How to Use XY-MD02: Examples, Pinouts, and Specs

Design with XY-MD02 in Cirkit Designer

Design with XY-MD02 in Cirkit DesignerIntroduction

The XY-MD02 is a versatile motor driver module designed to control the speed and direction of DC motors. It is commonly used in robotics, automation projects, and various DIY applications where precise motor control is required. The module typically supports features such as variable speed control, bidirectional control, and dynamic braking, making it an essential component for projects that require reliable and efficient motor management.

Explore Projects Built with XY-MD02

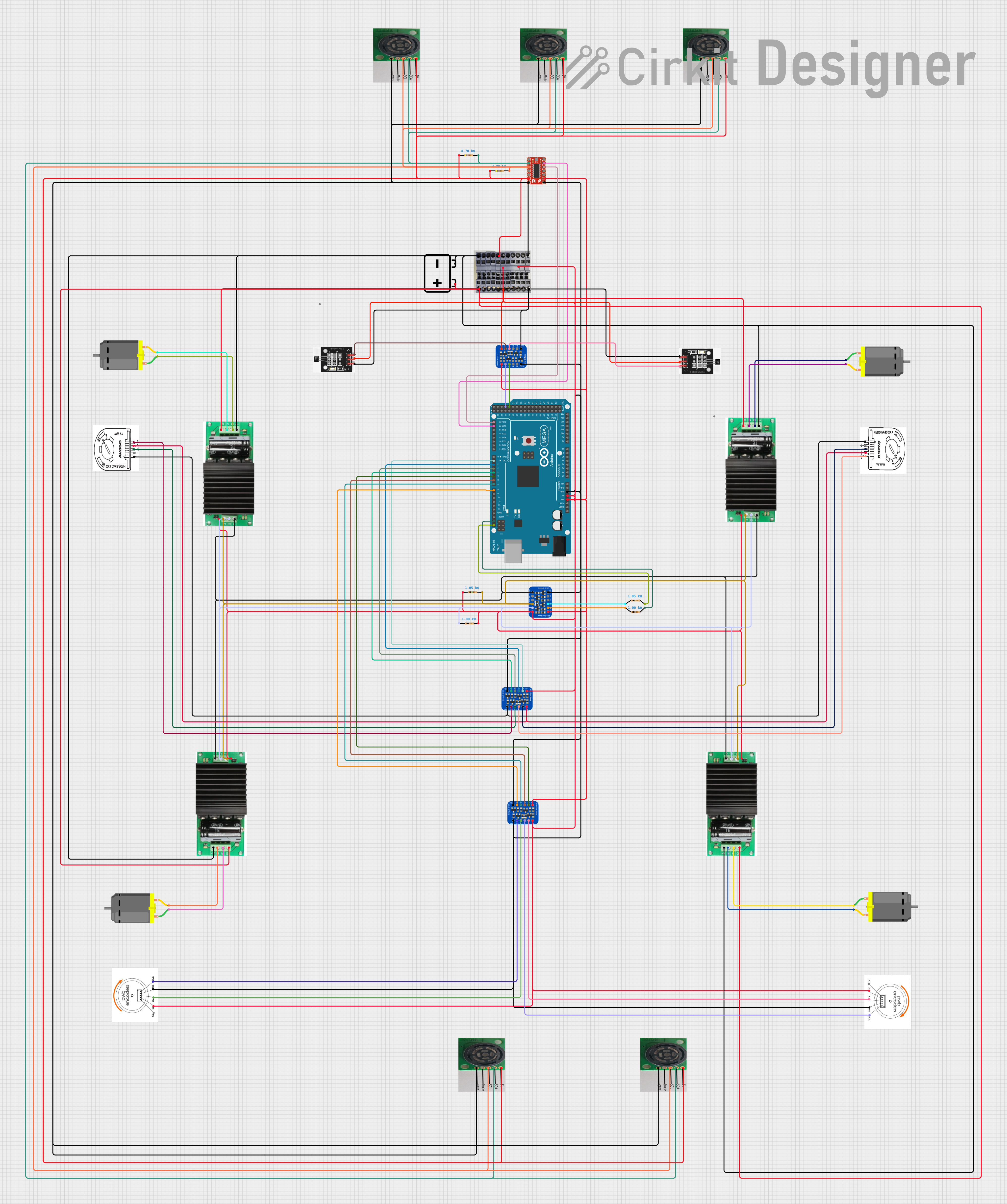

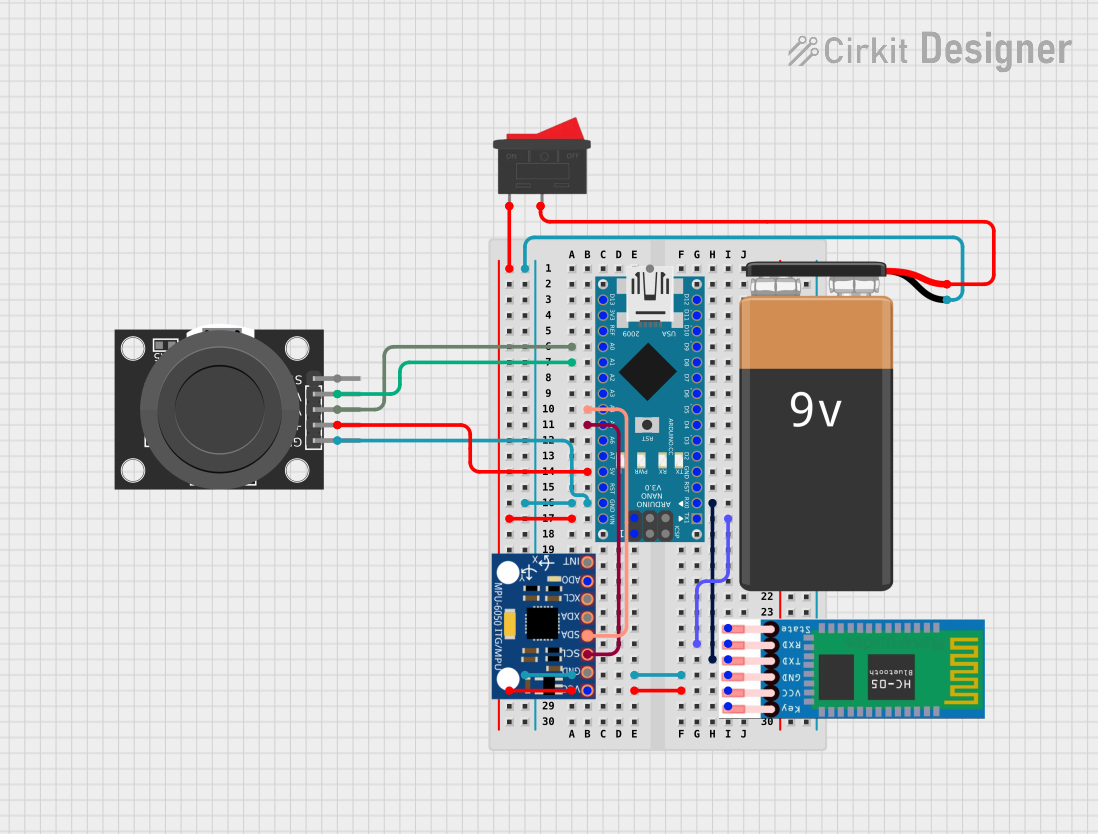

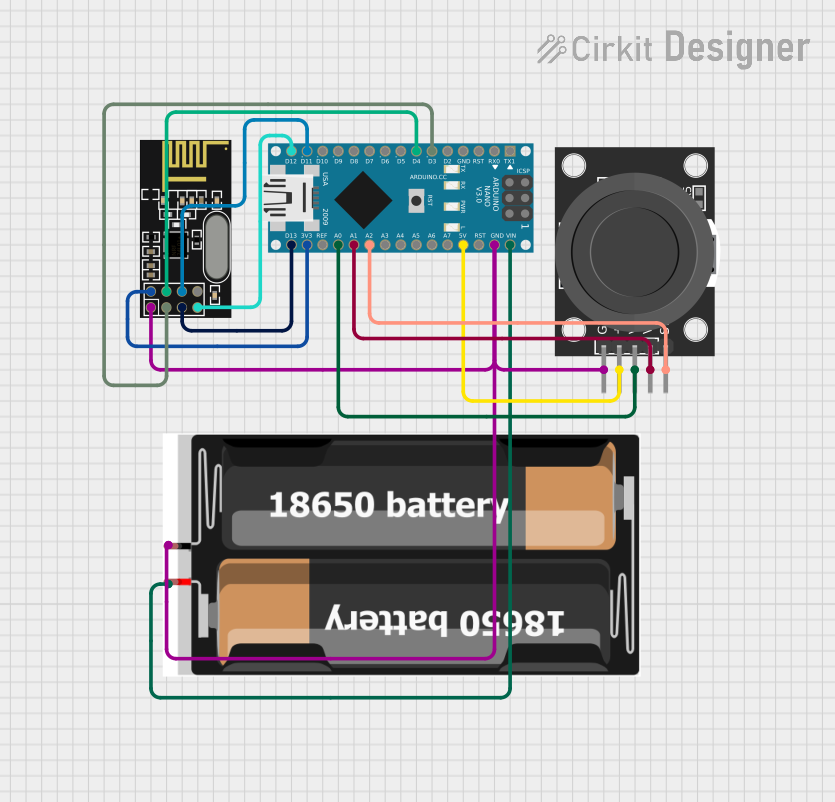

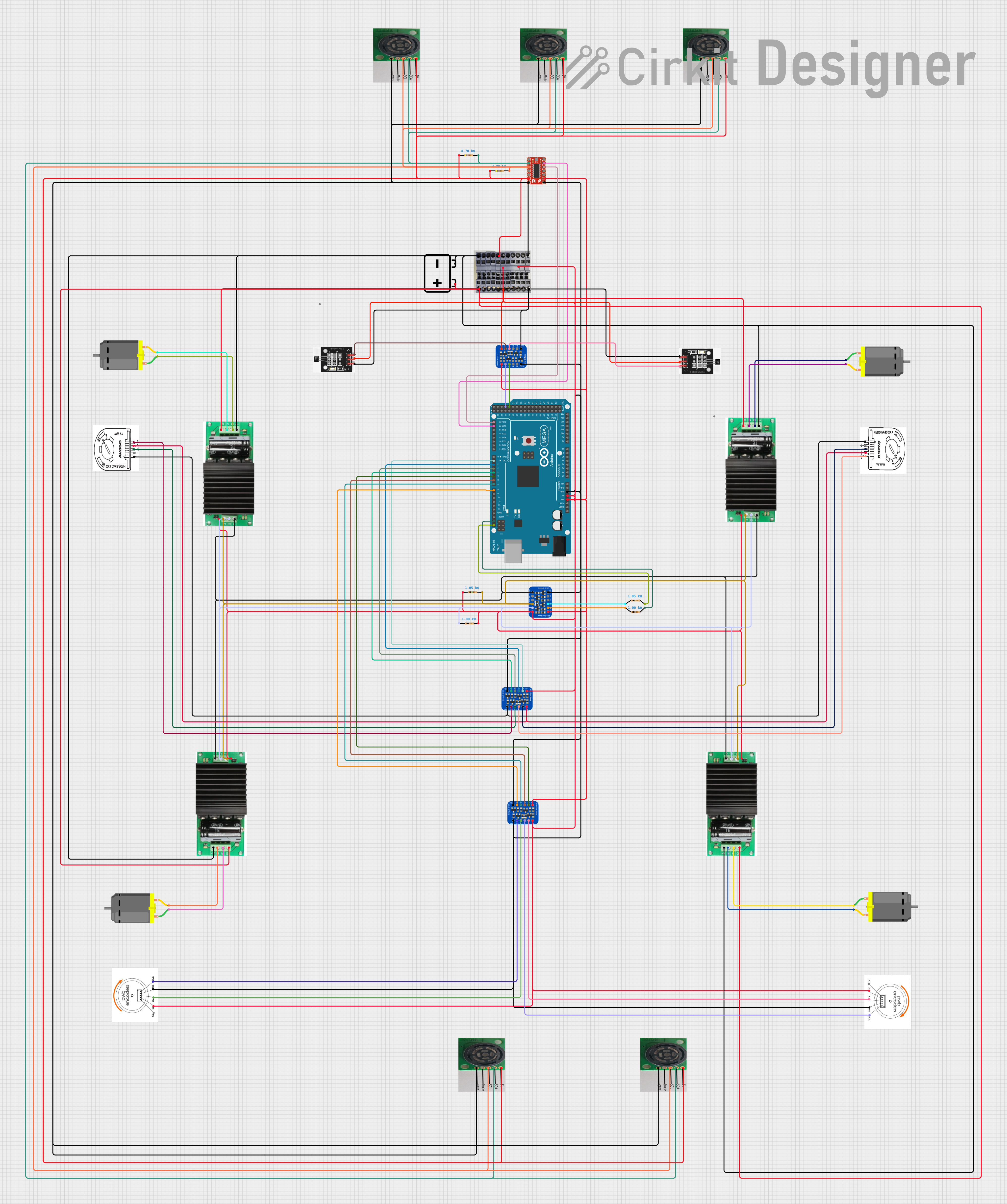

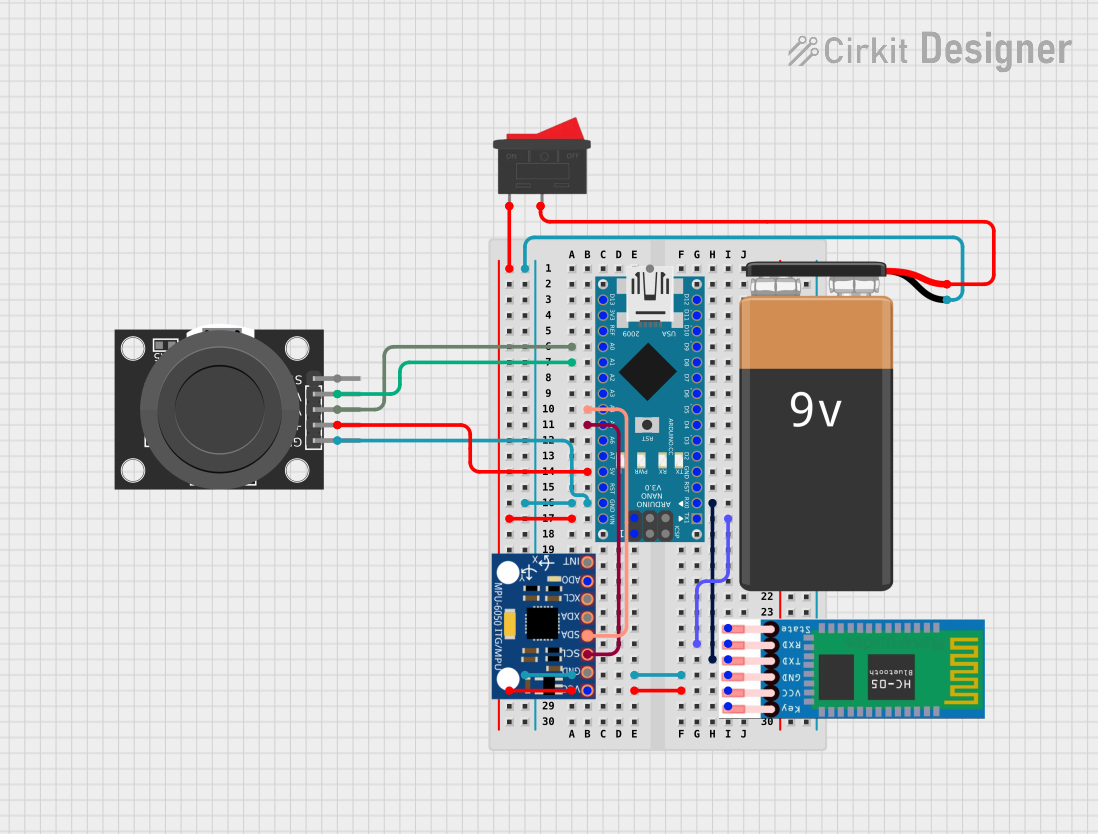

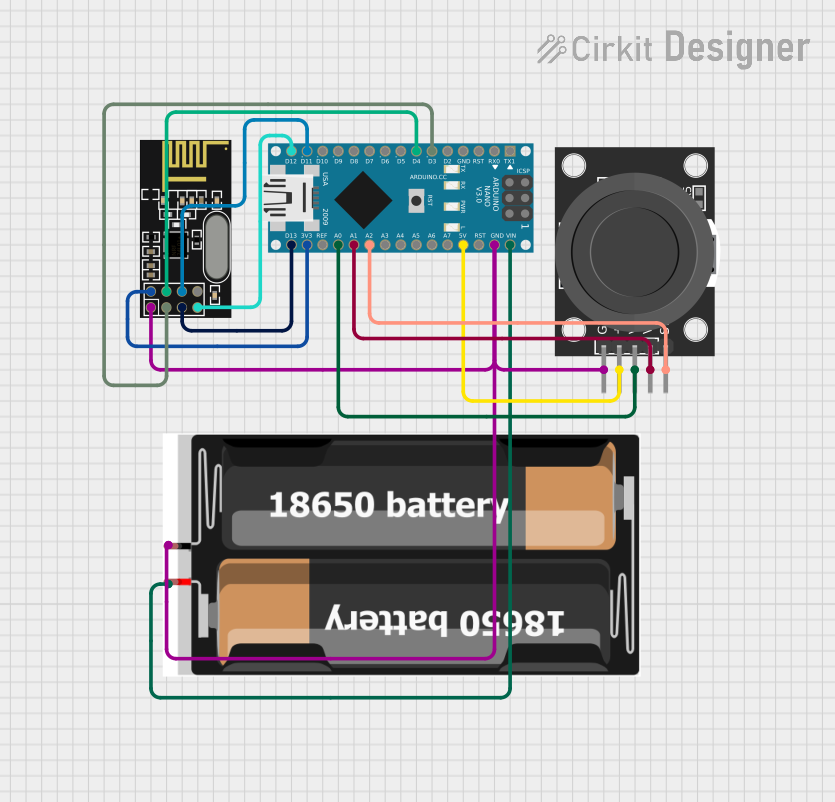

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with XY-MD02

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Driving motors for robotic arms, wheels, or tracks.

- Automation Systems: Controlling actuators in automated machinery.

- Hobby Projects: Managing motors in model vehicles or custom-built machines.

- Educational Purposes: Teaching the principles of motor control in STEM programs.

Technical Specifications

Key Technical Details

- Operating Voltage: Typically ranges from 6V to 30V.

- Continuous Current Rating: Up to a certain limit, often around 3A to 10A.

- Peak Current Rating: A higher current for short durations, subject to module design.

- Control Signal Voltage: Compatible with standard logic levels (e.g., 5V).

- Control Method: PWM (Pulse Width Modulation) for speed control, logic inputs for direction.

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply for the motor (6V-30V) |

| 2 | GND | Ground connection |

| 3 | AIN1 | Direction control input 1 |

| 4 | AIN2 | Direction control input 2 |

| 5 | PWMA | PWM input for speed control |

| 6 | STBY | Standby mode activation (active low) |

| 7 | BIN1 | Direction control input for second motor (if applicable) |

| 8 | BIN2 | Direction control input for second motor (if applicable) |

| 9 | PWMB | PWM input for second motor speed control (if applicable) |

Usage Instructions

How to Use the Component in a Circuit

- Power Connections: Connect the VCC and GND pins to your DC power supply, ensuring it matches the module's voltage requirements.

- Motor Connections: Attach the motor's leads to the output terminals of the XY-MD02.

- Control Signal Connections: Connect AIN1 and AIN2 to your control circuitry (e.g., microcontroller) to set the motor's direction. Connect PWMA to a PWM-capable pin on your controller for speed control.

- Standby Mode: Optionally, connect the STBY pin to a digital output on your controller to enable or disable the motor driver.

Important Considerations and Best Practices

- Ensure the power supply does not exceed the maximum voltage rating of the module.

- Do not exceed the continuous current rating to prevent overheating and potential damage.

- Use a PWM frequency that is within the module's operating range for optimal performance.

- Implement proper cooling if operating near the current limits or in high-temperature environments.

- Always double-check wiring before powering up to prevent shorts and component damage.

Troubleshooting and FAQs

Common Issues Users Might Face

- Motor not spinning: Check power supply connections, ensure control signals are being sent, and verify that the STBY pin is not active (low).

- Overheating: Reduce the load on the motor, improve cooling, or check for shorts in the wiring.

- Inconsistent motor speed: Ensure PWM signal is stable and within the correct frequency range.

Solutions and Tips for Troubleshooting

- Use a multimeter to verify power supply voltage and continuity in connections.

- Test the control signals with an oscilloscope to ensure they are within specifications.

- If the motor driver enters a protection mode, disconnect power, check for issues, and then reconnect.

Example Code for Arduino UNO

// Define control pins

const int pwmPin = 3; // PWMA pin connected to Arduino pin 3

const int dirPin1 = 4; // AIN1 pin connected to Arduino pin 4

const int dirPin2 = 5; // AIN2 pin connected to Arduino pin 5

void setup() {

// Set control pins as outputs

pinMode(pwmPin, OUTPUT);

pinMode(dirPin1, OUTPUT);

pinMode(dirPin2, OUTPUT);

}

void loop() {

// Set motor direction to forward

digitalWrite(dirPin1, HIGH);

digitalWrite(dirPin2, LOW);

// Ramp up the speed

for (int speed = 0; speed <= 255; speed++) {

analogWrite(pwmPin, speed);

delay(10);

}

// Ramp down the speed

for (int speed = 255; speed >= 0; speed--) {

analogWrite(pwmPin, speed);

delay(10);

}

// Change motor direction to reverse

digitalWrite(dirPin1, LOW);

digitalWrite(dirPin2, HIGH);

// Repeat the ramp up and down for reverse direction

for (int speed = 0; speed <= 255; speed++) {

analogWrite(pwmPin, speed);

delay(10);

}

for (int speed = 255; speed >= 0; speed--) {

analogWrite(pwmPin, speed);

delay(10);

}

}

This example demonstrates basic forward and reverse control of a DC motor using the XY-MD02 motor driver module with an Arduino UNO. The analogWrite function is used to control the speed of the motor through PWM, while the digitalWrite functions set the direction. The motor speed is ramped up and down in both forward and reverse directions.