How to Use Peristaltic Pump: Examples, Pinouts, and Specs

Design with Peristaltic Pump in Cirkit Designer

Design with Peristaltic Pump in Cirkit DesignerIntroduction

A peristaltic pump is a versatile and reliable component used in various applications where contamination-free pumping is required. It operates on the principle of positive displacement, using rollers or shoes to compress and release a flexible tube, creating a vacuum that draws fluid through the tube. This design ensures that the fluid only contacts the inside of the tubing, preventing cross-contamination and making the pump ideal for handling sensitive, sterile, or aggressive fluids.

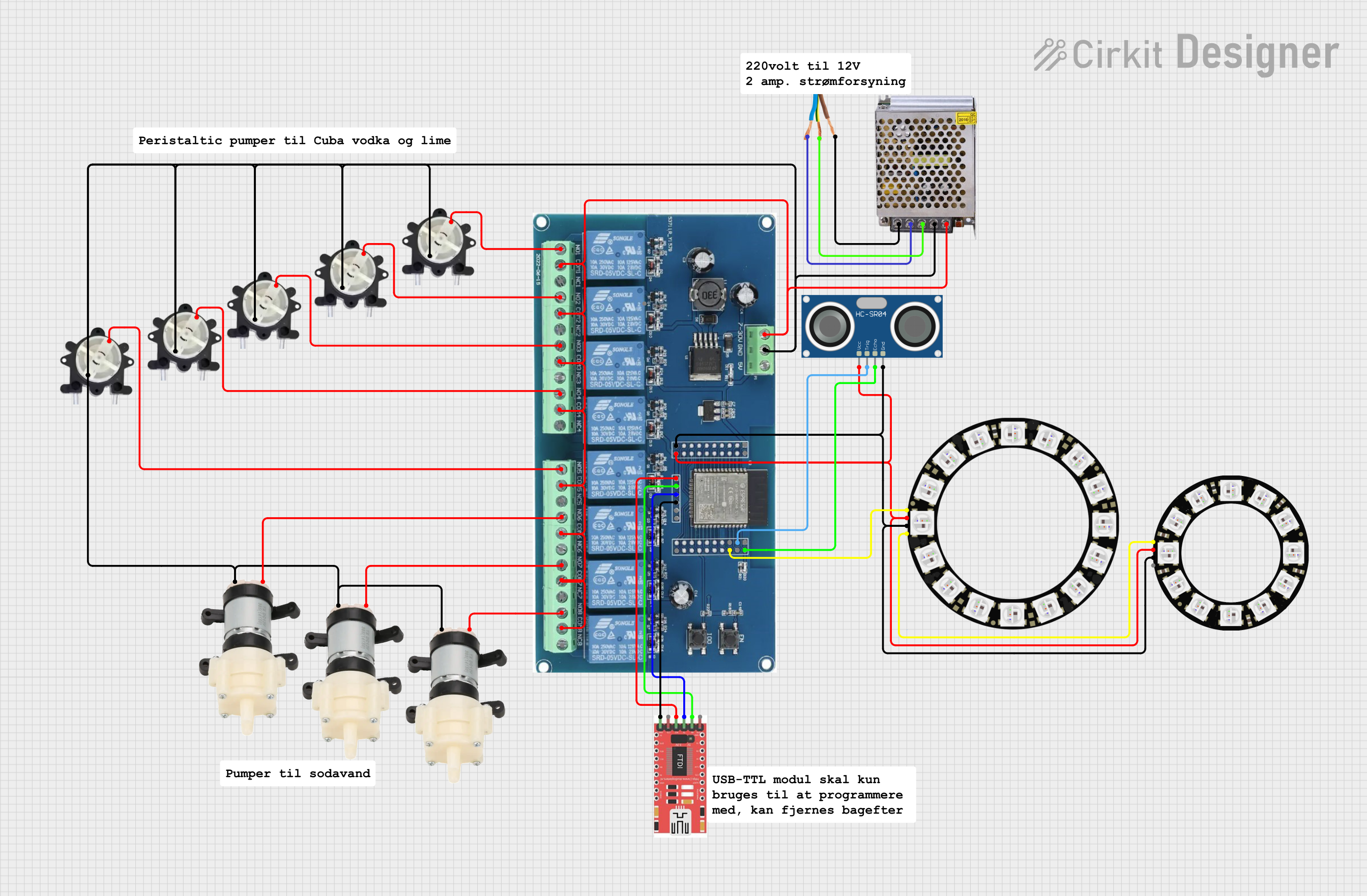

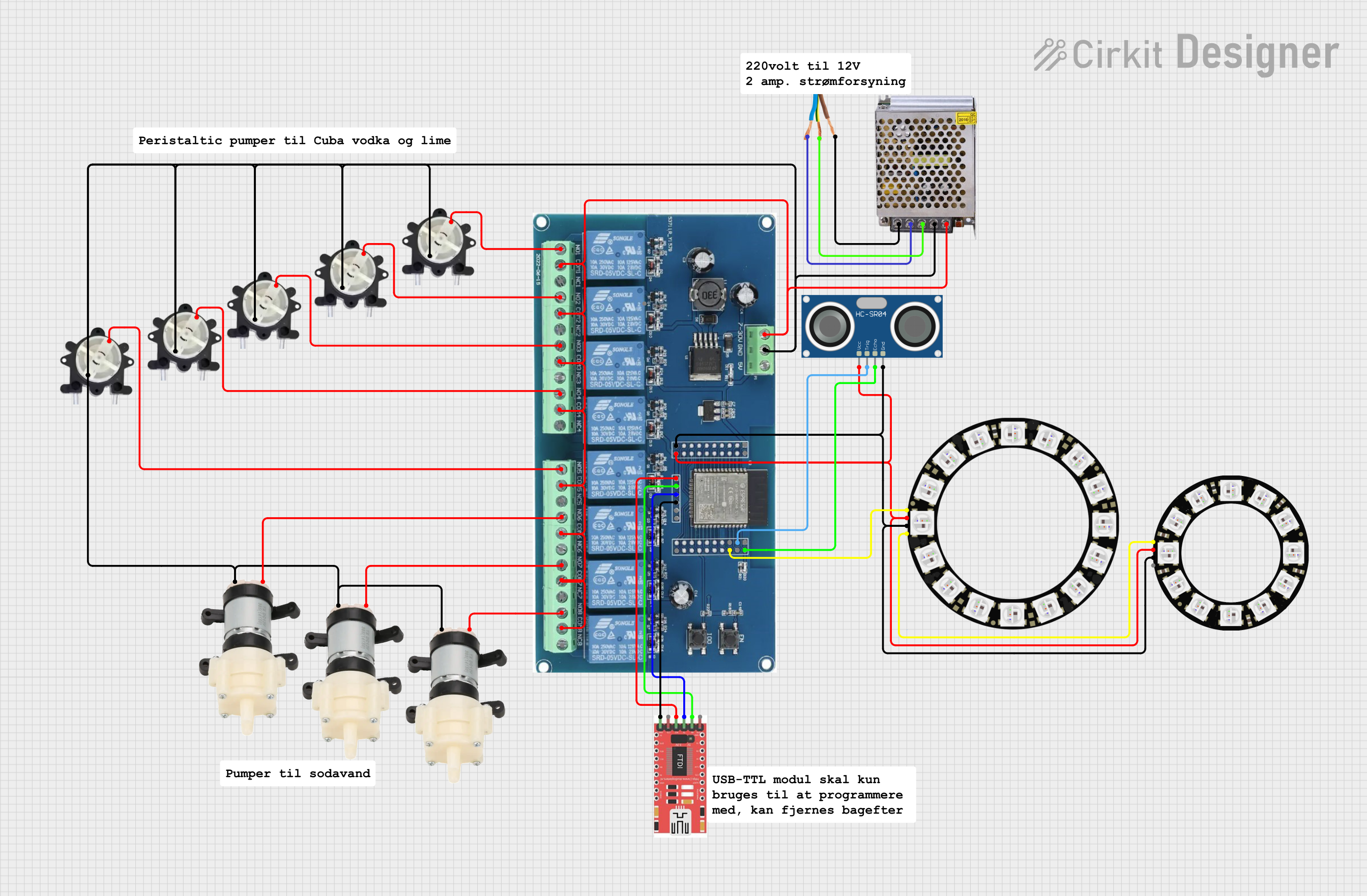

Explore Projects Built with Peristaltic Pump

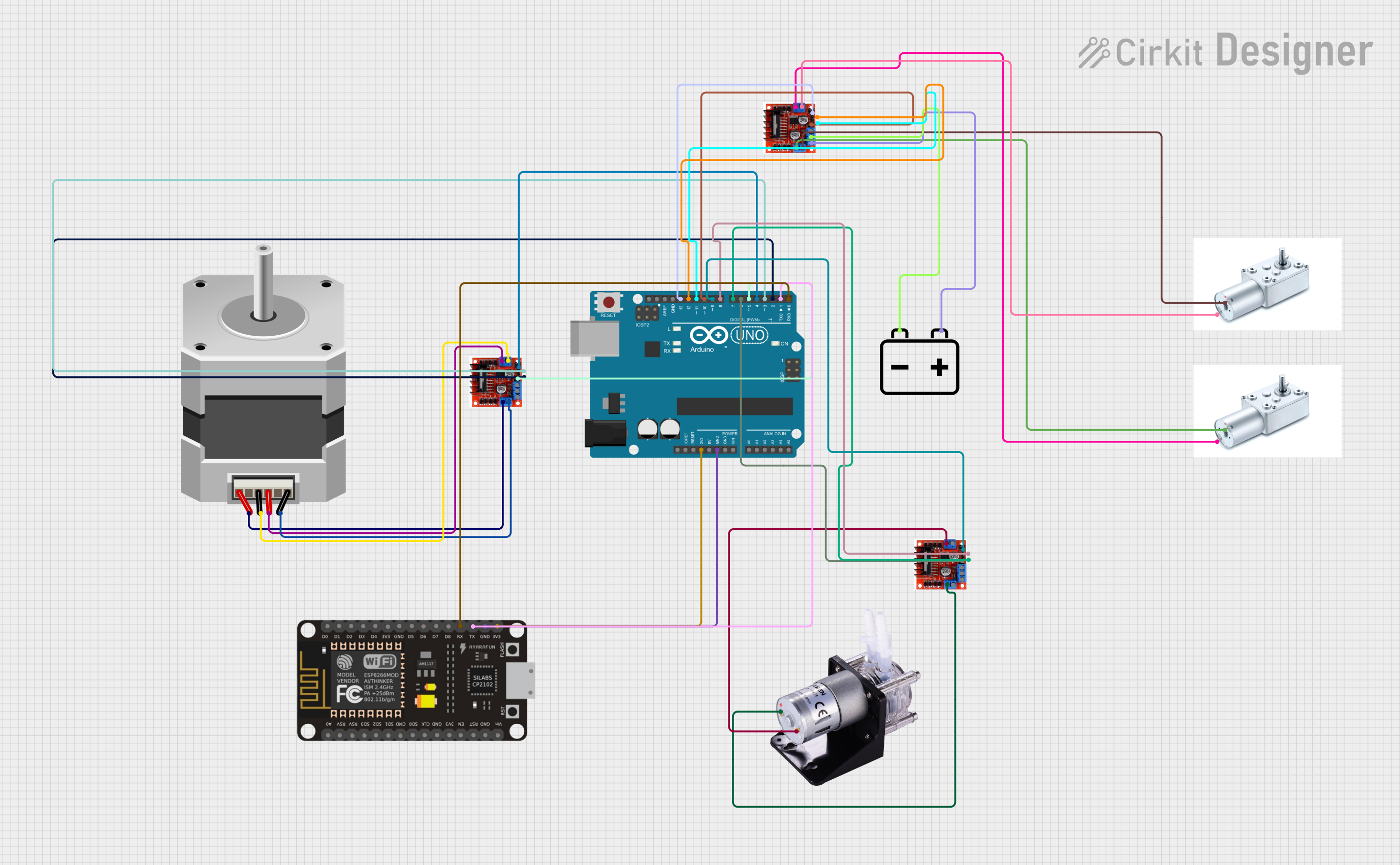

Open Project in Cirkit Designer

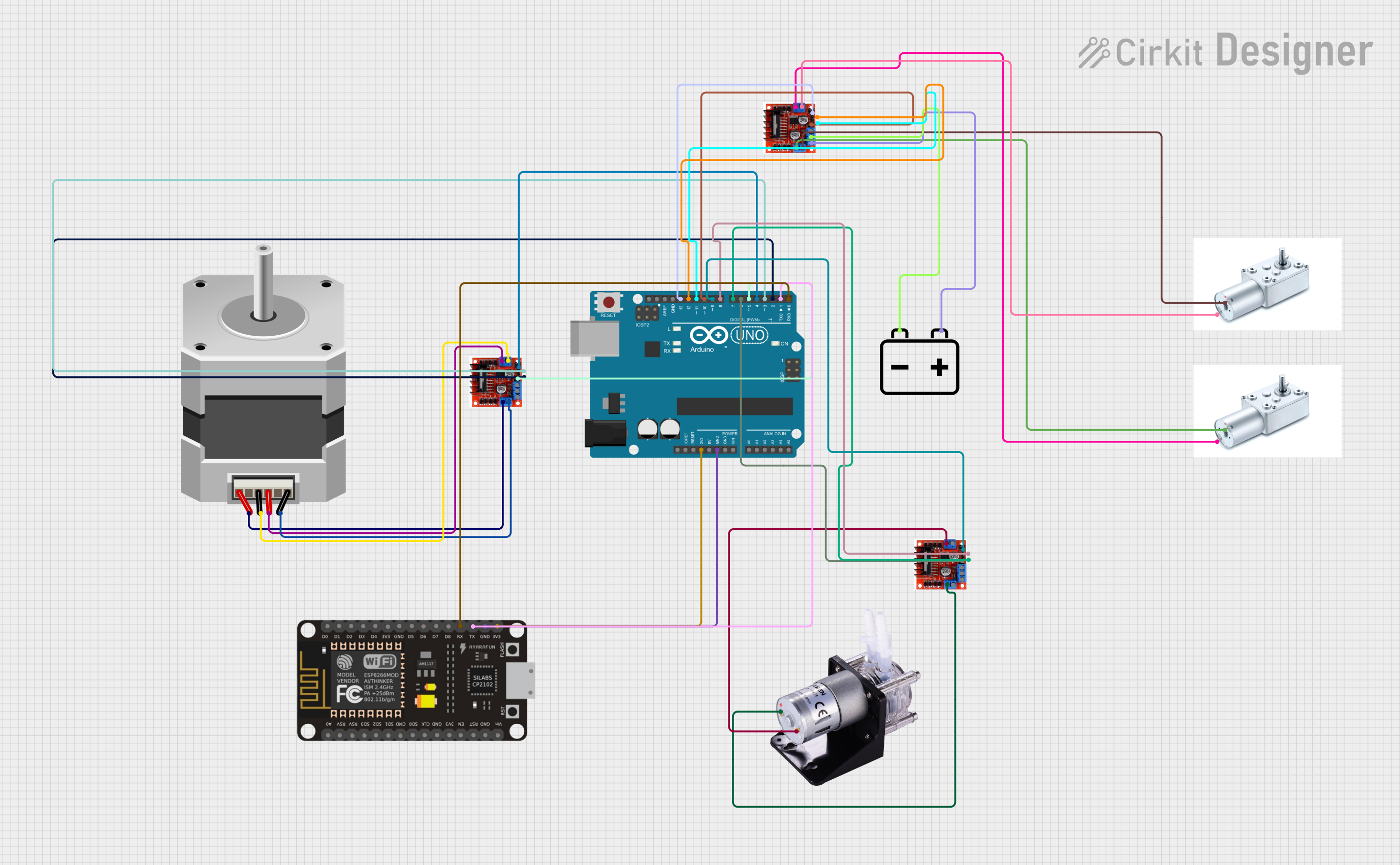

Open Project in Cirkit Designer

Open Project in Cirkit Designer

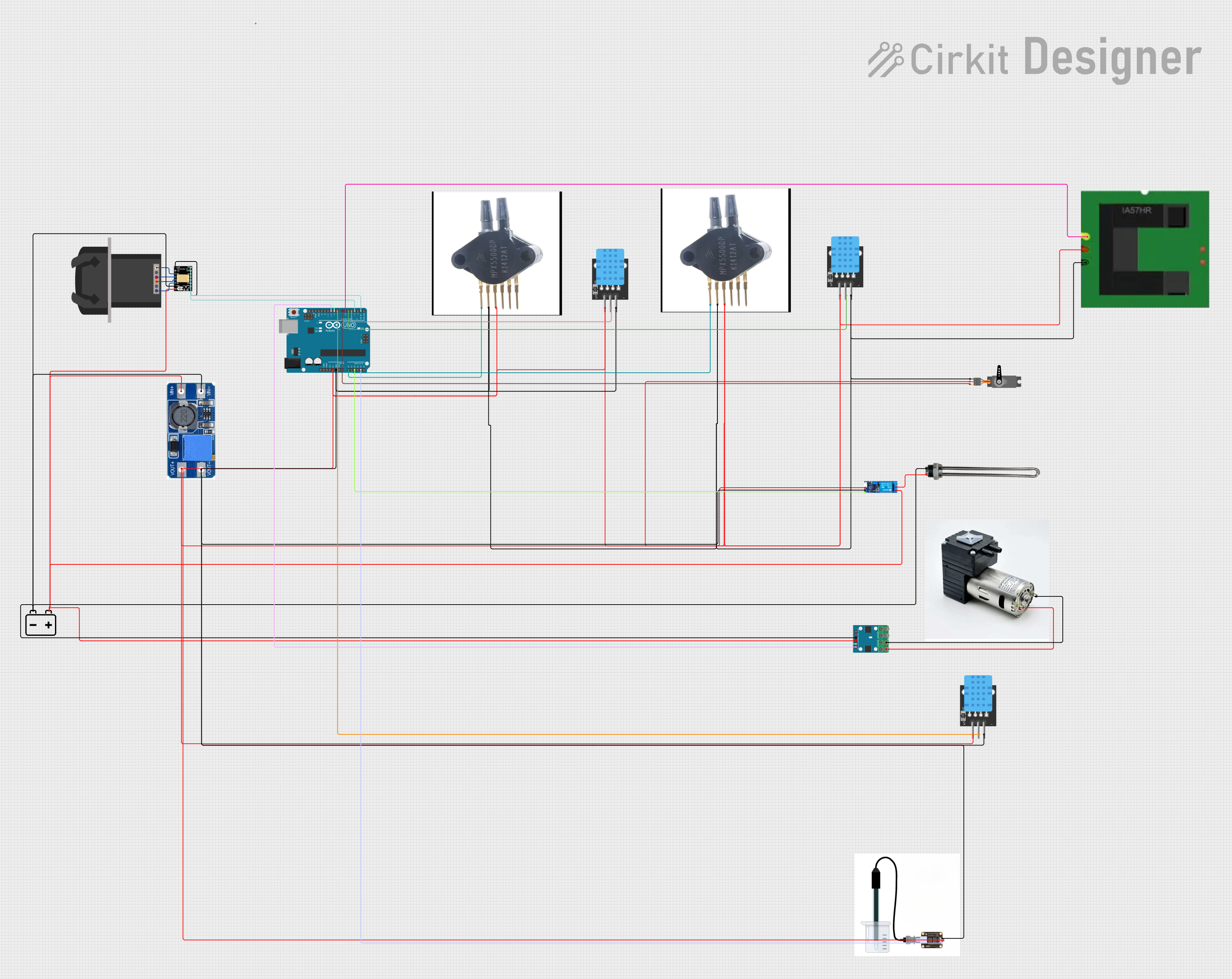

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Peristaltic Pump

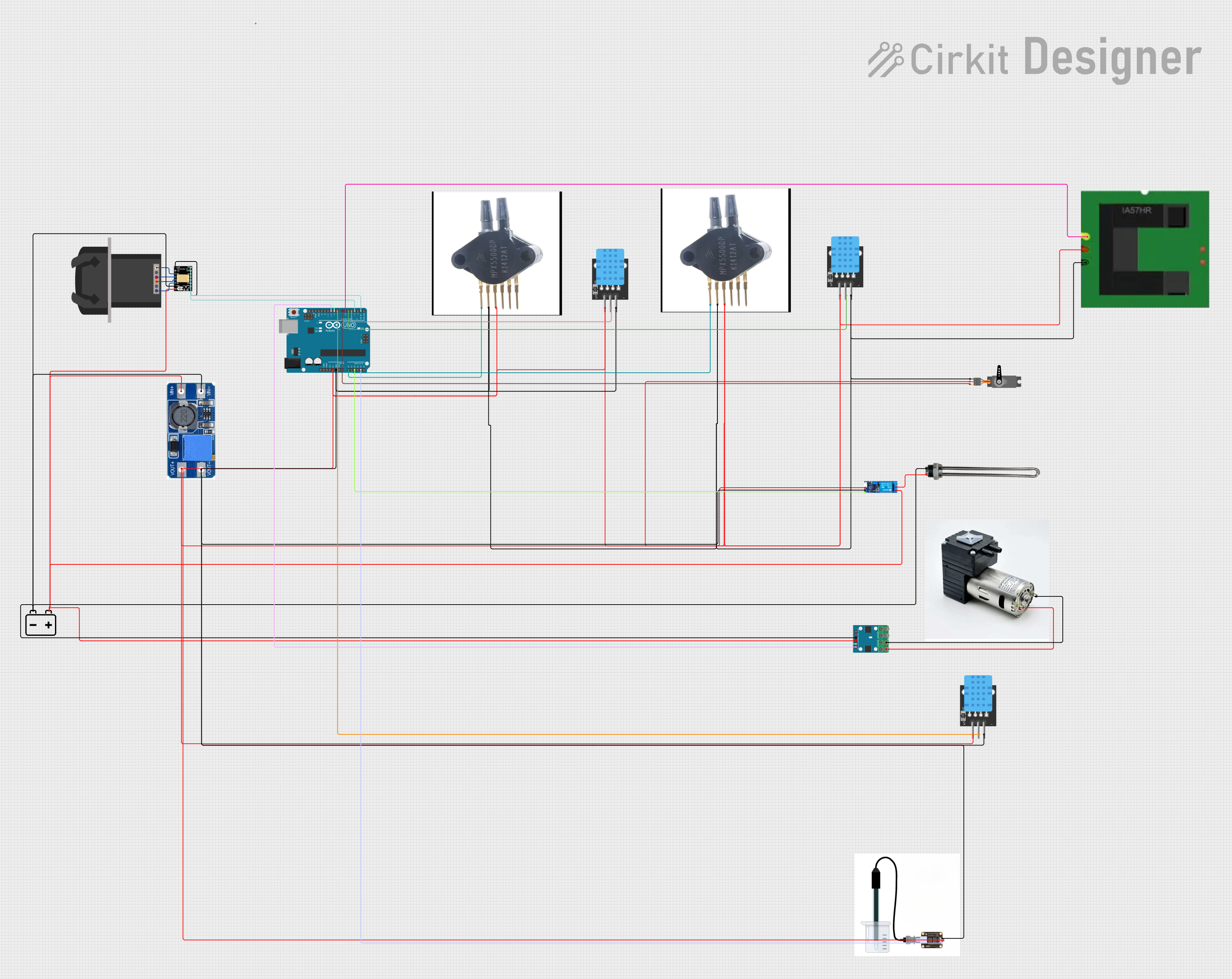

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Medical devices (e.g., IV fluid administration)

- Laboratory equipment (e.g., automated sample handling)

- Chemical dosing and processing

- Food and beverage production

- Aquarium and hydroponics systems

Technical Specifications

Key Technical Details

- Voltage: Typically 12V or 24V DC

- Current: Varies depending on pump size and speed

- Power Ratings: Varies; check manufacturer's datasheet

- Flow Rate: Range from mL/min to L/min, depending on pump size

- Operating Environment: Temperature and chemical compatibility based on tubing material

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | V+ (Power Supply) | Connect to positive voltage |

| 2 | GND (Ground) | Connect to system ground |

| 3 | PWM (Speed Control) | Optional for speed regulation |

| 4 | DIR (Direction) | Optional for direction control |

Usage Instructions

How to Use the Component in a Circuit

- Power Connections: Connect the V+ and GND pins to a suitable power supply, ensuring that the voltage matches the pump's requirements.

- Speed Control (Optional): If speed control is desired, connect the PWM pin to a PWM-capable output on a microcontroller.

- Direction Control (Optional): To control the direction of the pump, connect the DIR pin to a digital output on a microcontroller.

Important Considerations and Best Practices

- Tubing Selection: Choose tubing that is compatible with the fluid being pumped and the operating environment.

- Power Supply: Ensure that the power supply can handle the current requirements of the pump at the desired operating speed.

- Priming: Before first use, prime the pump by running it with fluid until all air is expelled from the tubing.

- Mounting: Secure the pump to prevent vibrations and ensure consistent operation.

Example Arduino UNO Code

// Define the control pins

const int pwmPin = 3; // Connect to the PWM pin on the pump

const int dirPin = 4; // Connect to the DIR pin on the pump

void setup() {

pinMode(pwmPin, OUTPUT);

pinMode(dirPin, OUTPUT);

// Start the pump at 50% speed in the forward direction

analogWrite(pwmPin, 128); // PWM value for 50% speed (0-255)

digitalWrite(dirPin, HIGH); // Set direction to forward

}

void loop() {

// Pump control logic goes here

}

Troubleshooting and FAQs

Common Issues Users Might Face

- Pump Not Operating: Ensure power supply is correctly connected and providing the right voltage.

- Low Flow Rate: Check for blockages or air bubbles in the tubing. Ensure the tubing is properly seated in the pump.

- Inconsistent Flow: Verify that the pump is securely mounted and that the power supply is stable.

Solutions and Tips for Troubleshooting

- Priming the Pump: If air is trapped in the system, run the pump with fluid to prime it.

- Power Supply Issues: Use a multimeter to check the voltage and current supplied to the pump.

- Tubing Wear: Regularly inspect and replace tubing to prevent leaks and maintain performance.

FAQs

Q: Can the pump run dry? A: Running the pump dry can shorten its lifespan. Always ensure there is fluid in the tubing.

Q: How do I clean the pump? A: Clean the pump by running a suitable cleaning solution through the tubing, following the manufacturer's guidelines.

Q: What is the maximum fluid temperature the pump can handle? A: The maximum fluid temperature depends on the tubing material. Refer to the tubing specifications for temperature limits.