How to Use ADXL345: Examples, Pinouts, and Specs

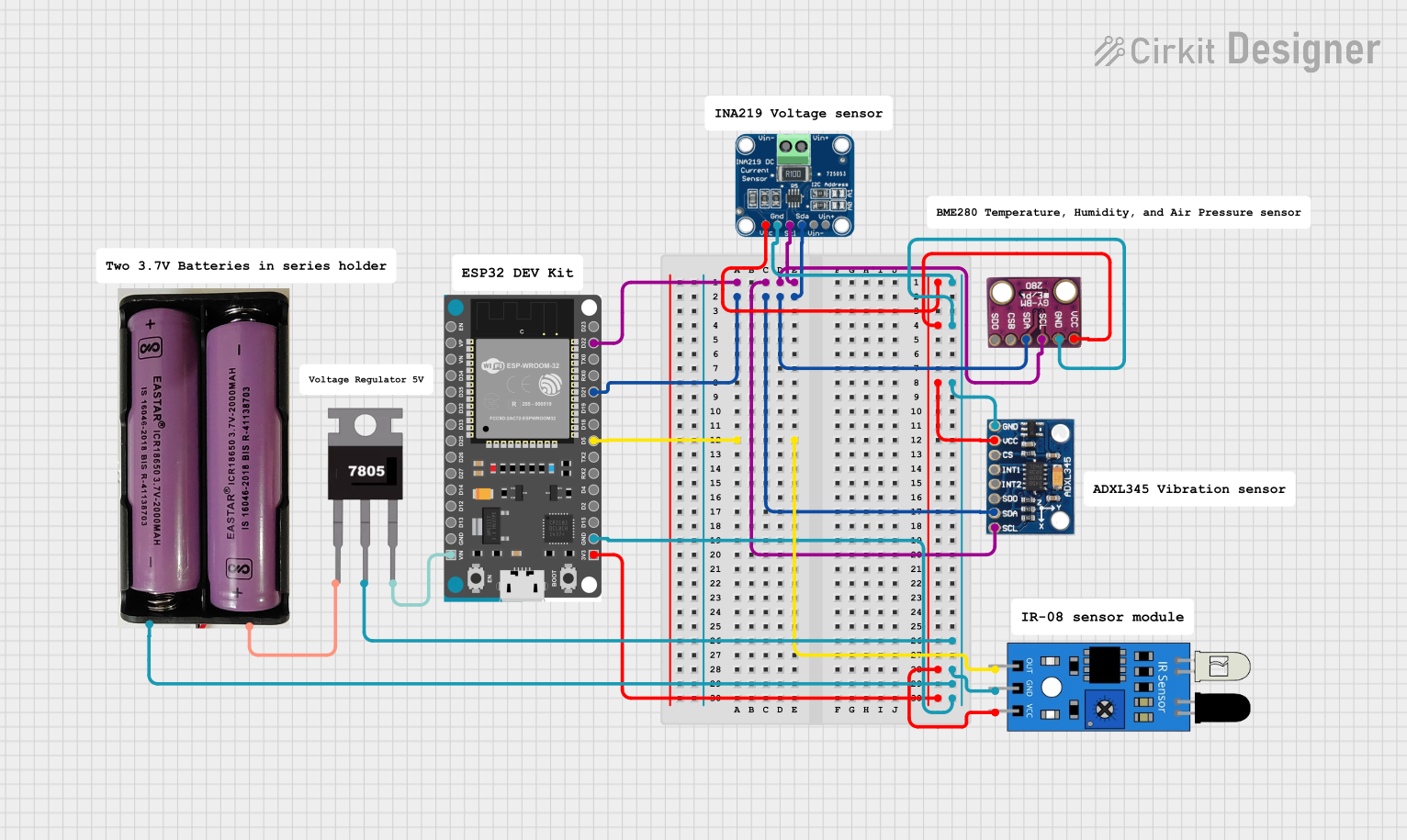

Design with ADXL345 in Cirkit Designer

Design with ADXL345 in Cirkit DesignerIntroduction

The ADXL345 is a small, thin, low-power, 3-axis accelerometer with a digital output. It is capable of measuring acceleration in three dimensions (X, Y, and Z axes) with high resolution (13-bit) and a wide measurement range of ±2 g, ±4 g, ±8 g, or ±16 g. The device communicates via I²C or SPI interfaces, making it versatile and easy to integrate into a variety of systems.

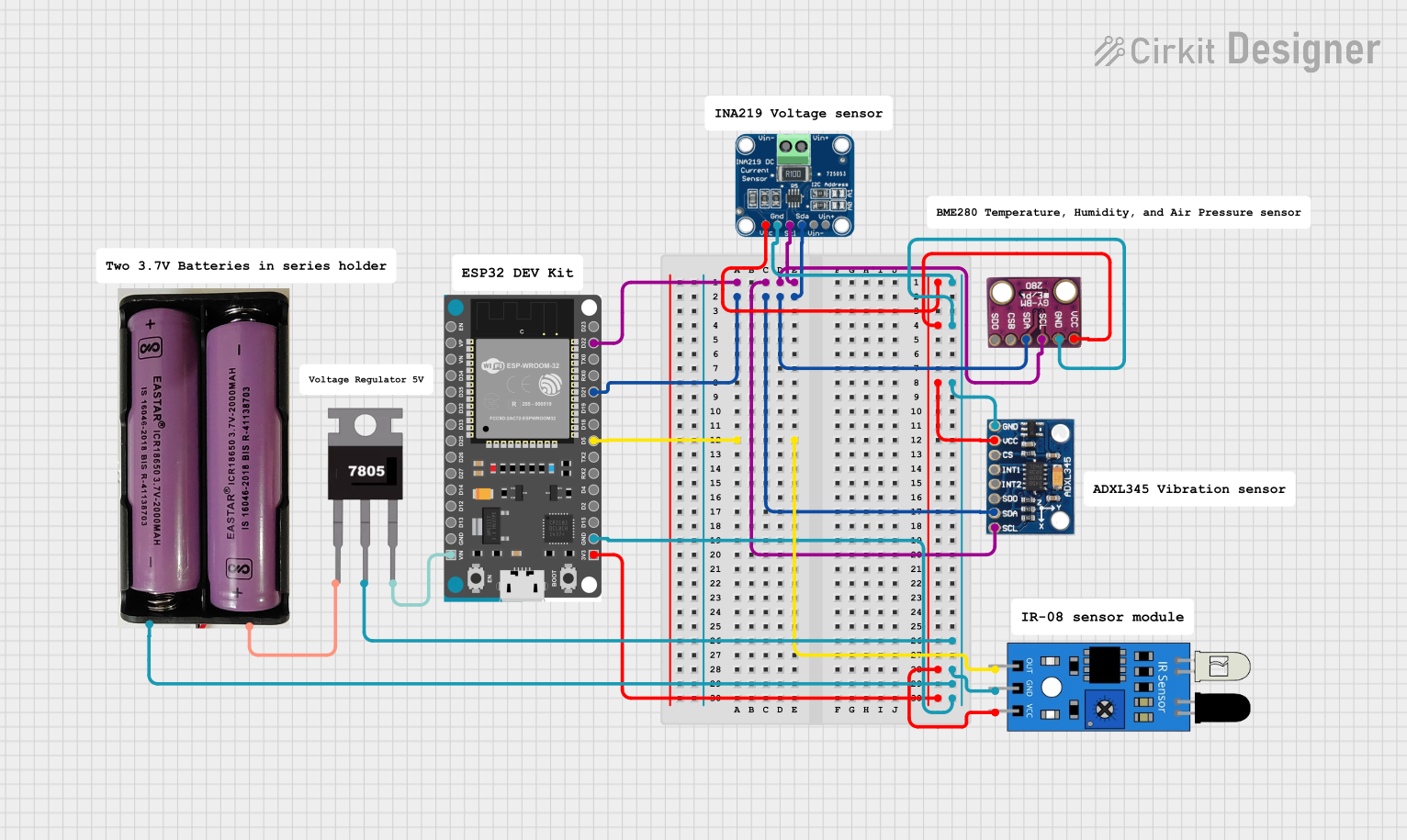

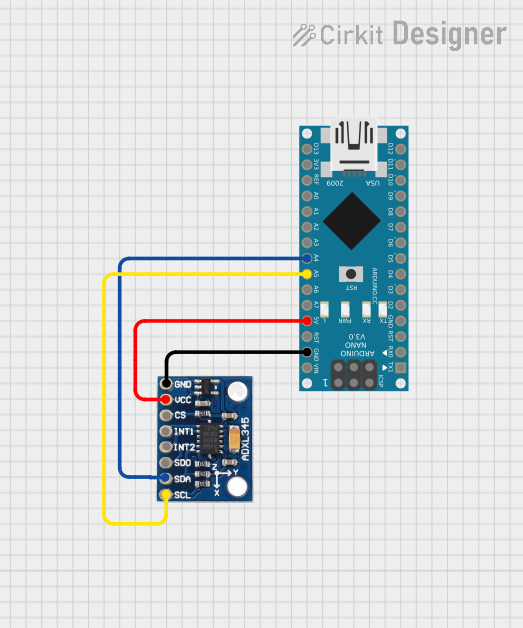

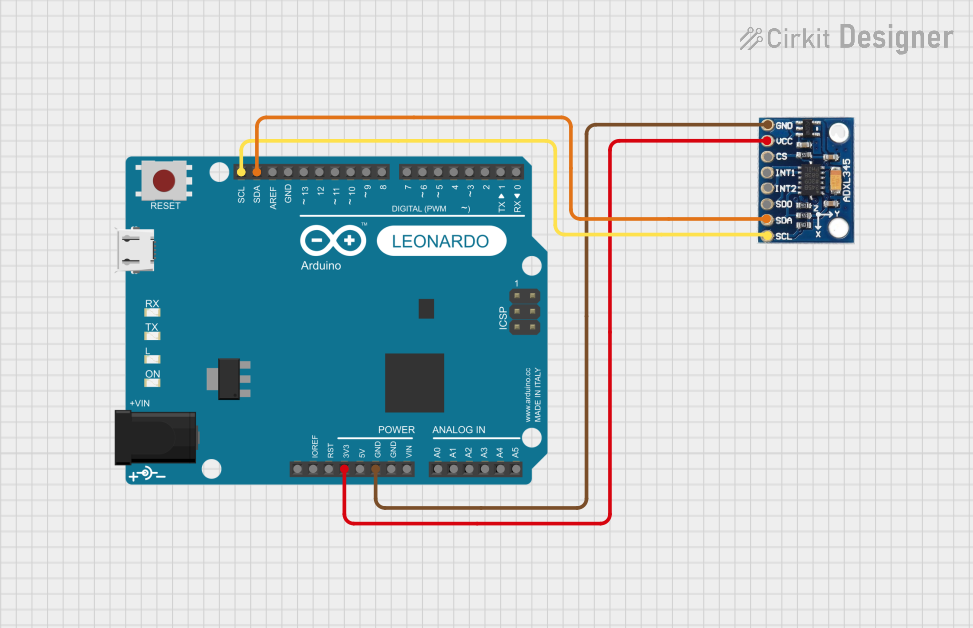

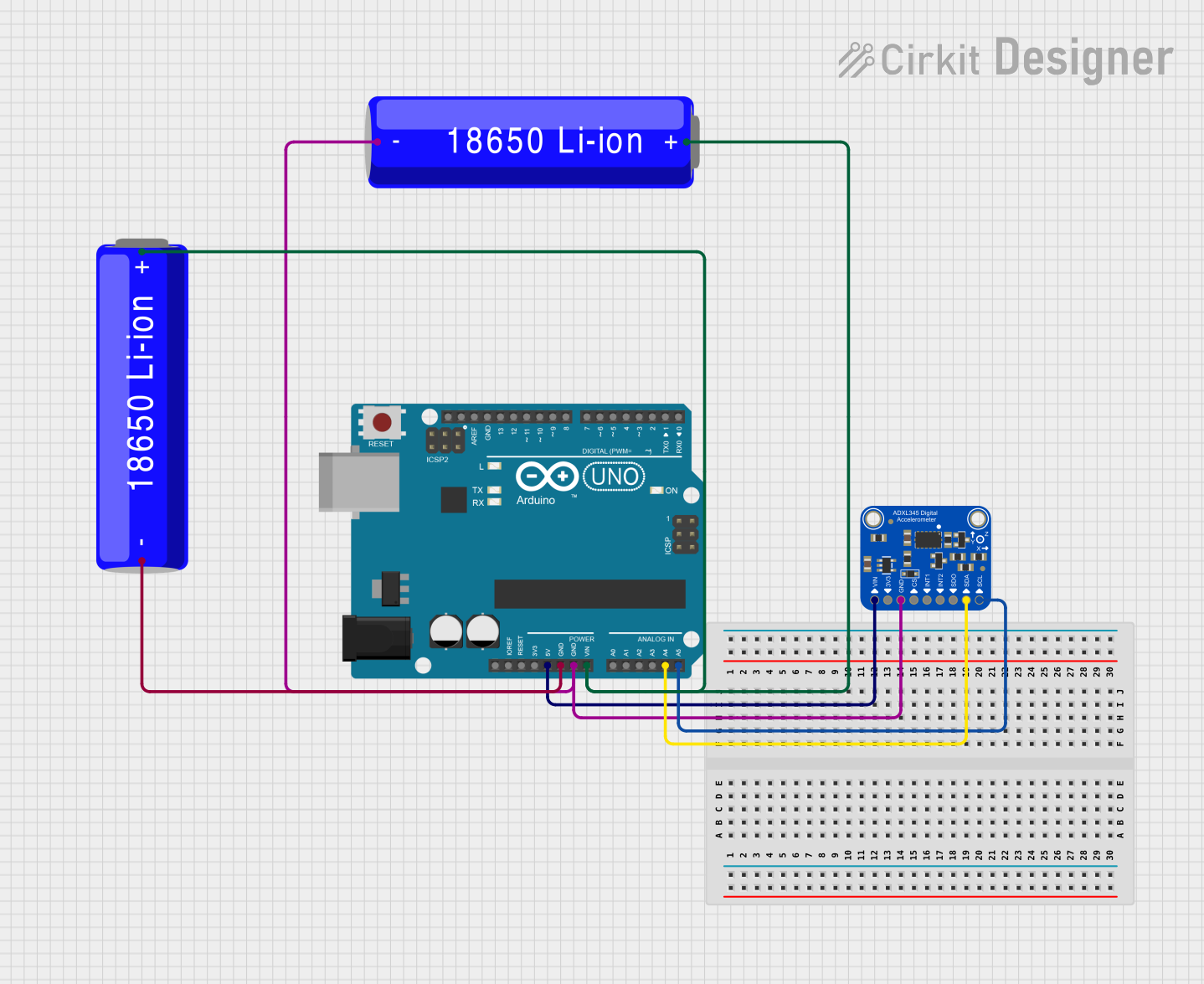

Explore Projects Built with ADXL345

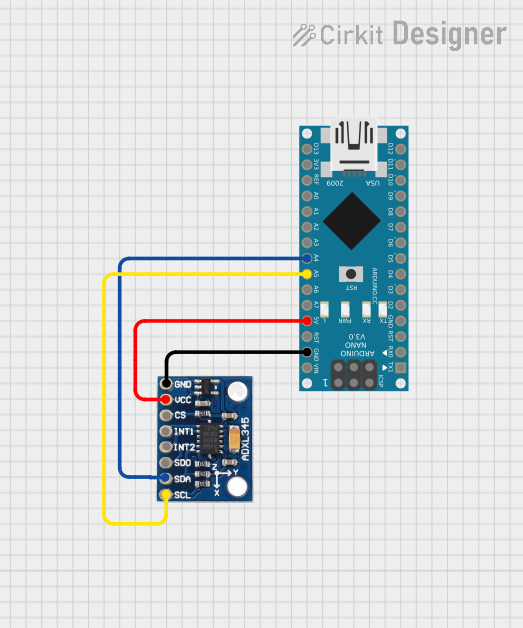

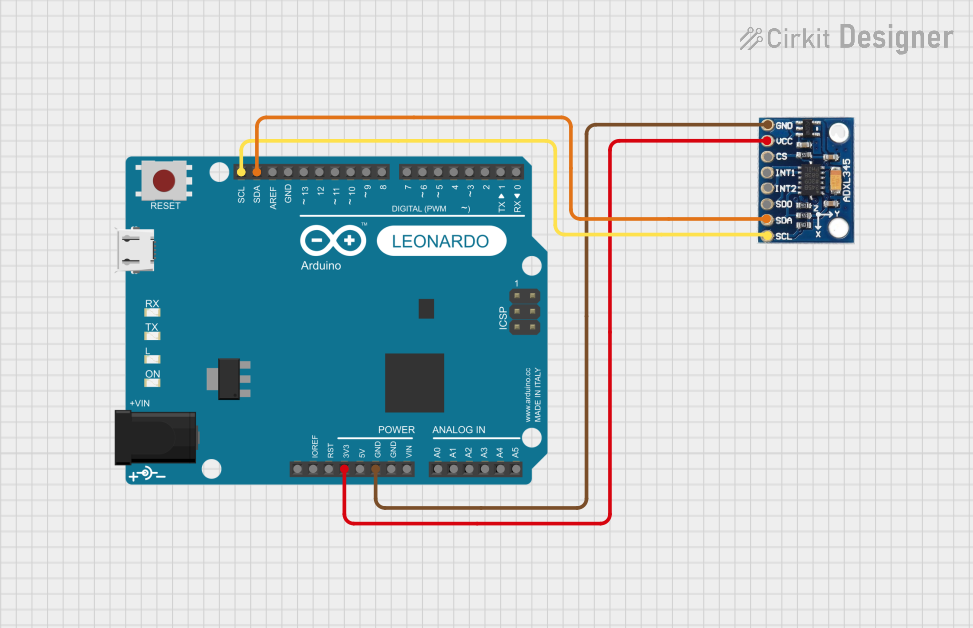

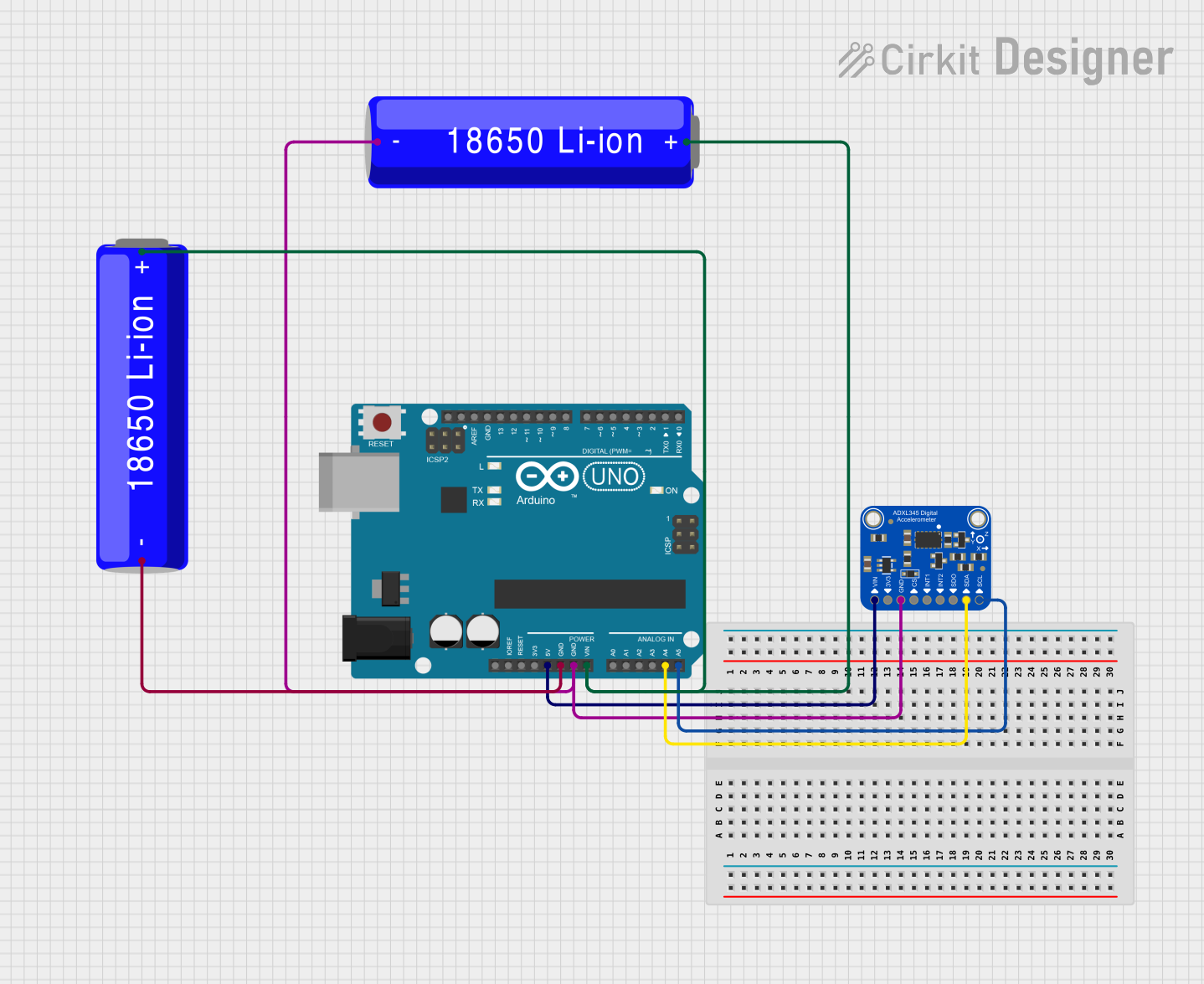

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with ADXL345

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Mobile devices for screen orientation and motion detection

- Wearable technology for activity tracking

- Gaming controllers for motion sensing

- Robotics for tilt and vibration measurement

- Industrial equipment for vibration monitoring

- Automotive systems for impact detection and navigation

Technical Specifications

The ADXL345 is designed for low-power operation and high performance. Below are its key technical details:

| Parameter | Value |

|---|---|

| Supply Voltage (VDD) | 2.0 V to 3.6 V |

| I/O Voltage (VDDIO) | 1.7 V to VDD |

| Measurement Range | ±2 g, ±4 g, ±8 g, ±16 g |

| Resolution | 13-bit |

| Communication Interface | I²C (up to 400 kHz) or SPI (up to 5 MHz) |

| Power Consumption | 40 µA in measurement mode, 0.1 µA in standby |

| Operating Temperature Range | -40°C to +85°C |

| Dimensions | 3 mm × 5 mm × 1 mm (L × W × H) |

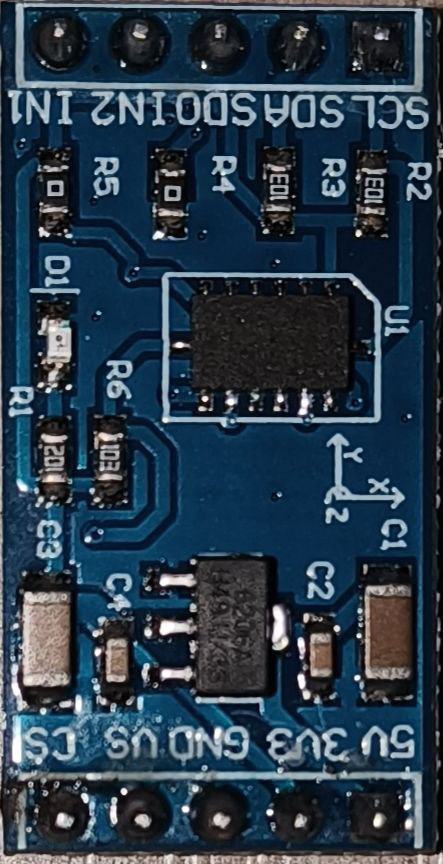

Pin Configuration and Descriptions

The ADXL345 is typically available in a 14-pin LGA package. Below is the pinout and description:

| Pin | Name | Description |

|---|---|---|

| 1 | VDD | Power supply (2.0 V to 3.6 V) |

| 2 | GND | Ground |

| 3 | CS | Chip Select (SPI mode) or I²C Address Select |

| 4 | INT1 | Interrupt 1 output |

| 5 | INT2 | Interrupt 2 output |

| 6 | SCL/SCLK | I²C Clock / SPI Serial Clock |

| 7 | SDA/SDI/SDO | I²C Data / SPI Data In / Data Out |

| 8-14 | NC | No Connect (leave unconnected) |

Usage Instructions

How to Use the ADXL345 in a Circuit

- Power Supply: Connect the VDD pin to a 3.3 V power source and the GND pin to ground.

- Communication Interface: Choose between I²C or SPI:

- For I²C, connect the SCL and SDA pins to the corresponding I²C lines on your microcontroller.

- For SPI, connect the SCLK, SDI, and CS pins to the SPI lines on your microcontroller.

- Interrupts: Use the INT1 and INT2 pins to handle interrupts for specific events (e.g., free-fall detection, activity detection).

- Pull-Up Resistors: For I²C communication, use pull-up resistors (typically 4.7 kΩ) on the SCL and SDA lines.

- Bypass Capacitor: Place a 0.1 µF ceramic capacitor close to the VDD pin for power supply decoupling.

Important Considerations and Best Practices

- Voltage Levels: Ensure the I/O voltage levels match your microcontroller's logic levels.

- Measurement Range: Configure the measurement range (±2 g, ±4 g, etc.) based on your application requirements.

- Data Rate: Set an appropriate output data rate (ODR) to balance power consumption and performance.

- Mounting: Minimize mechanical stress and vibrations during mounting to avoid measurement errors.

Example Code for Arduino UNO

Below is an example of how to interface the ADXL345 with an Arduino UNO using I²C:

#include <Wire.h> // Include the Wire library for I²C communication

#define ADXL345_ADDRESS 0x53 // I²C address of the ADXL345

#define POWER_CTL 0x2D // Power control register

#define DATA_FORMAT 0x31 // Data format register

#define DATAX0 0x32 // X-axis data register (low byte)

// Function to initialize the ADXL345

void setupADXL345() {

Wire.begin(); // Initialize I²C communication

Wire.beginTransmission(ADXL345_ADDRESS);

Wire.write(POWER_CTL); // Select the power control register

Wire.write(0x08); // Set the device to measurement mode

Wire.endTransmission();

Wire.beginTransmission(ADXL345_ADDRESS);

Wire.write(DATA_FORMAT); // Select the data format register

Wire.write(0x01); // Set range to ±4 g

Wire.endTransmission();

}

void setup() {

Serial.begin(9600); // Initialize serial communication

setupADXL345(); // Initialize the ADXL345

}

void loop() {

int16_t x, y, z;

// Read X-axis data

Wire.beginTransmission(ADXL345_ADDRESS);

Wire.write(DATAX0); // Request starting from the X-axis low byte

Wire.endTransmission(false);

Wire.requestFrom(ADXL345_ADDRESS, 6); // Request 6 bytes (X, Y, Z)

if (Wire.available() == 6) {

x = Wire.read() | (Wire.read() << 8); // Combine low and high bytes

y = Wire.read() | (Wire.read() << 8);

z = Wire.read() | (Wire.read() << 8);

}

// Print the acceleration values

Serial.print("X: "); Serial.print(x);

Serial.print(" Y: "); Serial.print(y);

Serial.print(" Z: "); Serial.println(z);

delay(500); // Wait for 500 ms

}

Troubleshooting and FAQs

Common Issues and Solutions

No Communication with the ADXL345

- Cause: Incorrect I²C address or wiring.

- Solution: Verify the I²C address (default is 0x53) and check all connections.

Incorrect or No Data Output

- Cause: Device not in measurement mode.

- Solution: Ensure the POWER_CTL register is set to enable measurement mode.

High Noise in Readings

- Cause: Poor power supply decoupling or mechanical vibrations.

- Solution: Add a 0.1 µF capacitor near the VDD pin and minimize external vibrations.

Interrupts Not Triggering

- Cause: Interrupts not configured correctly.

- Solution: Verify the interrupt configuration registers and ensure the INT1/INT2 pins are connected.

FAQs

Q: Can the ADXL345 operate at 5 V?

A: No, the maximum supply voltage is 3.6 V. Use a voltage regulator or level shifter if needed.Q: How do I change the measurement range?

A: Write to the DATA_FORMAT register to set the desired range (±2 g, ±4 g, etc.).Q: What is the maximum sampling rate?

A: The ADXL345 supports a maximum output data rate of 3200 Hz.Q: Can I use both I²C and SPI simultaneously?

A: No, you must choose one communication interface at a time.