How to Use Fan: Examples, Pinouts, and Specs

Design with Fan in Cirkit Designer

Design with Fan in Cirkit DesignerIntroduction

A fan is a device that creates airflow by rotating blades, commonly used for cooling or ventilation in electronic circuits and systems. It is an essential component in thermal management, helping to dissipate heat generated by electronic components such as processors, power supplies, and other heat-sensitive devices. Fans are available in various sizes, voltages, and configurations to suit different applications.

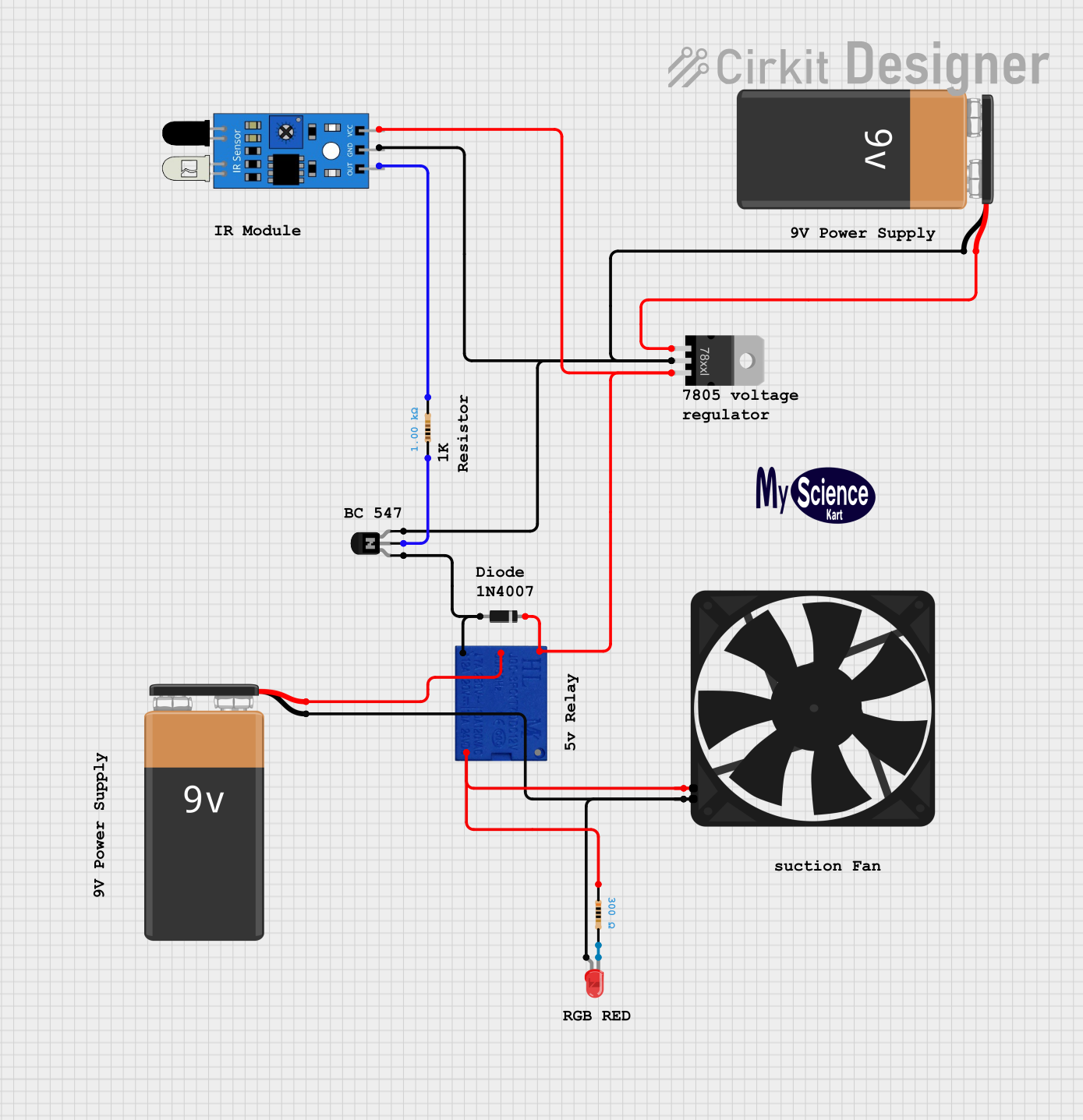

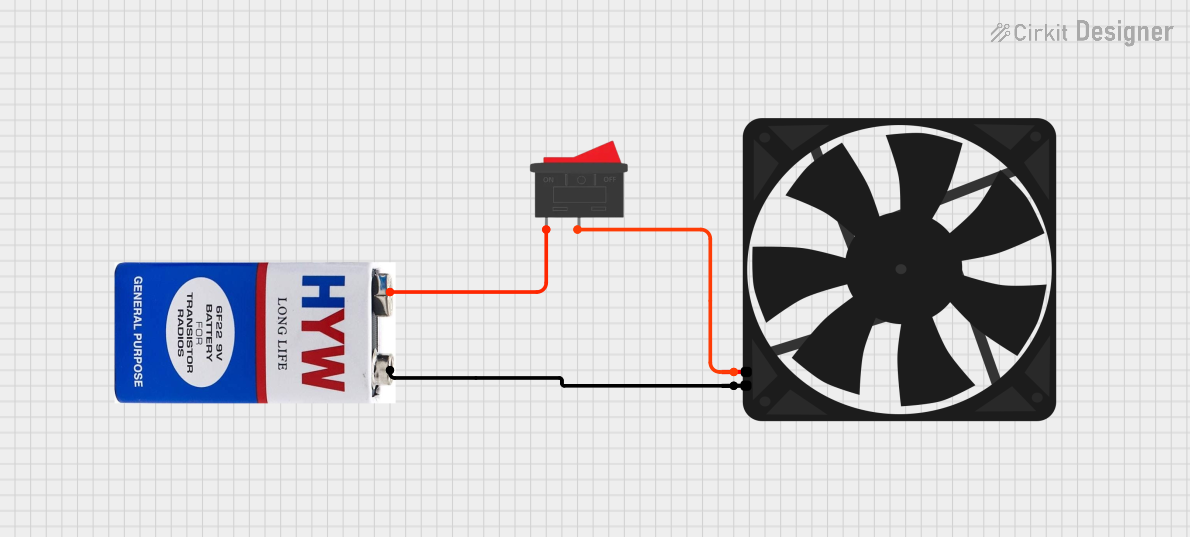

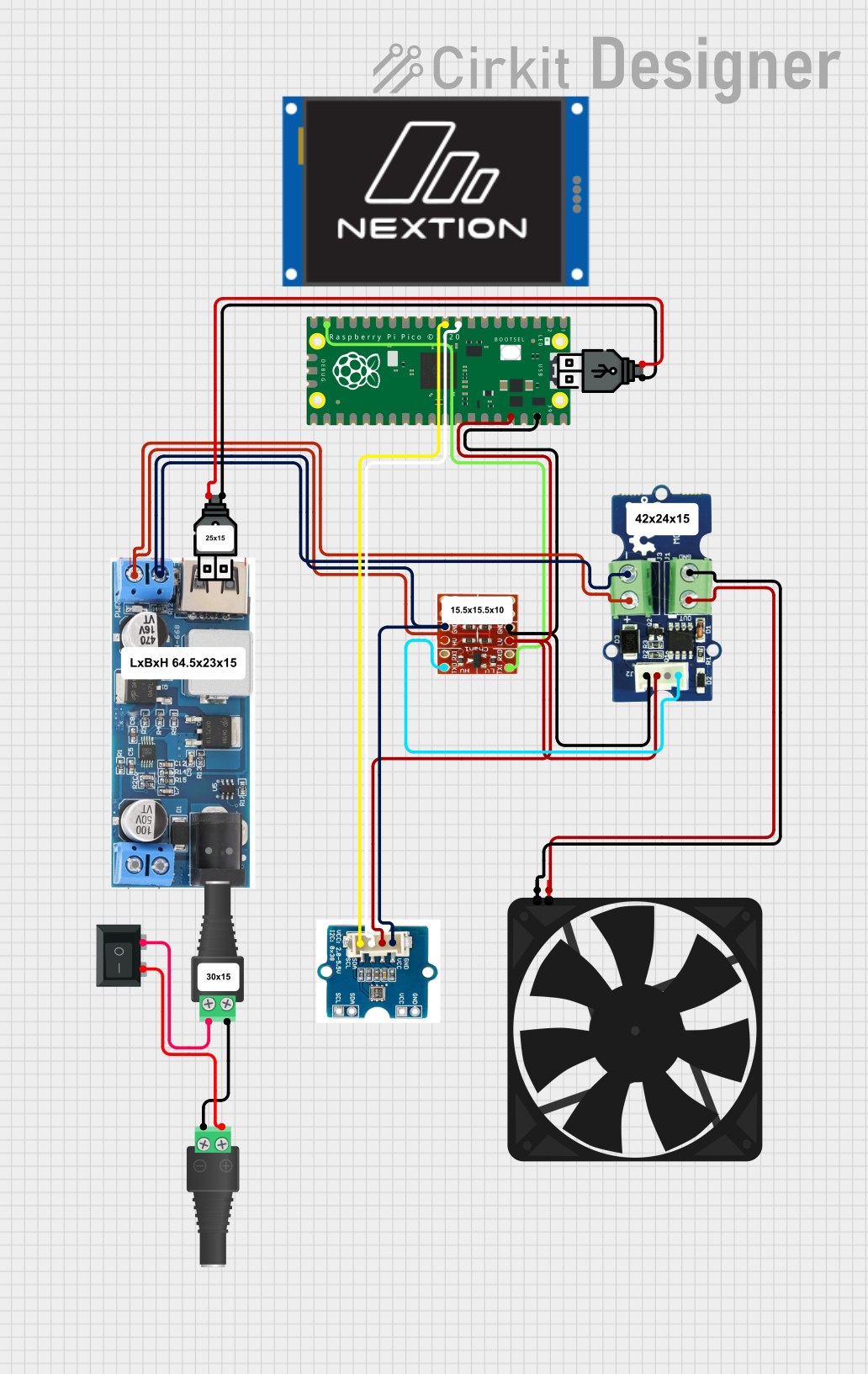

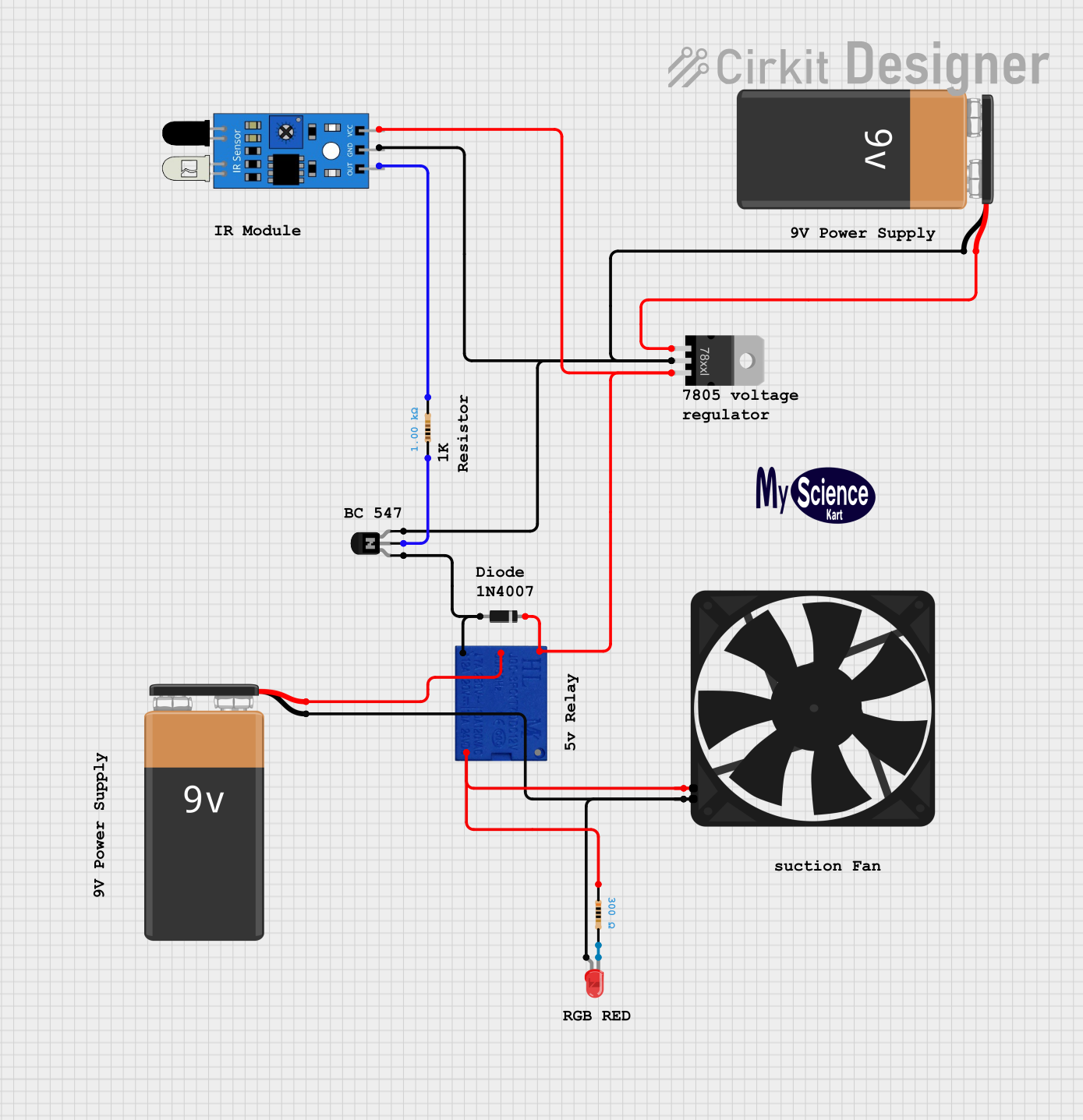

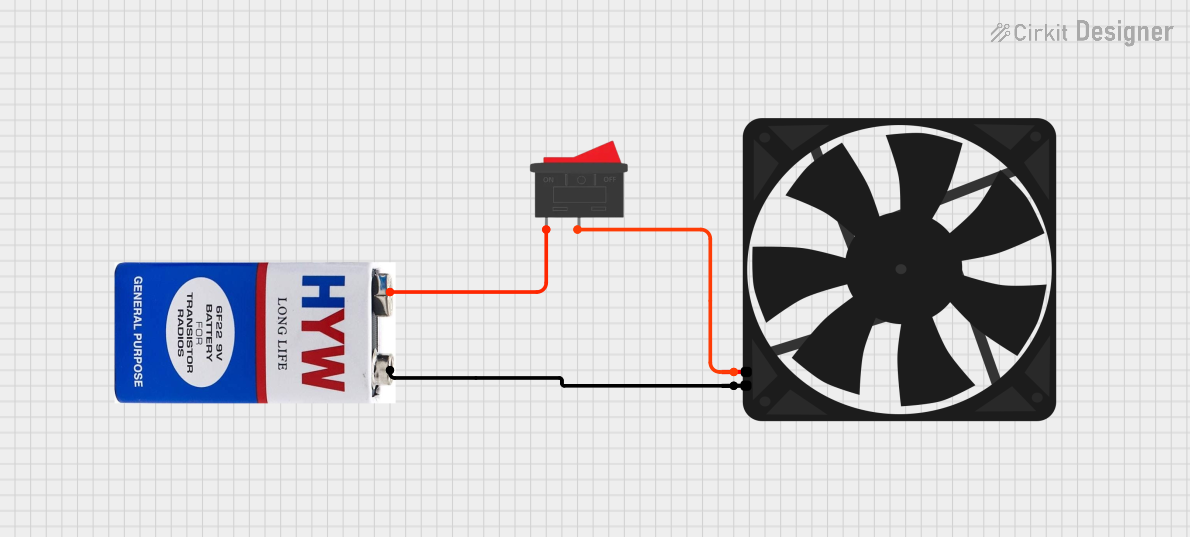

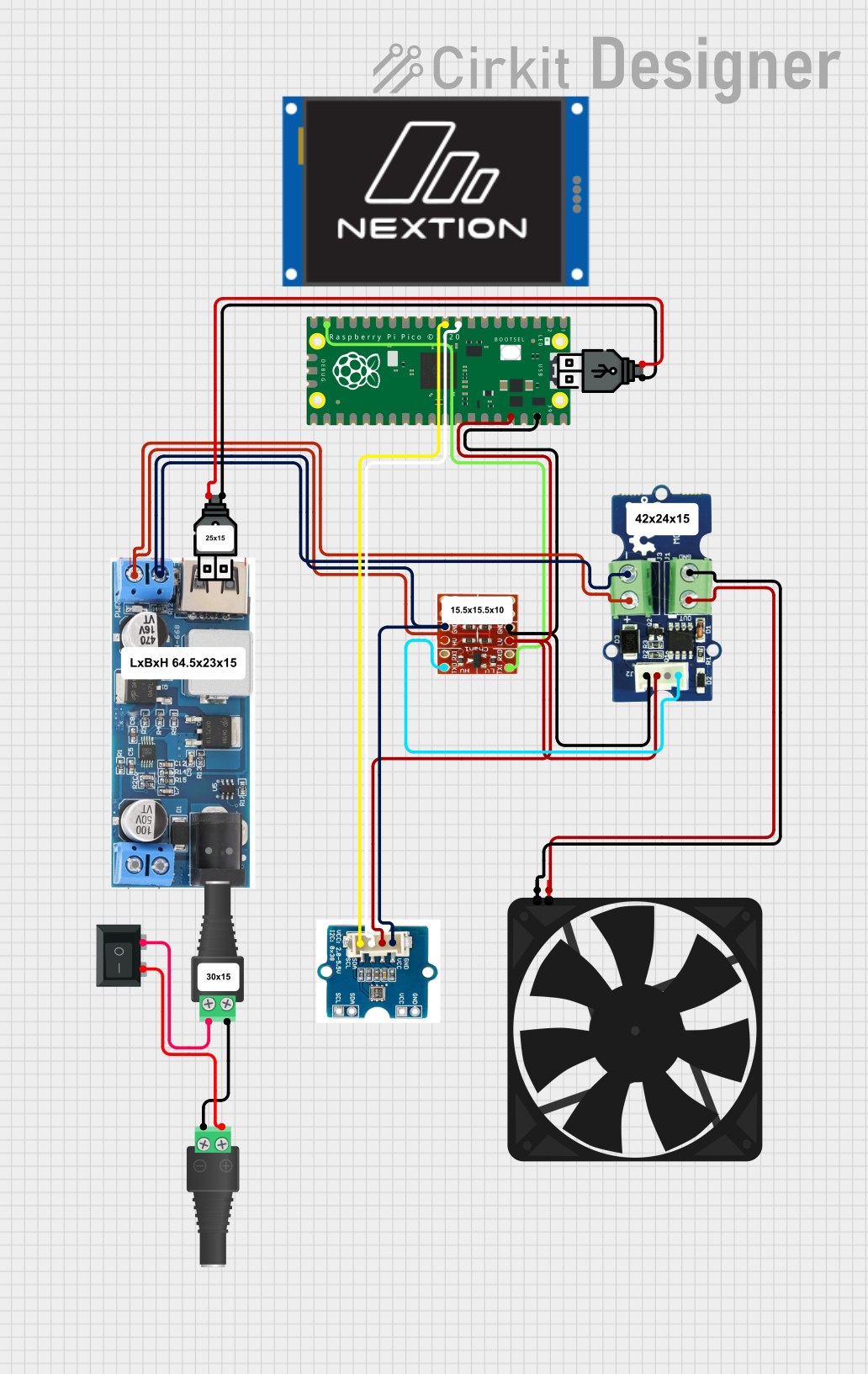

Explore Projects Built with Fan

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Fan

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Cooling computer processors, graphics cards, and power supplies

- Ventilation in enclosures and cabinets for electronic systems

- Heat dissipation in industrial equipment

- Air circulation in home appliances and HVAC systems

- Cooling for 3D printers and other hobbyist projects

Technical Specifications

Below are the general technical specifications for a standard DC brushless fan. Specifications may vary depending on the specific model and manufacturer.

Key Technical Details

- Operating Voltage: 5V, 12V, or 24V DC (common variants)

- Current Consumption: 0.1A to 0.5A (depending on size and voltage)

- Power Rating: Typically 0.5W to 5W

- Speed: 1000 to 5000 RPM (Revolutions Per Minute)

- Airflow: 10 to 100 CFM (Cubic Feet per Minute)

- Noise Level: 20 to 40 dBA

- Bearing Type: Sleeve bearing or ball bearing

- Connector Type: 2-pin, 3-pin, or 4-pin (PWM control)

Pin Configuration and Descriptions

The pin configuration for a 3-pin and 4-pin fan is detailed below:

3-Pin Fan

| Pin Number | Name | Description |

|---|---|---|

| 1 | GND | Ground connection |

| 2 | VCC | Power supply (e.g., 12V DC) |

| 3 | Tachometer | Outputs a signal for speed monitoring |

4-Pin Fan

| Pin Number | Name | Description |

|---|---|---|

| 1 | GND | Ground connection |

| 2 | VCC | Power supply (e.g., 12V DC) |

| 3 | Tachometer | Outputs a signal for speed monitoring |

| 4 | PWM | Pulse Width Modulation for speed control |

Usage Instructions

How to Use the Fan in a Circuit

- Power Connection: Connect the VCC pin to the appropriate voltage source (e.g., 12V DC) and the GND pin to the ground of the circuit.

- Speed Monitoring (Optional): If using a 3-pin or 4-pin fan, connect the Tachometer pin to a microcontroller or monitoring circuit to measure the fan's speed.

- Speed Control (Optional): For 4-pin fans, connect the PWM pin to a microcontroller or PWM signal generator to control the fan speed.

Important Considerations and Best Practices

- Voltage Compatibility: Ensure the fan's operating voltage matches the power supply in your circuit.

- Current Rating: Verify that the power supply can provide sufficient current for the fan.

- Orientation: Install the fan in the correct orientation to direct airflow as needed.

- Noise Reduction: Use rubber mounts or grommets to minimize vibration and noise.

- PWM Signal: For 4-pin fans, use a PWM signal with a frequency of 25 kHz for optimal speed control.

Example: Connecting a 4-Pin Fan to an Arduino UNO

Below is an example of how to control a 4-pin fan using an Arduino UNO:

// Example: Controlling a 4-pin fan with PWM using Arduino UNO

const int pwmPin = 9; // PWM pin connected to the fan's PWM input

const int fanSpeed = 128; // Set fan speed (0 to 255, where 255 is full speed)

void setup() {

pinMode(pwmPin, OUTPUT); // Set the PWM pin as an output

}

void loop() {

analogWrite(pwmPin, fanSpeed); // Send PWM signal to control fan speed

delay(1000); // Keep the fan running at the set speed

}

Troubleshooting and FAQs

Common Issues and Solutions

Fan Does Not Spin

- Cause: Incorrect voltage or loose connections.

- Solution: Verify the power supply voltage and ensure all connections are secure.

Fan Spins Slowly

- Cause: Insufficient current or low PWM duty cycle.

- Solution: Check the power supply's current rating and increase the PWM duty cycle if applicable.

Excessive Noise

- Cause: Vibration or worn-out bearings.

- Solution: Use vibration dampeners or replace the fan if the bearings are damaged.

No Speed Feedback

- Cause: Tachometer pin not connected or incompatible monitoring circuit.

- Solution: Ensure the Tachometer pin is properly connected to a compatible input.

FAQs

Q: Can I use a 3-pin fan with a 4-pin connector?

A: Yes, you can connect a 3-pin fan to a 4-pin connector. The fan will operate at full speed, but you will not have PWM speed control.

Q: What is the typical lifespan of a fan?

A: The lifespan depends on the bearing type. Sleeve bearings typically last 30,000 hours, while ball bearings can last up to 50,000 hours or more.

Q: Can I use a fan with an AC power supply?

A: No, DC fans require a DC power supply. For AC applications, use an AC fan designed for the appropriate voltage and frequency.

Q: How do I clean a fan?

A: Use compressed air to remove dust and debris. Avoid disassembling the fan unless necessary.