How to Use Phidgets Motor Control : Examples, Pinouts, and Specs

Design with Phidgets Motor Control in Cirkit Designer

Design with Phidgets Motor Control in Cirkit DesignerIntroduction

The Phidgets Motor Control (Part ID: 1-Motor) is a versatile interface designed for controlling DC motors. It allows for precise speed and direction control, making it an essential component in robotics, automation, and other motor-driven projects. This motor controller is ideal for applications requiring smooth motor operation, such as conveyor systems, robotic arms, and automated vehicles.

With its user-friendly interface and robust design, the Phidgets Motor Control is suitable for both beginners and experienced engineers. It can be easily integrated into microcontroller-based systems, including Arduino, Raspberry Pi, and other development platforms.

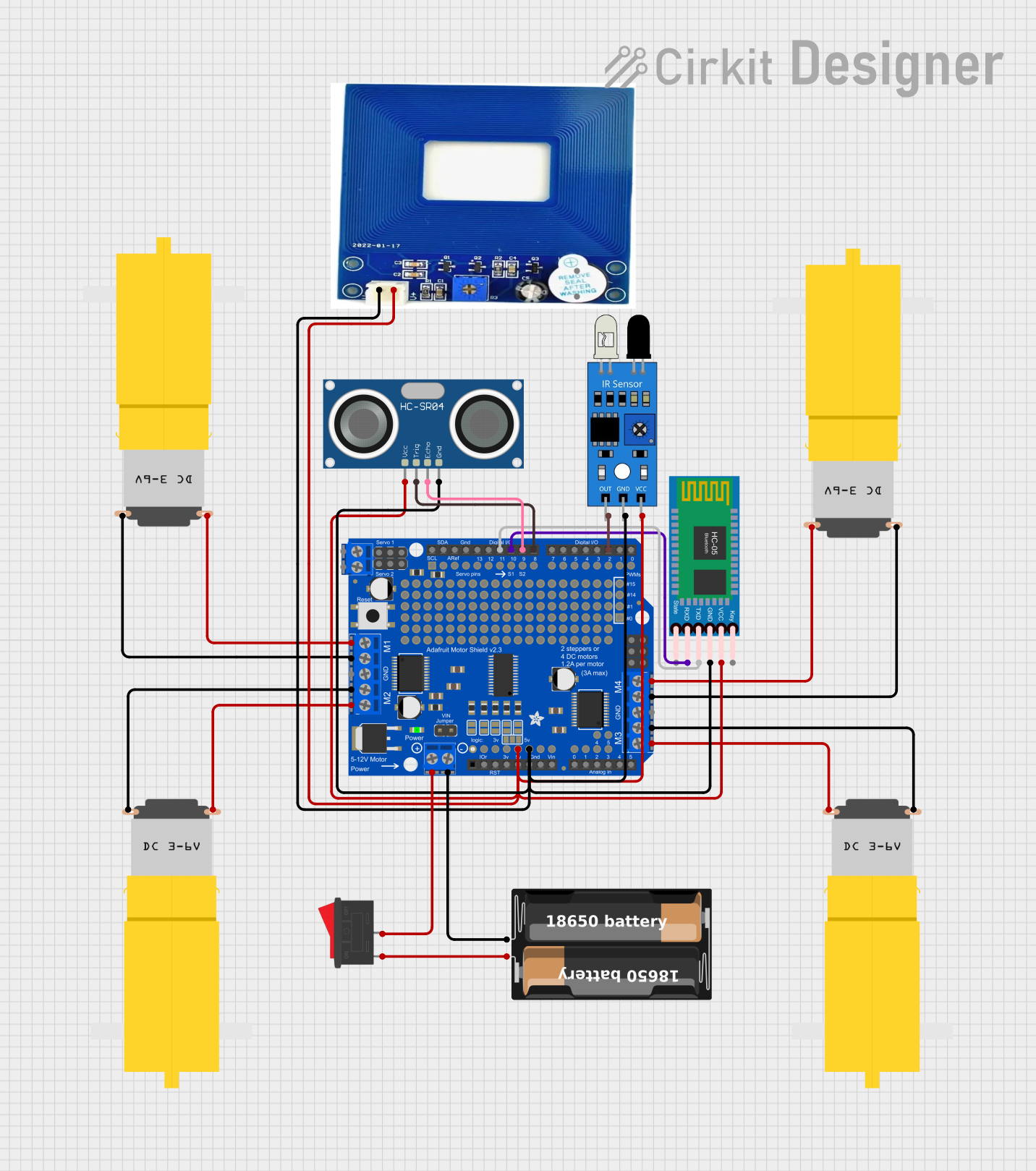

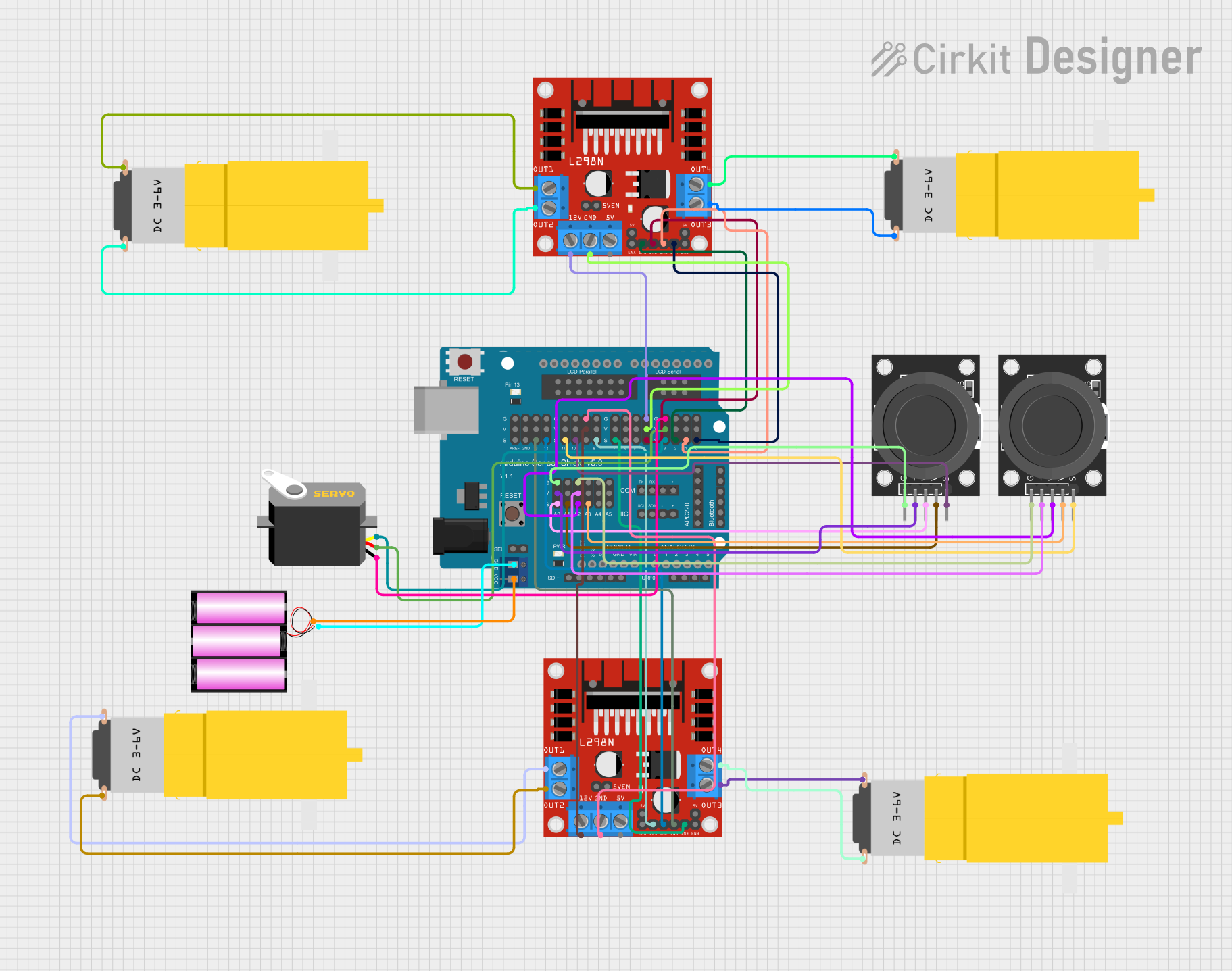

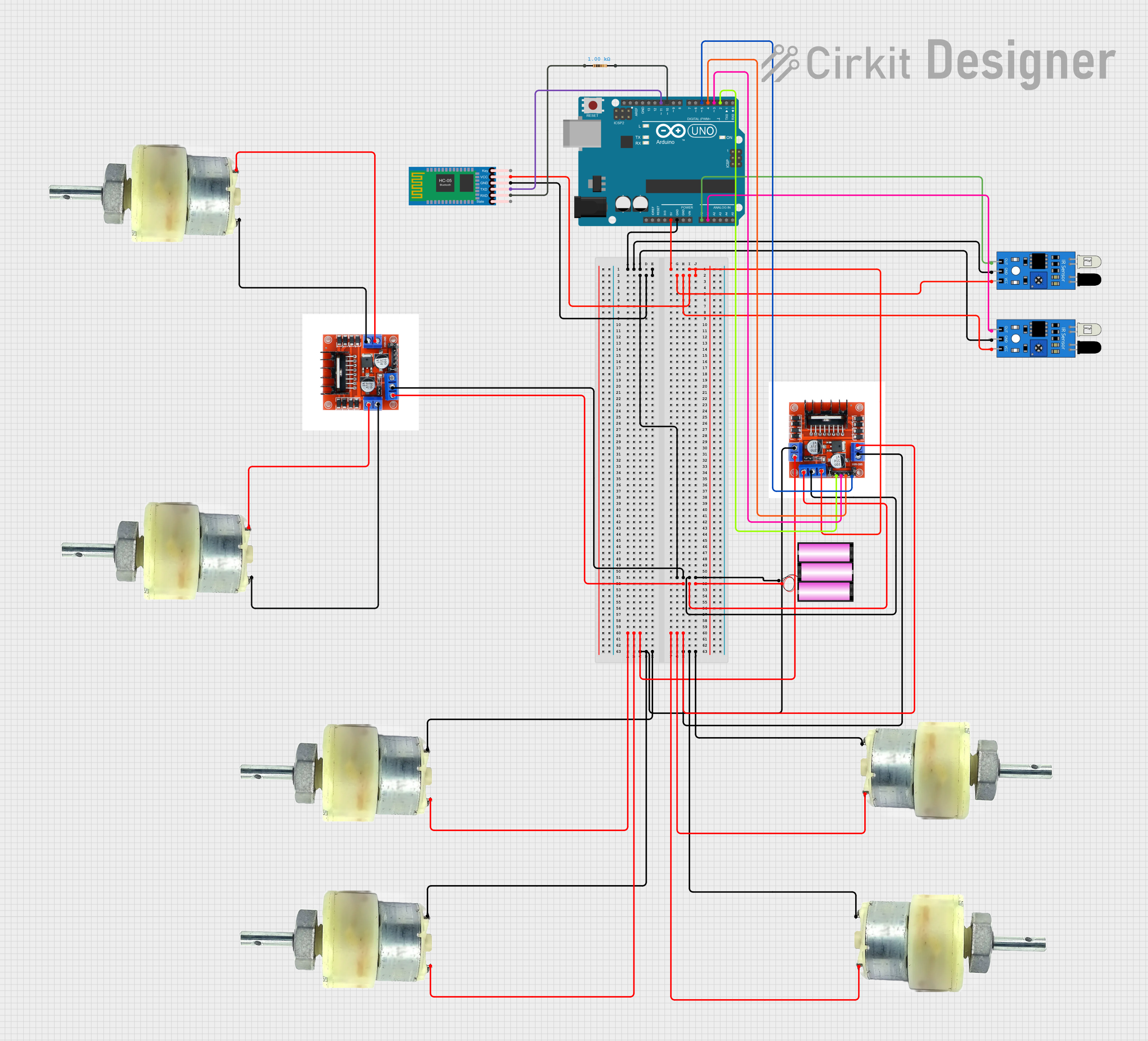

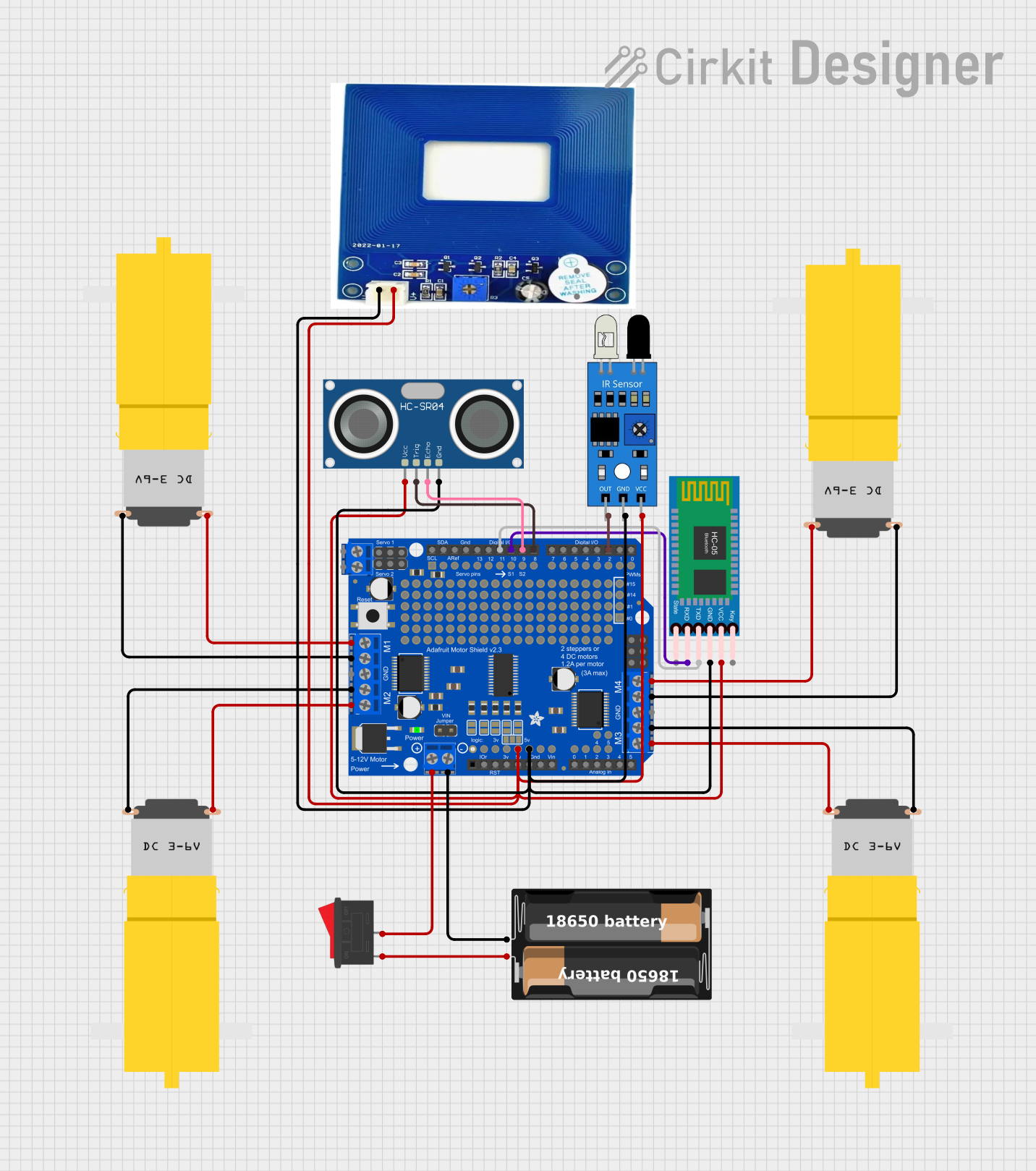

Explore Projects Built with Phidgets Motor Control

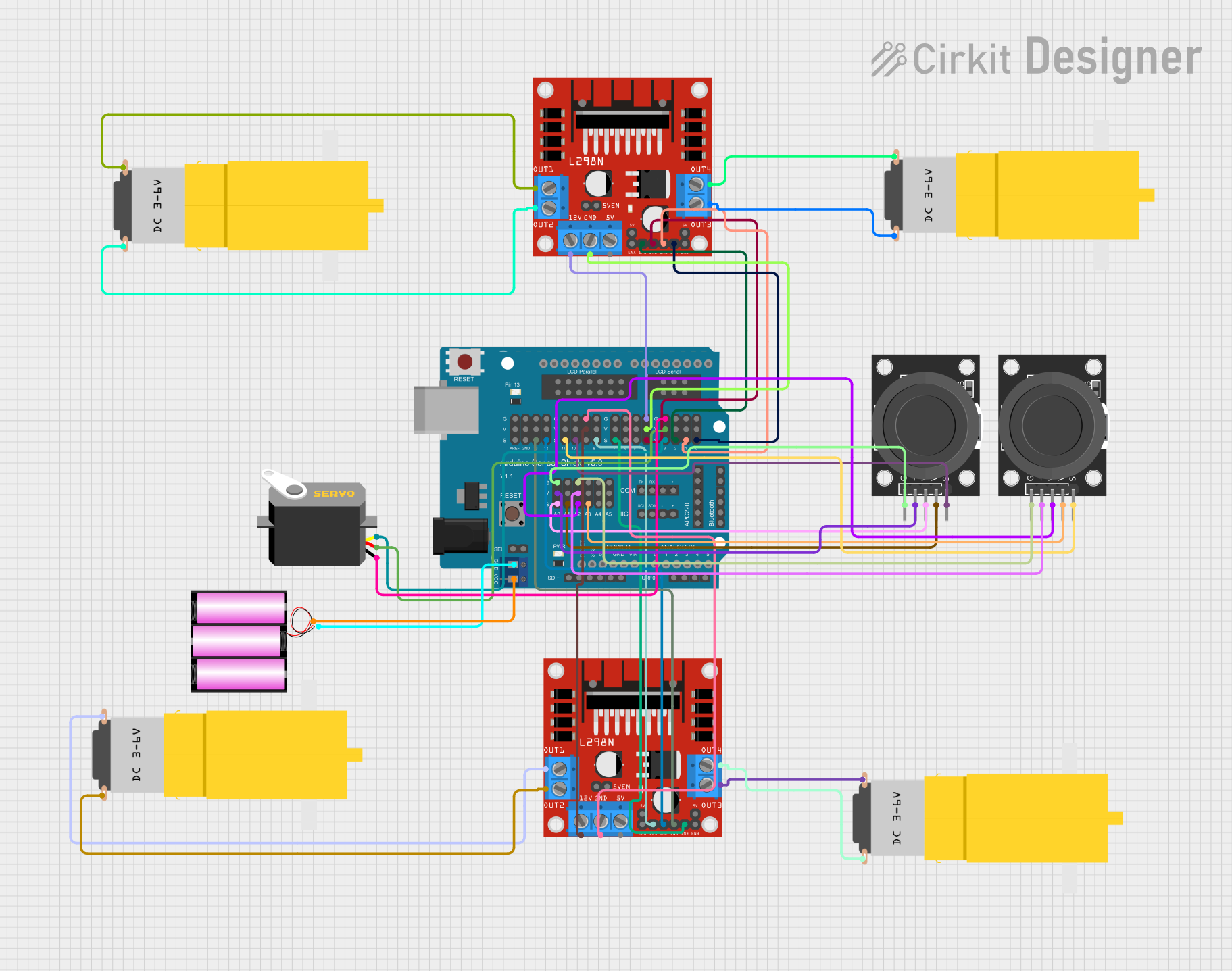

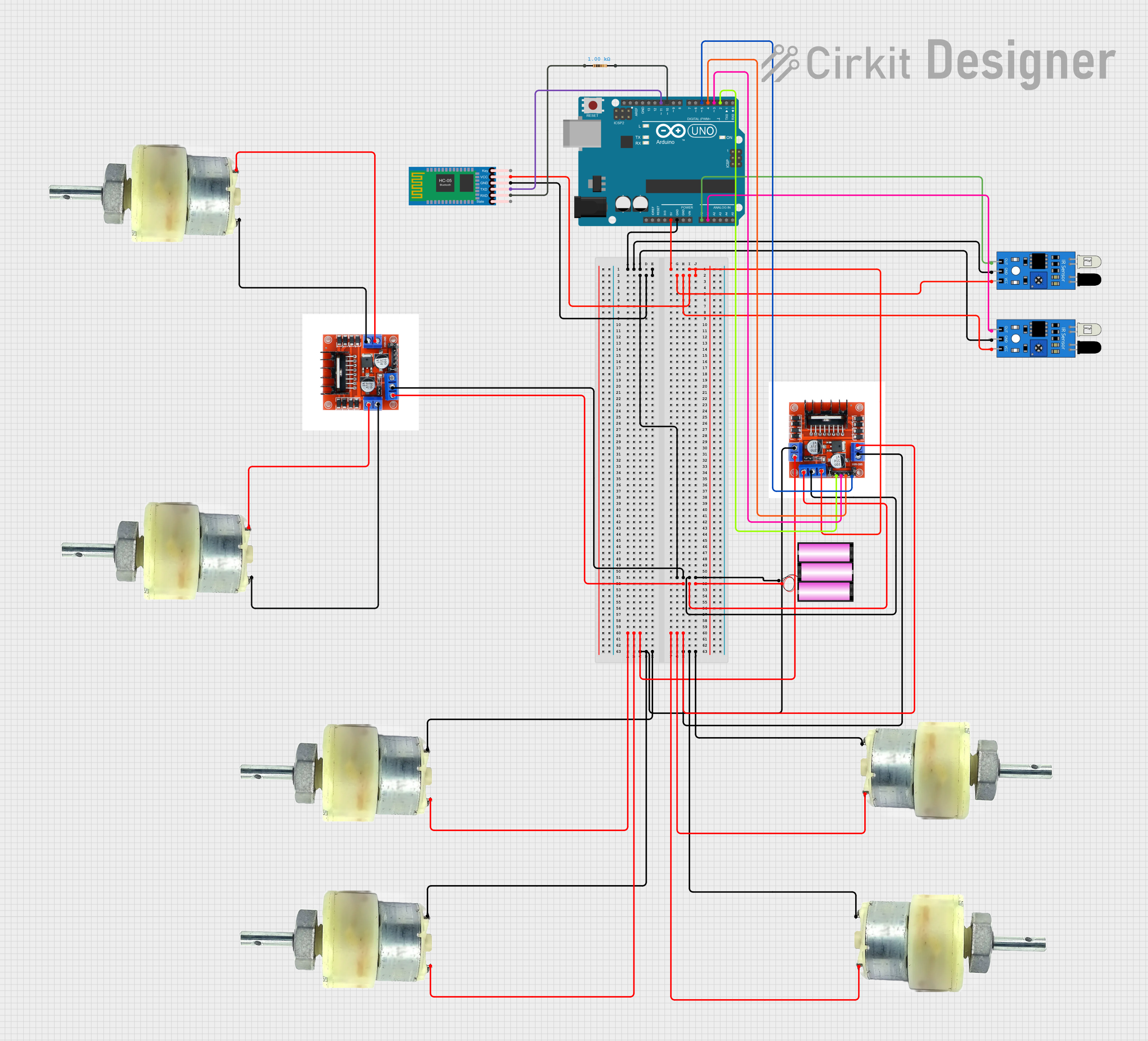

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Phidgets Motor Control

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the key technical details of the Phidgets Motor Control:

General Specifications

- Manufacturer: Phidgets

- Part ID: 1-Motor

- Input Voltage Range: 6V to 15V DC

- Maximum Continuous Current: 4A

- Peak Current: 5A (for short durations)

- Control Interface: USB or GPIO

- Motor Type Supported: Brushed DC motors

- Direction Control: Forward and reverse

- Speed Control: PWM (Pulse Width Modulation) with 0% to 100% duty cycle

- Operating Temperature: -20°C to 50°C

Pin Configuration and Descriptions

The Phidgets Motor Control has the following pin configuration:

| Pin Name | Description | Type |

|---|---|---|

| V+ | Positive motor power supply (6V-15V DC) | Power Input |

| GND | Ground connection | Power Input |

| M+ | Positive motor terminal | Motor Output |

| M- | Negative motor terminal | Motor Output |

| DIR | Direction control input (HIGH/LOW) | Digital Input |

| PWM | Speed control input (PWM signal) | Digital Input |

| USB | USB interface for PC control | Communication |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect a DC power supply (6V to 15V) to the

V+andGNDpins. Ensure the power supply can provide sufficient current for your motor. - Motor Connection: Connect the motor terminals to the

M+andM-pins. Ensure the motor is a brushed DC motor compatible with the controller. - Control Signals:

- Use the

DIRpin to control the motor's direction. Set it HIGH for forward and LOW for reverse. - Use the

PWMpin to control the motor's speed. Provide a PWM signal with a duty cycle between 0% (stopped) and 100% (full speed).

- Use the

- USB Control: Optionally, connect the USB interface to a PC for software-based control using the Phidgets API.

Important Considerations and Best Practices

- Heat Dissipation: The controller may heat up during operation. Ensure proper ventilation or use a heatsink if necessary.

- Current Limiting: Avoid exceeding the maximum continuous current rating (4A) to prevent damage.

- Signal Quality: Use a clean and stable PWM signal for precise speed control.

- Polarity: Double-check the polarity of the power supply and motor connections to avoid damage.

Example: Using with Arduino UNO

Below is an example of how to control the Phidgets Motor Control using an Arduino UNO:

// Define pin connections

const int dirPin = 7; // Direction control pin

const int pwmPin = 6; // PWM speed control pin

void setup() {

// Set pin modes

pinMode(dirPin, OUTPUT);

pinMode(pwmPin, OUTPUT);

}

void loop() {

// Set motor direction to forward

digitalWrite(dirPin, HIGH);

// Gradually increase motor speed

for (int speed = 0; speed <= 255; speed++) {

analogWrite(pwmPin, speed); // Send PWM signal to control speed

delay(20); // Wait for 20ms

}

// Hold at full speed for 2 seconds

delay(2000);

// Gradually decrease motor speed

for (int speed = 255; speed >= 0; speed--) {

analogWrite(pwmPin, speed); // Decrease PWM signal

delay(20); // Wait for 20ms

}

// Set motor direction to reverse

digitalWrite(dirPin, LOW);

// Repeat the same speed ramp-up and ramp-down process

for (int speed = 0; speed <= 255; speed++) {

analogWrite(pwmPin, speed);

delay(20);

}

delay(2000);

for (int speed = 255; speed >= 0; speed--) {

analogWrite(pwmPin, speed);

delay(20);

}

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Running:

- Cause: Incorrect power supply or loose connections.

- Solution: Verify the power supply voltage and current. Check all connections.

Motor Running in the Wrong Direction:

- Cause: Incorrect

DIRpin signal or reversed motor connections. - Solution: Check the

DIRpin signal. Swap the motor connections if necessary.

- Cause: Incorrect

Motor Speed Not Changing:

- Cause: PWM signal not being sent or incorrect duty cycle.

- Solution: Verify the PWM signal using an oscilloscope or multimeter.

Controller Overheating:

- Cause: Exceeding the maximum current rating or poor ventilation.

- Solution: Reduce the motor load or improve ventilation.

FAQs

Can I use this controller with a stepper motor? No, the Phidgets Motor Control is designed for brushed DC motors only.

What software can I use with the USB interface? You can use the Phidgets API, which supports multiple programming languages, including Python, C++, and Java.

Is reverse polarity protection included? No, ensure correct polarity to avoid damaging the controller.

Can I control multiple motors with one controller? No, this controller is designed for a single motor. Use additional controllers for multiple motors.

This documentation provides a comprehensive guide to using the Phidgets Motor Control effectively. For further assistance, refer to the official Phidgets support resources.