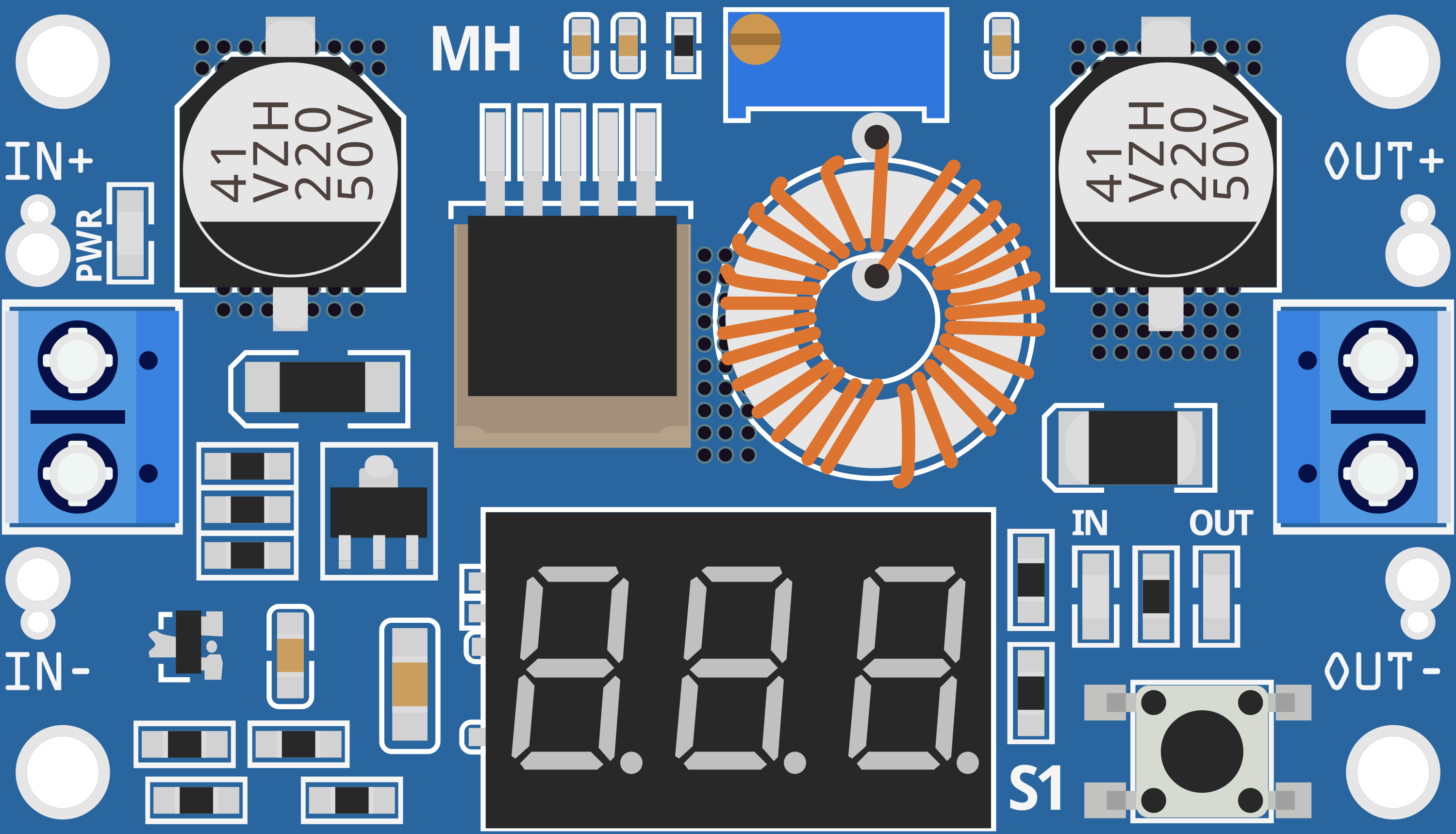

How to Use XL4015 5A DC Buck Step-down: Examples, Pinouts, and Specs

Design with XL4015 5A DC Buck Step-down in Cirkit Designer

Design with XL4015 5A DC Buck Step-down in Cirkit DesignerIntroduction

The XL4015 is a high-efficiency DC-DC buck converter capable of delivering up to 5A of output current. It steps down a higher input voltage to a lower output voltage while maintaining high efficiency, making it ideal for a wide range of applications. This component is commonly used in battery charging circuits, LED drivers, and regulated power supplies for microcontrollers and other electronic devices.

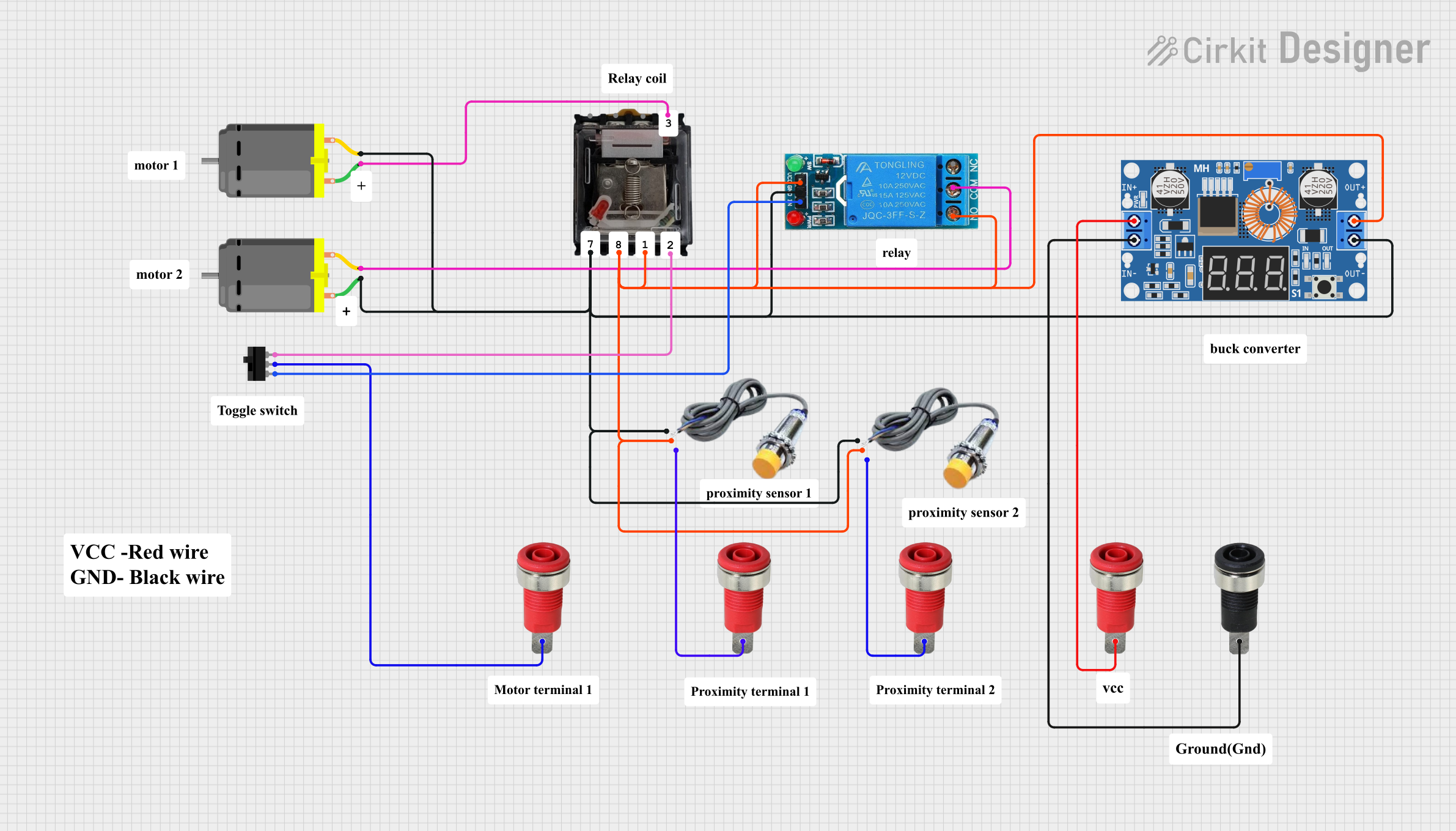

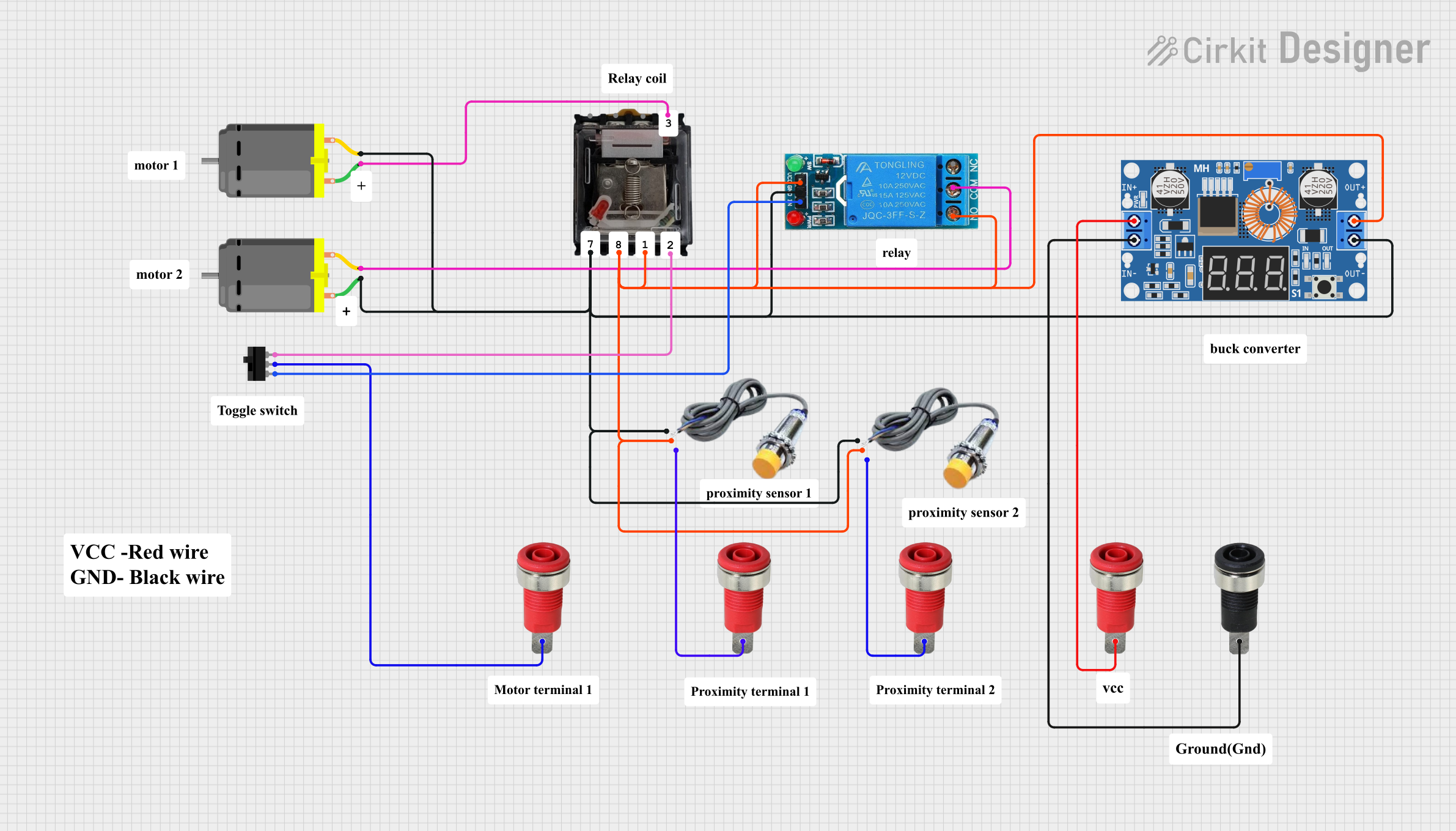

Explore Projects Built with XL4015 5A DC Buck Step-down

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with XL4015 5A DC Buck Step-down

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Battery charging (e.g., lithium-ion, lead-acid batteries)

- LED lighting systems

- Power supplies for microcontrollers (e.g., Arduino, Raspberry Pi)

- Voltage regulation in DIY electronics projects

- Solar power systems

Technical Specifications

The XL4015 is a versatile and robust component with the following key specifications:

| Parameter | Value |

|---|---|

| Input Voltage Range | 4V to 38V |

| Output Voltage Range | 1.25V to 36V (adjustable via potentiometer) |

| Maximum Output Current | 5A |

| Output Power | Up to 75W |

| Efficiency | Up to 96% |

| Switching Frequency | 180 kHz |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 51mm x 26mm x 14mm |

Pin Configuration and Descriptions

The XL4015 module typically has the following pinout:

| Pin Name | Description |

|---|---|

| VIN | Input voltage pin. Connect the higher input voltage (4V to 38V). |

| VOUT | Output voltage pin. Provides the regulated lower output voltage (1.25V to 36V). |

| GND | Ground pin. Common ground for input and output. |

Usage Instructions

How to Use the XL4015 in a Circuit

Connect Input Voltage (VIN):

- Connect the positive terminal of the input power source to the

VINpin. - Connect the negative terminal of the input power source to the

GNDpin.

- Connect the positive terminal of the input power source to the

Connect Output Load (VOUT):

- Connect the positive terminal of the load to the

VOUTpin. - Connect the negative terminal of the load to the

GNDpin.

- Connect the positive terminal of the load to the

Adjust Output Voltage:

- Use the onboard potentiometer to adjust the output voltage.

- Turn the potentiometer clockwise to increase the output voltage and counterclockwise to decrease it.

- Use a multimeter to measure the output voltage while adjusting.

Ensure Proper Heat Dissipation:

- The XL4015 can handle up to 5A of current, but it may generate heat at higher loads.

- Attach a heatsink to the module if operating at high currents for extended periods.

Optional Capacitors:

- For improved stability, you can add input and output capacitors (e.g., 100µF electrolytic capacitors) near the

VINandVOUTpins.

- For improved stability, you can add input and output capacitors (e.g., 100µF electrolytic capacitors) near the

Important Considerations and Best Practices

- Input Voltage: Ensure the input voltage is at least 1.5V higher than the desired output voltage.

- Current Limitation: Do not exceed the 5A current limit to avoid damaging the module.

- Polarity: Double-check the polarity of the input and output connections to prevent reverse polarity damage.

- Load Testing: Test the module with a dummy load before connecting sensitive devices.

Example: Using XL4015 with Arduino UNO

The XL4015 can be used to power an Arduino UNO by stepping down a higher voltage (e.g., 12V) to 5V. Here's an example:

- Connect a 12V power source to the

VINandGNDpins of the XL4015. - Adjust the output voltage to 5V using the potentiometer.

- Connect the

VOUTpin to the Arduino's 5V pin and theGNDpin to the Arduino's GND pin.

Sample Arduino Code

If you're using the XL4015 to power sensors or peripherals connected to the Arduino, here's a simple example:

// Example: Reading a sensor powered by the XL4015 module

// Ensure the XL4015 output is set to 5V before connecting to the Arduino.

const int sensorPin = A0; // Analog pin connected to the sensor output

int sensorValue = 0; // Variable to store the sensor reading

void setup() {

Serial.begin(9600); // Initialize serial communication

pinMode(sensorPin, INPUT); // Set the sensor pin as input

}

void loop() {

sensorValue = analogRead(sensorPin); // Read the sensor value

Serial.print("Sensor Value: ");

Serial.println(sensorValue); // Print the sensor value to the Serial Monitor

delay(1000); // Wait for 1 second before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage:

- Cause: Incorrect input connections or insufficient input voltage.

- Solution: Verify the input voltage is within the 4V to 38V range and check the polarity.

Output Voltage Not Adjustable:

- Cause: Faulty potentiometer or incorrect adjustment.

- Solution: Turn the potentiometer slowly and ensure you're measuring the output voltage correctly.

Overheating:

- Cause: High current load or insufficient cooling.

- Solution: Attach a heatsink to the module and ensure proper ventilation.

Load Not Powering On:

- Cause: Output voltage too low or load requires more current than the module can provide.

- Solution: Adjust the output voltage to the required level and ensure the load current is within the 5A limit.

FAQs

Q: Can the XL4015 be used to charge a lithium-ion battery?

A: Yes, the XL4015 can be used for lithium-ion battery charging. However, you must set the output voltage to match the battery's charging voltage and use a current-limiting resistor or circuit to prevent overcharging.

Q: Is the XL4015 suitable for powering sensitive electronics?

A: Yes, but it's recommended to add output capacitors to reduce voltage ripple and ensure stable operation.

Q: Can the XL4015 step up voltage?

A: No, the XL4015 is a buck converter and can only step down voltage.

Q: How do I calculate the power dissipation of the module?

A: Power dissipation can be estimated as ( P_{loss} = (1 - \text{Efficiency}) \times P_{output} ). For high currents, ensure proper cooling.

By following this documentation, you can effectively use the XL4015 in your projects and troubleshoot common issues.