure the motor's voltage and current ratings are within the module's specifications.

- Control Signals: Use the PWM pin for step signals and the RST pin for resetting the driver. Optionally, use the SPI interface for advanced configuration and diagnostics.

- Microstepping Configuration: Configure the microstepping resolution via SPI or by using the onboard jumpers (if available).

- Enable the Driver: Once all connections are made, enable the driver by providing appropriate control signals.

Important Considerations and Best Practices

- Cooling: Ensure adequate cooling for the module, especially when driving motors at high currents.

- Power Supply: Use a stable and noise-free power supply to avoid erratic motor behavior.

- Wiring: Keep motor wiring as short as possible to minimize noise and interference.

- SPI Configuration: For advanced features like current control and diagnostics, use the SPI interface with a microcontroller.

Example Code for Arduino UNO

Below is an example of how to control the Silent Step Click using an Arduino UNO:

// Example code to control Silent Step Click with Arduino UNO

// This code generates step pulses to rotate the stepper motor

#define STEP_PIN 3 // Connect to PWM pin on Silent Step Click

#define DIR_PIN 4 // Connect to direction control pin (if used)

void setup() {

pinMode(STEP_PIN, OUTPUT); // Set STEP_PIN as output

pinMode(DIR_PIN, OUTPUT); // Set DIR_PIN as output

digitalWrite(DIR_PIN, LOW); // Set initial direction (LOW or HIGH)

}

void loop() {

// Generate step pulses to rotate the motor

digitalWrite(STEP_PIN, HIGH); // Set step pin HIGH

delayMicroseconds(500); // Wait for 500 microseconds

digitalWrite(STEP_PIN, LOW); // Set step pin LOW

delayMicroseconds(500); // Wait for 500 microseconds

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Ensure the motor is properly connected to the module.

- Verify that the power supply voltage matches the motor's requirements.

- Check the control signals (STEP and DIR) from the microcontroller.

Overheating:

- Ensure proper cooling for the module.

- Reduce the motor current via SPI configuration or onboard settings.

Erratic Motor Behavior:

- Check for loose connections or noisy power supply.

- Use shielded cables for motor connections to reduce interference.

No Response from SPI:

- Verify the SPI connections (CS, SCK, MISO, MOSI).

- Ensure the microcontroller's SPI settings match the module's requirements.

FAQs

Can I use this module with a 12V stepper motor? Yes, as long as the motor's voltage and current ratings are within the module's specifications.

What is the maximum microstepping resolution? The Silent Step Click supports up to 1/256 microstepping resolution.

Is the module compatible with 5V logic? Yes, the module is compatible with both 3.3V and 5V logic levels.

How do I configure advanced features like current control? Use the SPI interface to configure advanced features. Refer to the TMC2130 datasheet for detailed instructions.