How to Use valve solenoid water: Examples, Pinouts, and Specs

Design with valve solenoid water in Cirkit Designer

Design with valve solenoid water in Cirkit DesignerIntroduction

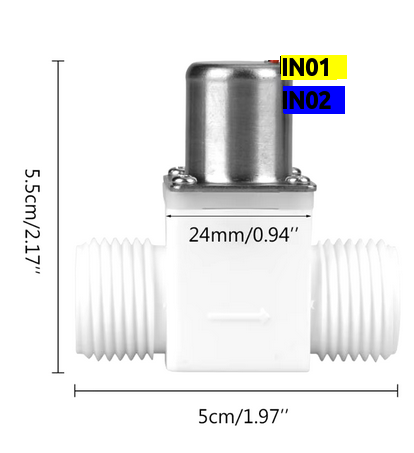

The AFU 211B Valve Solenoid Water is an electromechanical device designed to control the flow of water in a system. It operates by using an electric current to generate a magnetic field, which in turn moves a plunger to open or close the valve. This component is commonly used in applications such as irrigation systems, automatic faucets, and fluid control systems in appliances.

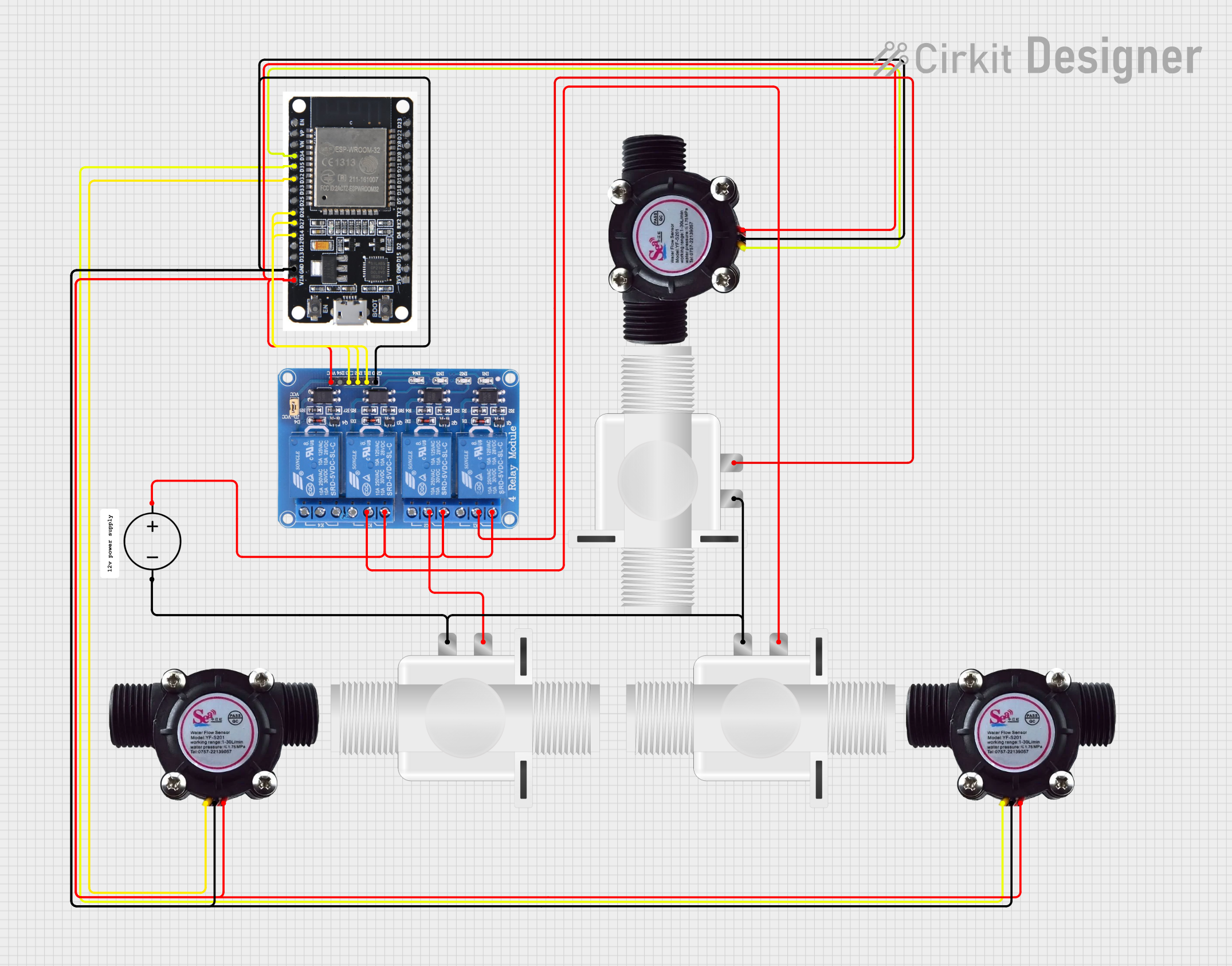

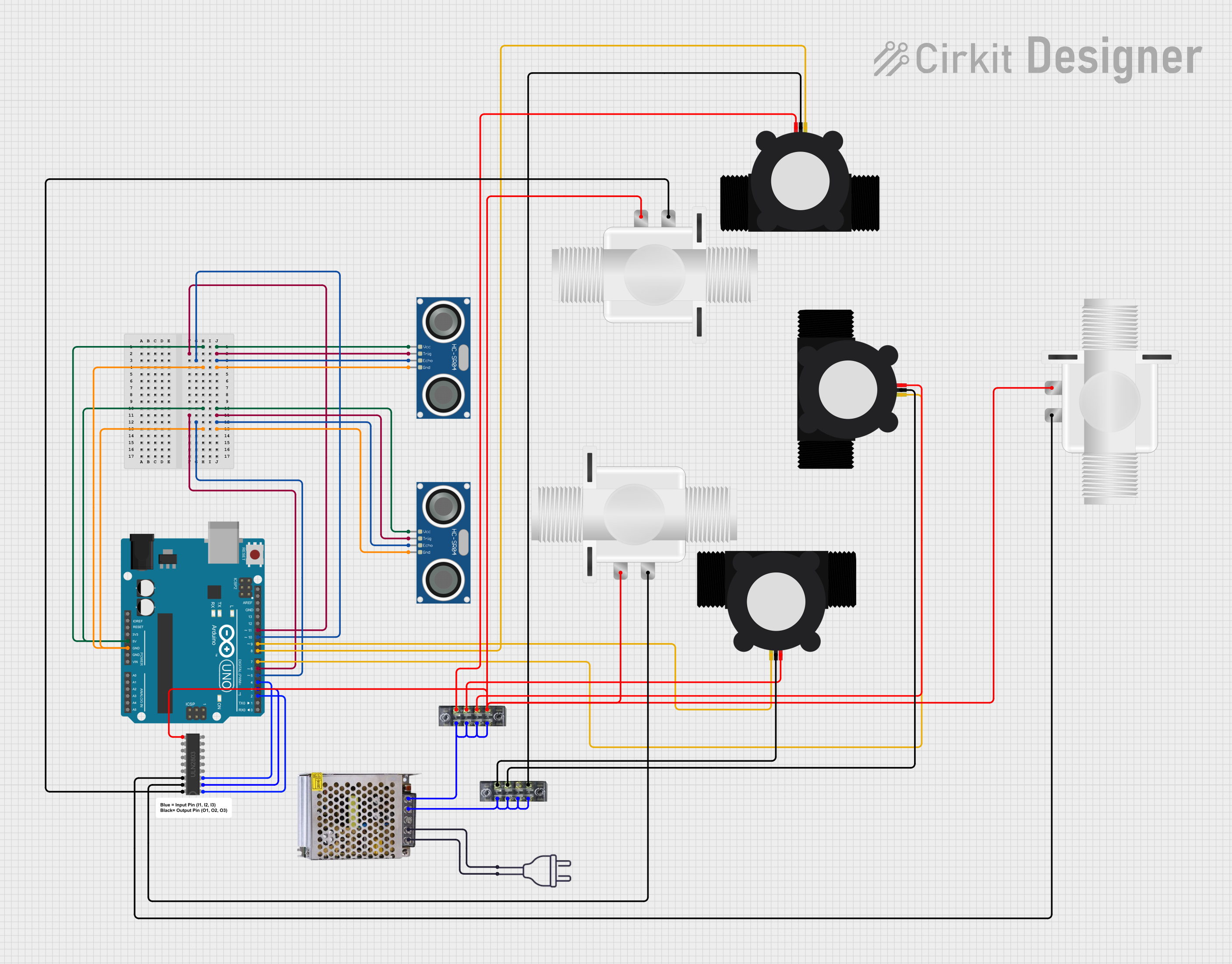

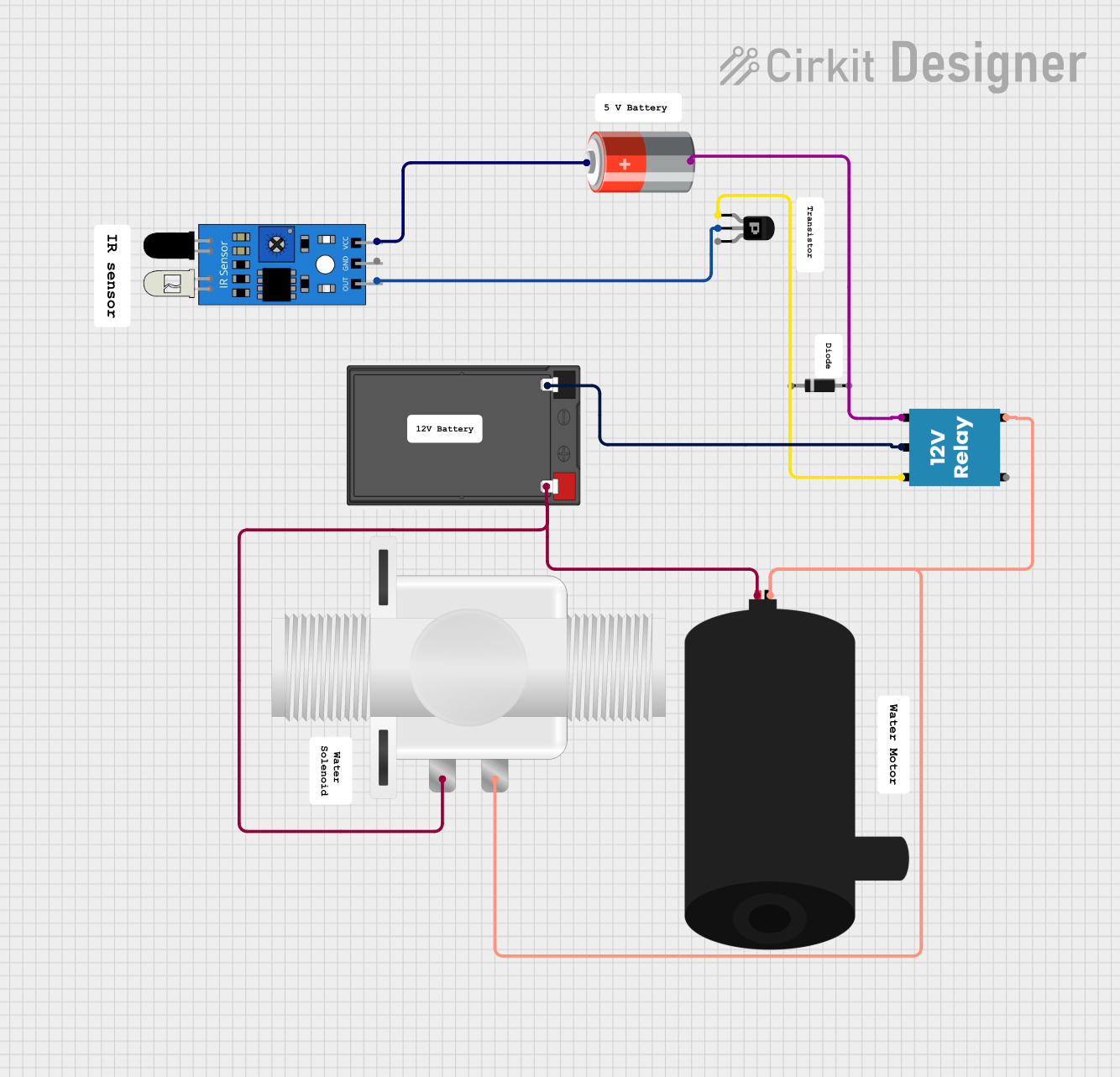

Explore Projects Built with valve solenoid water

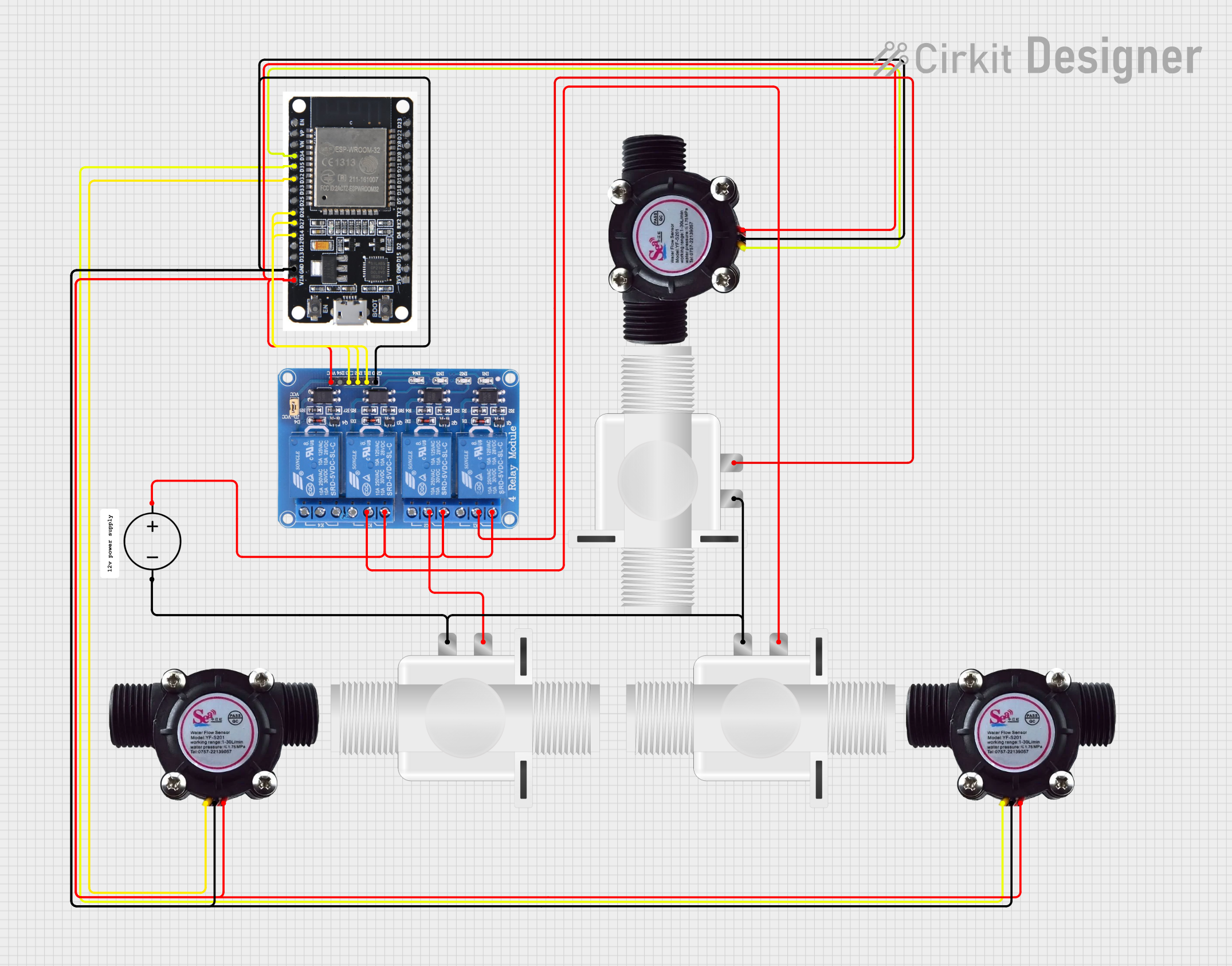

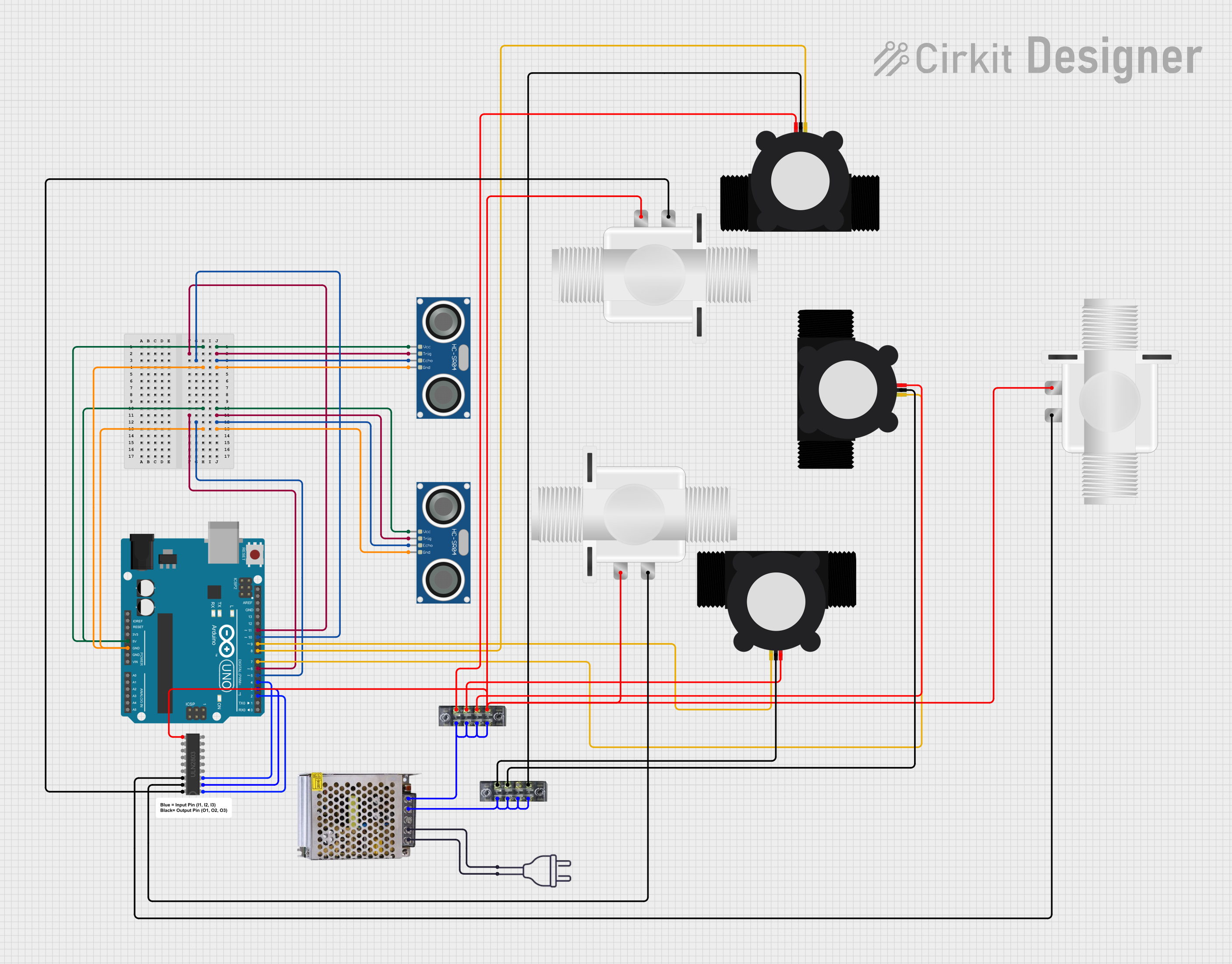

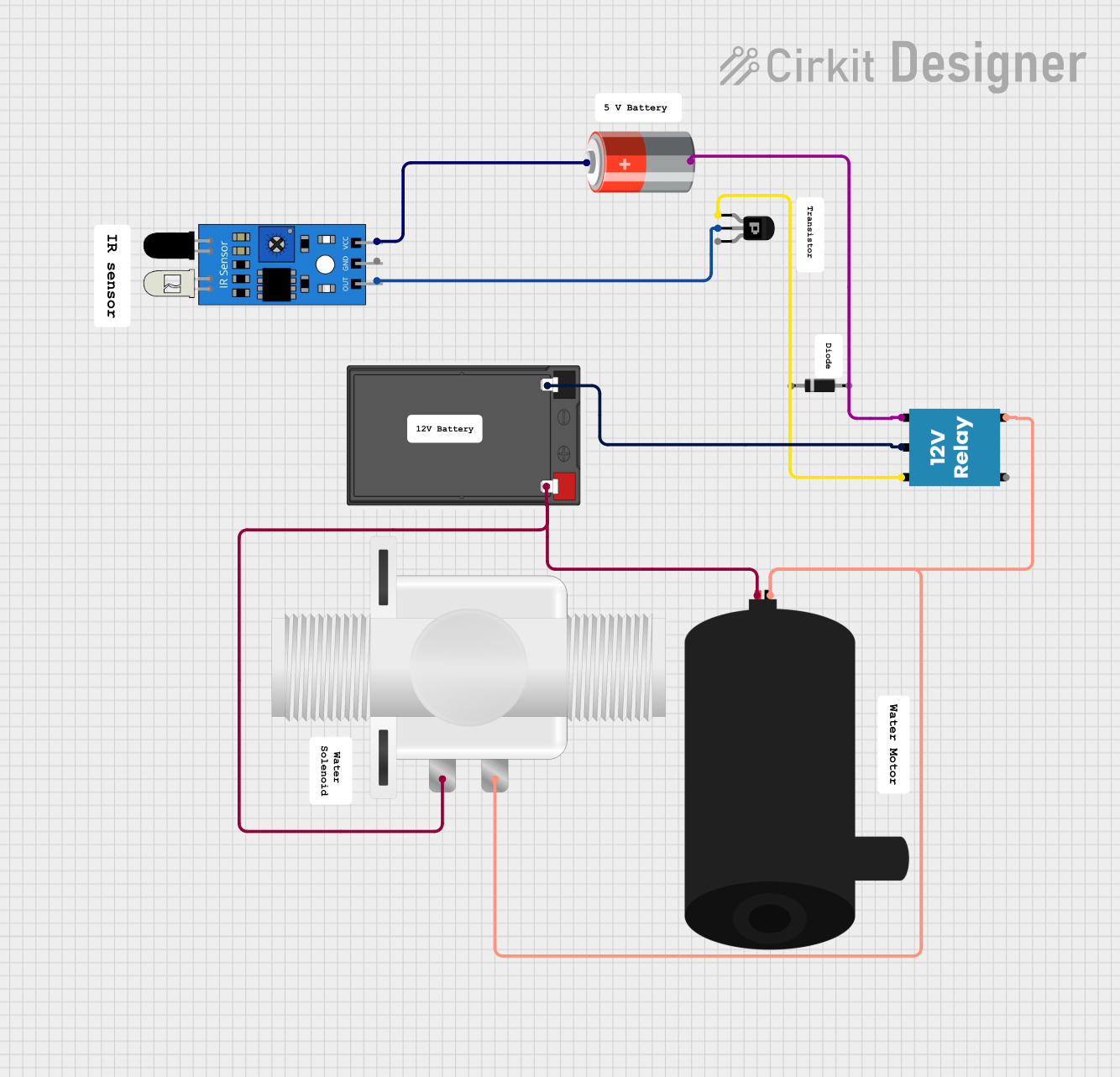

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with valve solenoid water

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Characteristics

- Manufacturer: AFU

- Part ID: 211B

- Type: Normally Closed (NC) or Normally Open (NO) (Specify when ordering)

- Operation: Direct Acting

- Body Material: Brass or Stainless Steel (Specify when ordering)

- Seal Material: NBR, EPDM, or VITON (Specify when ordering)

Electrical Ratings

- Operating Voltage: 12VDC, 24VDC, or 220VAC (Specify when ordering)

- Power Consumption: 8W (for DC versions), 10VA (for AC versions)

- Duty Cycle: 100% ED (Continuous Duty)

Performance

- Pressure Range: 0 to 10 bar

- Temperature Range: 1°C to 80°C (fluid temperature)

- Response Time: <20ms (open), <30ms (close)

Pin Configuration and Descriptions

| Pin No. | Description | Note |

|---|---|---|

| 1 | Positive Supply (V+) | Connect to positive voltage |

| 2 | Negative Supply (V-) | Connect to ground or negative |

Usage Instructions

Integration into a Circuit

- Power Supply: Ensure that the power supply matches the operating voltage of the solenoid valve.

- Polarity: Connect the positive supply to Pin 1 and the negative supply to Pin 2.

- Water Connection: Attach the water inlet to the input port and the outlet to the output port. Ensure all connections are tight and leak-free.

- Control Signal: Use a relay or a transistor to switch the solenoid valve on and off. The control signal should be capable of handling the current requirements of the valve.

Best Practices

- Use a flyback diode across the solenoid coil to prevent voltage spikes when turning off the valve.

- Install a filter at the inlet to prevent debris from damaging the valve.

- Periodically test the valve to ensure proper operation.

- Avoid exceeding the specified pressure and temperature ranges.

Example Arduino UNO Code

// Define the solenoid valve control pin

const int solenoidPin = 7;

void setup() {

// Set the solenoid pin as an output

pinMode(solenoidPin, OUTPUT);

}

void loop() {

// Open the solenoid valve

digitalWrite(solenoidPin, HIGH);

delay(1000); // Keep the valve open for 1 second

// Close the solenoid valve

digitalWrite(solenoidPin, LOW);

delay(1000); // Keep the valve closed for 1 second

}

Troubleshooting and FAQs

Common Issues

- Valve Does Not Open: Check the power supply and control signal. Ensure the polarity is correct and the voltage matches the valve's requirements.

- Valve Leaks: Inspect the seal and connections. Replace the seal if necessary and tighten connections.

- Valve Does Not Close Completely: Debris may be obstructing the valve. Clean the valve and check for proper operation.

FAQs

Q: Can the valve be used with liquids other than water? A: Yes, but ensure the liquid is compatible with the valve's body and seal materials.

Q: How long can the valve remain energized? A: The valve is rated for 100% ED, meaning it can remain energized continuously.

Q: What is the life expectancy of the valve? A: The life expectancy depends on the operating conditions but is typically rated for millions of cycles.

For further assistance, please contact AFU customer support.