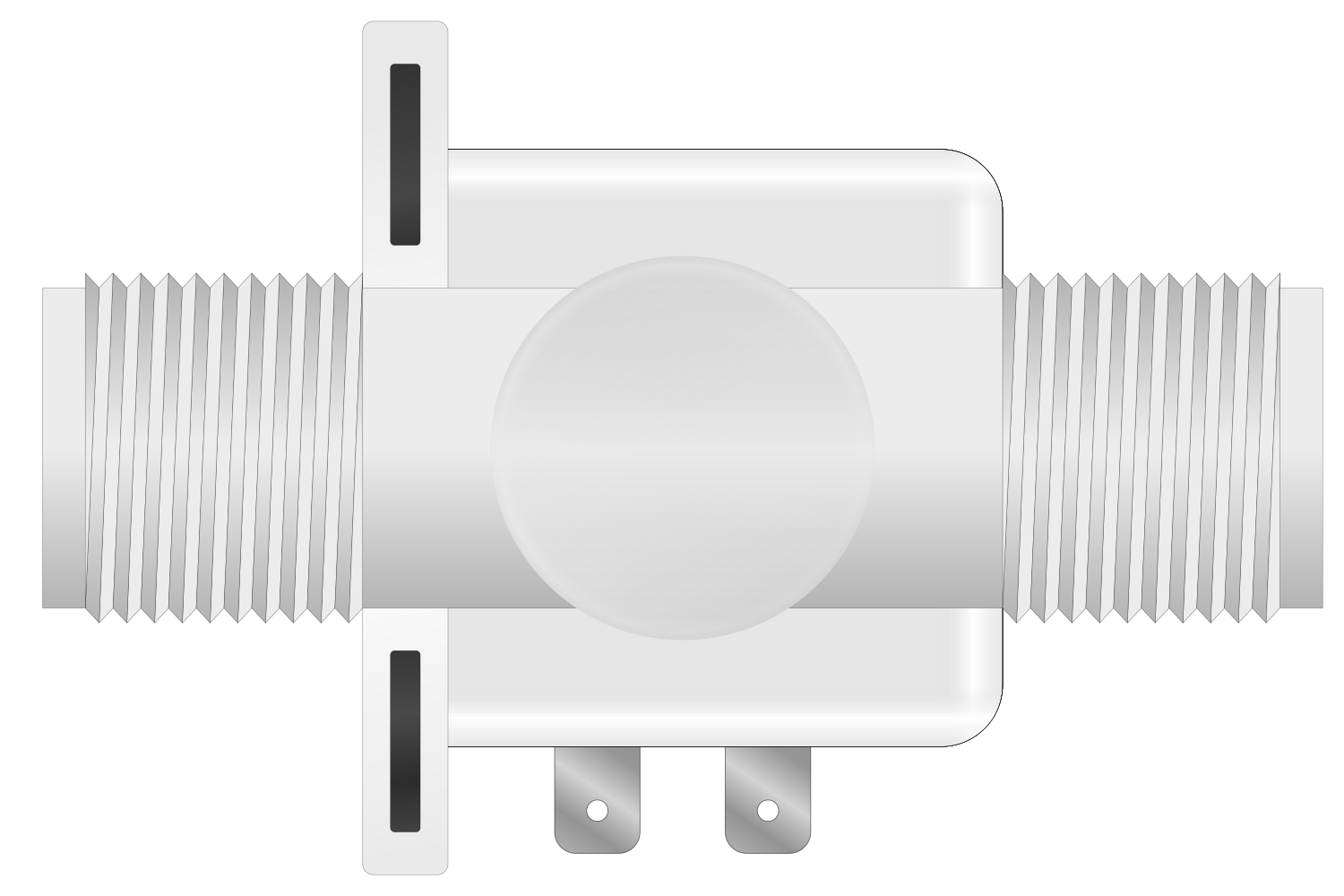

How to Use Plastic Solenoid Valve: Examples, Pinouts, and Specs

Design with Plastic Solenoid Valve in Cirkit Designer

Design with Plastic Solenoid Valve in Cirkit DesignerIntroduction

The Plastic Solenoid Valve is an electromechanical device designed to control the flow of fluids or gases within a system. It operates by using an electric current to generate a magnetic field within a solenoid coil, which in turn moves a plunger to open or close the valve. These valves are widely used in various applications, including water control systems, irrigation, home appliances, and pneumatic systems, due to their reliability and quick response times.

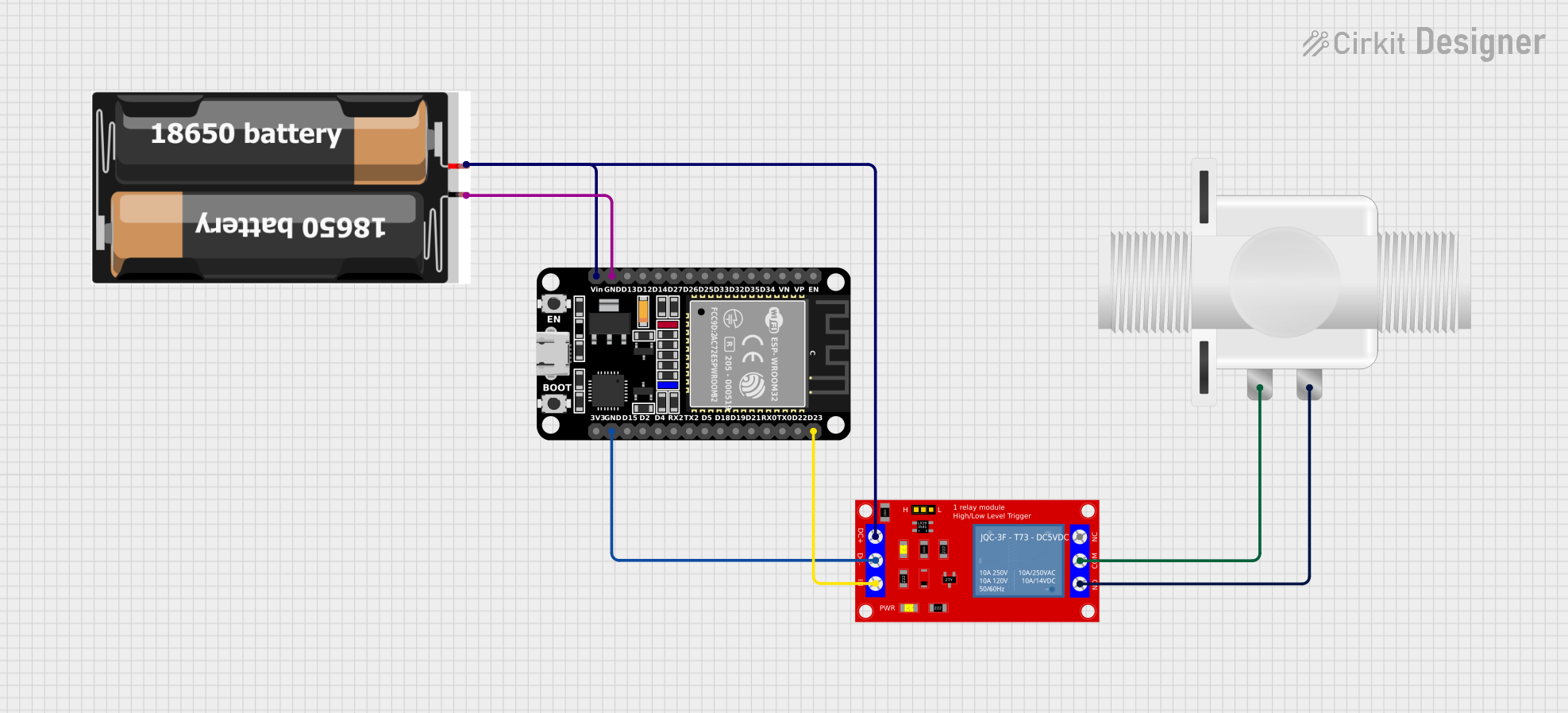

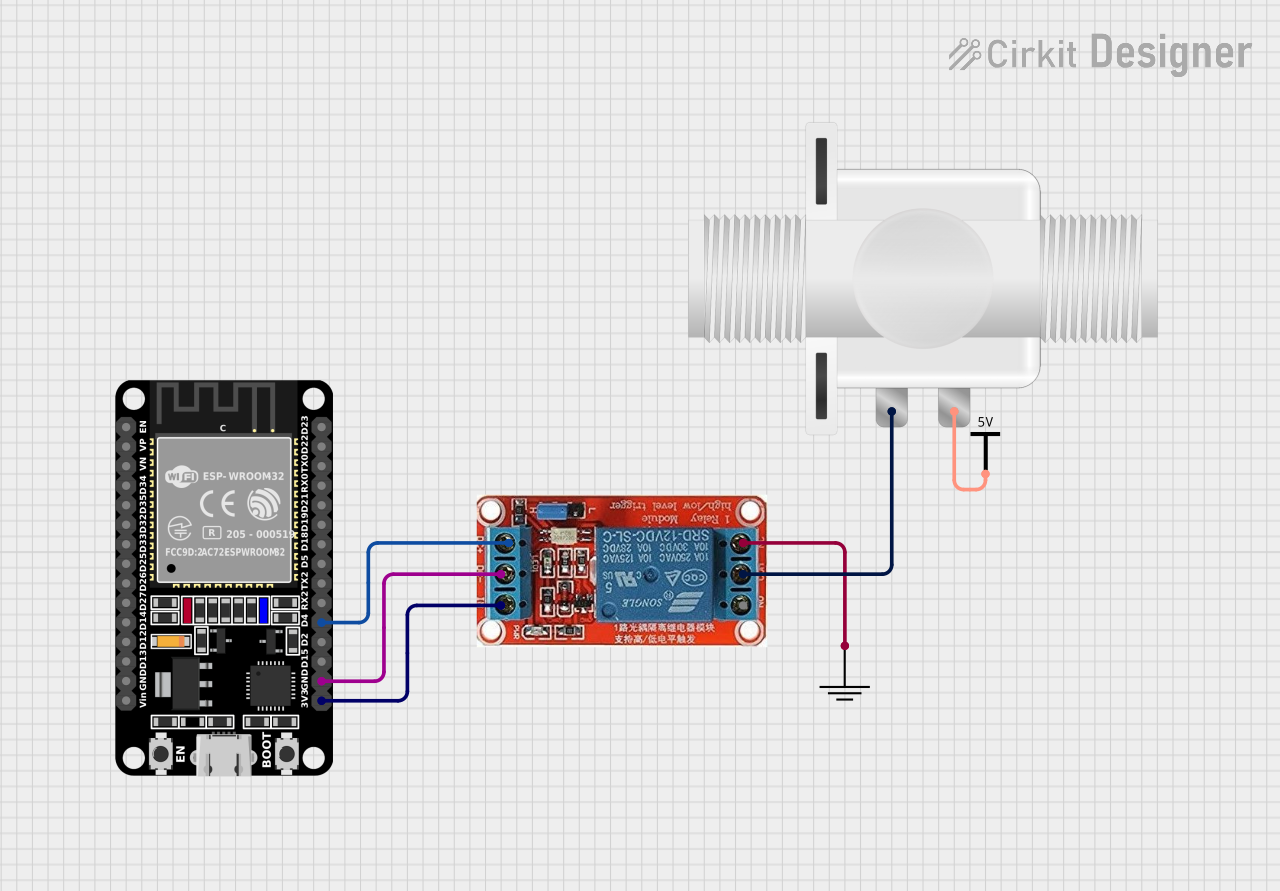

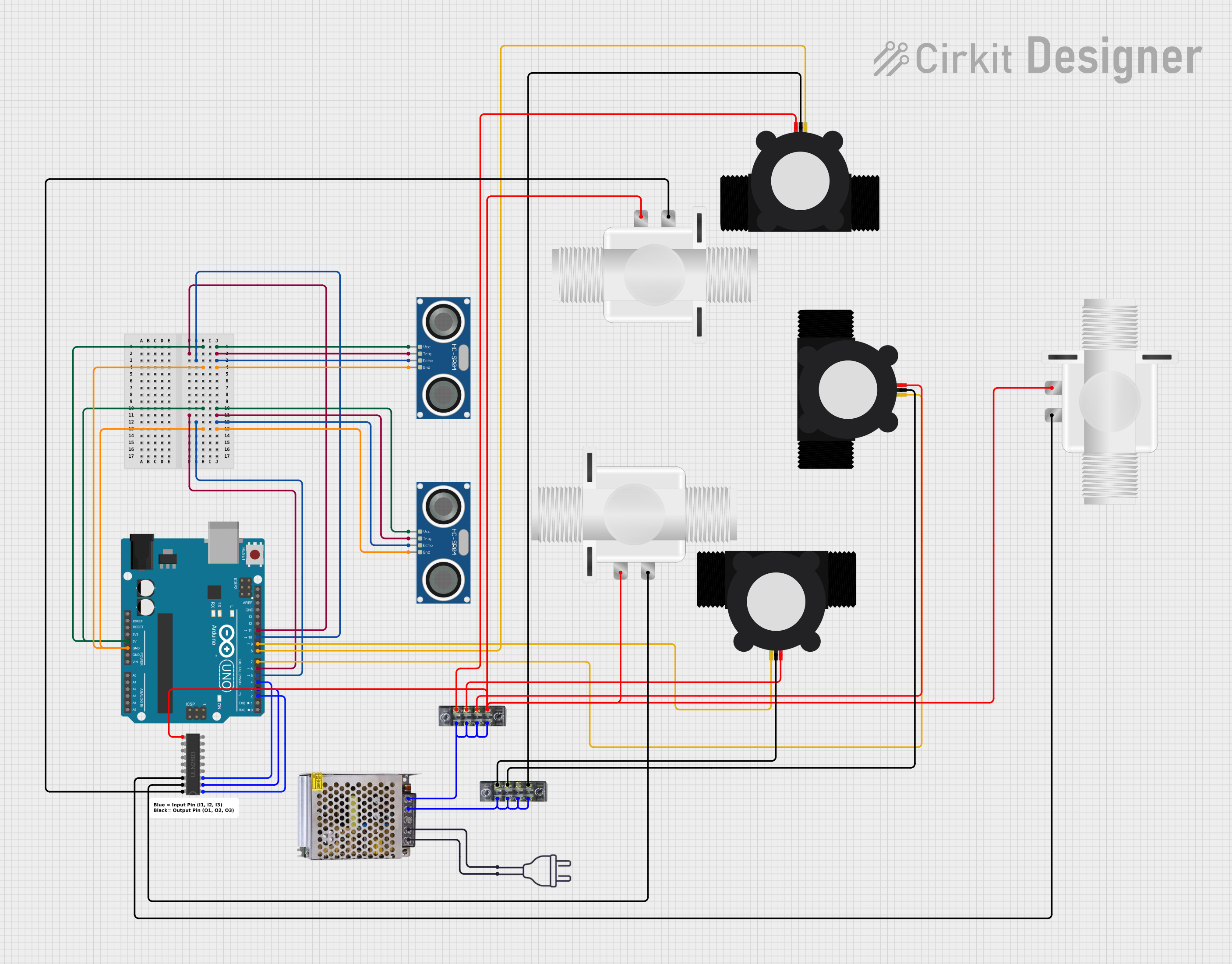

Explore Projects Built with Plastic Solenoid Valve

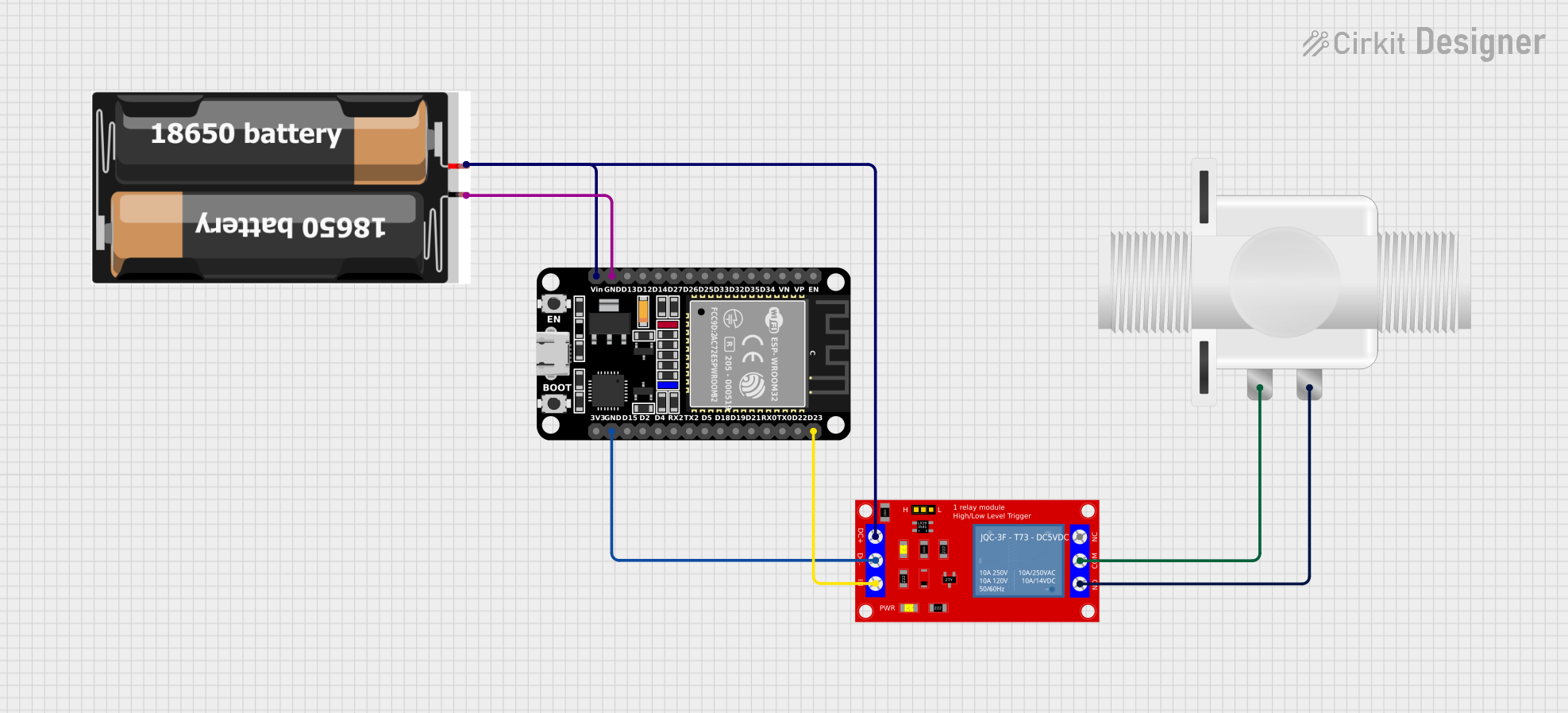

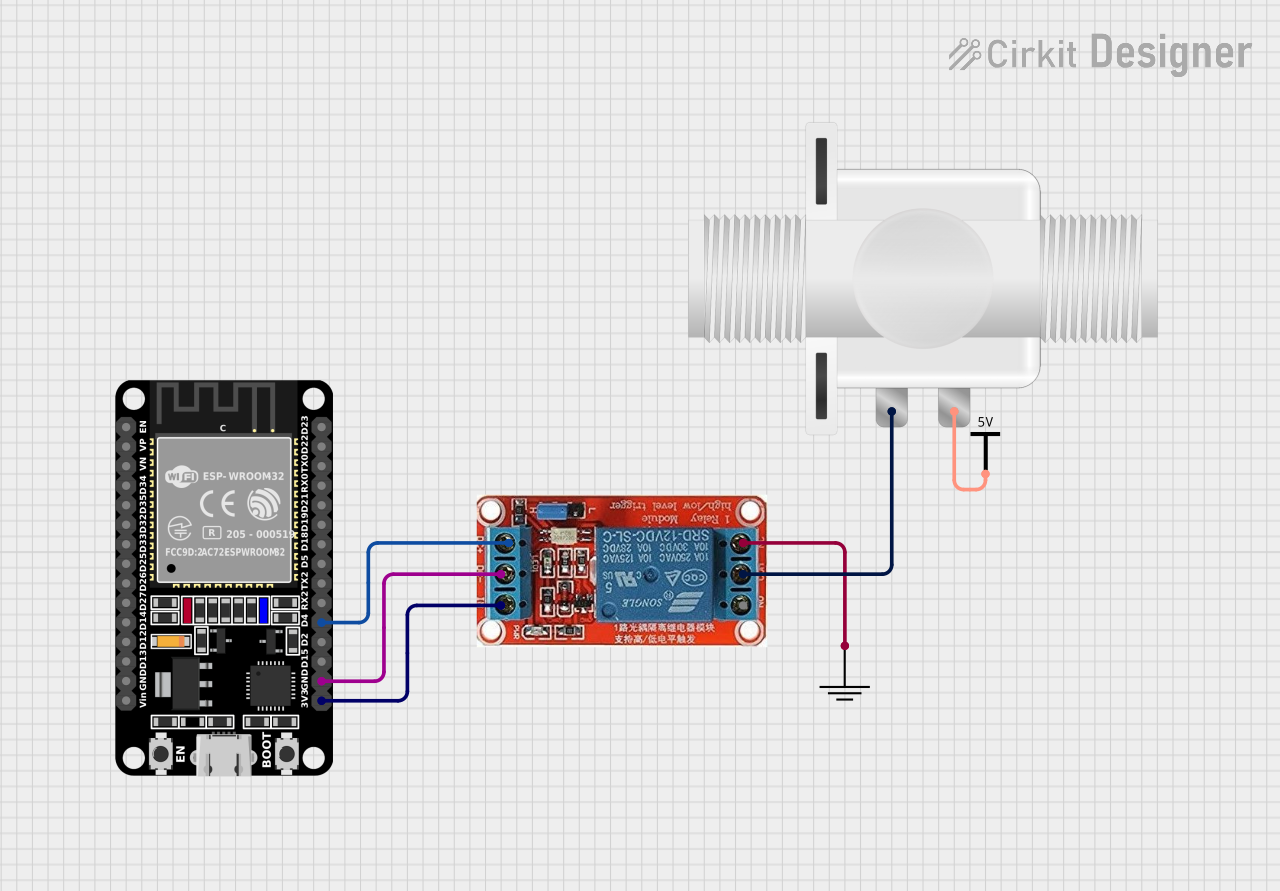

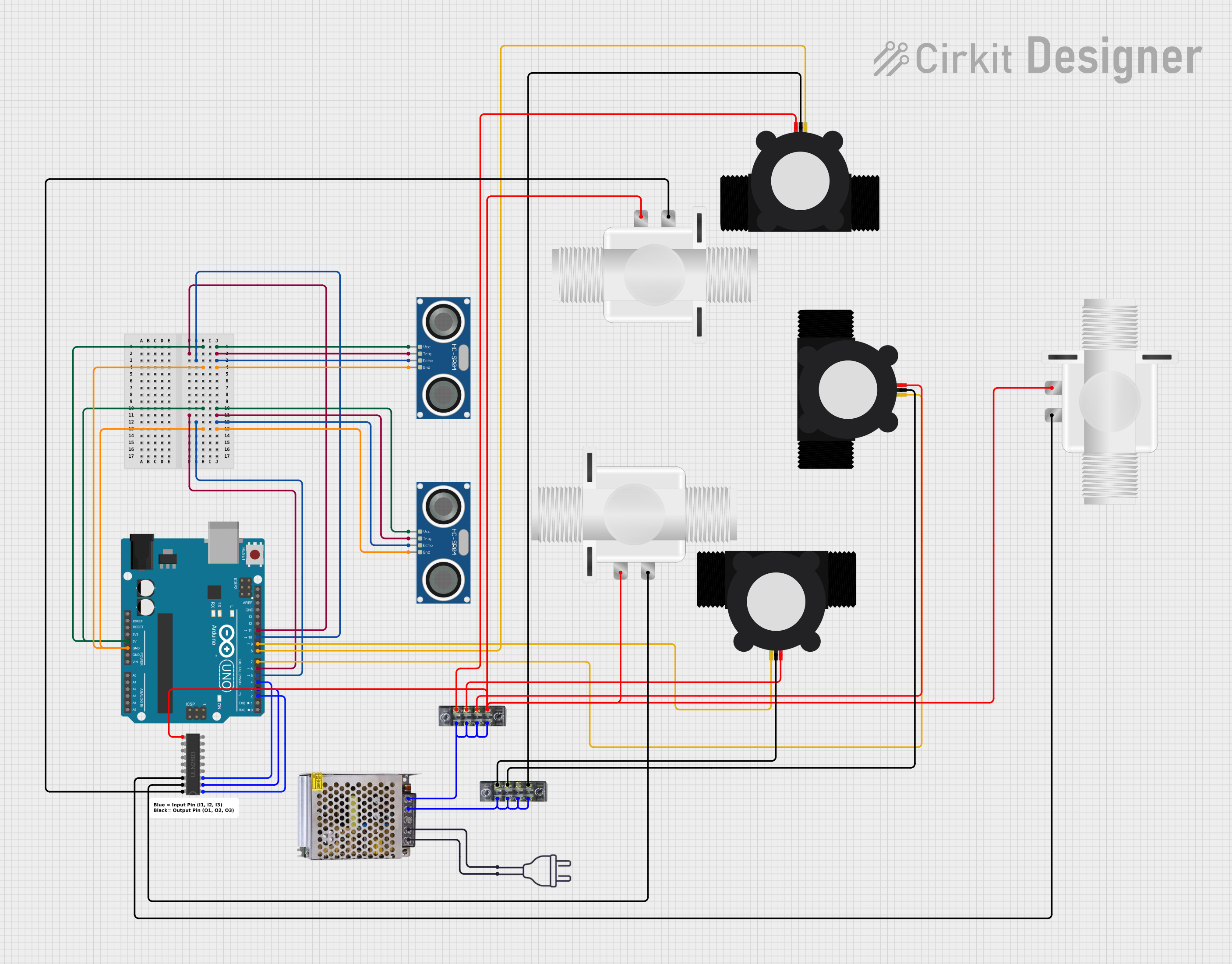

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Plastic Solenoid Valve

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Specifications

- Material: Plastic body (typically PVC or similar)

- Operation Mode: Normally closed (valve opens when energized)

- Fluid Temperature Range: 0°C to 50°C (32°F to 122°F)

- Ambient Temperature Range: 5°C to 40°C (41°F to 104°F)

- Life Expectancy: Typically 1 million cycles

Electrical Specifications

- Operating Voltage: 12V DC (commonly available)

- Current Draw: 200-500mA (depending on model)

- Power Consumption: Approx. 6W

Flow Specifications

- Pressure Range: 0 to 0.8MPa

- Flow Rate: Varies with valve size and pressure

Pin Configuration and Descriptions

| Pin | Description |

|---|---|

| 1 | Power (+12V DC) |

| 2 | Ground (0V) |

Usage Instructions

Integration into a Circuit

- Power Supply: Ensure that the power supply matches the operating voltage of the solenoid valve. A 12V DC power supply is typically used.

- Polarity: Connect the positive lead of the power supply to Pin 1 and the negative lead to Pin 2.

- Control Signal: Use a relay or a transistor to switch the solenoid valve on and off. The control signal can be provided by a microcontroller like an Arduino UNO.

Best Practices

- Waterproofing: Ensure that the solenoid valve is protected from water and moisture to prevent electrical shorts.

- Pressure Rating: Do not exceed the recommended pressure range to avoid damaging the valve.

- Heat Dissipation: Provide adequate ventilation around the solenoid coil to prevent overheating.

Example Arduino UNO Code

// Define the solenoid valve control pin

const int solenoidPin = 7;

void setup() {

// Set the solenoid pin as an output

pinMode(solenoidPin, OUTPUT);

}

void loop() {

// Open the solenoid valve

digitalWrite(solenoidPin, HIGH);

delay(1000); // Keep the valve open for 1 second

// Close the solenoid valve

digitalWrite(solenoidPin, LOW);

delay(1000); // Keep the valve closed for 1 second

}

Troubleshooting and FAQs

Common Issues

- Valve Does Not Open: Check the power supply and ensure that the voltage and current ratings are adequate. Inspect the wiring for any loose connections.

- Valve Stays Open: This could be due to a stuck plunger or a malfunctioning coil. Disconnect the power and inspect the valve for any debris or damage.

- Overheating: If the solenoid becomes too hot, it may be due to continuous operation or inadequate ventilation. Ensure the duty cycle allows for cooling periods.

FAQs

Q: Can the solenoid valve be used with liquids other than water? A: Yes, but ensure that the liquid is compatible with the valve's material and within the specified temperature range.

Q: How long can the solenoid valve remain energized? A: It depends on the model and design. Refer to the manufacturer's specifications for the maximum duty cycle.

Q: Is it possible to control the flow rate with the solenoid valve? A: Solenoid valves are typically on/off devices. To control flow rate, additional equipment like a flow control valve is required.

Remember to always refer to the manufacturer's datasheet for the most accurate and specific information regarding the operation and specifications of the Plastic Solenoid Valve.