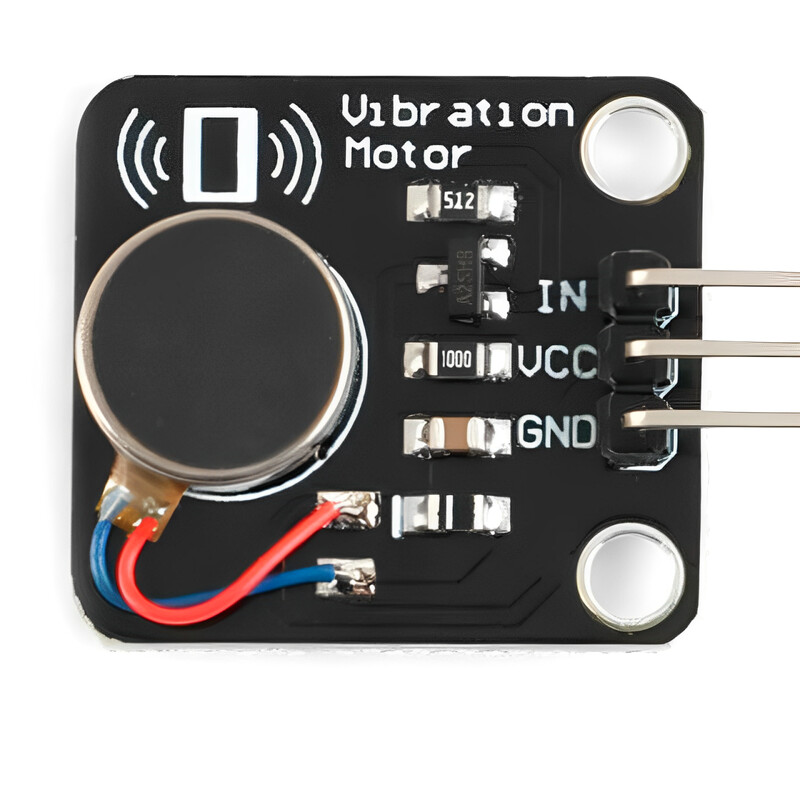

How to Use Motor Vibración: Examples, Pinouts, and Specs

Design with Motor Vibración in Cirkit Designer

Design with Motor Vibración in Cirkit DesignerIntroduction

A vibration motor is an electromechanical device that converts electrical energy into mechanical energy, producing vibrations. It is commonly used in applications where tactile feedback is desired, such as mobile devices, gaming controllers, wearables, and haptic feedback systems. These motors are compact, reliable, and easy to integrate into various electronic projects, making them a popular choice for both hobbyists and professionals.

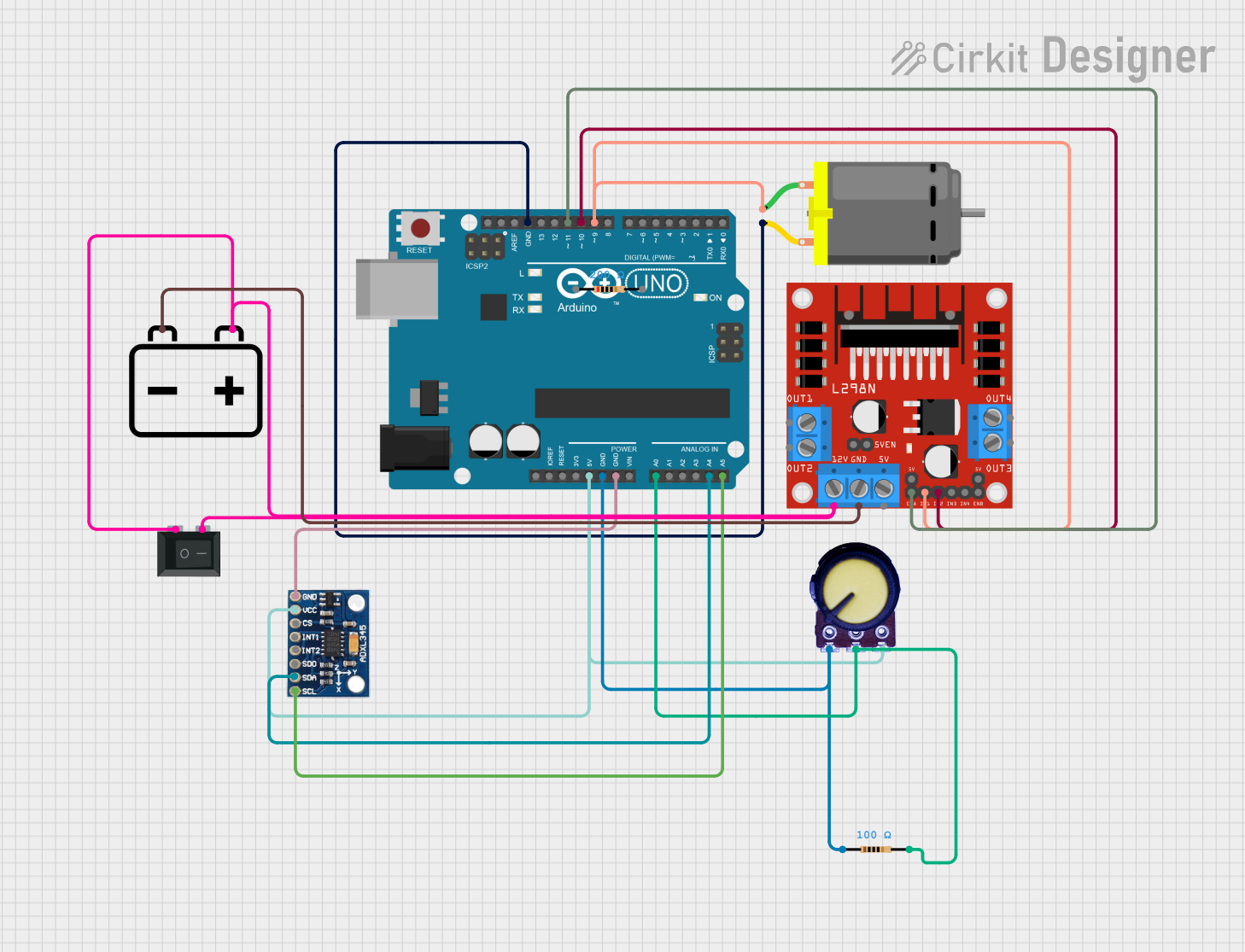

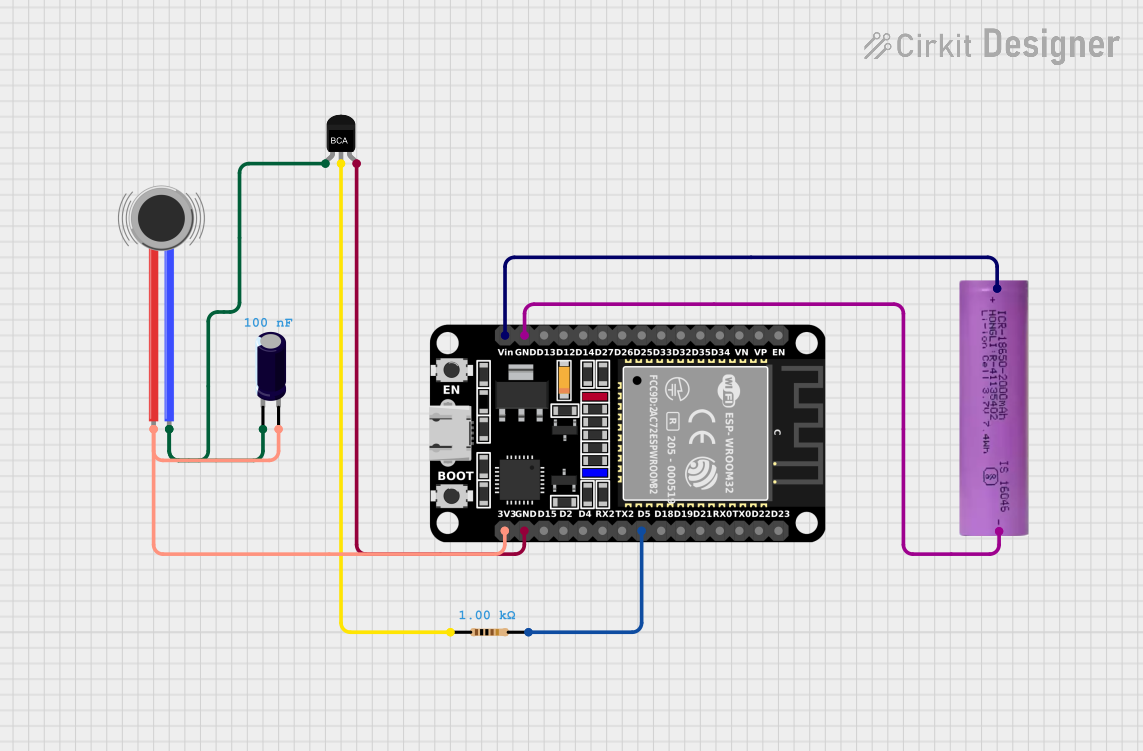

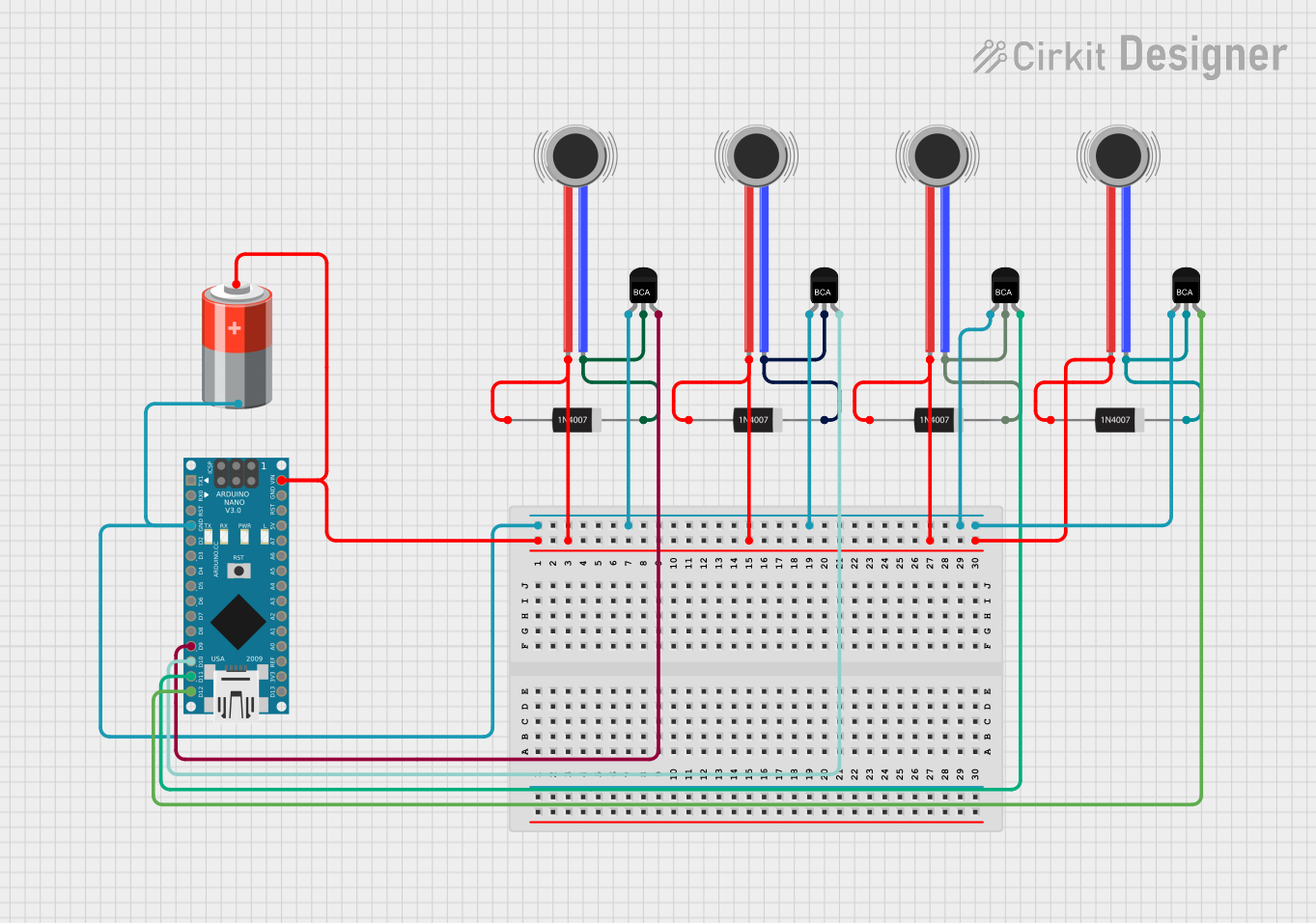

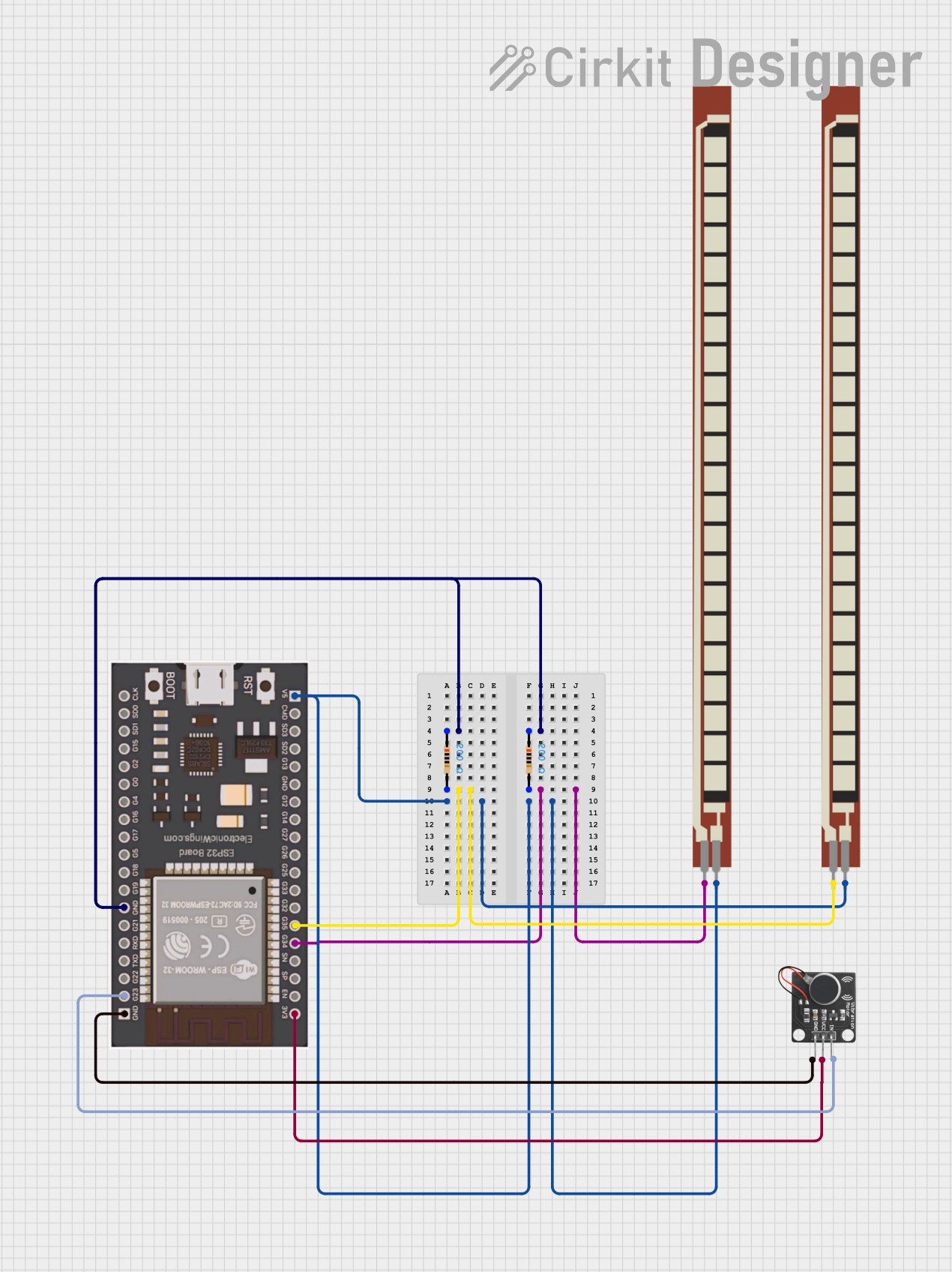

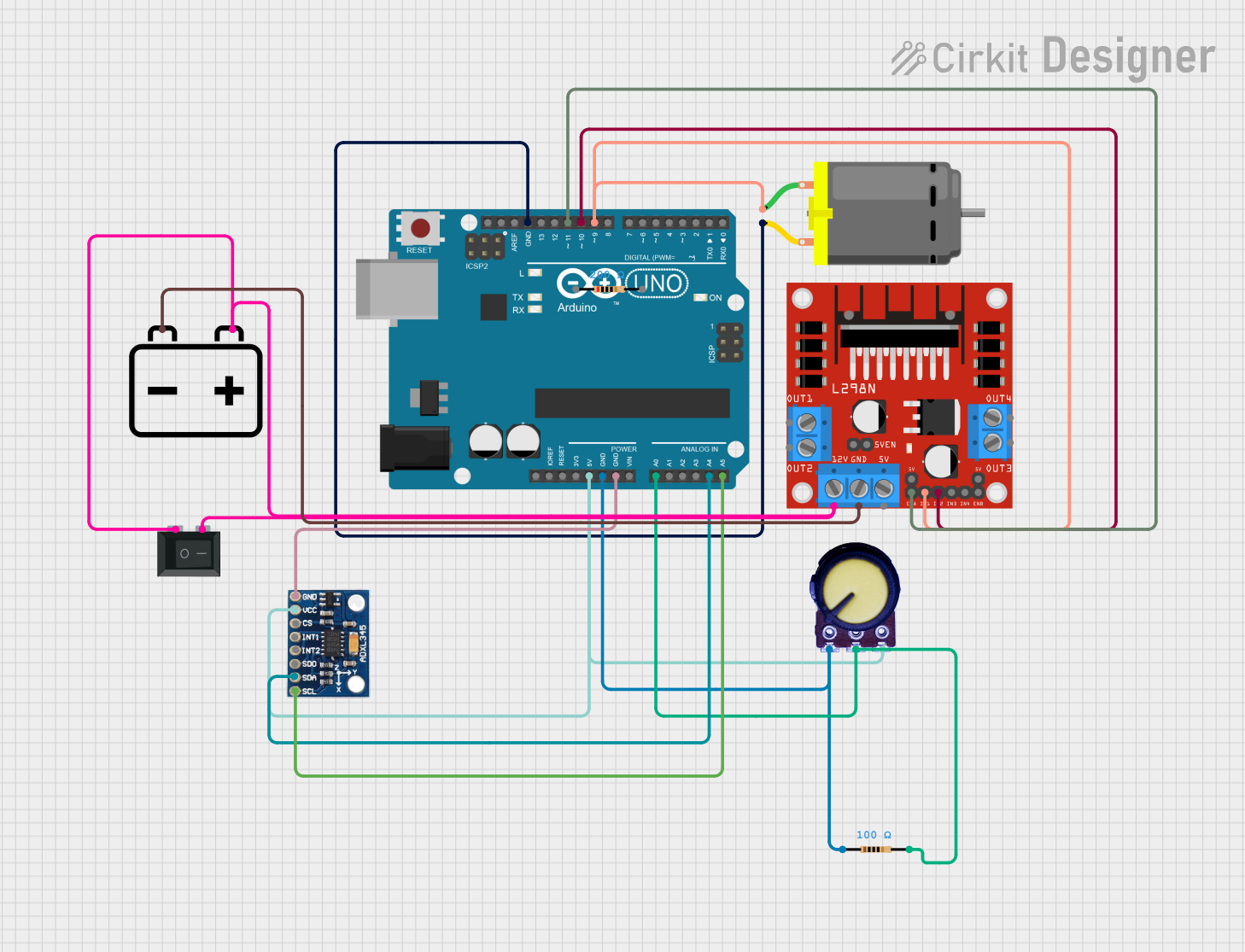

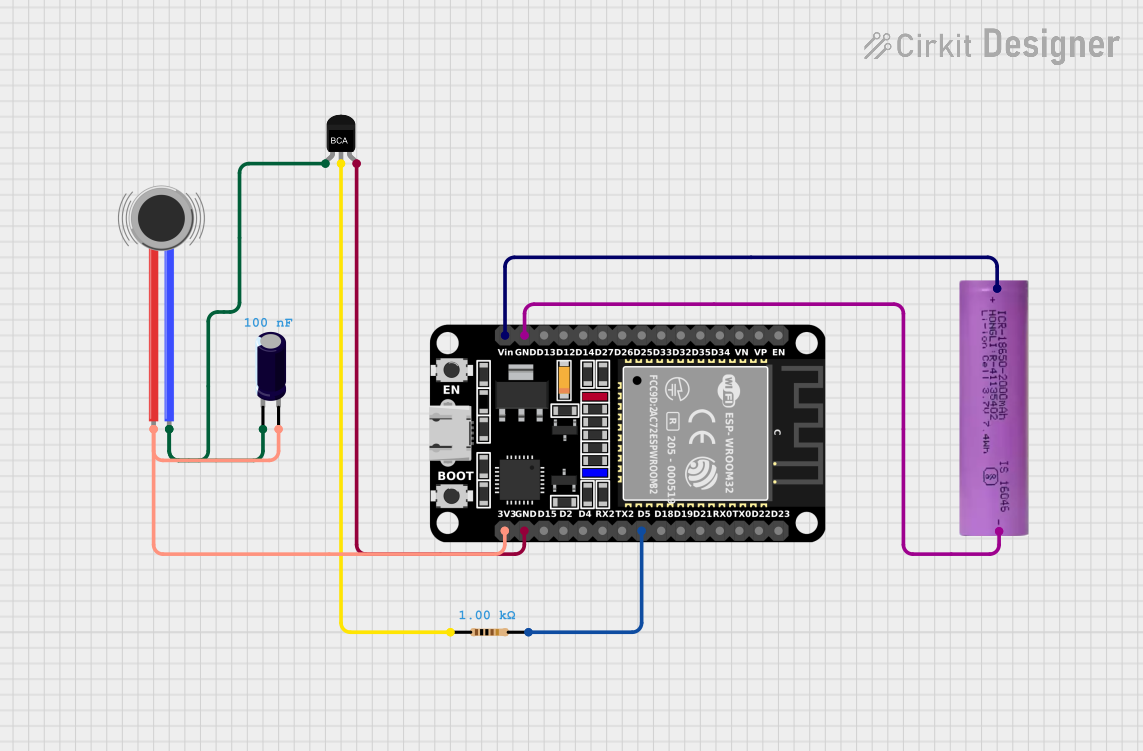

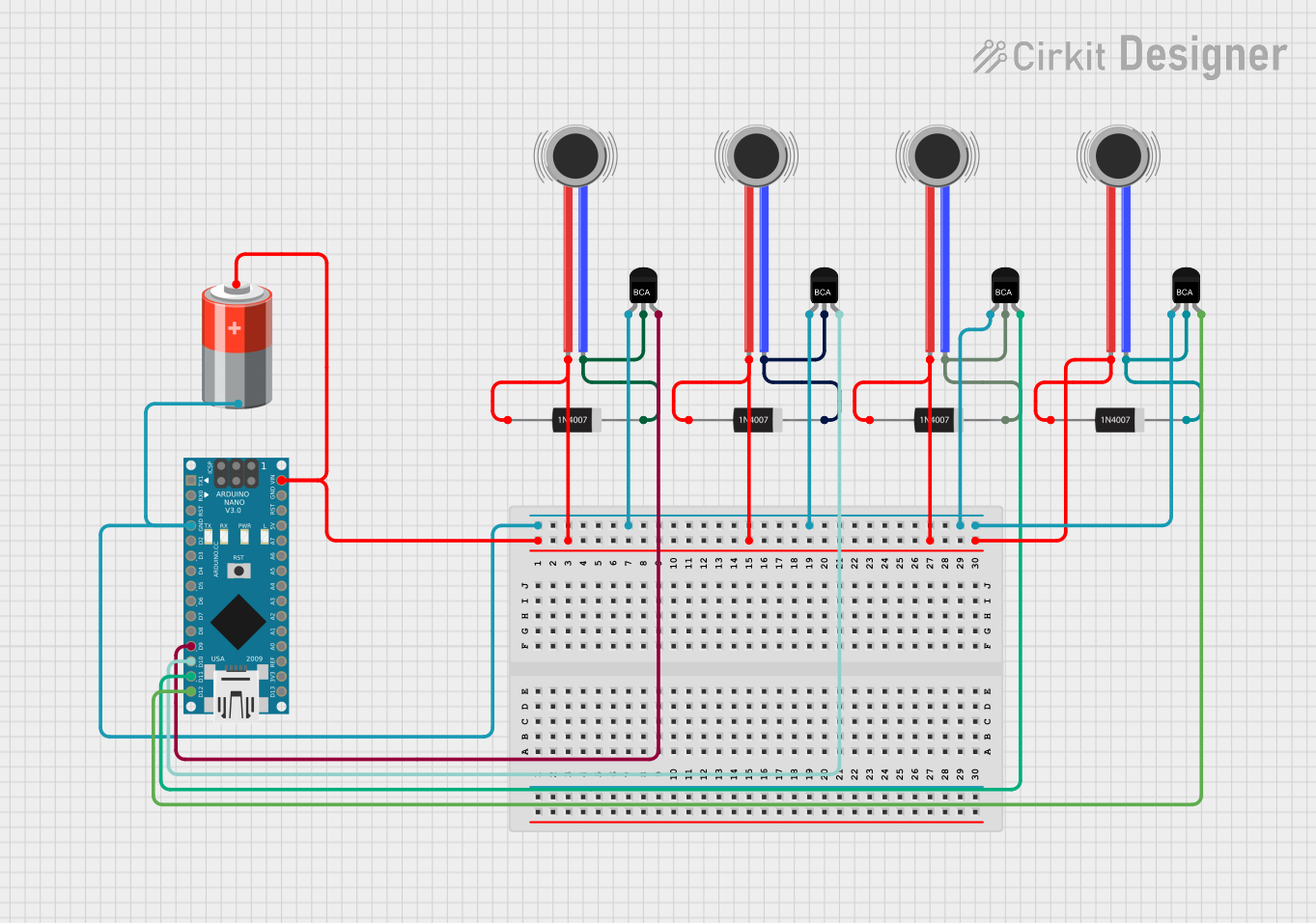

Explore Projects Built with Motor Vibración

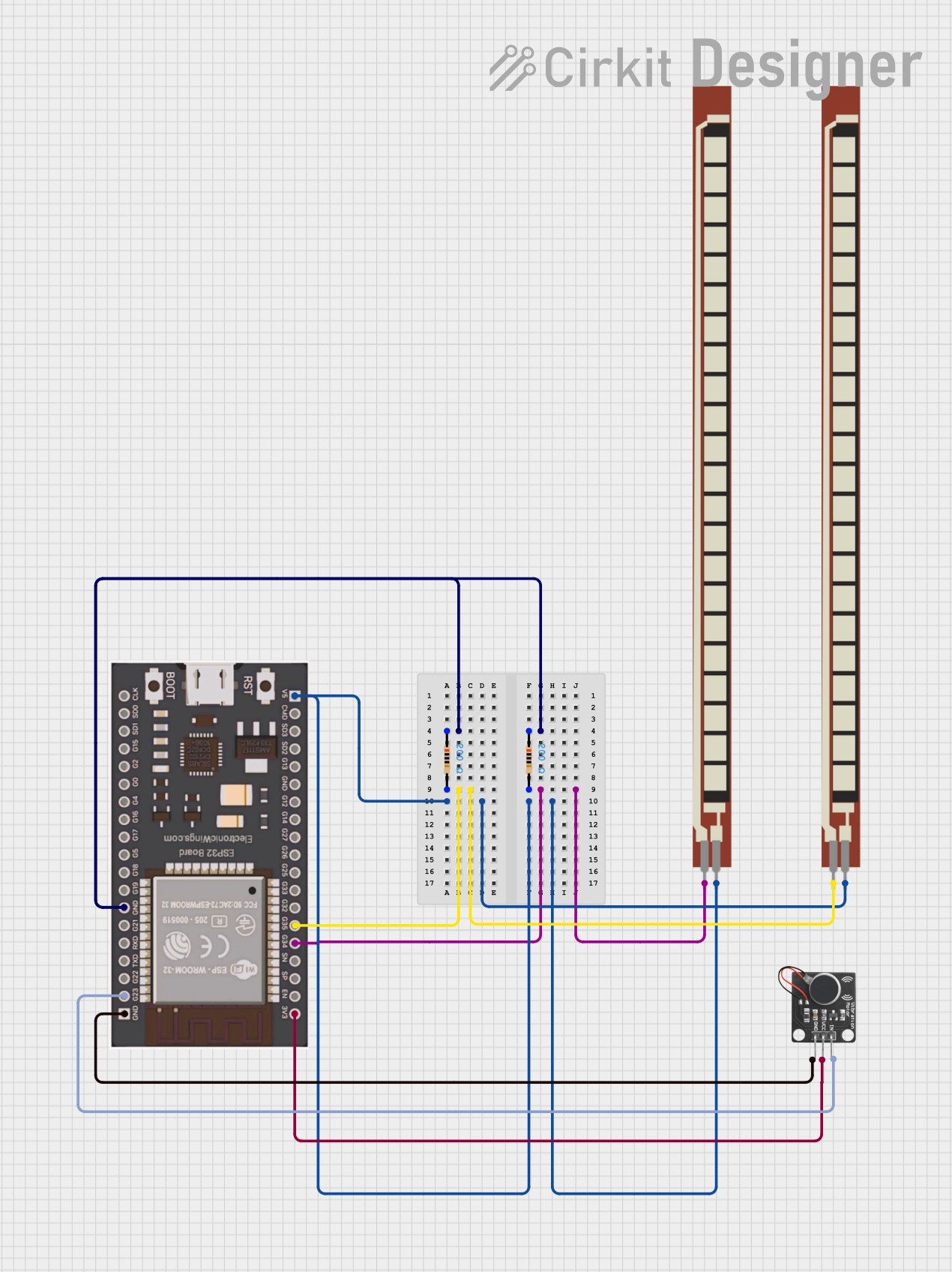

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Motor Vibración

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the key technical details for a typical vibration motor:

| Parameter | Value |

|---|---|

| Operating Voltage | 2V to 5V DC |

| Rated Voltage | 3V DC |

| Operating Current | 70mA to 120mA (at 3V) |

| Starting Voltage | ~2.0V DC |

| Vibration Frequency | ~100 Hz to 250 Hz |

| Dimensions | Varies (e.g., 10mm x 3mm for coin type) |

| Motor Type | Eccentric Rotating Mass (ERM) or Linear Resonant Actuator (LRA) |

Pin Configuration and Descriptions

The vibration motor typically has two pins for electrical connections:

| Pin | Description |

|---|---|

| Pin 1 | Positive terminal (+), connects to the power supply or control circuit. |

| Pin 2 | Negative terminal (-), connects to ground. |

Usage Instructions

How to Use the Motor in a Circuit

- Power Supply: Connect the motor to a DC power supply within its operating voltage range (e.g., 3V). Exceeding the voltage rating may damage the motor.

- Control: To control the motor, you can use a transistor or MOSFET as a switch. This allows you to turn the motor on and off using a microcontroller like an Arduino.

- PWM Control: For variable vibration intensity, use Pulse Width Modulation (PWM) to adjust the motor's speed.

Example Circuit with Arduino UNO

Below is an example of how to connect and control a vibration motor using an Arduino UNO:

Components Required:

- Vibration motor

- NPN transistor (e.g., 2N2222)

- 1 kΩ resistor

- Diode (e.g., 1N4007)

- Arduino UNO

- External power supply (if needed)

Circuit Diagram:

- Connect the positive terminal of the motor to the collector of the NPN transistor.

- Connect the emitter of the transistor to ground.

- Place a diode across the motor terminals (cathode to positive terminal) to protect against back EMF.

- Connect the base of the transistor to a PWM-capable pin on the Arduino (e.g., Pin 9) through a 1 kΩ resistor.

- Connect the Arduino ground to the ground of the motor circuit.

Arduino Code:

// Arduino code to control a vibration motor using PWM

const int motorPin = 9; // PWM pin connected to the transistor base

void setup() {

pinMode(motorPin, OUTPUT); // Set motorPin as an output

}

void loop() {

analogWrite(motorPin, 128); // Set motor speed to 50% (128 out of 255)

delay(1000); // Run motor for 1 second

analogWrite(motorPin, 0); // Turn off motor

delay(1000); // Wait for 1 second

}

Important Considerations and Best Practices

- Back EMF Protection: Always use a flyback diode across the motor terminals to protect the circuit from voltage spikes caused by the motor's inductive load.

- Heat Dissipation: Ensure proper ventilation or heat dissipation for the transistor or MOSFET used in the circuit.

- Power Supply: Use a stable power supply to avoid fluctuations that could affect motor performance.

- Mounting: Securely mount the motor to prevent unwanted movement or noise during operation.

Troubleshooting and FAQs

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Motor does not vibrate | Insufficient voltage or loose connections | Check power supply and connections. |

| Motor vibrates weakly | Voltage too low or PWM duty cycle too small | Increase voltage or adjust PWM settings. |

| Motor gets hot | Overvoltage or prolonged operation | Reduce voltage or limit runtime. |

| Circuit not working after motor use | Back EMF damage | Ensure a flyback diode is installed. |

FAQs

Can I connect the motor directly to an Arduino pin?

- No, the motor's current draw exceeds the Arduino's pin capacity. Use a transistor or MOSFET to control the motor.

What type of vibration motor should I use for my project?

- For compact devices, use a coin-type motor. For stronger vibrations, consider a cylindrical motor.

How do I reduce noise from the motor?

- Use rubber mounts or vibration-dampening materials to minimize noise and mechanical stress.

By following this documentation, you can effectively integrate and troubleshoot a vibration motor in your electronic projects.