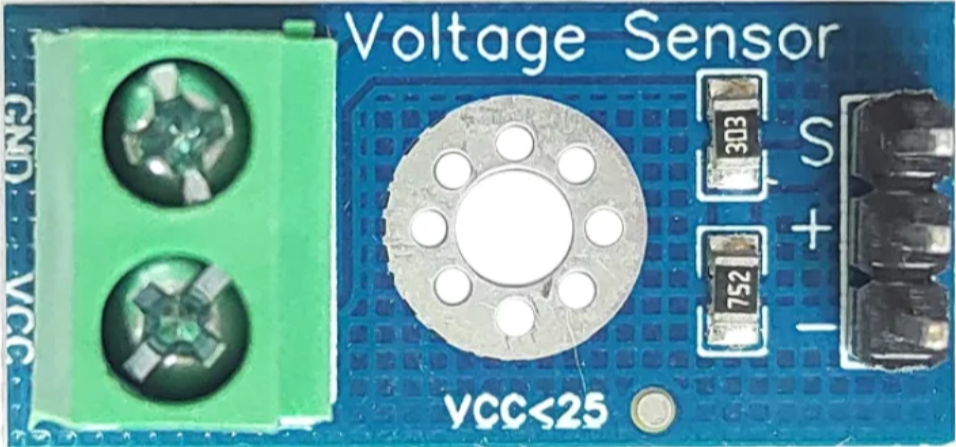

How to Use Voltage Sensor DC 25V: Examples, Pinouts, and Specs

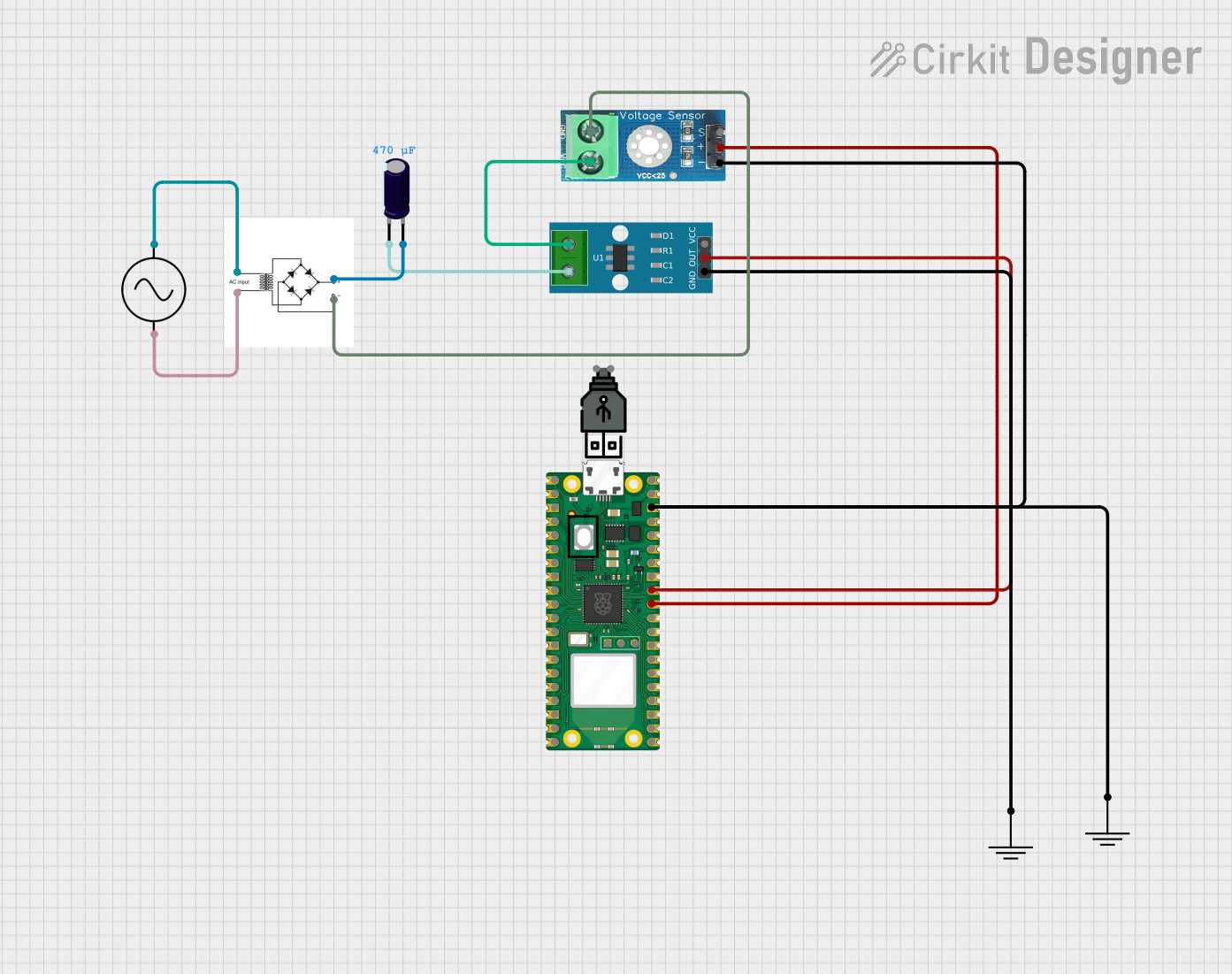

Design with Voltage Sensor DC 25V in Cirkit Designer

Design with Voltage Sensor DC 25V in Cirkit DesignerIntroduction

The Voltage Sensor DC 25V is a device designed to measure the voltage level in a DC circuit, with a maximum input voltage of 25 volts. It provides real-time feedback, making it an essential tool for monitoring and control applications. This sensor is widely used in battery monitoring systems, power supply diagnostics, and embedded systems where voltage measurement is critical.

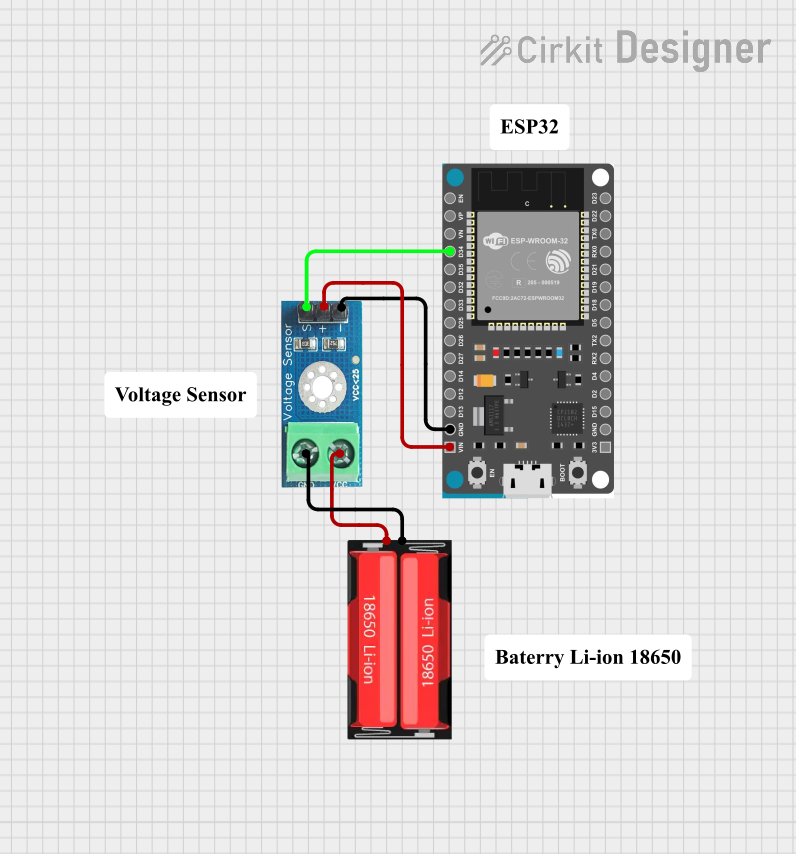

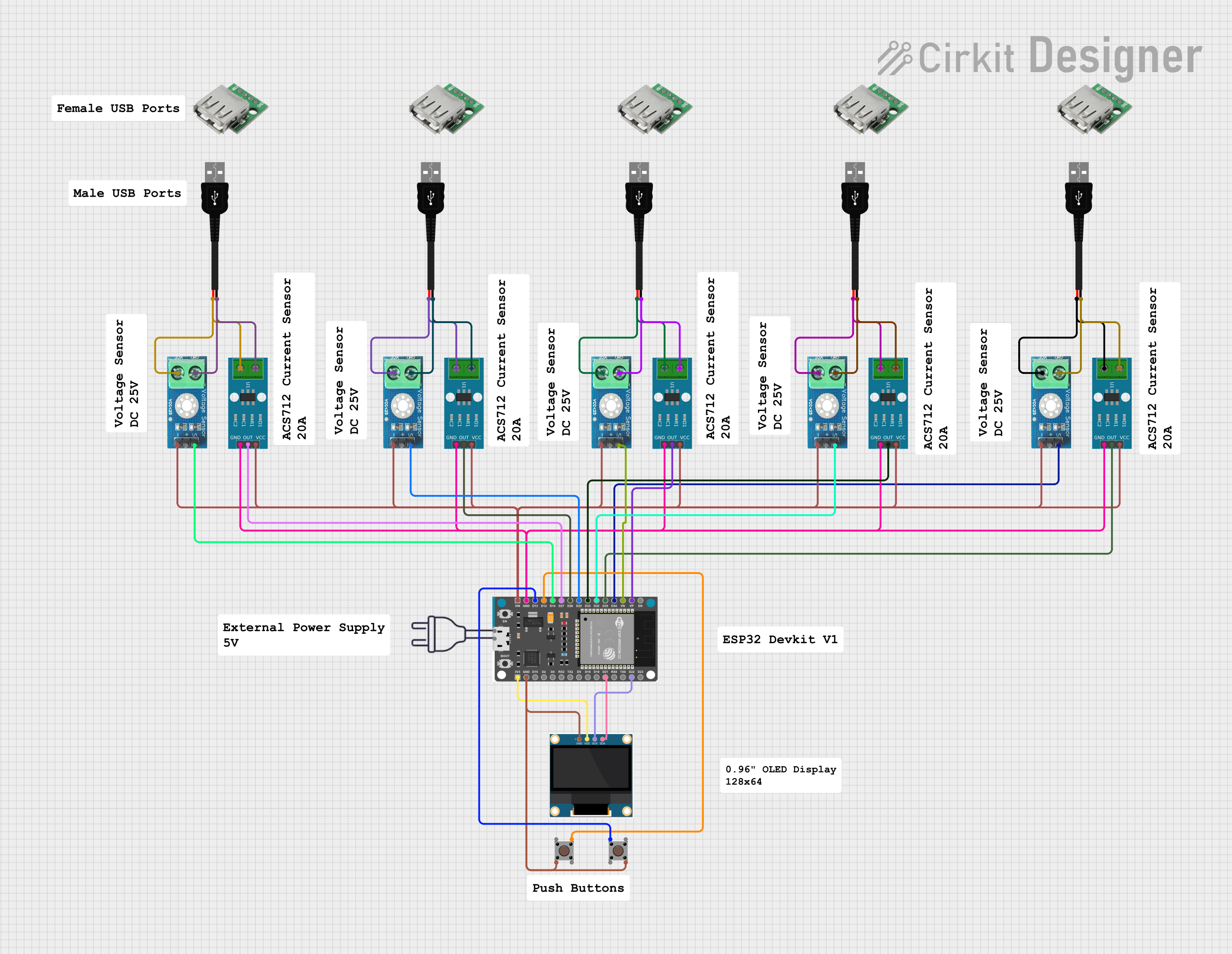

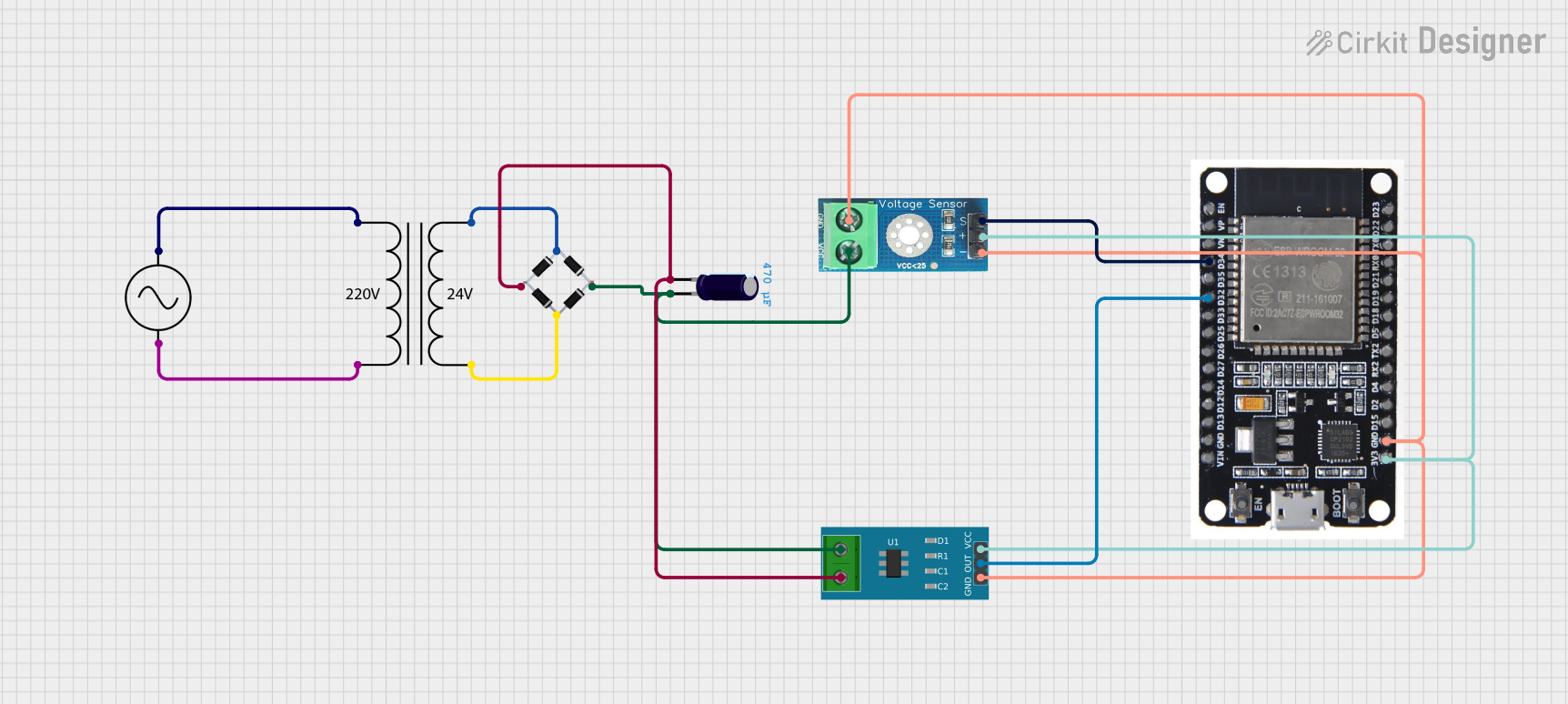

Explore Projects Built with Voltage Sensor DC 25V

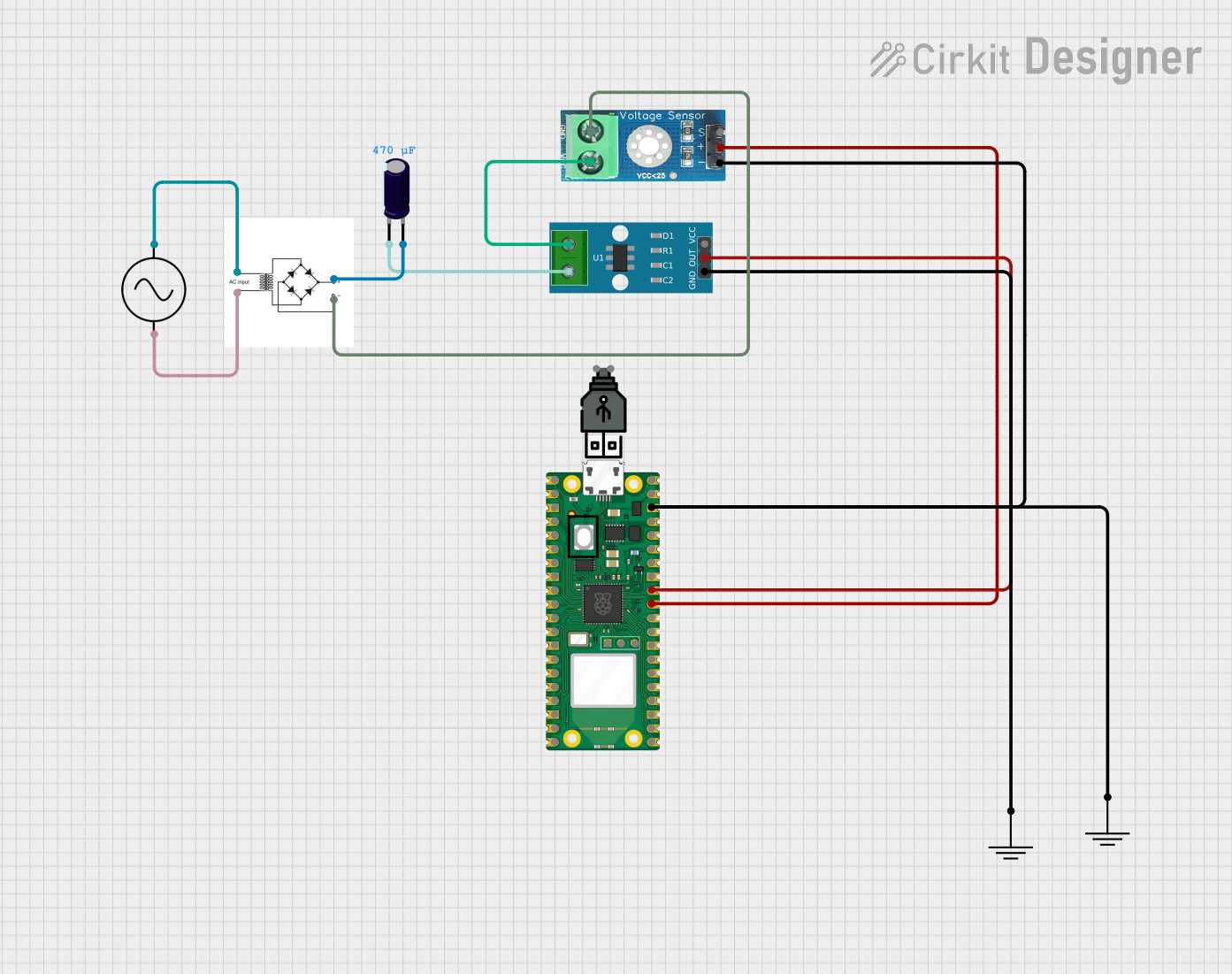

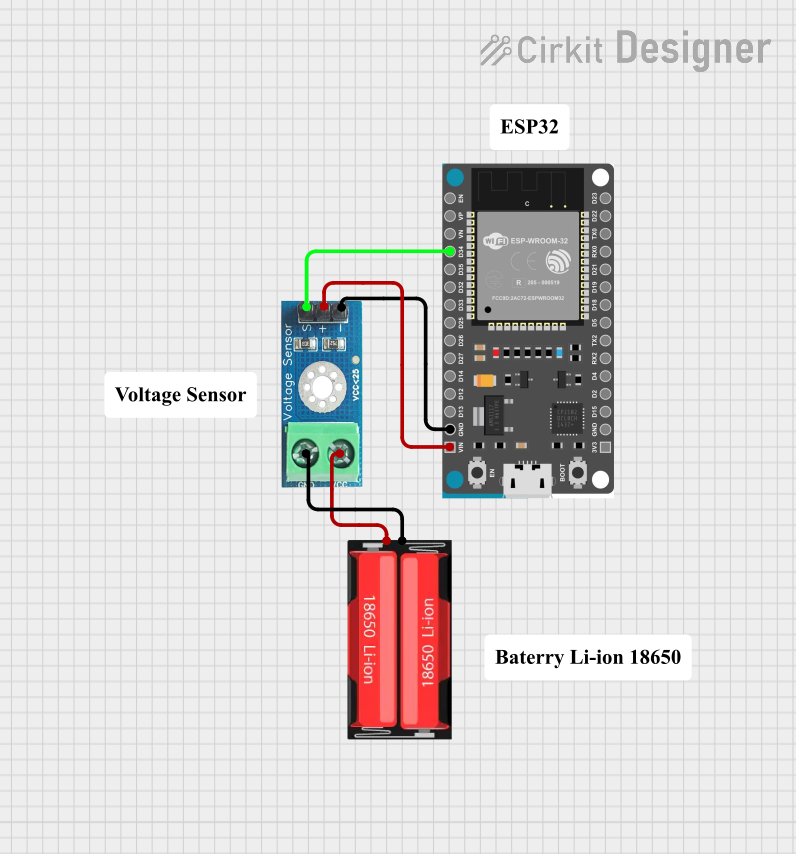

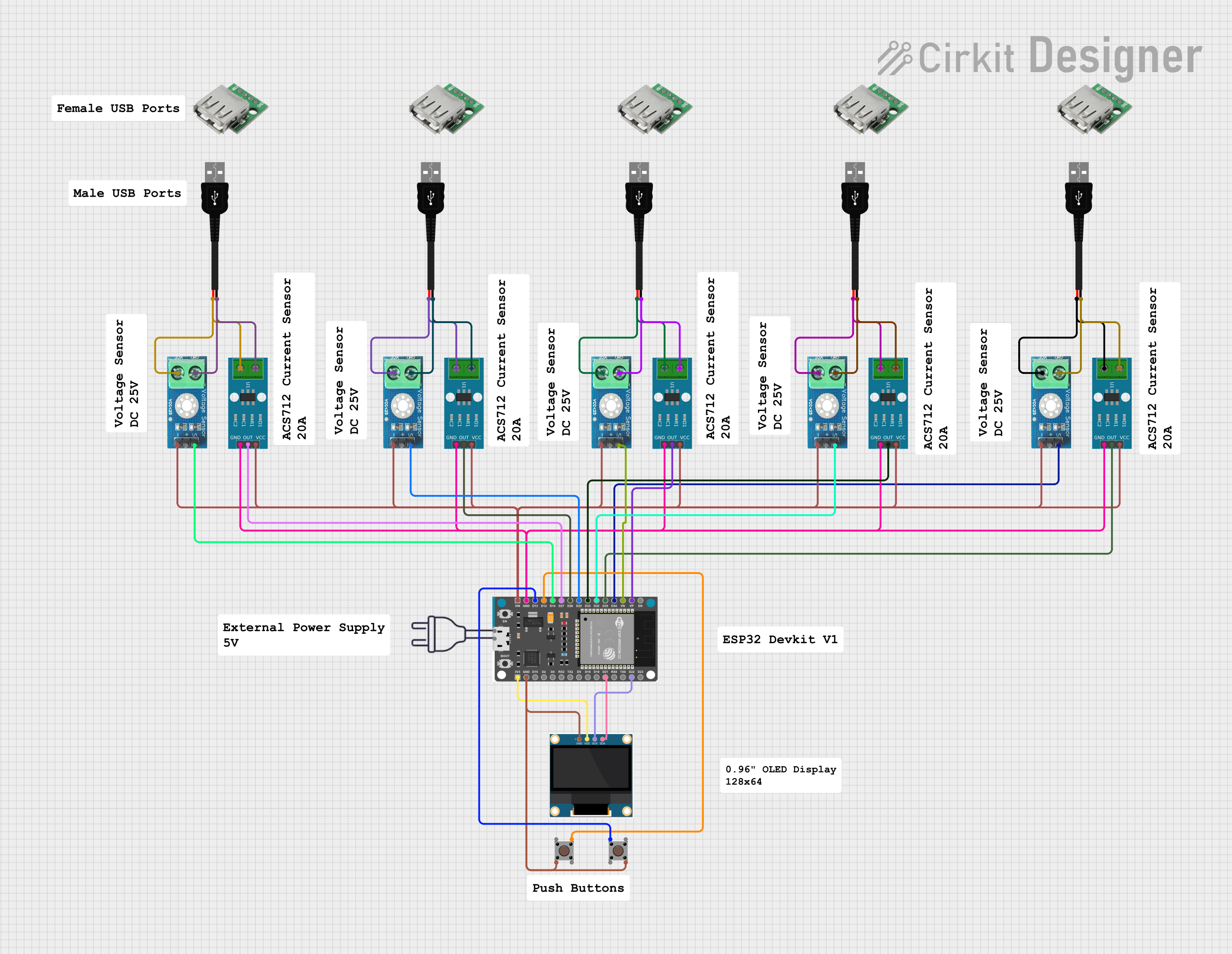

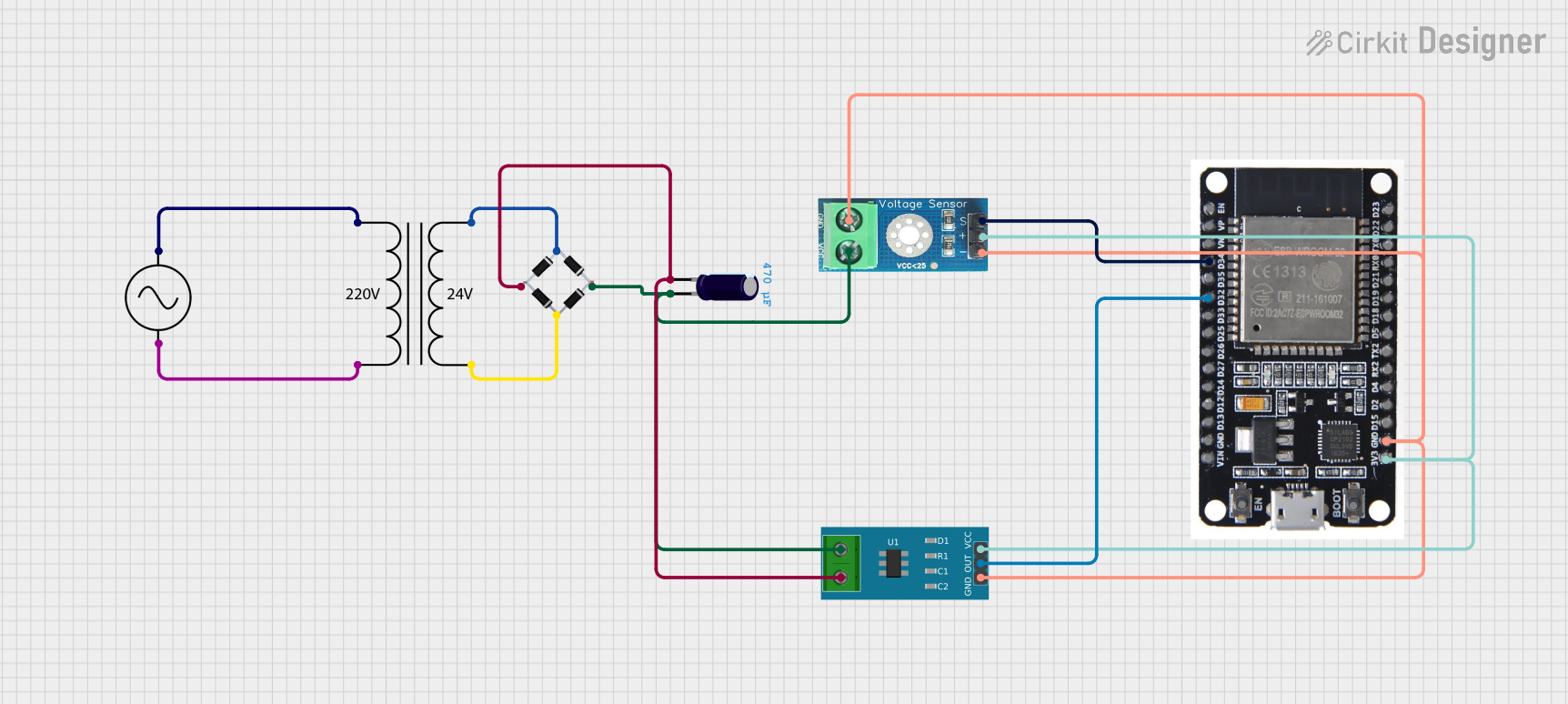

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Voltage Sensor DC 25V

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Battery voltage monitoring in renewable energy systems

- Power supply diagnostics in electronic circuits

- Voltage measurement in Arduino and other microcontroller-based projects

- Real-time voltage feedback for automation and control systems

Technical Specifications

The Voltage Sensor DC 25V is a compact and efficient module with the following key specifications:

| Parameter | Value |

|---|---|

| Input Voltage Range | 0V to 25V DC |

| Output Voltage Range | 0V to 5V DC |

| Voltage Divider Ratio | 5:1 |

| Accuracy | ±1% |

| Operating Temperature | -40°C to 85°C |

| Dimensions | 30mm x 12mm x 10mm |

| Weight | 5g |

Pin Configuration and Descriptions

The Voltage Sensor DC 25V typically has a 4-pin interface. The pinout is as follows:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (typically 3.3V or 5V) |

| 2 | GND | Ground connection |

| 3 | VIN+ | Positive terminal of the voltage to be measured |

| 4 | VOUT | Output voltage proportional to the input voltage |

Usage Instructions

How to Use the Component in a Circuit

- Power the Sensor: Connect the

VCCpin to a 3.3V or 5V power source and theGNDpin to the ground of your circuit. - Connect the Voltage Source: Attach the positive terminal of the voltage source to the

VIN+pin. Ensure the input voltage does not exceed 25V. - Read the Output: The

VOUTpin provides an analog voltage proportional to the input voltage. This can be read using an analog-to-digital converter (ADC) on a microcontroller, such as an Arduino.

Important Considerations and Best Practices

- Voltage Divider Ratio: The sensor uses a 5:1 voltage divider. For example, an input voltage of 25V will result in an output voltage of 5V.

- Input Voltage Limit: Do not exceed the 25V input limit, as this may damage the sensor.

- Calibration: For precise measurements, calibrate the sensor by comparing its output with a known reference voltage.

- Noise Reduction: Use decoupling capacitors near the sensor to reduce noise in the output signal.

Example: Using the Voltage Sensor with Arduino UNO

Below is an example of how to use the Voltage Sensor DC 25V with an Arduino UNO to measure and display voltage:

// Define the analog pin connected to the sensor's VOUT pin

const int sensorPin = A0;

// Voltage divider ratio (5:1)

const float voltageDividerRatio = 5.0;

// Reference voltage of the Arduino (typically 5V)

const float referenceVoltage = 5.0;

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

}

void loop() {

// Read the analog value from the sensor

int sensorValue = analogRead(sensorPin);

// Convert the analog value to a voltage

float outputVoltage = (sensorValue / 1023.0) * referenceVoltage;

// Calculate the input voltage using the voltage divider ratio

float inputVoltage = outputVoltage * voltageDividerRatio;

// Print the input voltage to the Serial Monitor

Serial.print("Input Voltage: ");

Serial.print(inputVoltage);

Serial.println(" V");

delay(1000); // Wait for 1 second before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage:

- Cause: Incorrect wiring or no power supply.

- Solution: Double-check the connections, ensuring

VCCandGNDare properly connected.

Inaccurate Voltage Readings:

- Cause: Calibration error or noise in the circuit.

- Solution: Calibrate the sensor using a known reference voltage and add decoupling capacitors to reduce noise.

Sensor Overheating:

- Cause: Input voltage exceeds 25V.

- Solution: Ensure the input voltage is within the specified range.

Arduino Reads Zero Voltage:

- Cause: Incorrect analog pin configuration or damaged sensor.

- Solution: Verify the analog pin connection and test the sensor with a multimeter.

FAQs

Q1: Can this sensor measure AC voltage?

A1: No, the Voltage Sensor DC 25V is designed for DC voltage measurement only.

Q2: What happens if the input voltage exceeds 25V?

A2: Exceeding 25V may damage the sensor permanently. Always ensure the input voltage is within the specified range.

Q3: Can I use this sensor with a 3.3V microcontroller?

A3: Yes, the sensor is compatible with 3.3V systems. However, ensure the output voltage does not exceed the ADC input range of your microcontroller.

Q4: How do I improve the accuracy of the sensor?

A4: Use a high-resolution ADC, calibrate the sensor, and minimize noise in the circuit.

This documentation provides all the necessary details to effectively use the Voltage Sensor DC 25V in your projects.