How to Use 15PinMotorConnector: Examples, Pinouts, and Specs

Design with 15PinMotorConnector in Cirkit Designer

Design with 15PinMotorConnector in Cirkit DesignerIntroduction

The 15PinMotorConnector is a versatile and robust connector designed to interface motors with control systems. It provides a secure and reliable connection for both power and signal transmission, ensuring efficient motor operation. This connector is commonly used in industrial automation, robotics, and other applications requiring precise motor control.

Explore Projects Built with 15PinMotorConnector

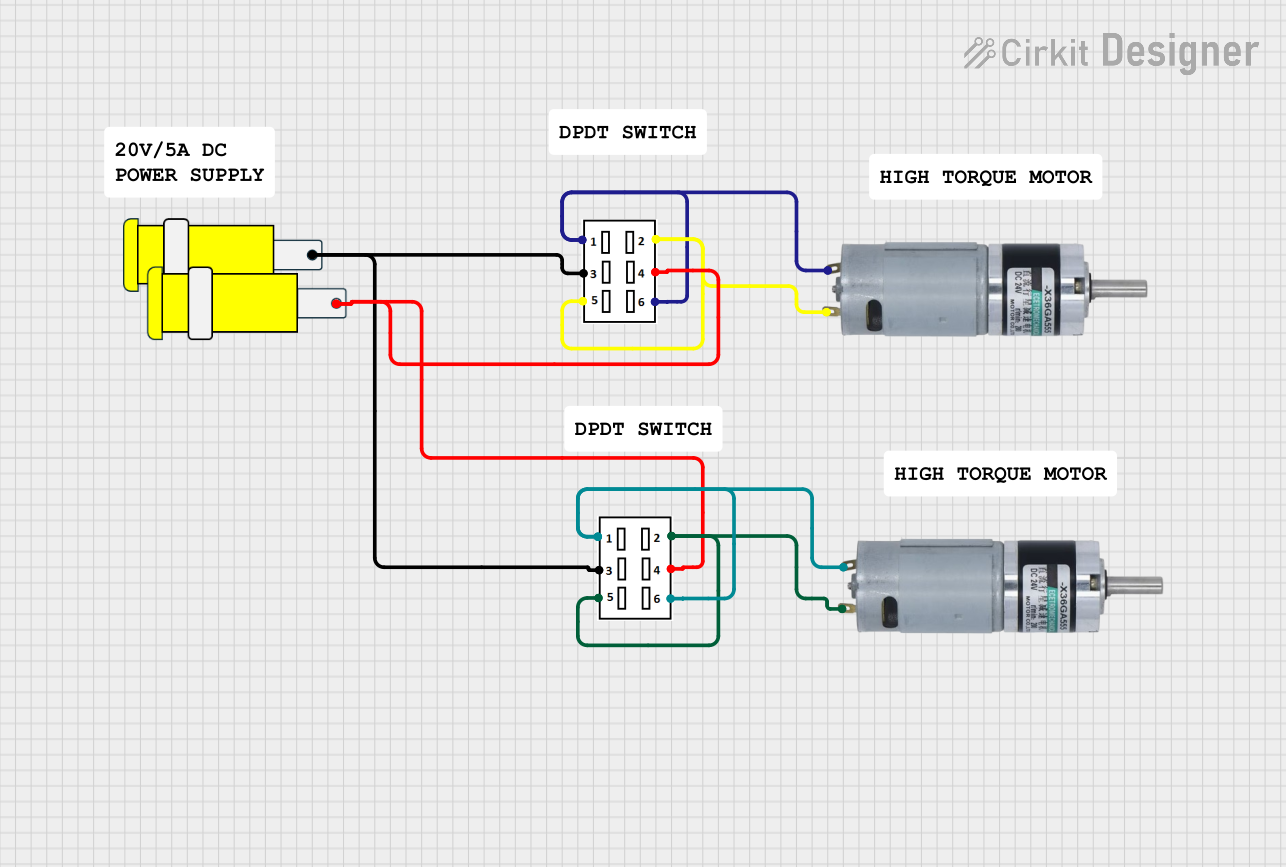

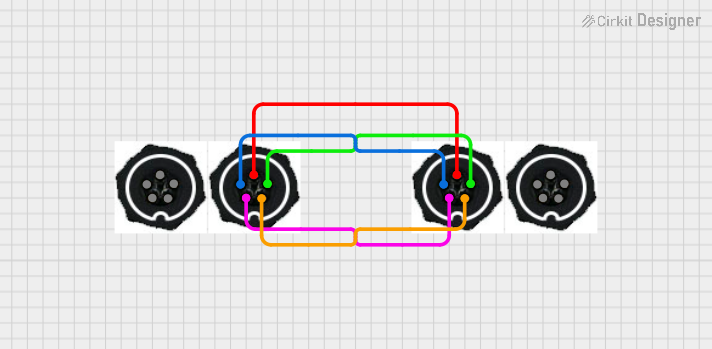

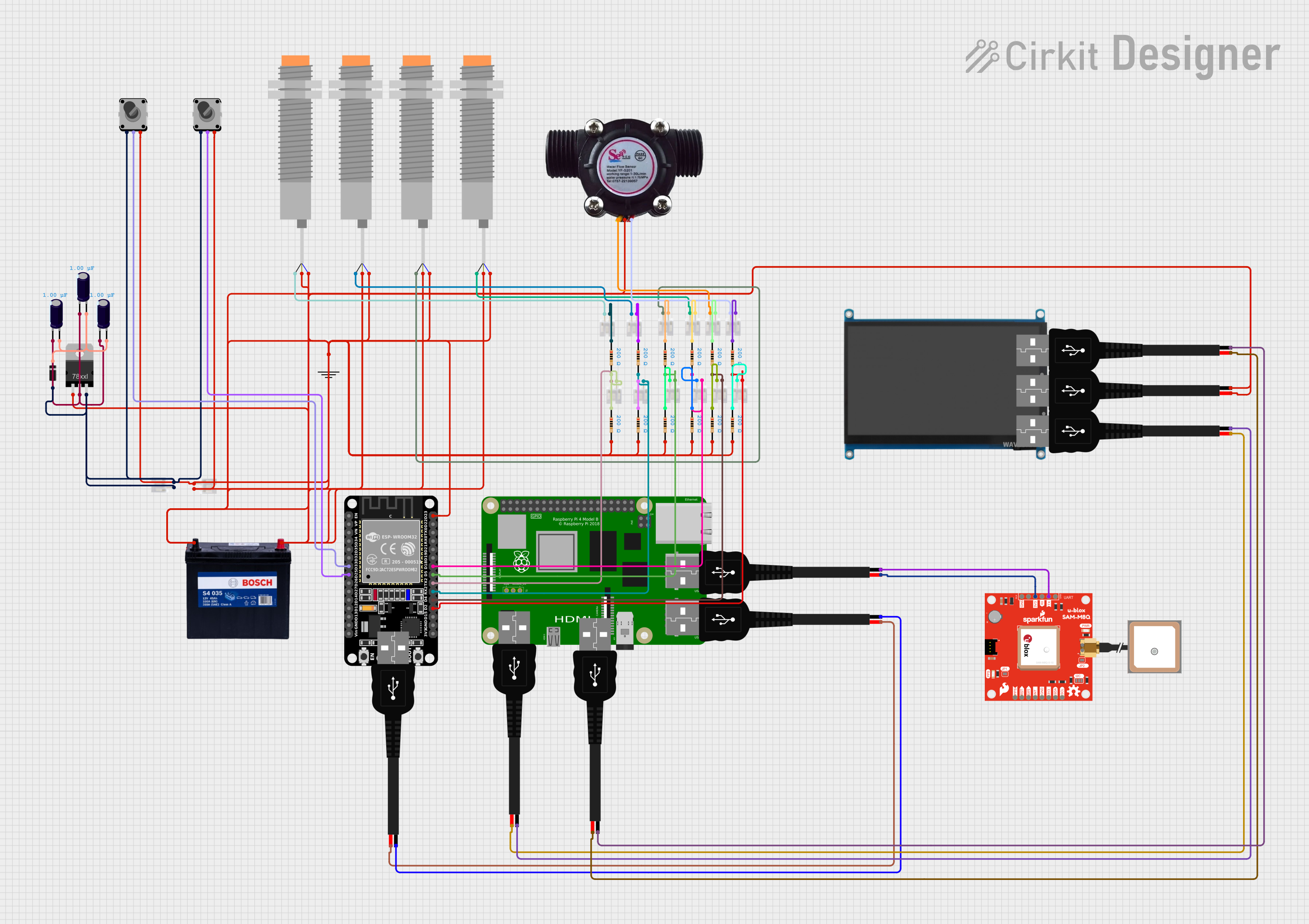

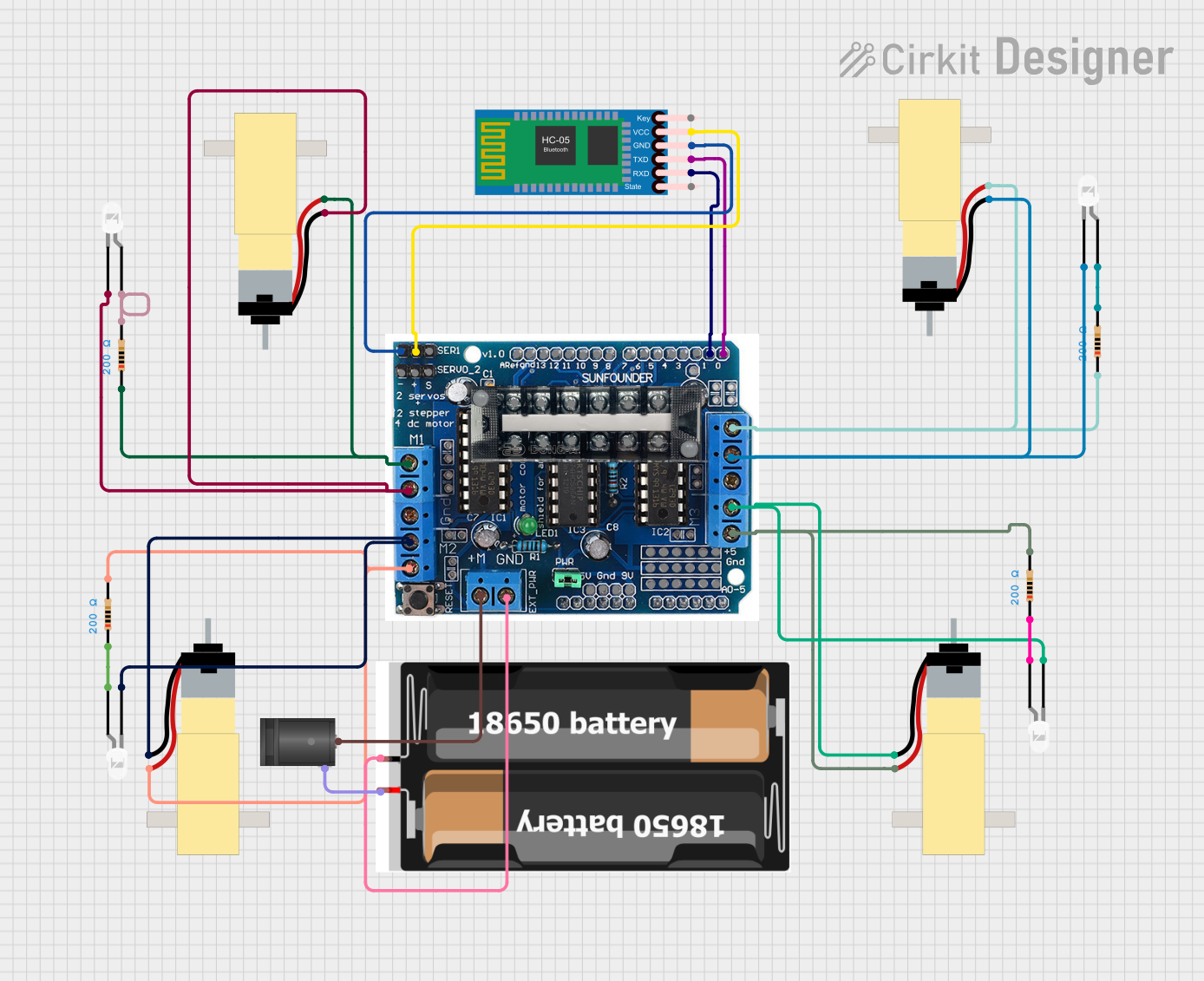

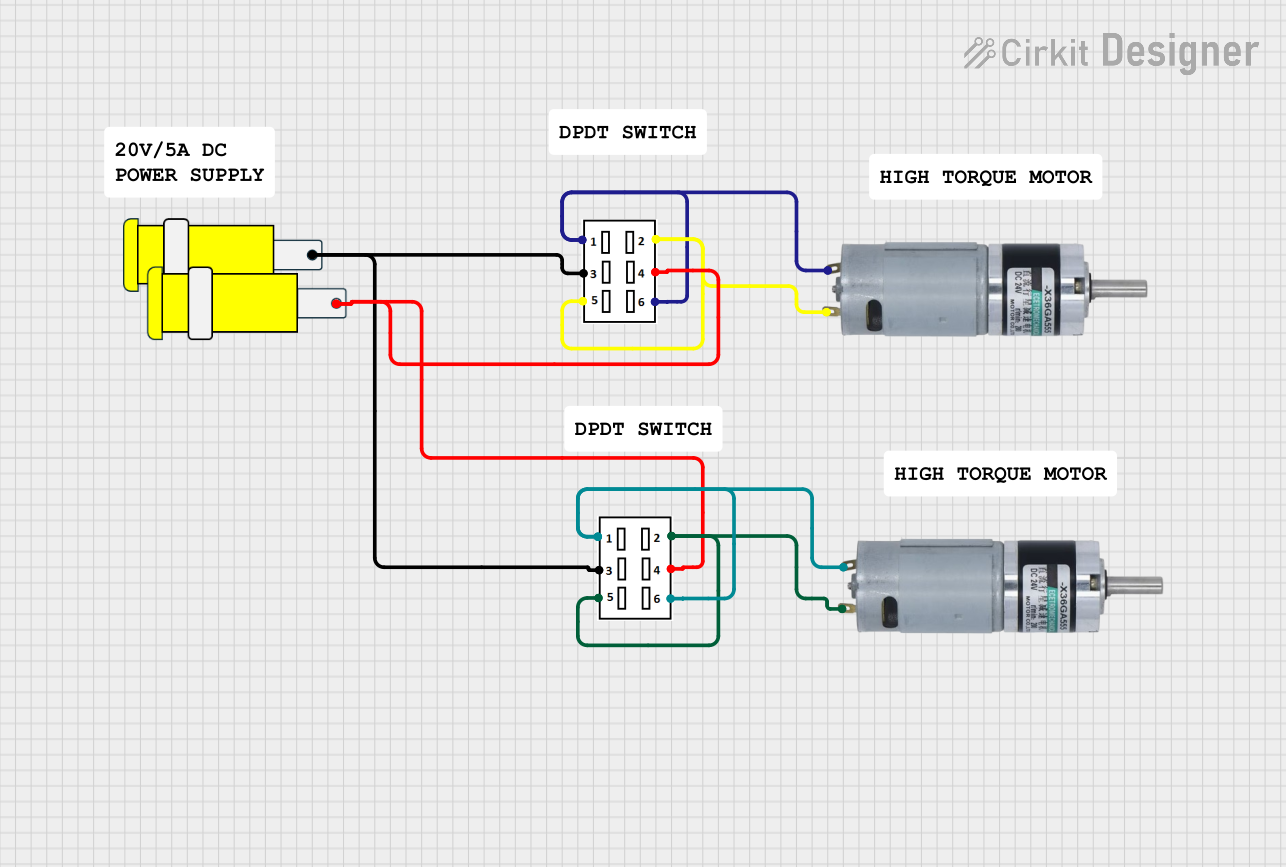

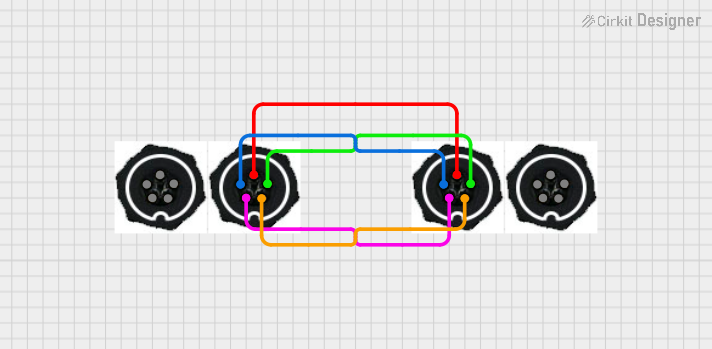

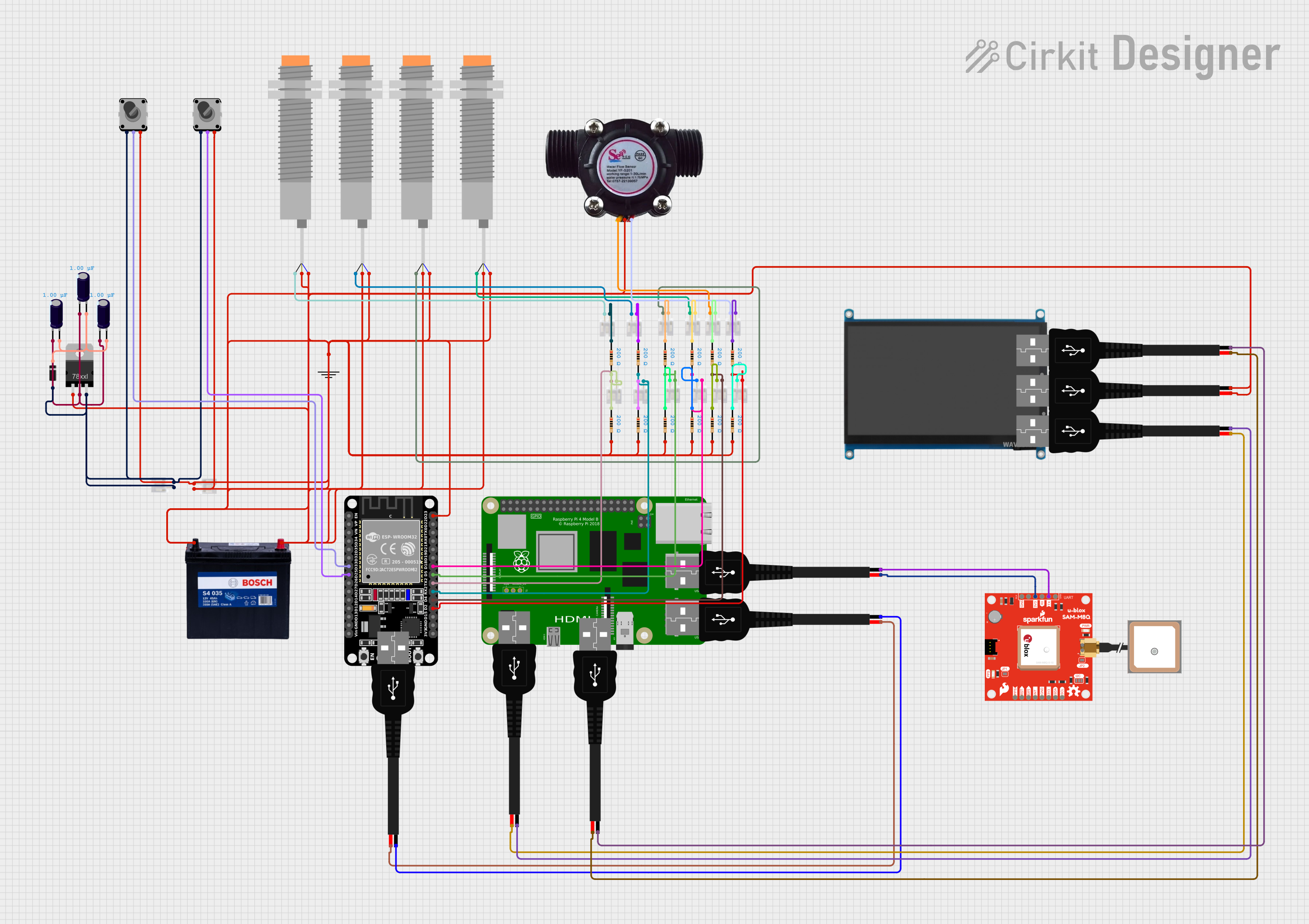

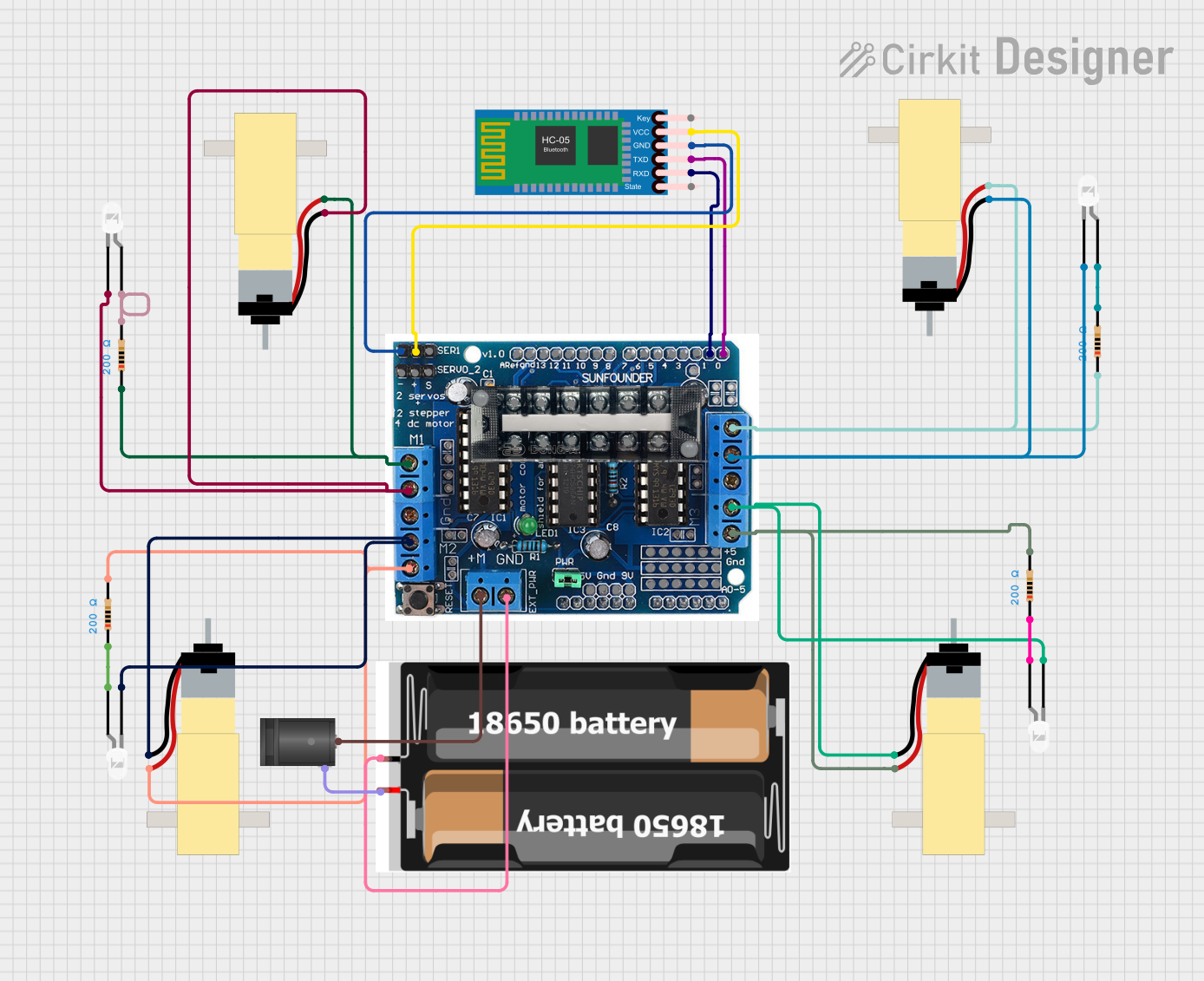

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 15PinMotorConnector

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial automation systems

- Robotics and mechatronics

- CNC machines and 3D printers

- Electric vehicles and motorized equipment

- Servo motor and stepper motor control systems

Technical Specifications

The 15PinMotorConnector is designed to handle both power and signal lines, making it suitable for a wide range of motor control applications. Below are the key technical details:

General Specifications

| Parameter | Value |

|---|---|

| Number of Pins | 15 |

| Voltage Rating | Up to 48V DC |

| Current Rating | Up to 5A per pin |

| Operating Temperature | -40°C to +85°C |

| Connector Type | Male/Female (Mating Pair) |

| Contact Material | Gold-plated copper alloy |

| Insulation Resistance | ≥ 1000 MΩ |

| Durability | 500 mating cycles |

Pin Configuration and Descriptions

The 15PinMotorConnector features a standardized pinout for motor control applications. Below is the pin configuration:

| Pin Number | Function | Description |

|---|---|---|

| 1 | Motor Phase A+ | Positive terminal for motor phase A |

| 2 | Motor Phase A- | Negative terminal for motor phase A |

| 3 | Motor Phase B+ | Positive terminal for motor phase B |

| 4 | Motor Phase B- | Negative terminal for motor phase B |

| 5 | Motor Phase C+ | Positive terminal for motor phase C |

| 6 | Motor Phase C- | Negative terminal for motor phase C |

| 7 | Ground (GND) | Common ground for power and signals |

| 8 | Power Supply +V | Positive power supply input |

| 9 | Power Supply -V | Negative power supply input |

| 10 | Encoder A+ | Encoder signal A positive |

| 11 | Encoder A- | Encoder signal A negative |

| 12 | Encoder B+ | Encoder signal B positive |

| 13 | Encoder B- | Encoder signal B negative |

| 14 | Hall Sensor Signal | Hall effect sensor output |

| 15 | Temperature Sensor | Motor temperature sensor output |

Usage Instructions

How to Use the 15PinMotorConnector in a Circuit

- Identify the Pins: Refer to the pin configuration table to understand the function of each pin.

- Connect Power Lines: Attach the power supply to the

Power Supply +VandPower Supply -Vpins. Ensure the voltage and current ratings are within the specified limits. - Connect Motor Phases: Connect the motor windings to the corresponding

Motor Phasepins (A+, A-, B+, B-, C+, C-). - Connect Signal Lines: If your motor uses an encoder or sensors, connect the encoder and sensor outputs to the appropriate pins.

- Secure the Connection: Ensure the connector is firmly mated to prevent loose connections during operation.

Important Considerations and Best Practices

- Check Compatibility: Ensure the connector matches the motor and control system specifications.

- Avoid Overloading: Do not exceed the voltage and current ratings to prevent damage.

- Proper Insulation: Use heat-shrink tubing or other insulation methods to protect exposed wires.

- Secure Mounting: Use screws or locking mechanisms to secure the connector in place.

- Test Connections: Verify all connections with a multimeter before powering the system.

Example: Connecting to an Arduino UNO

The 15PinMotorConnector can be used with an Arduino UNO for motor control. Below is an example of interfacing a motor with an encoder:

Circuit Connections

- Connect

Power Supply +VandPower Supply -Vto an external motor driver. - Connect

Encoder A+andEncoder B+to Arduino digital pins 2 and 3, respectively. - Connect

Ground (GND)to the Arduino GND pin.

Sample Code

// Example code for reading motor encoder signals with Arduino UNO

const int encoderA = 2; // Pin connected to Encoder A+

const int encoderB = 3; // Pin connected to Encoder B+

volatile int encoderCount = 0; // Variable to store encoder count

void setup() {

pinMode(encoderA, INPUT); // Set Encoder A pin as input

pinMode(encoderB, INPUT); // Set Encoder B pin as input

// Attach interrupt to Encoder A pin

attachInterrupt(digitalPinToInterrupt(encoderA), encoderISR, RISING);

Serial.begin(9600); // Initialize serial communication

}

void loop() {

// Print the encoder count to the Serial Monitor

Serial.print("Encoder Count: ");

Serial.println(encoderCount);

delay(500); // Delay for readability

}

// Interrupt Service Routine (ISR) for Encoder A

void encoderISR() {

// Check the state of Encoder B to determine direction

if (digitalRead(encoderB) == HIGH) {

encoderCount++; // Increment count for forward rotation

} else {

encoderCount--; // Decrement count for reverse rotation

}

}

Troubleshooting and FAQs

Common Issues and Solutions

Loose Connections

- Issue: The motor does not operate or operates intermittently.

- Solution: Ensure the connector is securely mated and all wires are properly soldered or crimped.

Overheating

- Issue: The connector or wires become excessively hot during operation.

- Solution: Check for overloading and ensure the current does not exceed 5A per pin.

Signal Interference

- Issue: Encoder or sensor signals are noisy or unreliable.

- Solution: Use shielded cables for signal lines and ensure proper grounding.

Incorrect Pin Connections

- Issue: The motor does not respond as expected.

- Solution: Double-check the pin configuration and wiring against the datasheet.

FAQs

Q1: Can the 15PinMotorConnector be used for AC motors?

A1: Yes, it can be used for AC motors, provided the voltage and current ratings are within the specified limits.

Q2: Is the connector waterproof?

A2: The standard version is not waterproof. For outdoor or wet environments, use a waterproof variant or additional sealing.

Q3: Can I use fewer than 15 pins?

A3: Yes, unused pins can be left unconnected, depending on your application requirements.

Q4: What tools are recommended for crimping the connector?

A4: Use a high-quality crimping tool designed for 15-pin connectors to ensure reliable connections.