How to Use L298N DC motor driver: Examples, Pinouts, and Specs

Design with L298N DC motor driver in Cirkit Designer

Design with L298N DC motor driver in Cirkit DesignerIntroduction

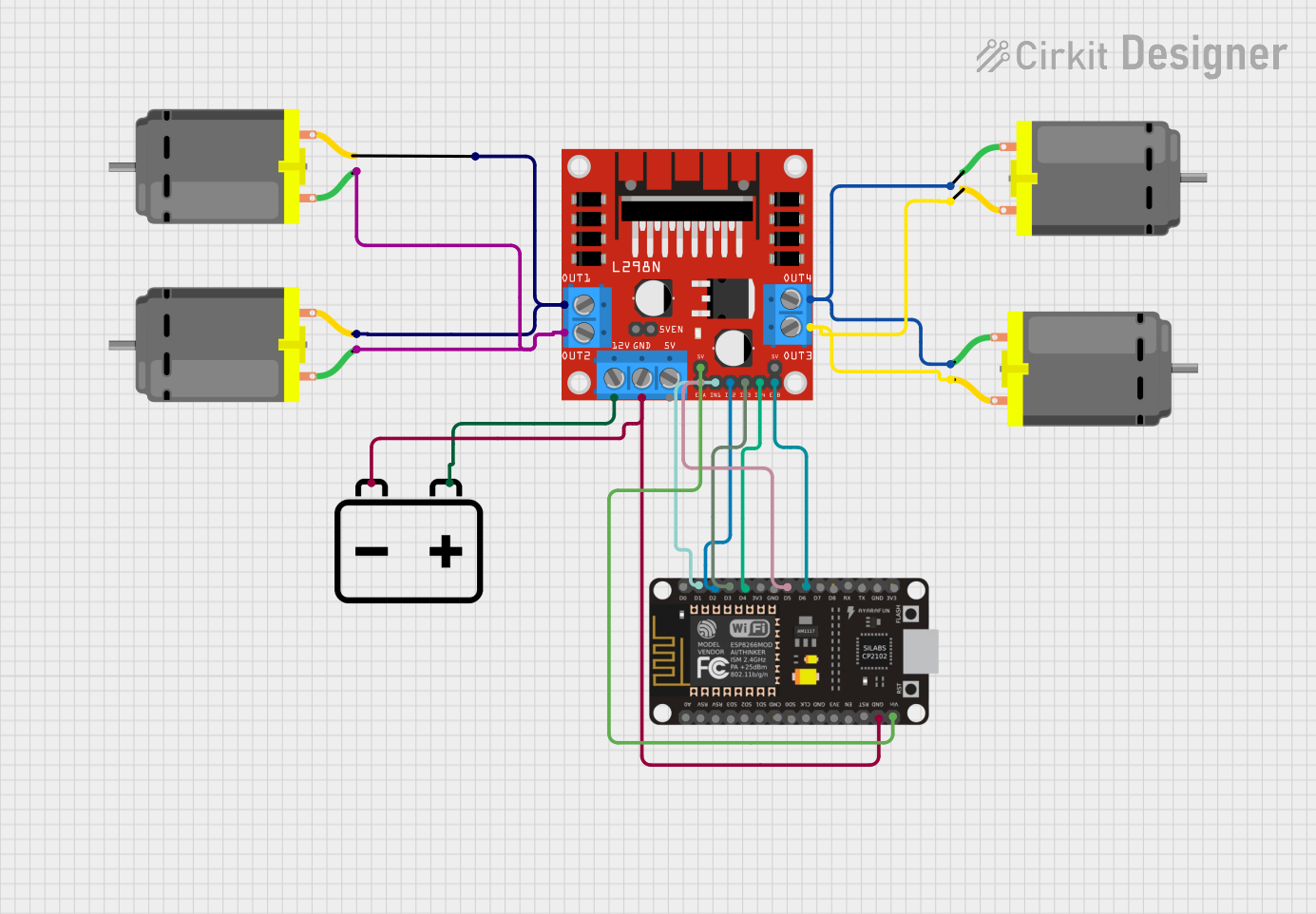

The L298N is a dual H-bridge motor driver module designed to control the direction and speed of DC motors using Pulse Width Modulation (PWM) signals. It is capable of driving two DC motors simultaneously, making it an ideal choice for robotics, automation, and other motor control applications. The module is robust, easy to use, and supports a wide range of motor voltages and currents, making it suitable for hobbyists and professionals alike.

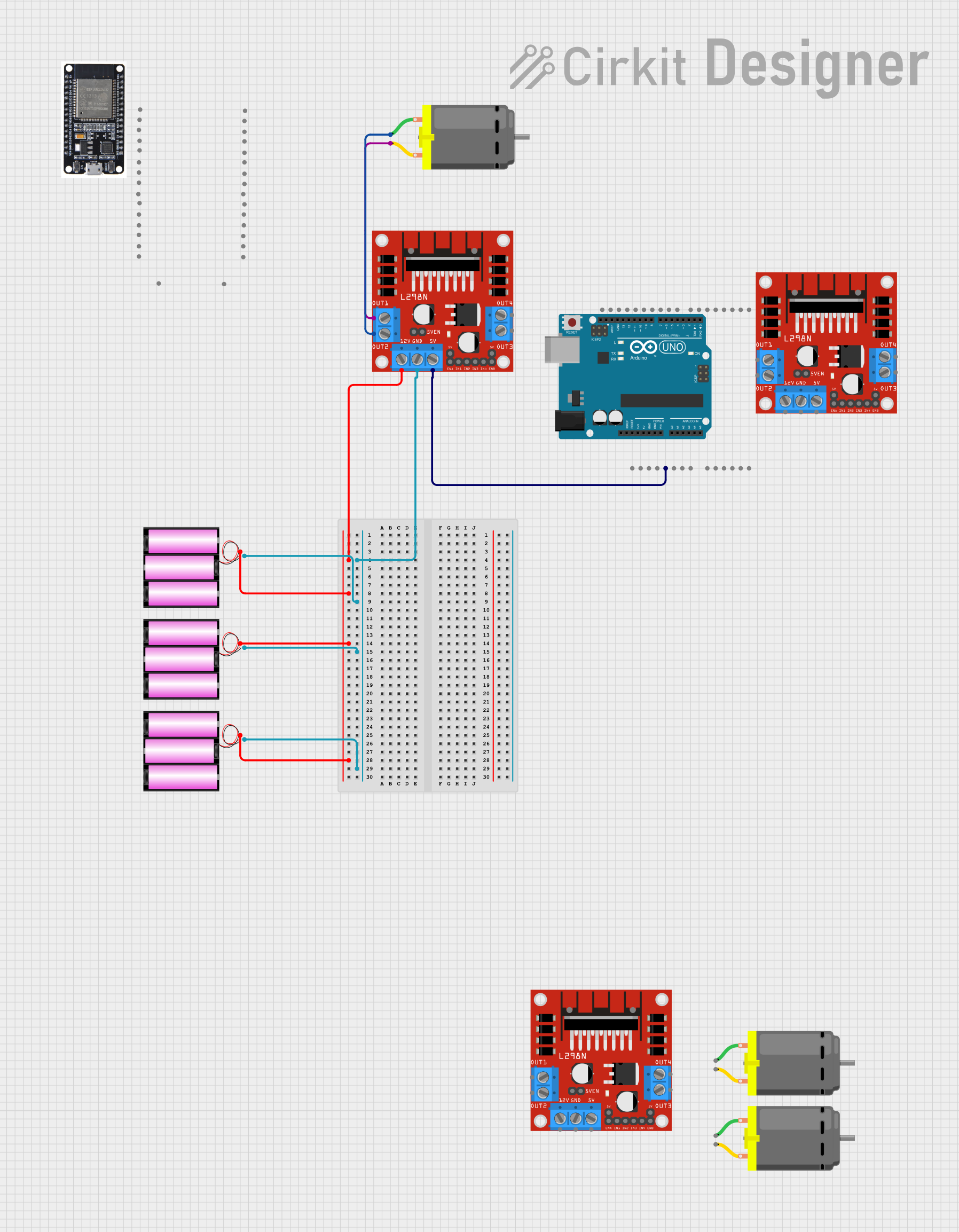

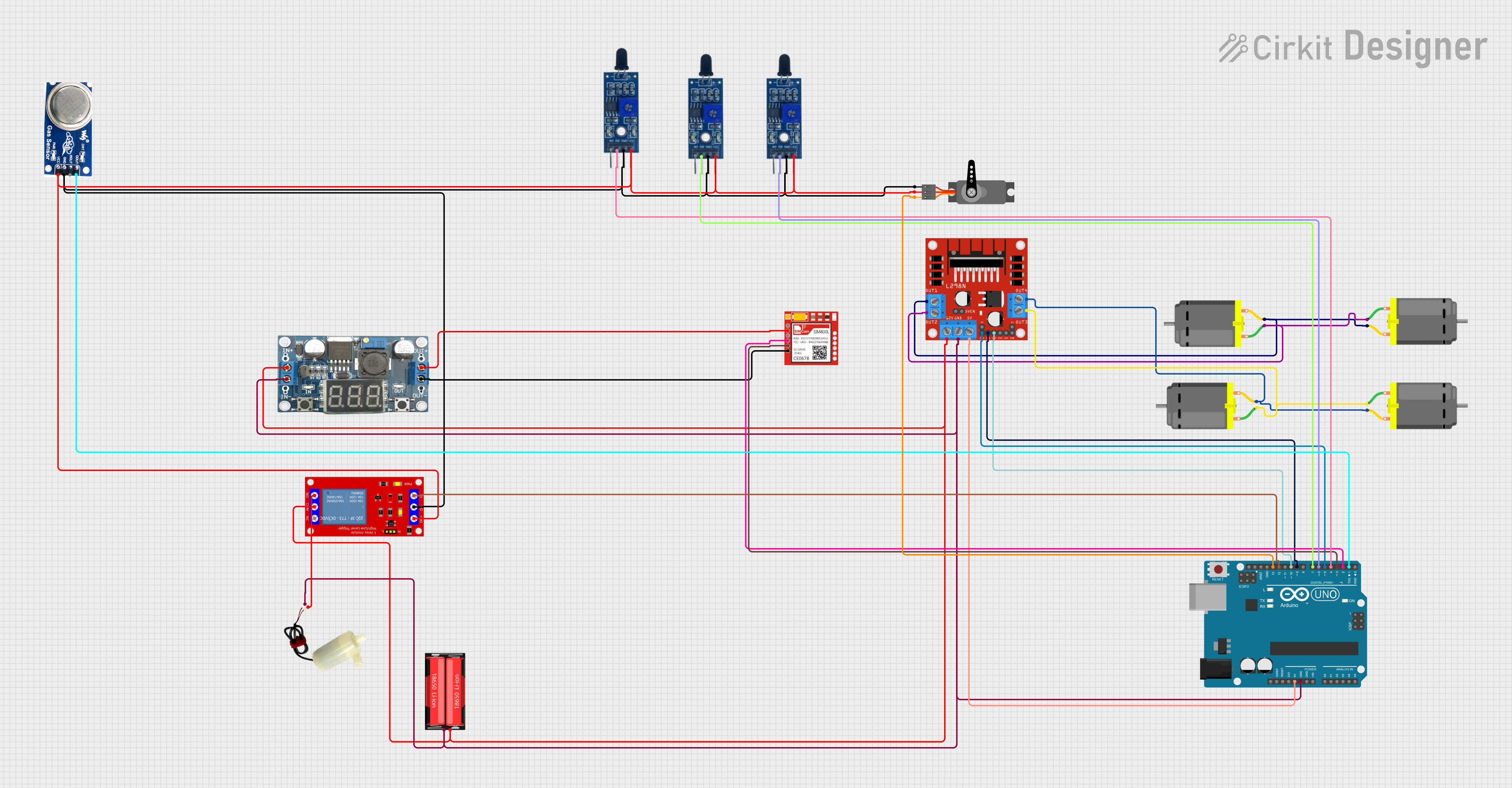

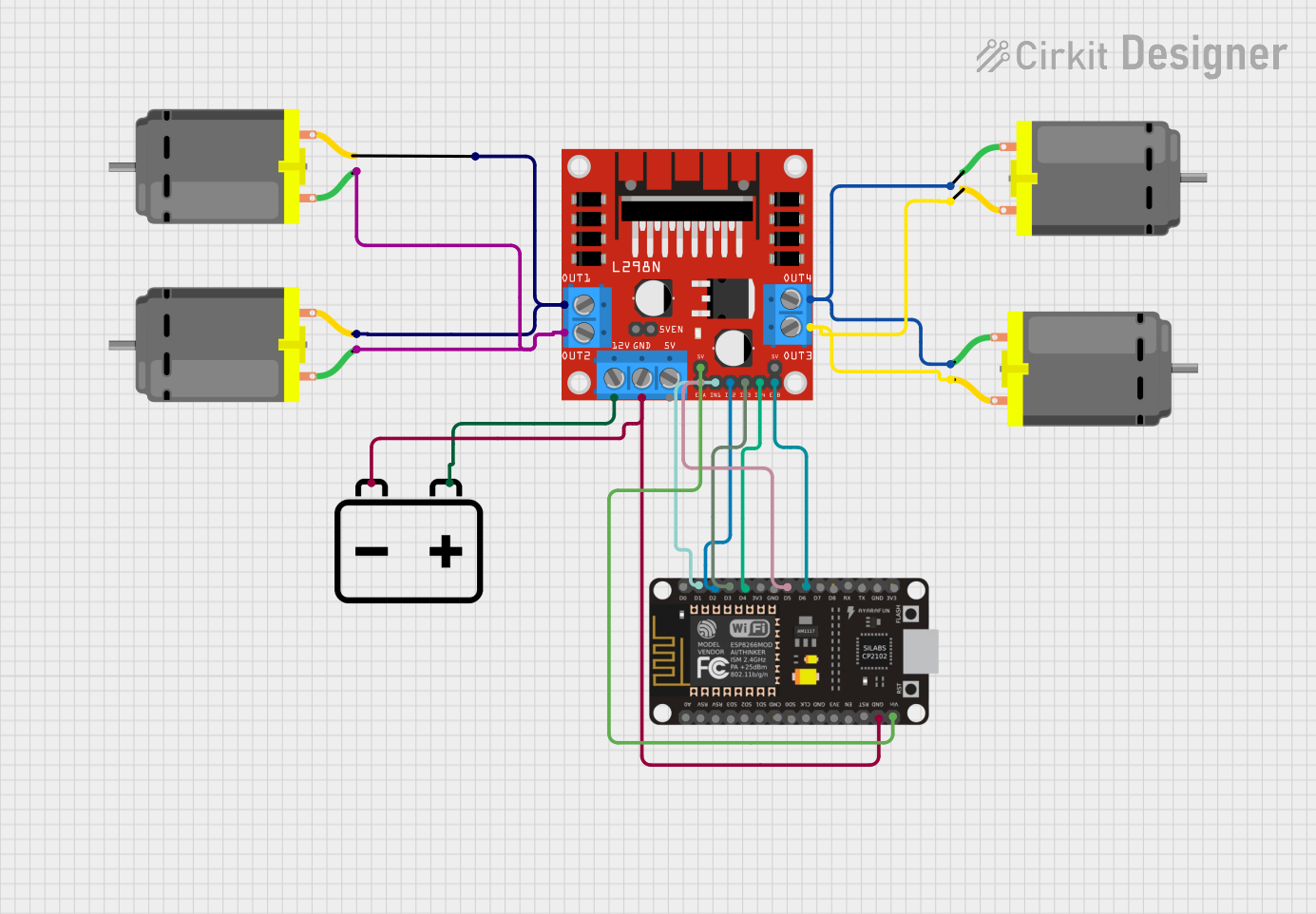

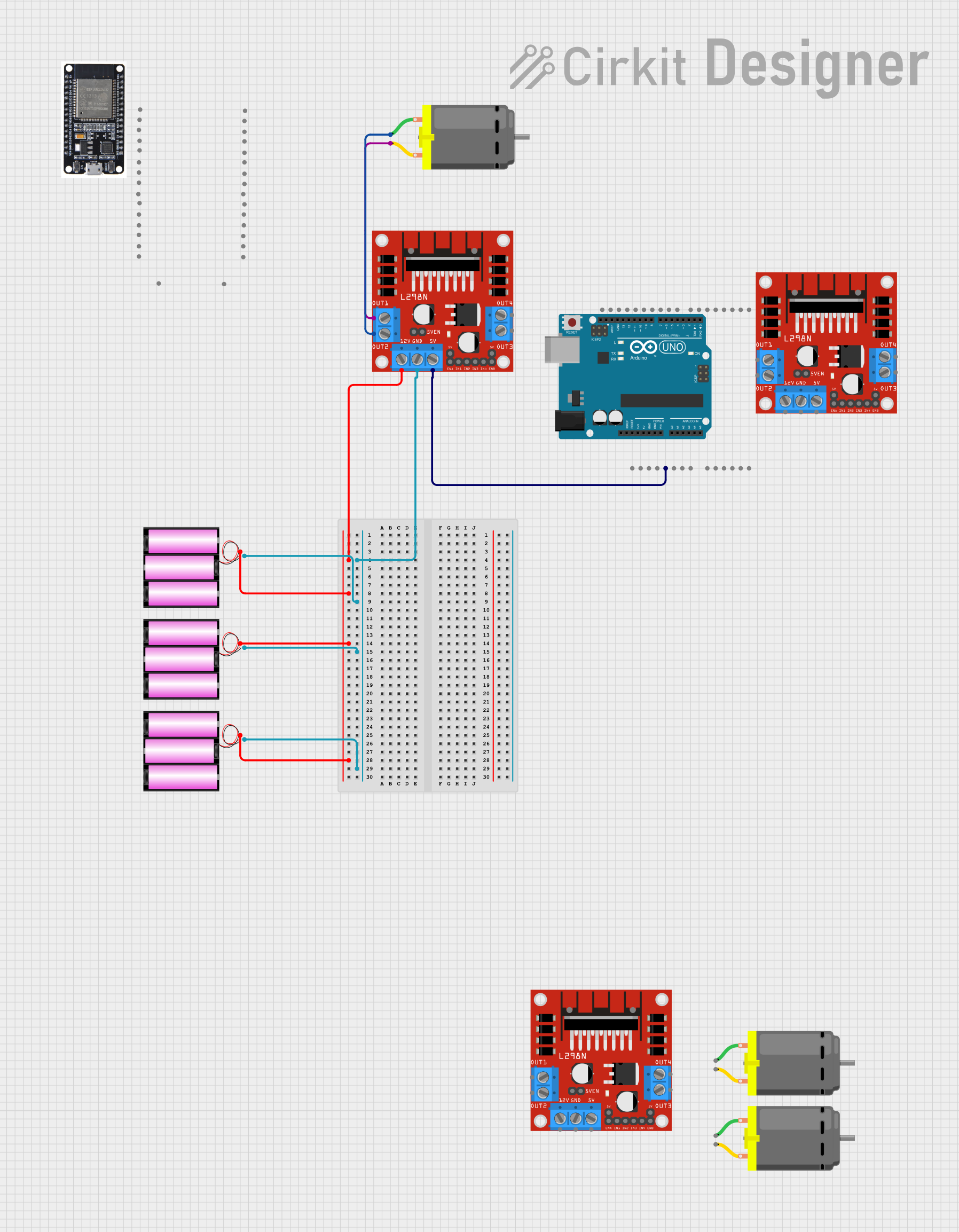

Explore Projects Built with L298N DC motor driver

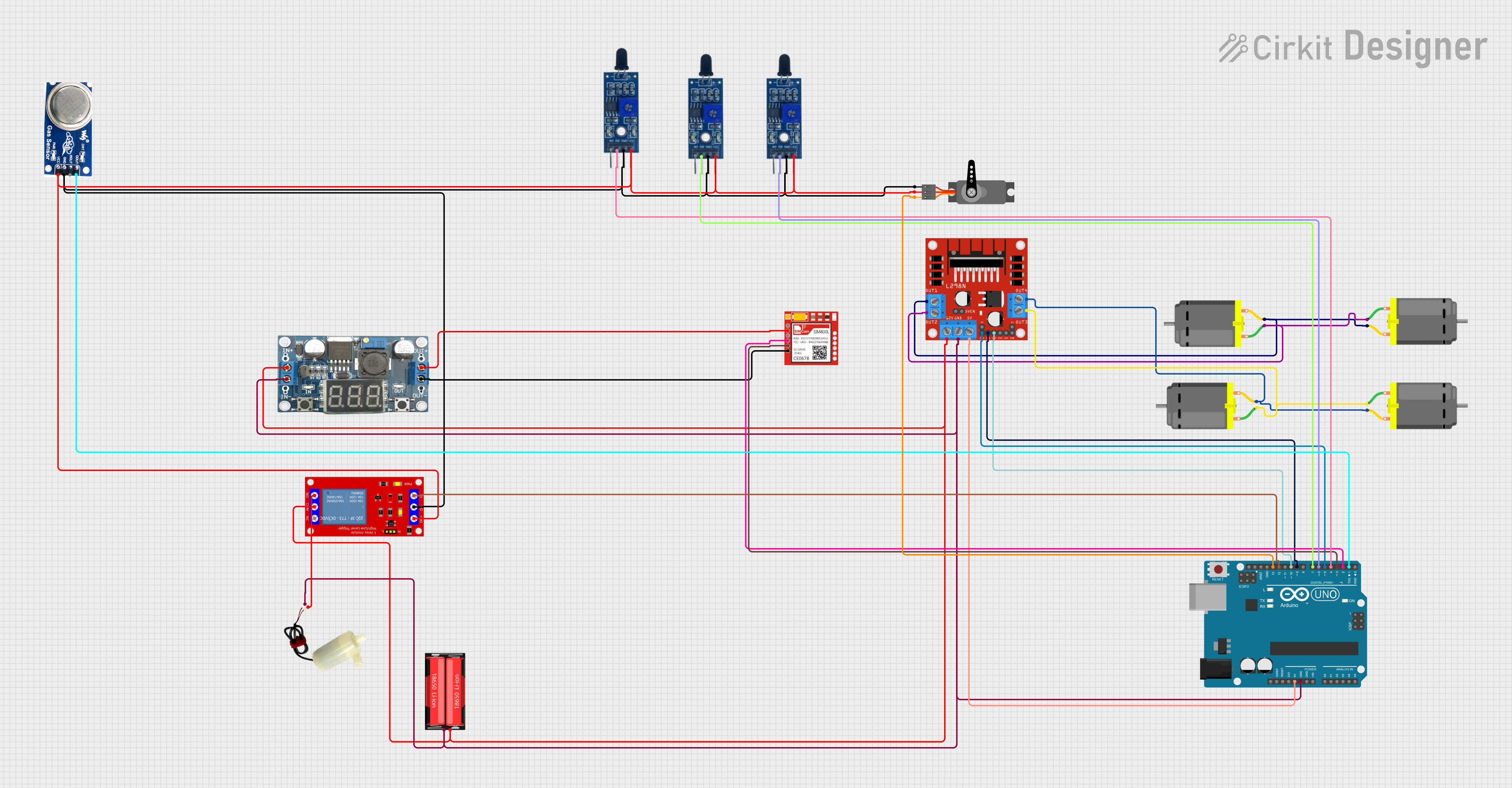

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with L298N DC motor driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics (e.g., controlling robot wheels)

- Conveyor belt systems

- Automated gates and doors

- DIY motorized projects

- Remote-controlled vehicles

Technical Specifications

Key Technical Details

- Operating Voltage (Logic): 5V

- Motor Supply Voltage (Vmotor): 5V to 35V

- Maximum Motor Current (per channel): 2A

- Peak Motor Current (per channel): 3A (short duration)

- Logic Current: 0 to 36mA

- Control Method: PWM for speed control, logic signals for direction

- Number of Channels: 2 (can drive two motors independently)

- Built-in Protection: Thermal shutdown and overcurrent protection

- Dimensions: Approximately 43mm x 43mm x 27mm

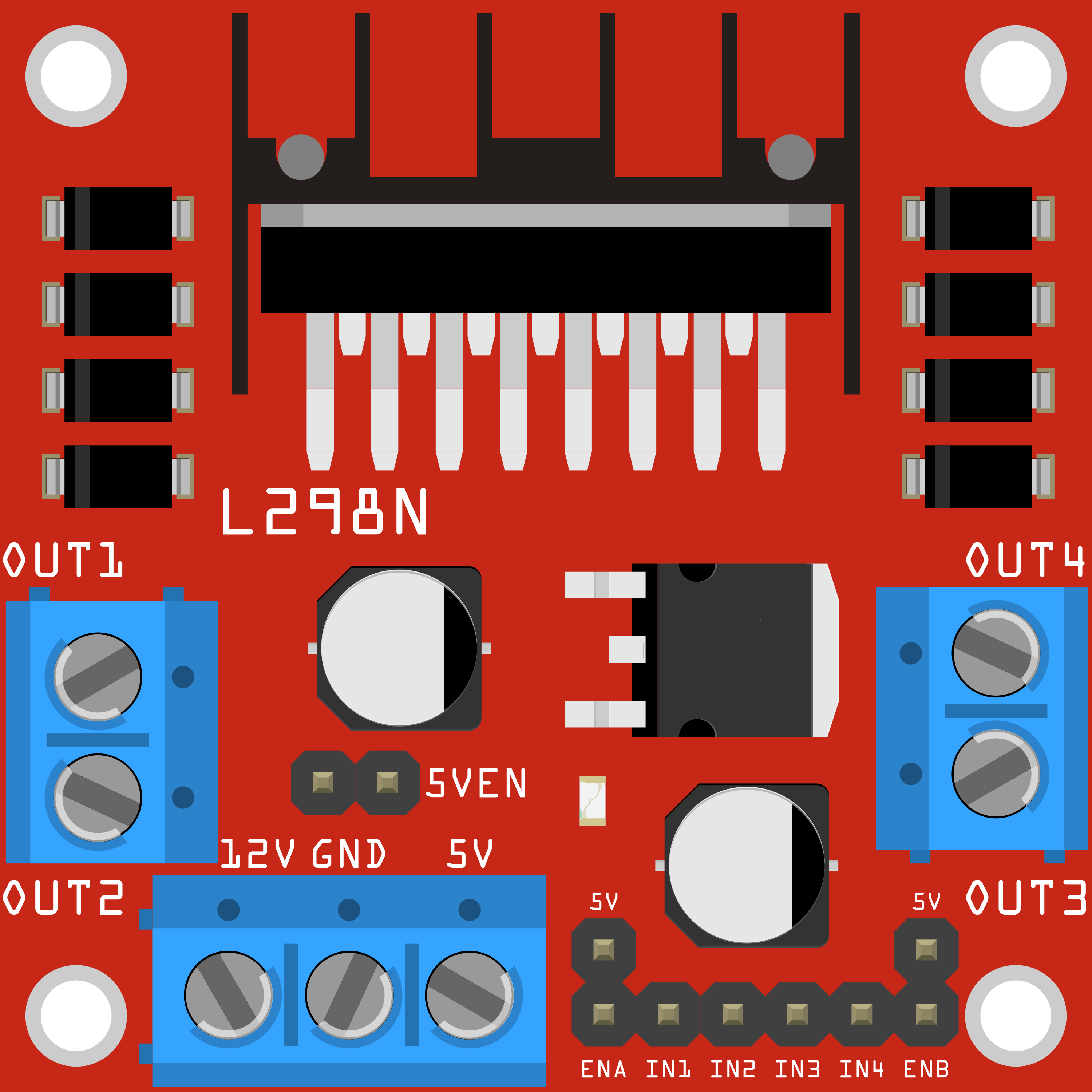

Pin Configuration and Descriptions

The L298N module has several pins and terminals for motor control and power input. Below is a detailed description:

Power and Motor Terminals

| Pin/Terminal | Description |

|---|---|

VCC |

Motor power supply (5V to 35V). Connect to the motor's power source. |

GND |

Ground connection. Common ground for logic and motor power. |

5V |

Logic power supply (5V). Can be used to power external logic circuits. |

OUT1 |

Output for Motor 1 (connect to one terminal of Motor 1). |

OUT2 |

Output for Motor 1 (connect to the other terminal of Motor 1). |

OUT3 |

Output for Motor 2 (connect to one terminal of Motor 2). |

OUT4 |

Output for Motor 2 (connect to the other terminal of Motor 2). |

Control Pins

| Pin | Description |

|---|---|

ENA |

Enable pin for Motor 1. Use PWM signal to control speed. |

ENB |

Enable pin for Motor 2. Use PWM signal to control speed. |

IN1 |

Input 1 for Motor 1. Logic HIGH/LOW controls motor direction. |

IN2 |

Input 2 for Motor 1. Logic HIGH/LOW controls motor direction. |

IN3 |

Input 1 for Motor 2. Logic HIGH/LOW controls motor direction. |

IN4 |

Input 2 for Motor 2. Logic HIGH/LOW controls motor direction. |

Usage Instructions

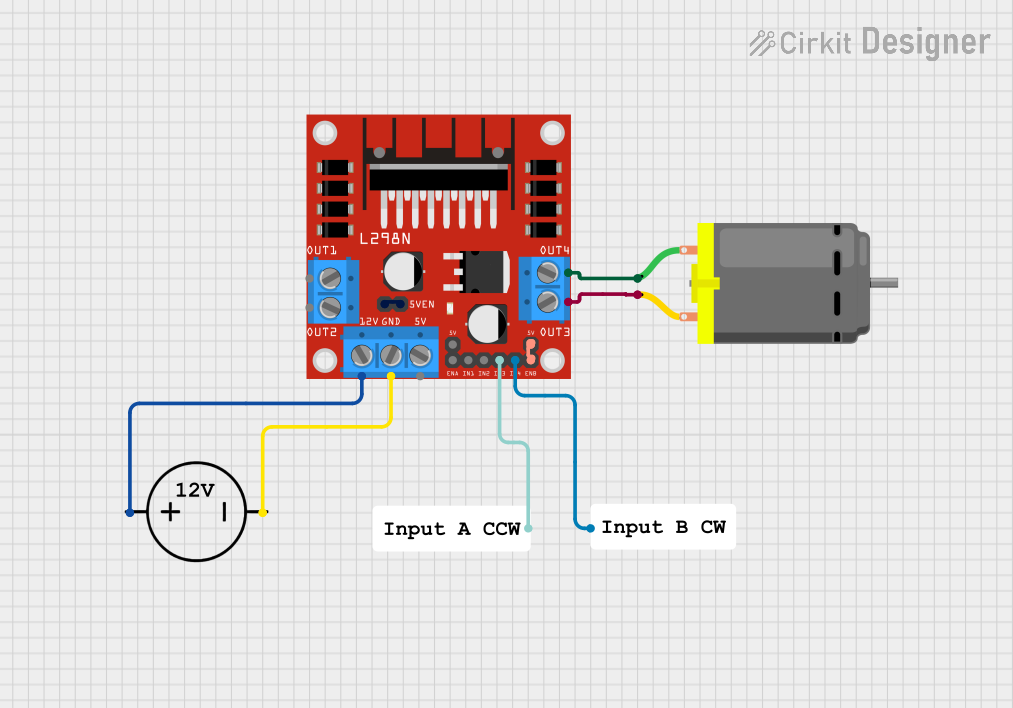

How to Use the L298N in a Circuit

Power Connections:

- Connect the motor power supply to the

VCCterminal (5V to 35V). - Connect the ground of the power supply to the

GNDterminal. - If the logic circuit (e.g., Arduino) is powered separately, ensure a common ground connection.

- Connect the motor power supply to the

Motor Connections:

- Connect the terminals of Motor 1 to

OUT1andOUT2. - Connect the terminals of Motor 2 to

OUT3andOUT4.

- Connect the terminals of Motor 1 to

Control Connections:

- Connect the

ENAandENBpins to PWM-capable pins on your microcontroller for speed control. - Connect

IN1,IN2,IN3, andIN4to digital pins on your microcontroller for direction control.

- Connect the

Logic Power:

- If the motor power supply is greater than 12V, do not use the onboard 5V regulator to power the logic circuit. Instead, provide a separate 5V supply to the

5Vpin.

- If the motor power supply is greater than 12V, do not use the onboard 5V regulator to power the logic circuit. Instead, provide a separate 5V supply to the

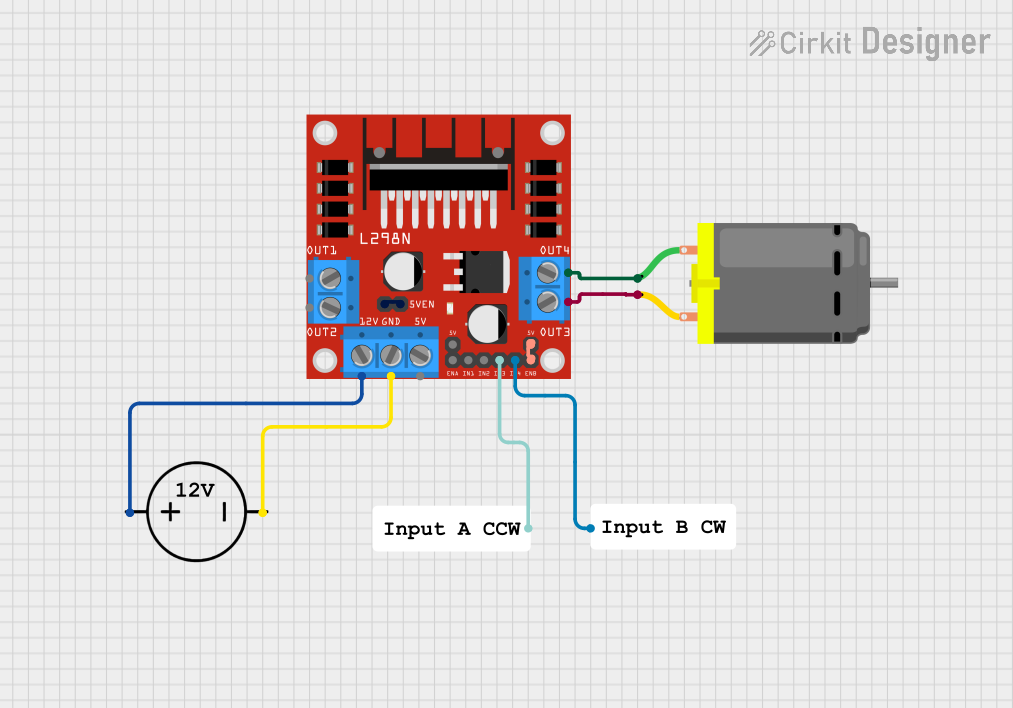

Example: Connecting to an Arduino UNO

Below is an example of how to control two DC motors using the L298N and an Arduino UNO.

Circuit Diagram

- Motor 1 terminals:

OUT1andOUT2 - Motor 2 terminals:

OUT3andOUT4 - Arduino connections:

ENA→ Pin 9 (PWM)ENB→ Pin 10 (PWM)IN1→ Pin 7IN2→ Pin 6IN3→ Pin 5IN4→ Pin 4

Arduino Code

// Define control pins for Motor 1

#define ENA 9 // PWM pin for speed control

#define IN1 7 // Direction control pin

#define IN2 6 // Direction control pin

// Define control pins for Motor 2

#define ENB 10 // PWM pin for speed control

#define IN3 5 // Direction control pin

#define IN4 4 // Direction control pin

void setup() {

// Set motor control pins as outputs

pinMode(ENA, OUTPUT);

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(ENB, OUTPUT);

pinMode(IN3, OUTPUT);

pinMode(IN4, OUTPUT);

}

void loop() {

// Example: Run Motor 1 forward at 50% speed

analogWrite(ENA, 128); // Set speed (0-255)

digitalWrite(IN1, HIGH); // Set direction

digitalWrite(IN2, LOW);

// Example: Run Motor 2 backward at 75% speed

analogWrite(ENB, 192); // Set speed (0-255)

digitalWrite(IN3, LOW); // Set direction

digitalWrite(IN4, HIGH);

delay(2000); // Run motors for 2 seconds

// Stop both motors

analogWrite(ENA, 0);

analogWrite(ENB, 0);

delay(2000); // Wait for 2 seconds

}

Important Considerations

- Ensure the motor power supply voltage matches the motor's specifications.

- Avoid exceeding the maximum current rating of 2A per channel.

- Use heat sinks or cooling if the module gets too hot during operation.

- Always connect a common ground between the L298N and the microcontroller.

Troubleshooting and FAQs

Common Issues and Solutions

Motors Not Running:

- Check all power connections and ensure the motor power supply is sufficient.

- Verify that the

ENAandENBpins are receiving PWM signals.

Motors Running in the Wrong Direction:

- Swap the connections of

IN1andIN2(orIN3andIN4) to reverse the direction. - Ensure the logic signals are correctly set for the desired direction.

- Swap the connections of

Module Overheating:

- Reduce the motor load or add a heat sink to the L298N chip.

- Ensure the motor current does not exceed 2A per channel.

Noisy Operation:

- Add capacitors (e.g., 0.1µF) across the motor terminals to reduce electrical noise.

FAQs

Q: Can the L298N drive stepper motors?

A: Yes, the L298N can drive stepper motors by controlling the two H-bridges. However, additional logic or libraries may be required for precise stepper motor control.

Q: Can I use the onboard 5V regulator to power my Arduino?

A: Yes, but only if the motor power supply is between 7V and 12V. For higher voltages, use a separate 5V power source.

Q: What happens if I exceed the current rating?

A: The module may overheat, and the built-in thermal shutdown will activate to protect the chip. However, repeated overcurrent conditions can damage the module.