How to Use Pt1000 Temperature sensor: Examples, Pinouts, and Specs

Design with Pt1000 Temperature sensor in Cirkit Designer

Design with Pt1000 Temperature sensor in Cirkit DesignerIntroduction

The Pt1000 temperature sensor is a type of Resistance Temperature Detector (RTD) that utilizes a platinum element with a resistance of 1000 ohms at 0°C. Known for its high accuracy and stability, the Pt1000 is widely used in industrial, scientific, and HVAC applications for precise temperature monitoring and control. Its linear resistance-temperature relationship makes it ideal for applications requiring reliable and repeatable temperature measurements.

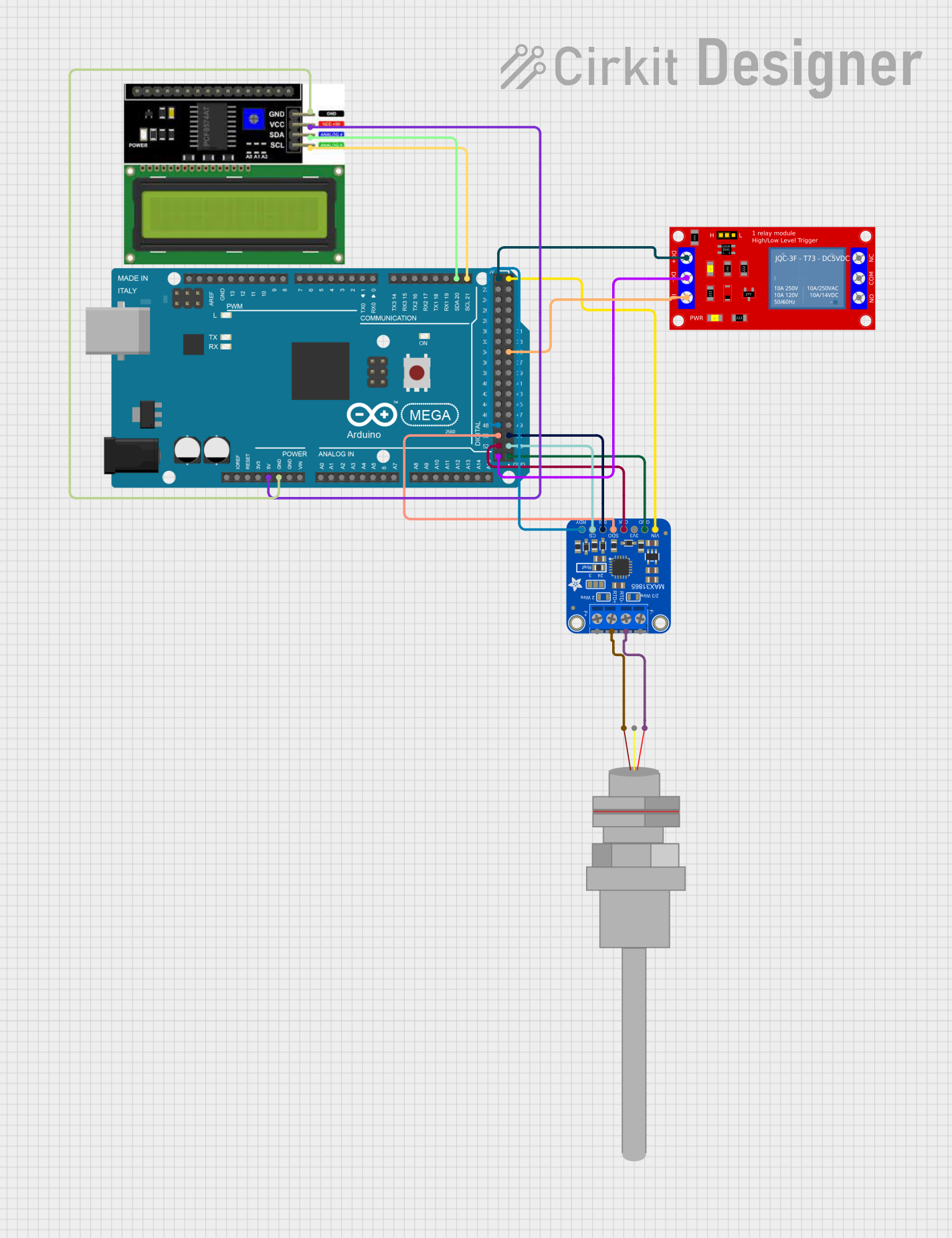

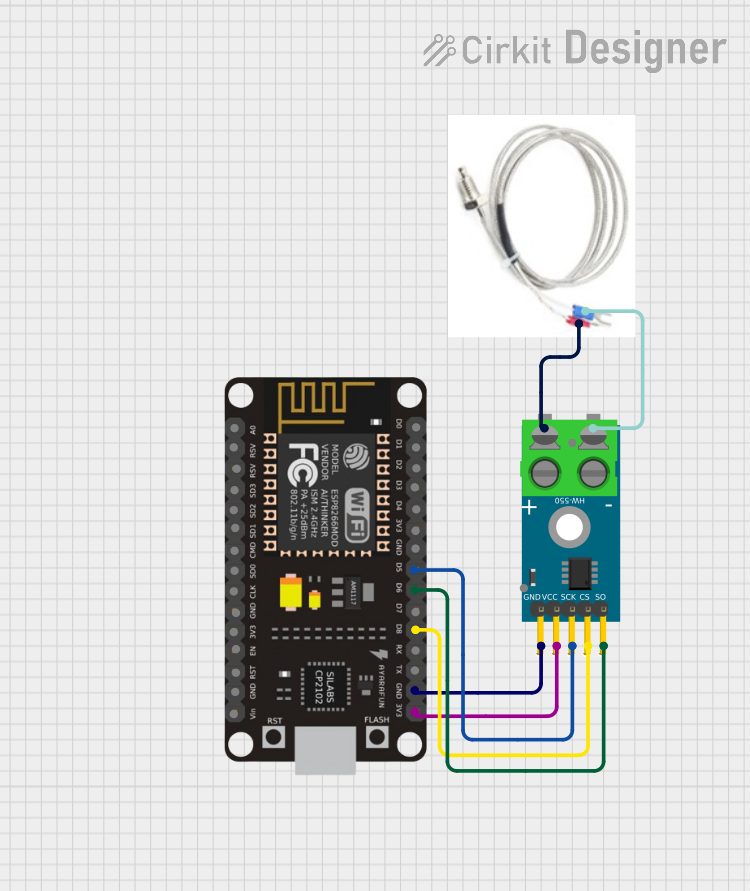

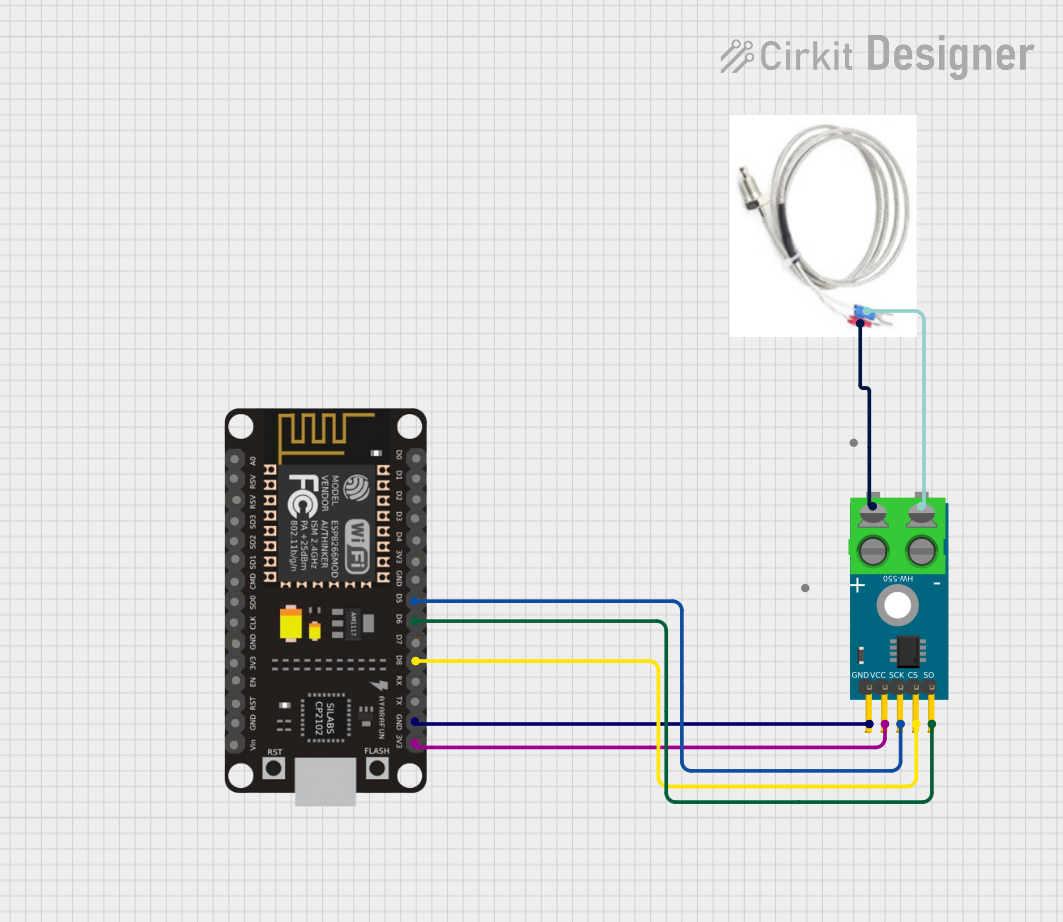

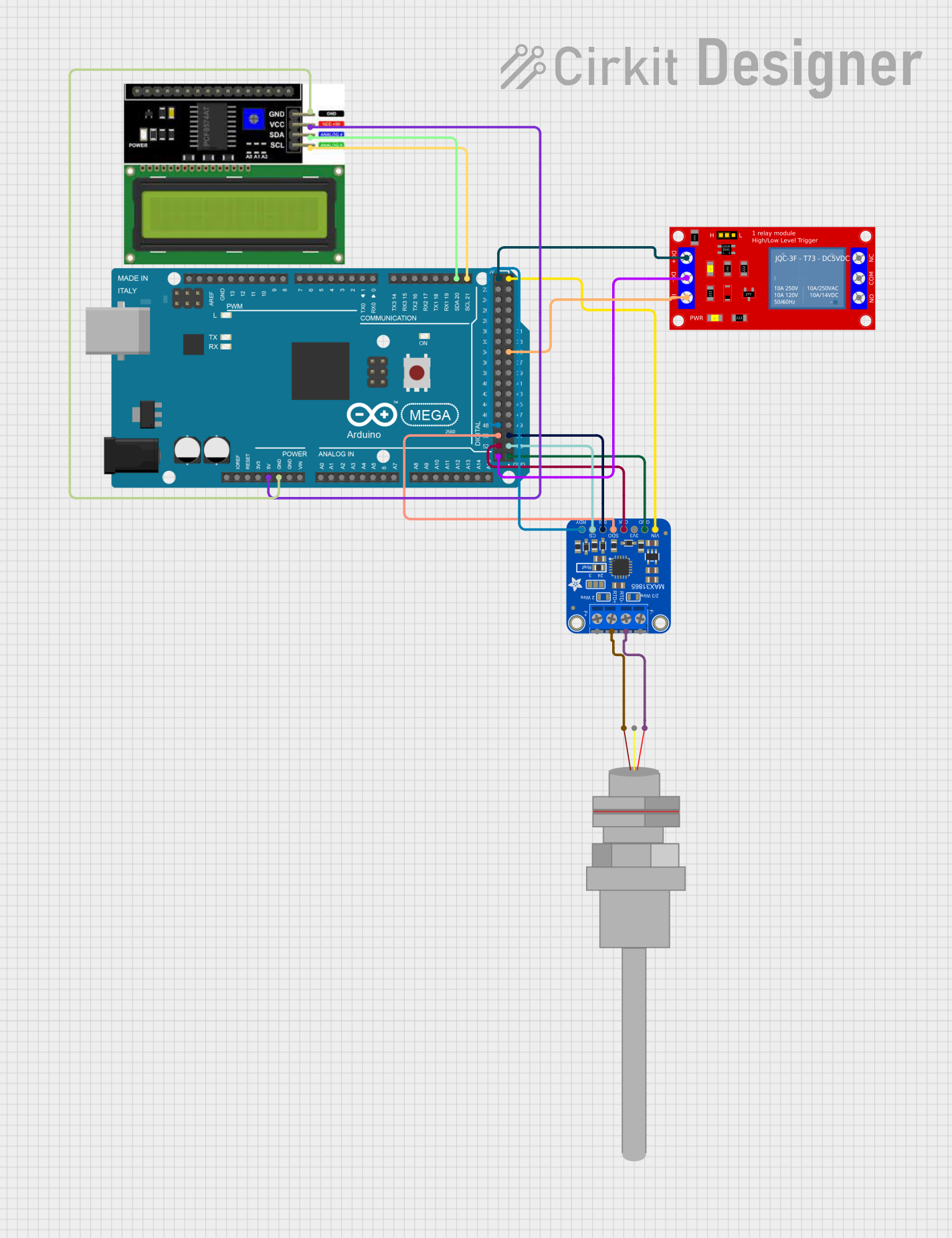

Explore Projects Built with Pt1000 Temperature sensor

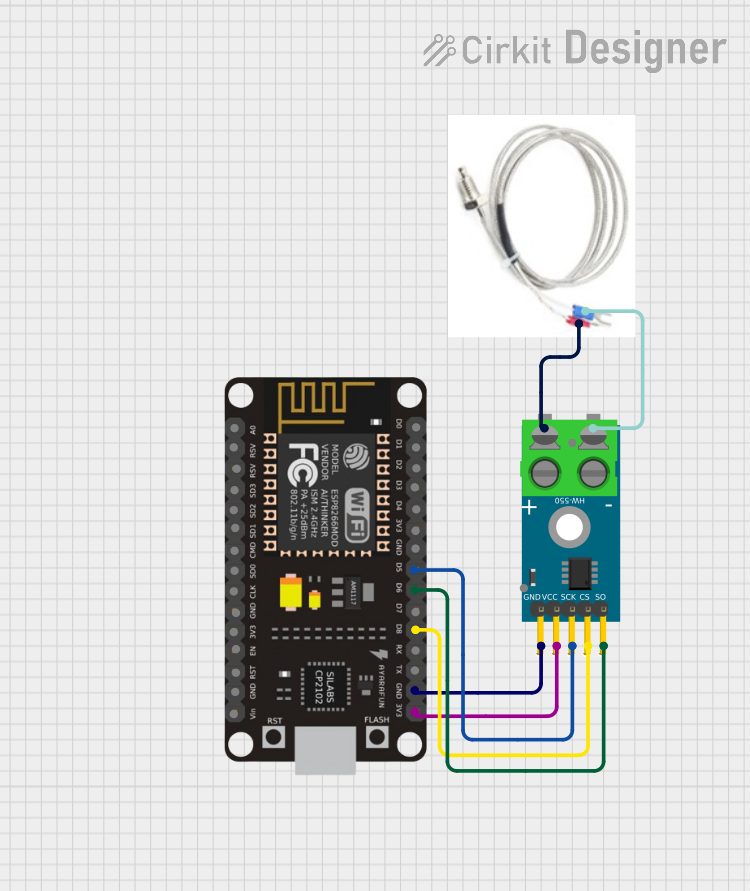

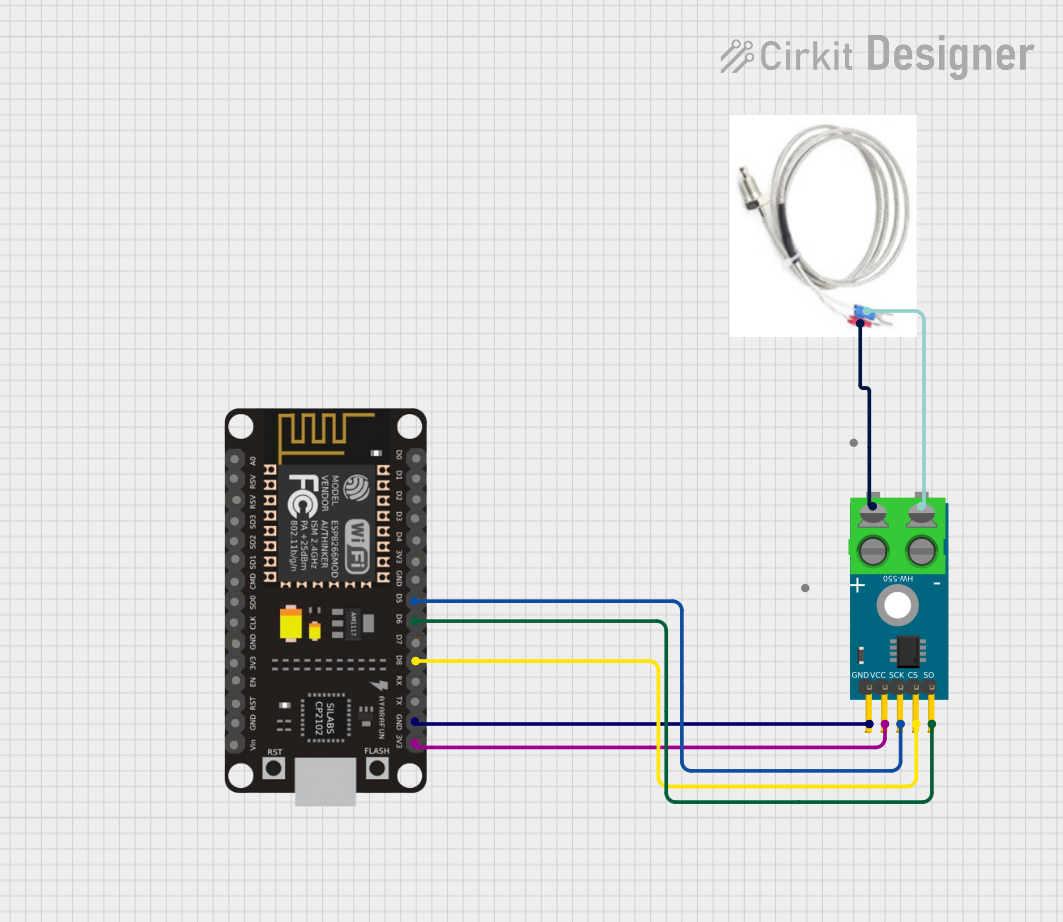

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Pt1000 Temperature sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Industrial process control and monitoring

- HVAC systems for temperature regulation

- Laboratory and scientific research

- Food and beverage processing

- Medical equipment for temperature sensing

Technical Specifications

The Pt1000 sensor is designed to provide accurate temperature readings over a wide range of operating conditions. Below are its key technical details:

| Parameter | Value |

|---|---|

| Resistance at 0°C | 1000 Ω |

| Temperature Range | -200°C to +850°C |

| Tolerance Class | Class A or Class B (varies by model) |

| Temperature Coefficient | ~0.00385 Ω/Ω/°C |

| Material | Platinum |

| Accuracy | ±(0.15 + 0.002 × |

| Self-Heating Coefficient | ~0.4°C/mW (in still air) |

Pin Configuration and Descriptions

The Pt1000 sensor typically comes in a 2-wire, 3-wire, or 4-wire configuration. Below is a description of each configuration:

2-Wire Configuration

| Pin | Description |

|---|---|

| Pin 1 | Platinum element connection (1) |

| Pin 2 | Platinum element connection (2) |

3-Wire Configuration

| Pin | Description |

|---|---|

| Pin 1 | Platinum element connection (1) |

| Pin 2 | Platinum element connection (2) |

| Pin 3 | Compensation lead |

4-Wire Configuration

| Pin | Description |

|---|---|

| Pin 1 | Platinum element connection (1) |

| Pin 2 | Platinum element connection (2) |

| Pin 3 | Compensation lead (1) |

| Pin 4 | Compensation lead (2) |

Usage Instructions

How to Use the Pt1000 in a Circuit

- Choose the Configuration: Determine whether a 2-wire, 3-wire, or 4-wire configuration is required based on the desired accuracy and application.

- For high-accuracy applications, use a 3-wire or 4-wire configuration to compensate for lead resistance.

- Connect to a Measurement Circuit: The Pt1000 sensor requires a current source and a voltage measurement circuit to determine resistance. Use a precision resistor and an operational amplifier for accurate readings.

- Interface with a Microcontroller: To interface with a microcontroller like an Arduino UNO, use an analog-to-digital converter (ADC) to measure the voltage across the sensor. A Wheatstone bridge circuit can also be used for better accuracy.

Example Arduino Code

Below is an example of how to interface a Pt1000 sensor with an Arduino UNO using a simple voltage divider circuit:

// Pt1000 Temperature Sensor Example with Arduino UNO

// This code reads the voltage from the Pt1000 sensor and calculates the temperature.

const int sensorPin = A0; // Analog pin connected to the voltage divider

const float R_ref = 1000.0; // Reference resistor value in ohms

const float T0 = 0.0; // Reference temperature in °C

const float R0 = 1000.0; // Resistance of Pt1000 at 0°C in ohms

const float alpha = 0.00385; // Temperature coefficient of Pt1000

void setup() {

Serial.begin(9600); // Initialize serial communication

}

void loop() {

int sensorValue = analogRead(sensorPin); // Read analog value

float voltage = sensorValue * (5.0 / 1023.0); // Convert to voltage

float R_pt1000 = (R_ref * voltage) / (5.0 - voltage); // Calculate sensor resistance

// Calculate temperature using the linear approximation formula

float temperature = (R_pt1000 - R0) / (R0 * alpha);

// Print the temperature to the Serial Monitor

Serial.print("Temperature: ");

Serial.print(temperature);

Serial.println(" °C");

delay(1000); // Wait 1 second before the next reading

}

Important Considerations

- Self-Heating: Minimize the current through the Pt1000 to reduce self-heating effects, which can cause measurement errors.

- Lead Resistance: For long cable runs, use a 3-wire or 4-wire configuration to compensate for lead resistance.

- Calibration: Periodically calibrate the sensor to maintain accuracy, especially in critical applications.

- Environmental Protection: Use appropriate enclosures or coatings to protect the sensor in harsh environments.

Troubleshooting and FAQs

Common Issues

Inaccurate Temperature Readings

- Cause: Lead resistance not compensated.

- Solution: Use a 3-wire or 4-wire configuration to eliminate lead resistance effects.

Fluctuating Readings

- Cause: Electrical noise or unstable power supply.

- Solution: Add decoupling capacitors and ensure a stable power source.

Sensor Damage

- Cause: Exposure to extreme temperatures or physical damage.

- Solution: Verify the operating temperature range and handle the sensor carefully.

Self-Heating Effects

- Cause: Excessive current through the sensor.

- Solution: Limit the current to a safe value (typically 1 mA or less).

FAQs

Can the Pt1000 be used with any microcontroller?

- Yes, as long as the microcontroller has an ADC and the appropriate interface circuitry.

What is the difference between Pt100 and Pt1000 sensors?

- The Pt1000 has a resistance of 1000 ohms at 0°C, while the Pt100 has 100 ohms. The Pt1000 is less affected by lead resistance, making it more suitable for long cable runs.

How do I protect the sensor in corrosive environments?

- Use a protective sheath or coating, such as stainless steel or Teflon, to shield the sensor.

What is the maximum cable length for a Pt1000 sensor?

- The maximum length depends on the configuration and application. For long distances, use a 3-wire or 4-wire setup to minimize errors.