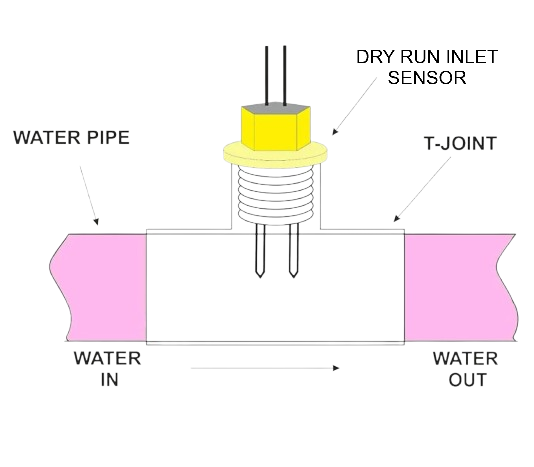

How to Use DRY RUN INLET SENSOR: Examples, Pinouts, and Specs

Design with DRY RUN INLET SENSOR in Cirkit Designer

Design with DRY RUN INLET SENSOR in Cirkit DesignerIntroduction

The DRY RUN INLET SENSOR by R.M ENTERPRISE (Part ID: SENSOR) is a specialized electronic component designed to detect the absence of water flow in a system. This sensor plays a critical role in protecting pumps and other water-dependent equipment from damage caused by dry running. By monitoring water flow, it ensures operational safety and enhances the longevity of the system.

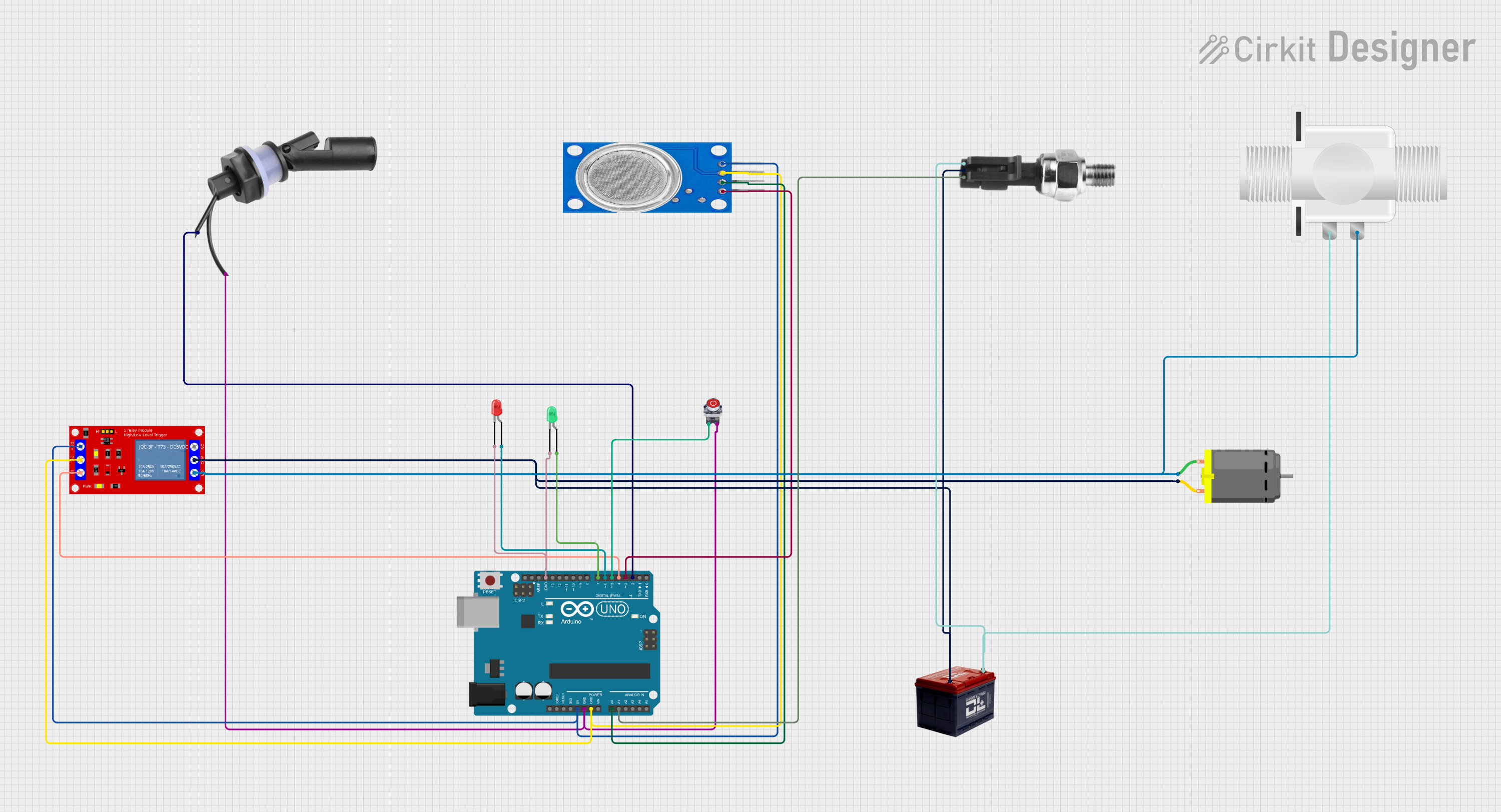

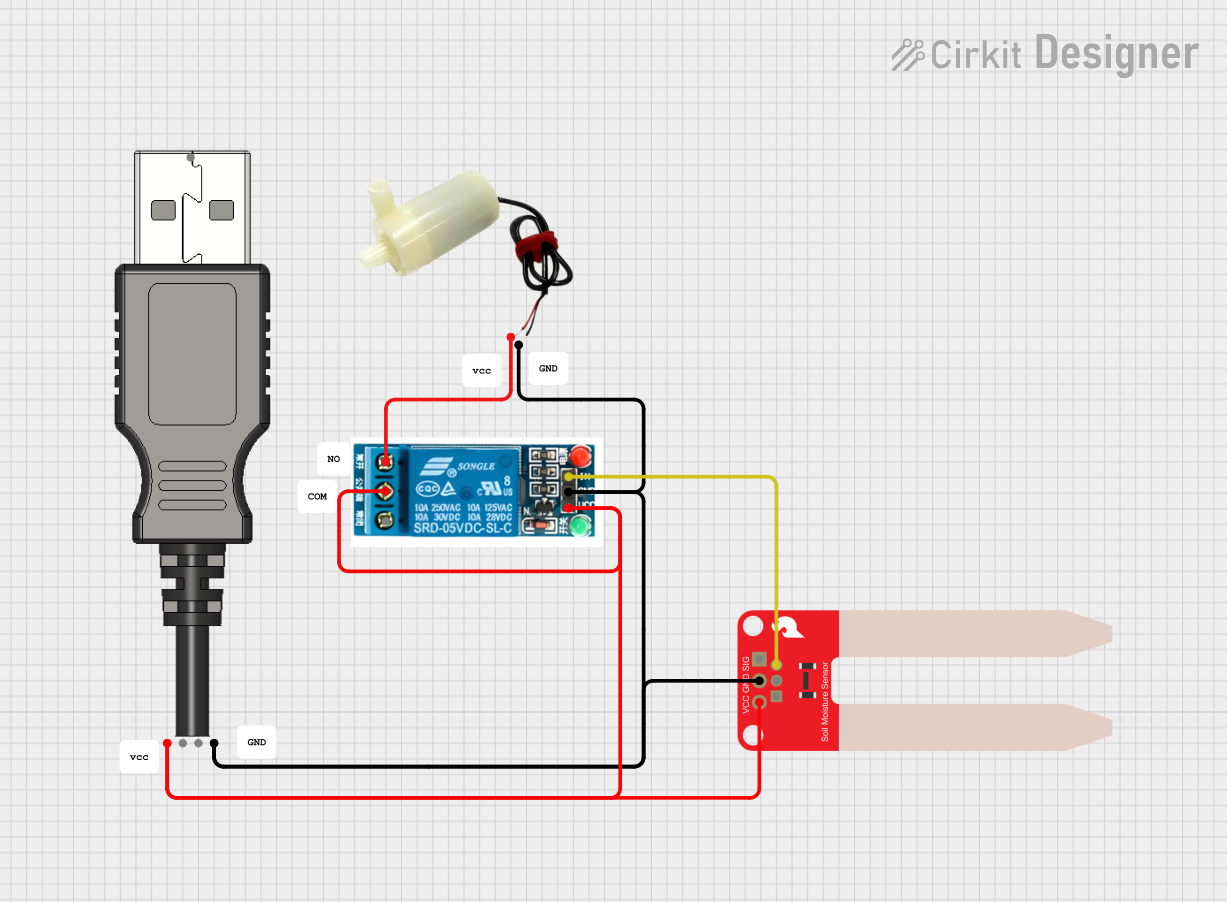

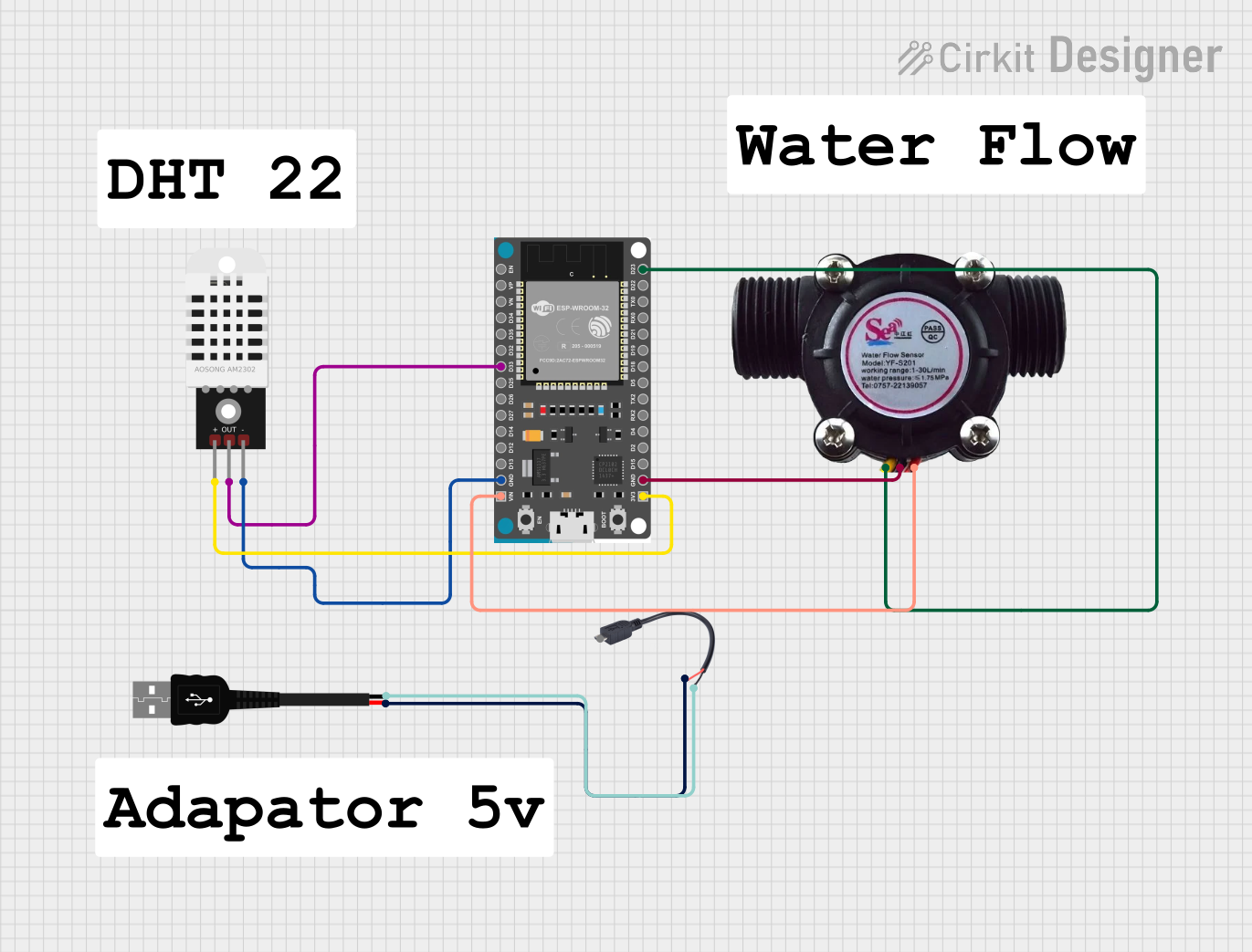

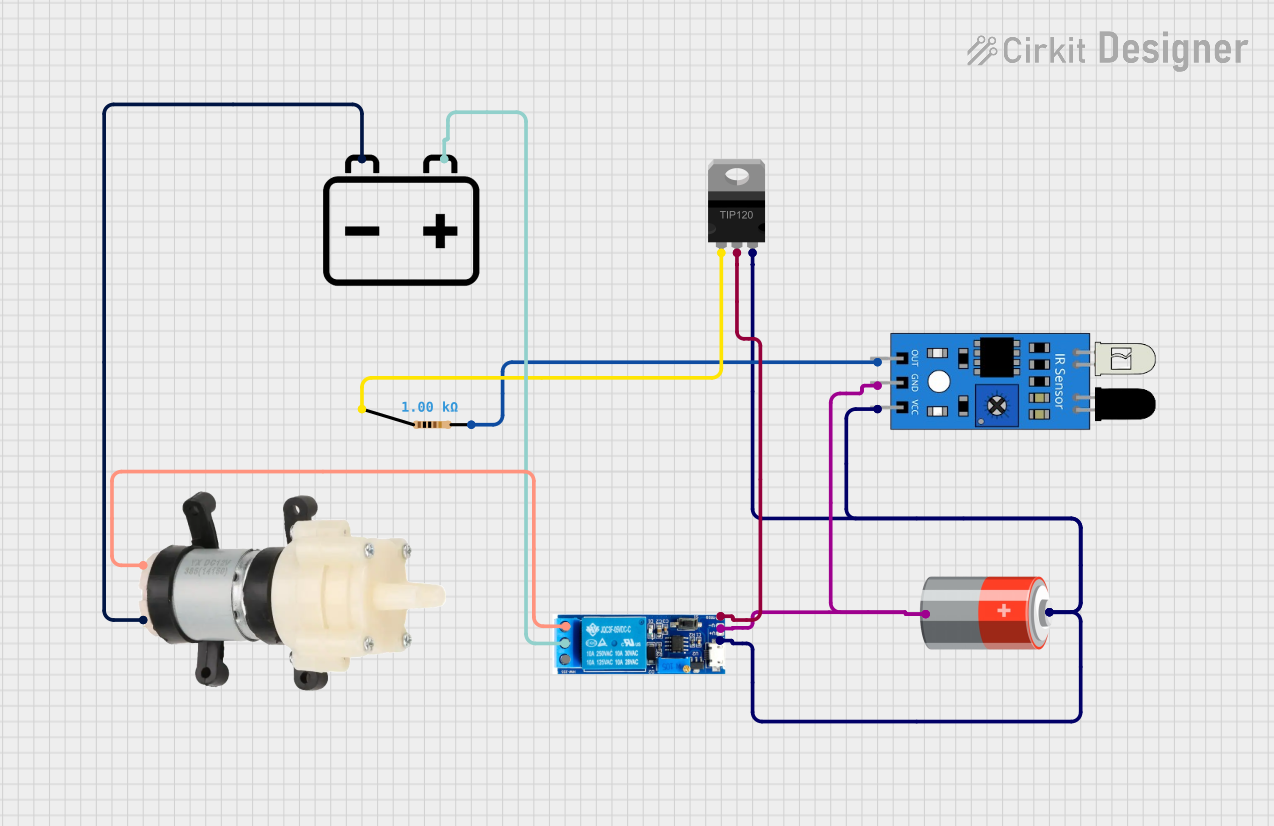

Explore Projects Built with DRY RUN INLET SENSOR

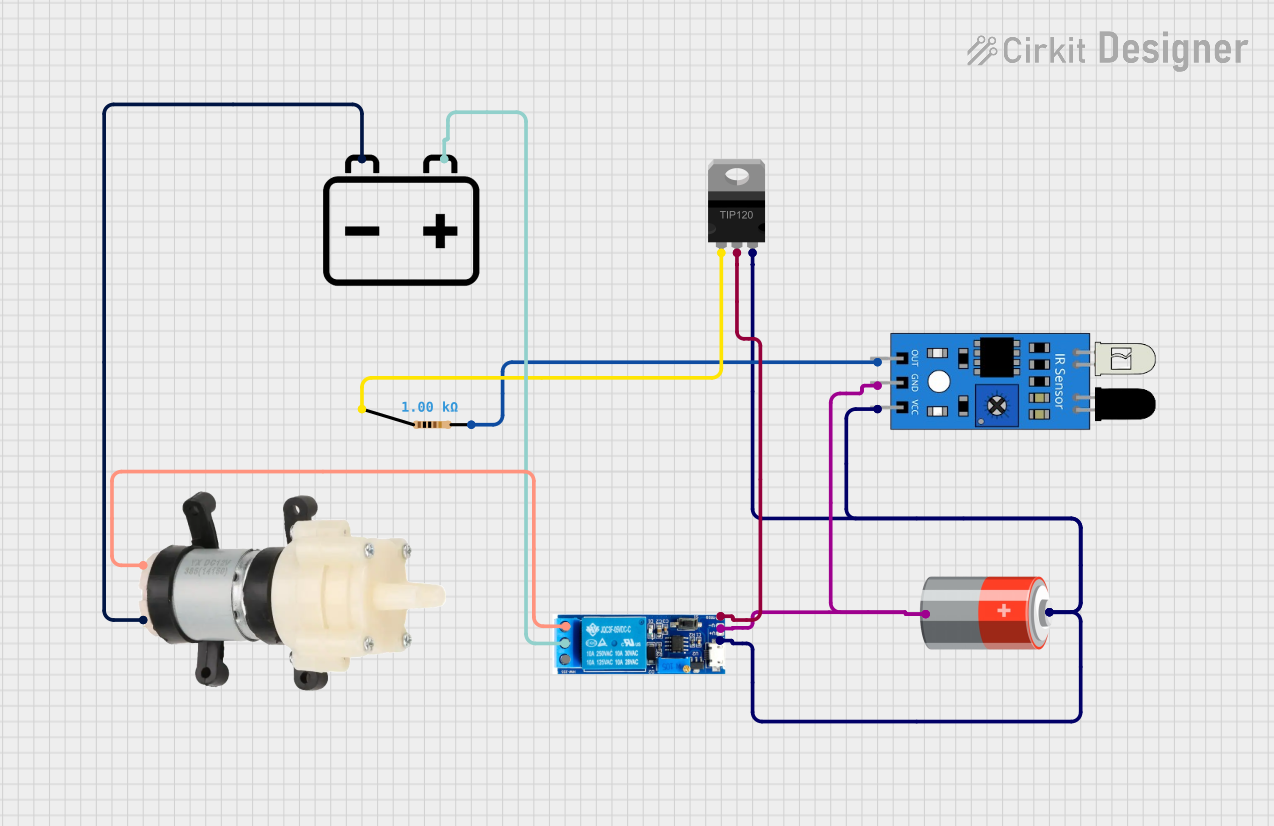

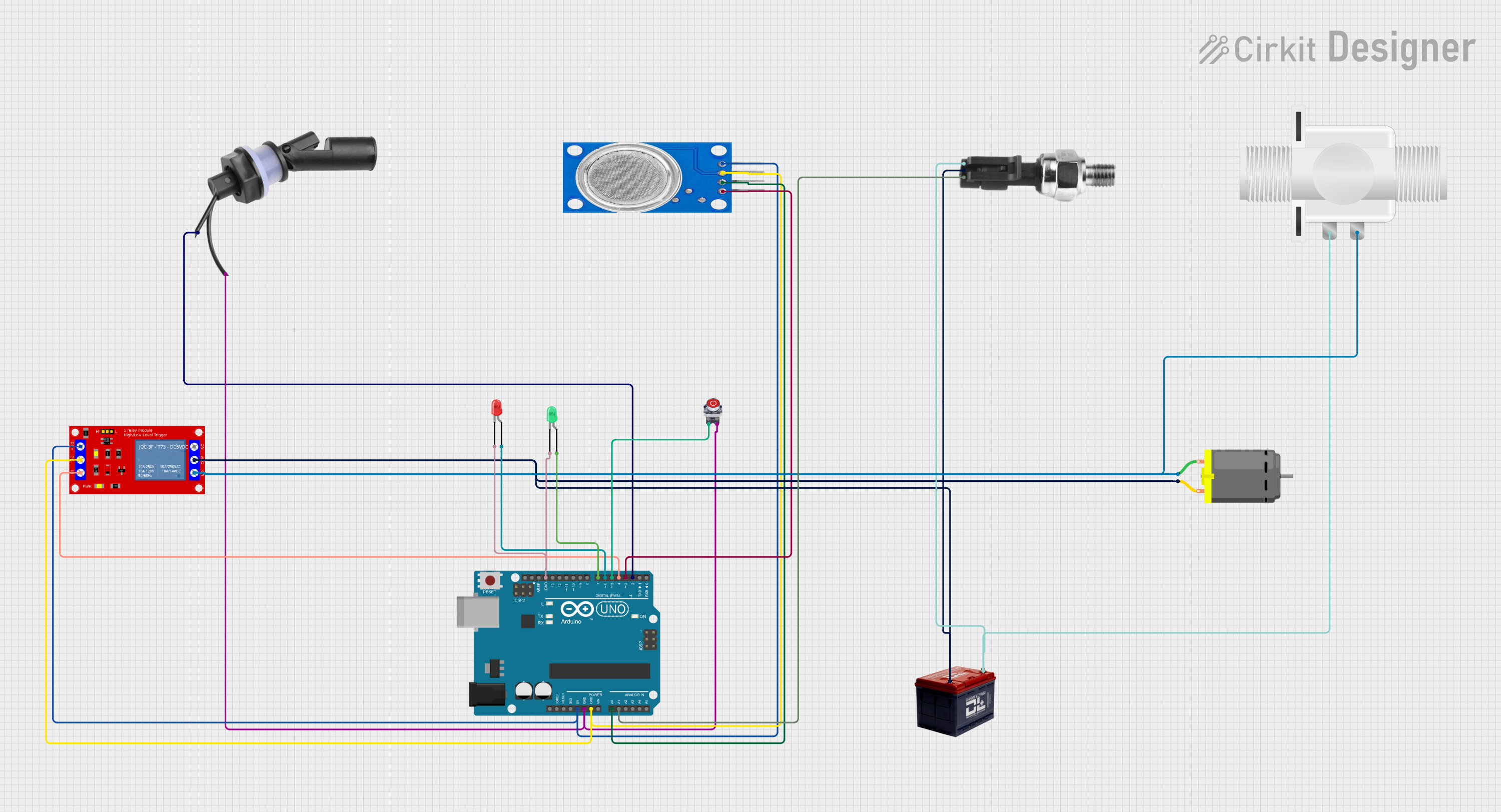

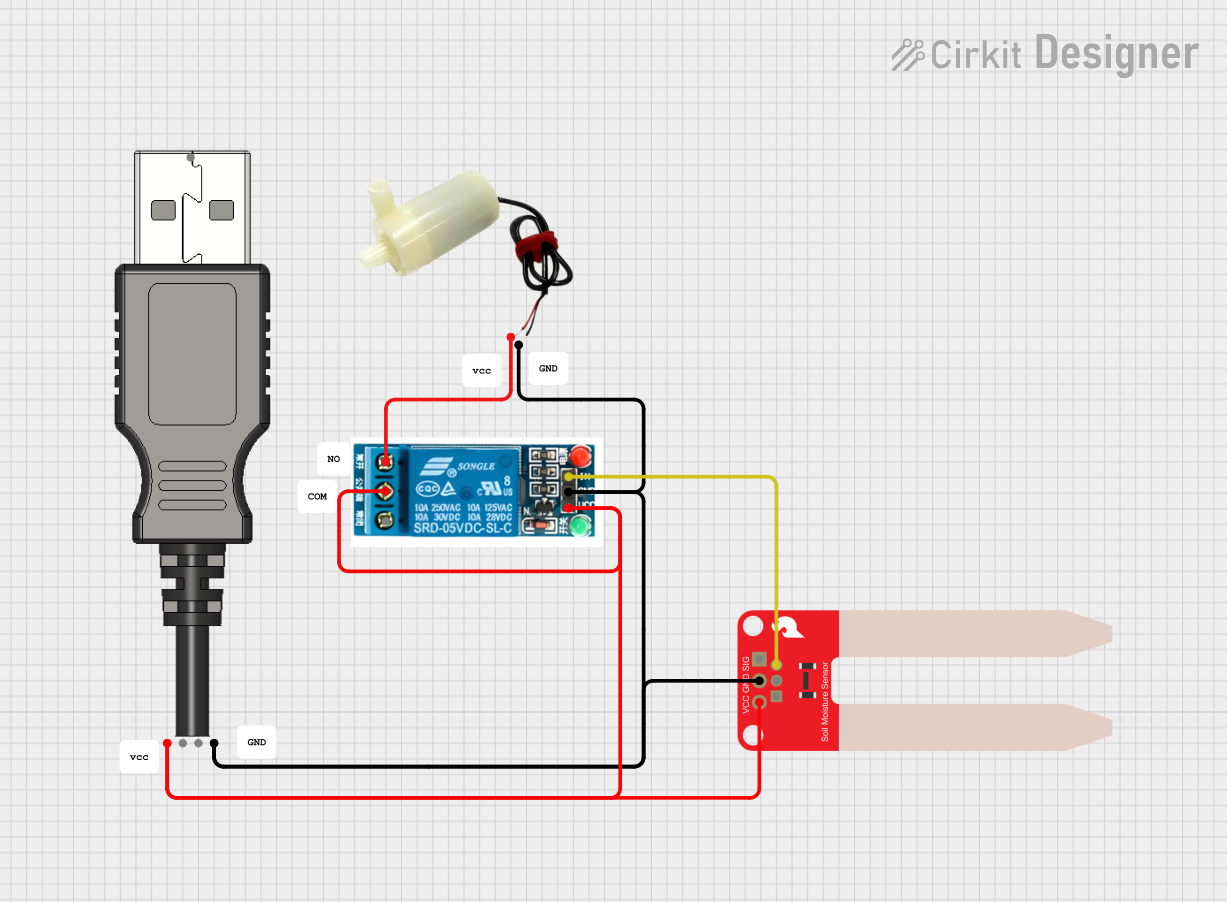

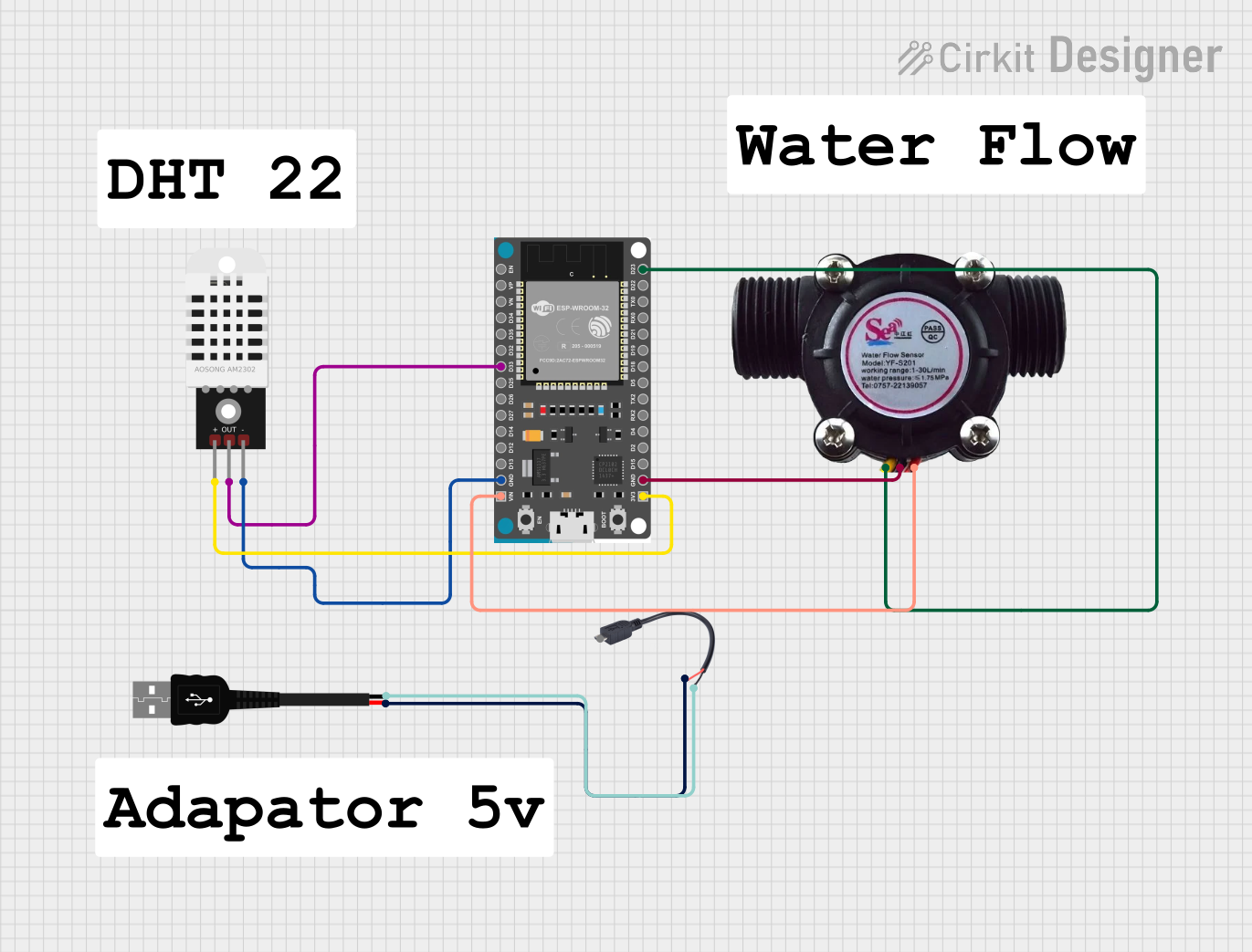

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DRY RUN INLET SENSOR

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Protection of water pumps in residential, industrial, and agricultural systems.

- Monitoring water flow in HVAC systems.

- Ensuring operational safety in irrigation systems.

- Preventing damage to equipment in water filtration and purification systems.

Technical Specifications

The following table outlines the key technical details of the DRY RUN INLET SENSOR:

| Parameter | Value |

|---|---|

| Operating Voltage | 5V to 24V DC |

| Current Consumption | ≤ 20 mA |

| Output Signal | Digital (High/Low) |

| Detection Method | Flow-based (absence of water flow) |

| Response Time | ≤ 100 ms |

| Operating Temperature | -10°C to 60°C |

| Housing Material | ABS Plastic |

| Dimensions | 50mm x 30mm x 20mm |

| Weight | 25 grams |

Pin Configuration and Descriptions

The DRY RUN INLET SENSOR has a 3-pin interface. The pin configuration is as follows:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (5V to 24V DC) |

| 2 | GND | Ground connection |

| 3 | OUT | Digital output signal (High: Water flow detected, Low: No flow) |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the VCC pin to a DC power source (5V to 24V) and the GND pin to the ground of the circuit.

- Output Signal: Connect the OUT pin to a microcontroller or monitoring system to read the sensor's output signal.

- Placement: Install the sensor in the water inlet line of the system. Ensure that the sensor is securely mounted and aligned with the flow direction.

- Signal Interpretation:

- A High signal on the OUT pin indicates water flow is present.

- A Low signal on the OUT pin indicates no water flow (dry run condition).

Important Considerations and Best Practices

- Ensure the sensor is installed in a clean and debris-free section of the water line to avoid false readings.

- Avoid exposing the sensor to temperatures or pressures beyond its specified operating range.

- Use appropriate pull-up or pull-down resistors on the OUT pin if required by your microcontroller.

- Regularly inspect the sensor for blockages or damage to maintain accuracy.

Example: Connecting to an Arduino UNO

Below is an example of how to connect and use the DRY RUN INLET SENSOR with an Arduino UNO:

Circuit Connections

- VCC: Connect to the Arduino's 5V pin.

- GND: Connect to the Arduino's GND pin.

- OUT: Connect to digital pin 2 on the Arduino.

Arduino Code

// DRY RUN INLET SENSOR Example Code

// This code reads the sensor's output and prints the status to the Serial Monitor.

const int sensorPin = 2; // OUT pin of the sensor connected to digital pin 2

int sensorState = 0; // Variable to store the sensor's state

void setup() {

pinMode(sensorPin, INPUT); // Set sensor pin as input

Serial.begin(9600); // Initialize serial communication

}

void loop() {

sensorState = digitalRead(sensorPin); // Read the sensor's output

if (sensorState == HIGH) {

// Water flow detected

Serial.println("Water flow detected.");

} else {

// No water flow (dry run condition)

Serial.println("No water flow detected! Check the system.");

}

delay(500); // Wait for 500ms before the next reading

}

Troubleshooting and FAQs

Common Issues Users Might Face

No Output Signal:

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Verify the connections and ensure the power supply voltage is within the specified range.

False Dry Run Detection:

- Cause: Debris or air bubbles in the water line.

- Solution: Clean the water line and ensure proper installation of the sensor.

Intermittent Output:

- Cause: Loose connections or fluctuating power supply.

- Solution: Check all connections and use a stable power source.

Sensor Overheating:

- Cause: Operating the sensor beyond its temperature range.

- Solution: Ensure the sensor is used within the specified temperature range (-10°C to 60°C).

FAQs

Q1: Can the sensor detect partial water flow?

A1: No, the sensor is designed to detect the presence or absence of water flow, not the flow rate.

Q2: Is the sensor waterproof?

A2: Yes, the sensor housing is made of ABS plastic and is water-resistant, but it should not be submerged.

Q3: Can the sensor be used with AC-powered systems?

A3: The sensor operates on DC power only. Use a DC power supply or a rectifier circuit for AC systems.

Q4: What is the maximum cable length for the sensor?

A4: The maximum cable length depends on the operating voltage and signal integrity. For best results, keep the cable length under 2 meters.

By following this documentation, users can effectively integrate the DRY RUN INLET SENSOR into their systems and ensure reliable operation.