How to Use verter_screw: Examples, Pinouts, and Specs

Design with verter_screw in Cirkit Designer

Design with verter_screw in Cirkit DesignerIntroduction

The Verter_Screw is a versatile and robust electronic component designed for securing and connecting wires within a circuit. It is commonly used in a variety of applications, including prototyping, industrial control systems, and consumer electronics. The Verter_Screw ensures a reliable and stable electrical connection, which is essential for the proper functioning of electronic circuits.

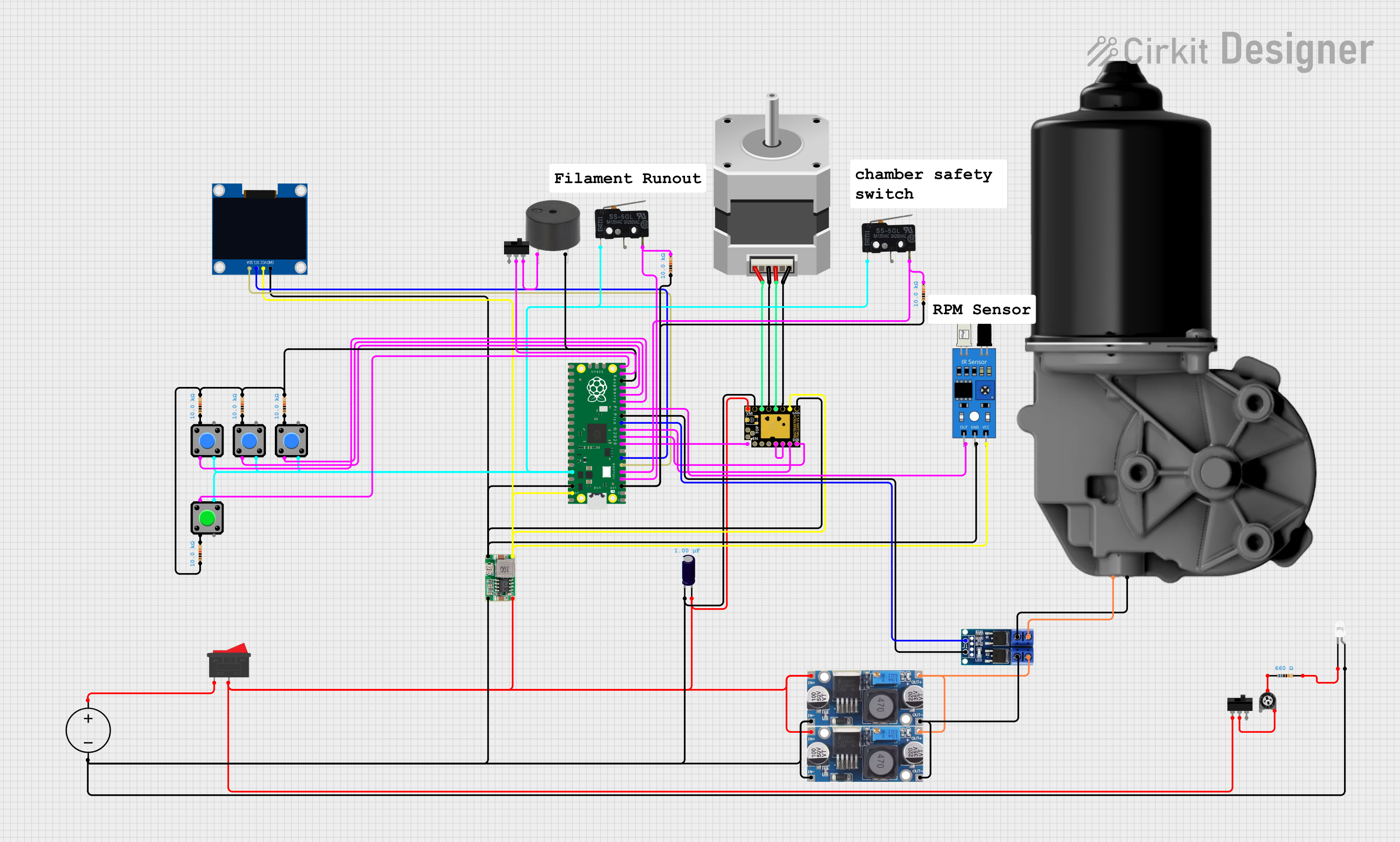

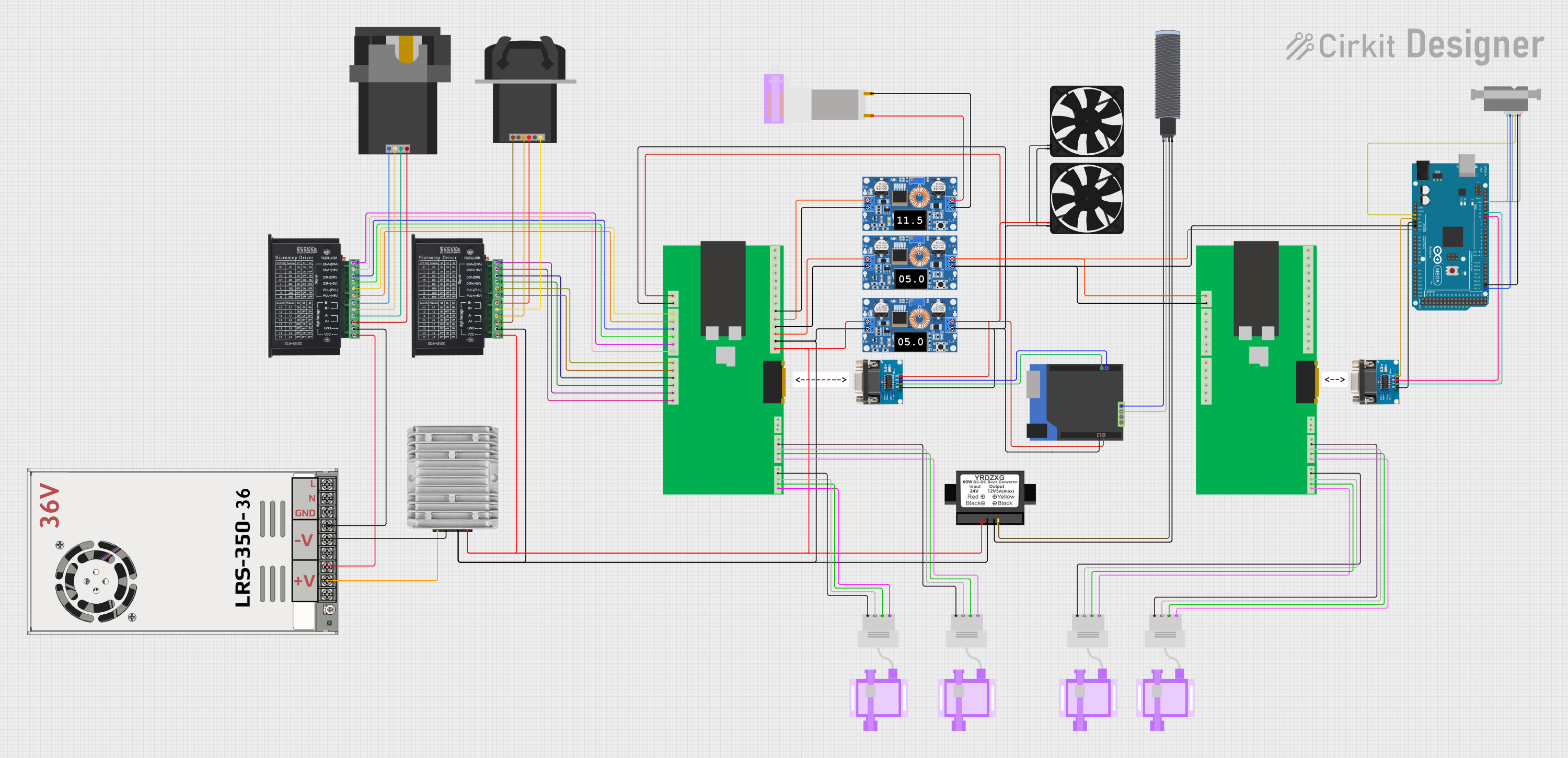

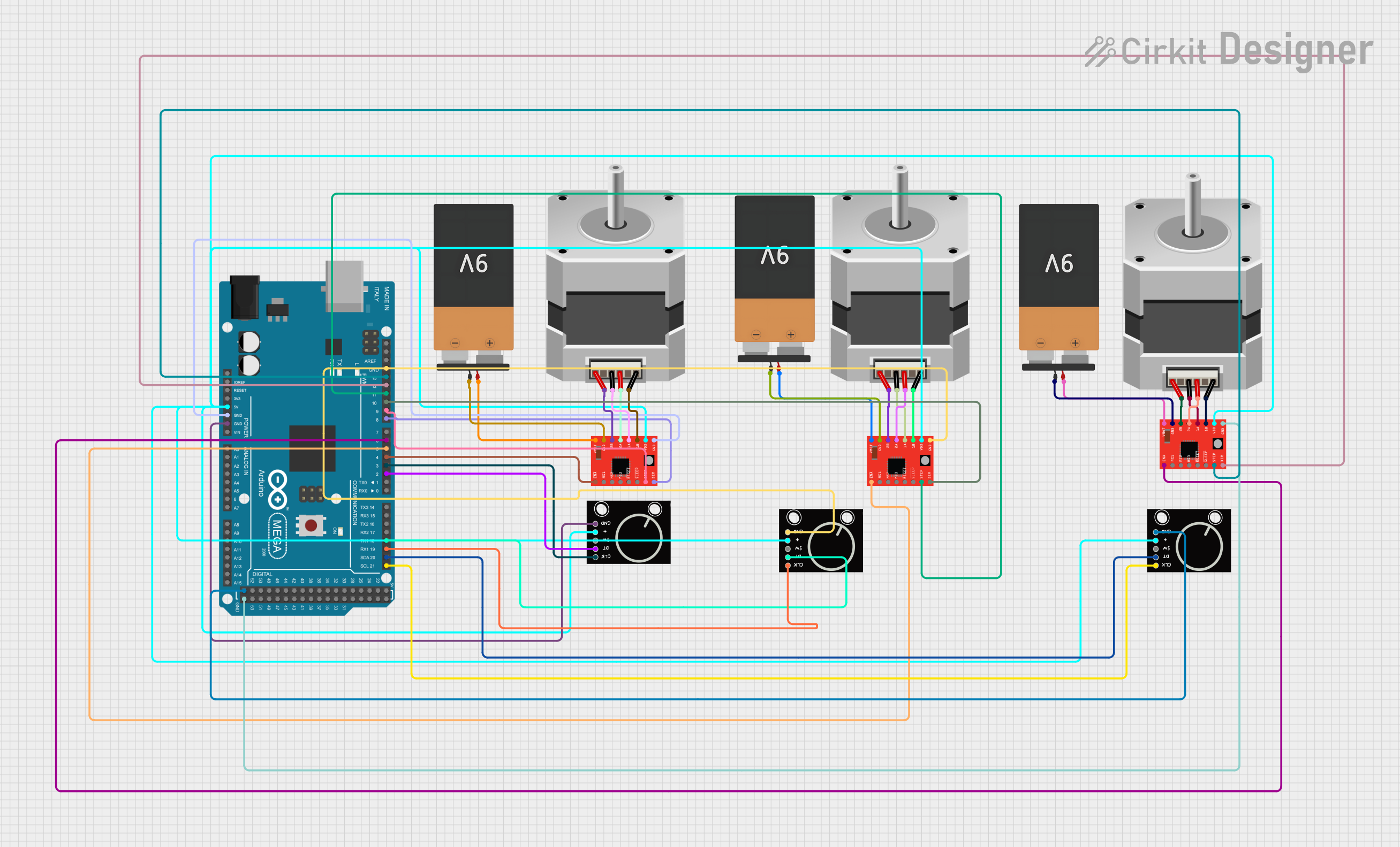

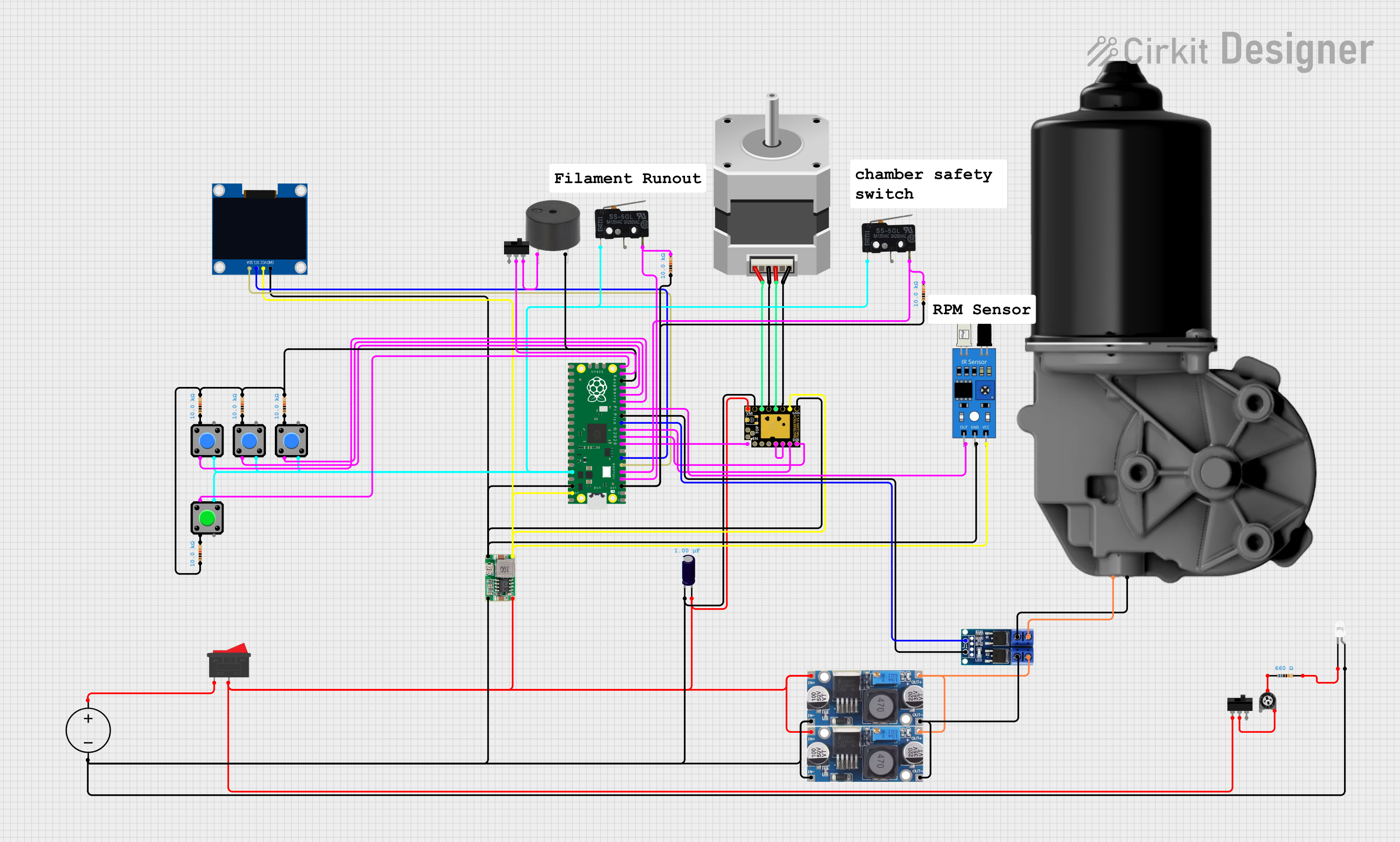

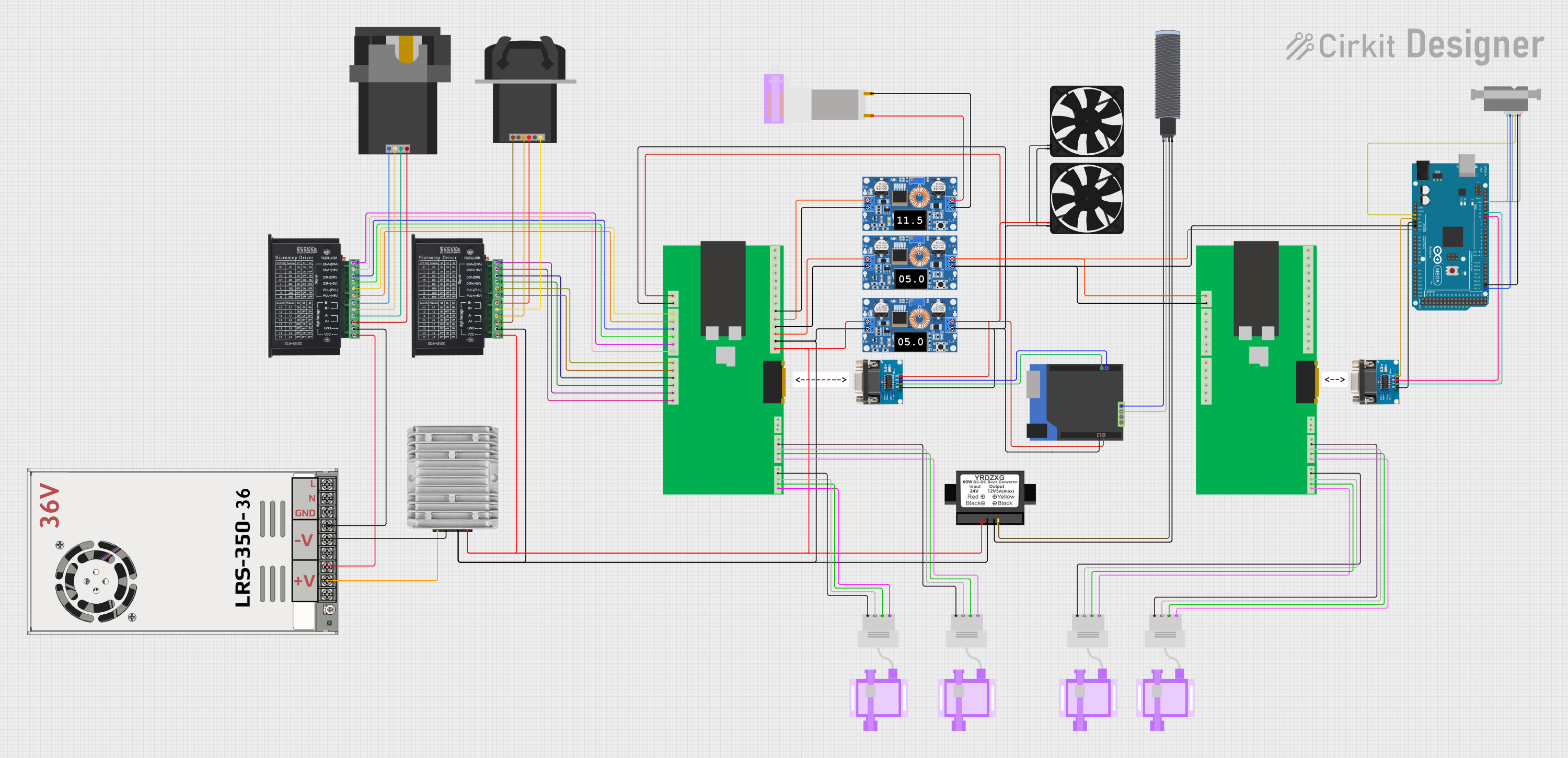

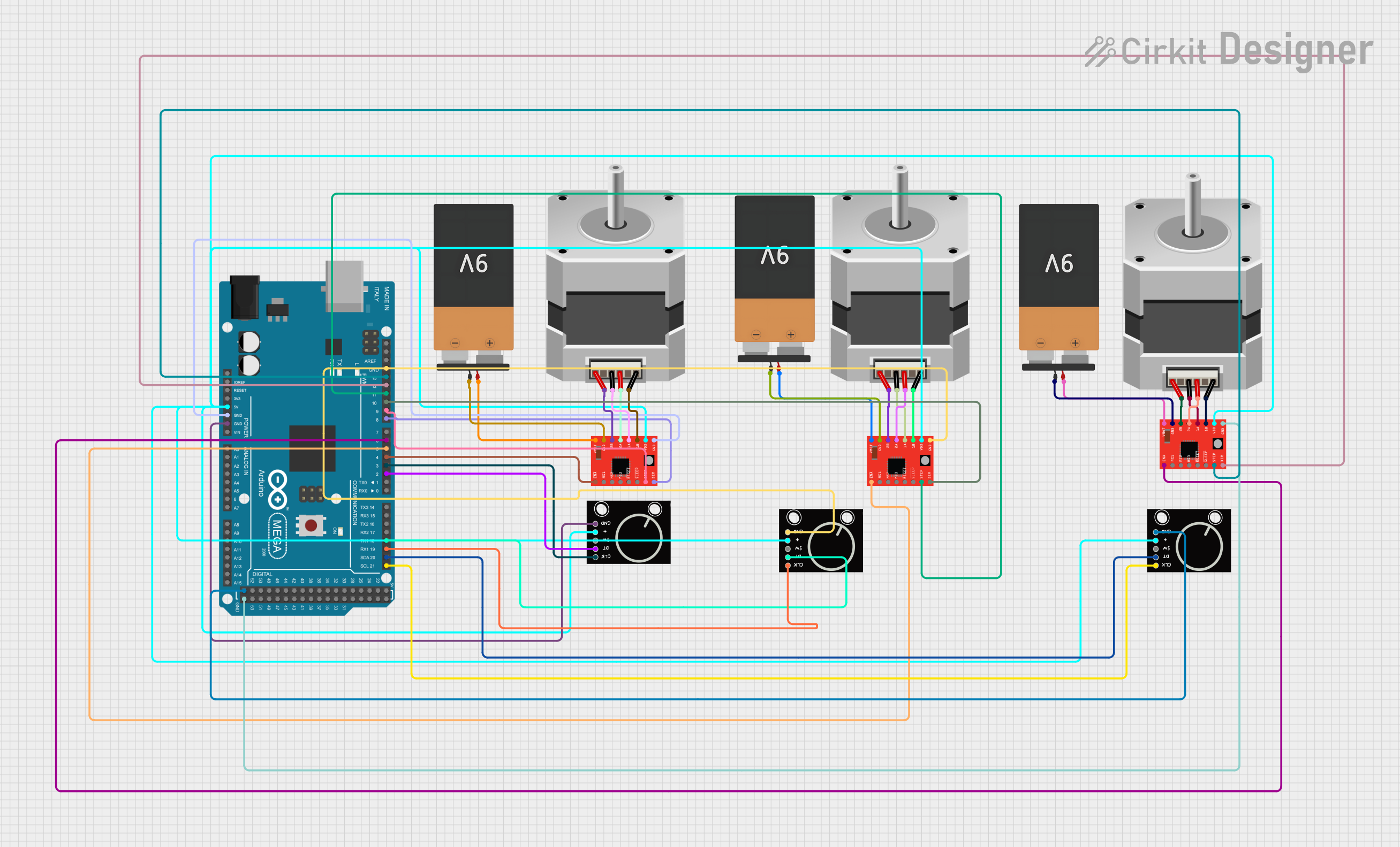

Explore Projects Built with verter_screw

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with verter_screw

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Prototyping on breadboards or perforated circuit boards

- Terminal blocks for power supply connections

- Industrial control panels for machinery and equipment

- Consumer electronics for internal wire management

- Robotics and automation systems for signal and power distribution

Technical Specifications

The Verter_Screw is designed to accommodate a range of wire sizes and types. Below are the key technical specifications and pin configuration details.

Key Technical Details

- Material: High-quality metal alloy for screw, plastic or metal for terminal block

- Wire Gauge Compatibility: Typically 12-24 AWG

- Voltage Rating: Up to 250V (depending on model)

- Current Rating: Up to 10A (depending on model)

- Torque Rating: 0.5 Nm (recommended maximum for tightening)

- Operating Temperature Range: -40°C to 105°C

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Wire Insertion Point | Connect the stripped wire end |

| 2 | Screw Tightening Point | Tighten to secure the wire |

| 3 | Terminal Block Connection | Connect to the circuit or panel |

Usage Instructions

How to Use the Verter_Screw in a Circuit

- Wire Preparation: Strip approximately 5-7 mm of insulation from the wire end to be connected.

- Insertion: Insert the stripped wire end into the wire insertion point (Pin 1).

- Securing the Wire: Use a suitable screwdriver to tighten the screw at the screw tightening point (Pin 2). Ensure the wire is held firmly in place.

- Connection to Circuit: Connect the terminal block (Pin 3) to the desired point in your circuit or to another Verter_Screw if daisy-chaining.

Important Considerations and Best Practices

- Do not exceed the recommended torque when tightening the screw to avoid damaging the wire.

- Ensure the wire is fully inserted before tightening to make a good electrical connection.

- Periodically check the tightness of the screw, especially in environments with vibration.

- Use wires within the specified gauge range to prevent loose connections or damage to the wire.

Troubleshooting and FAQs

Common Issues and Solutions

- Loose Connection: If the connection is intermittent, check the tightness of the screw and the integrity of the wire insertion.

- Stripped Screw: If the screw head is stripped, carefully remove it and replace it with a similar size screw.

- Overheating: Ensure the current passing through the wire does not exceed the Verter_Screw's current rating.

FAQs

Q: Can I reuse the Verter_Screw with different wires? A: Yes, the Verter_Screw is designed to be reusable. Ensure the previous wire is completely removed before inserting a new one.

Q: What is the maximum number of wires that can be connected to a single Verter_Screw? A: Typically, one Verter_Screw is designed for a single wire connection. However, multiple wires can be connected if they fit securely and do not exceed the current rating.

Q: Is the Verter_Screw suitable for outdoor applications? A: It depends on the specific model. Some Verter_Screws are rated for outdoor use with additional weatherproofing features.

Example Code for Arduino UNO Connection

// Example code to demonstrate how to connect an LED to an Arduino UNO

// using a Verter_Screw for the ground connection.

void setup() {

pinMode(13, OUTPUT); // Set the LED pin as an output

}

void loop() {

digitalWrite(13, HIGH); // Turn on the LED

delay(1000); // Wait for 1 second

digitalWrite(13, LOW); // Turn off the LED

delay(1000); // Wait for 1 second

}

// Note: Connect the anode of the LED to pin 13 on the Arduino.

// Connect the cathode to one end of a resistor (220 ohms recommended).

// Connect the other end of the resistor to the Verter_Screw (Pin 1).

// Secure the wire with the screw (Pin 2).

// Finally, connect the Verter_Screw's terminal block (Pin 3) to the Arduino's GND pin.

Remember to follow the usage instructions for wire preparation and connection to ensure a stable and secure electrical connection when using the Verter_Screw with your Arduino projects.