How to Use CT Close: Examples, Pinouts, and Specs

Design with CT Close in Cirkit Designer

Design with CT Close in Cirkit DesignerIntroduction

The CT Close, manufactured by 1 with part ID 2, is a switch or relay designed to close the circuit in a current transformer (CT). This action allows current to flow through the secondary winding, enabling accurate measurement or protection of electrical systems. CT Close components are essential in power monitoring, energy management, and protection systems in various industrial and commercial applications.

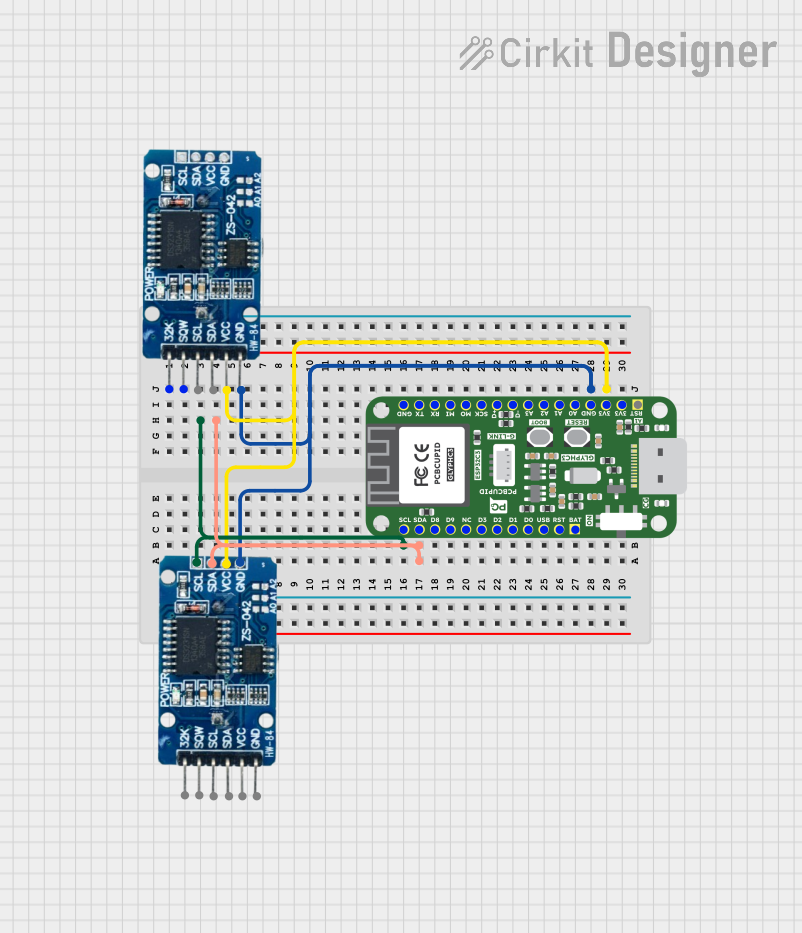

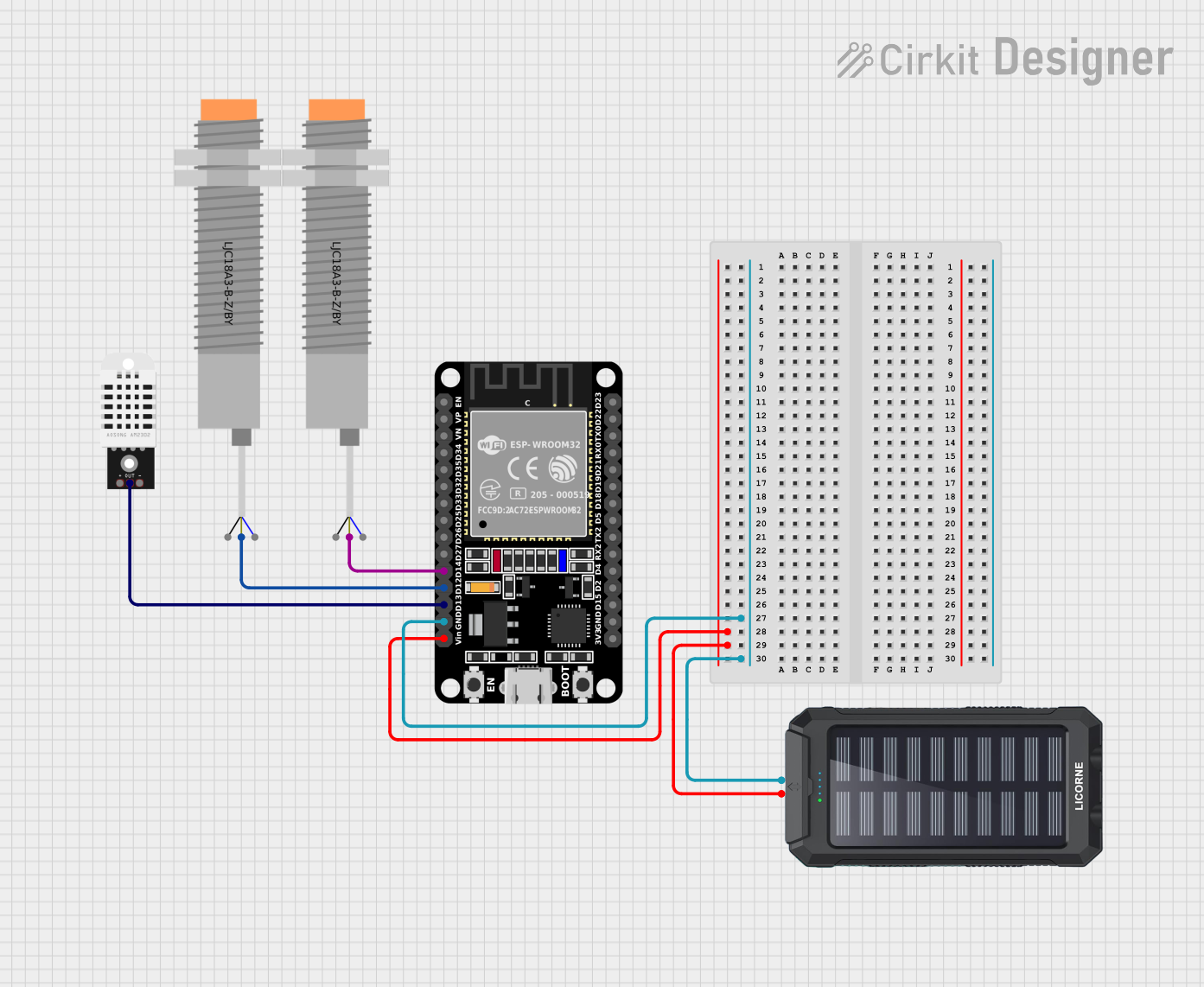

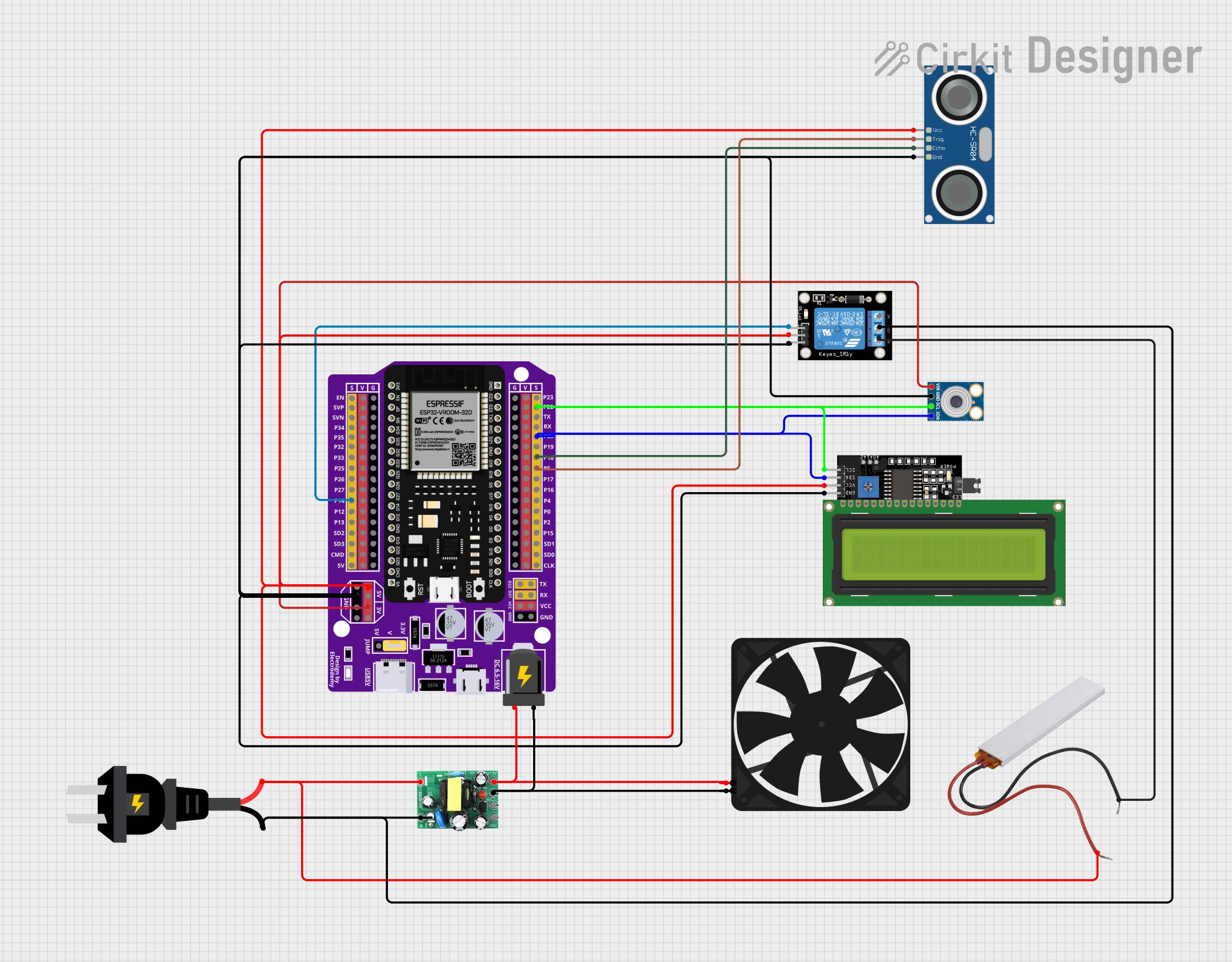

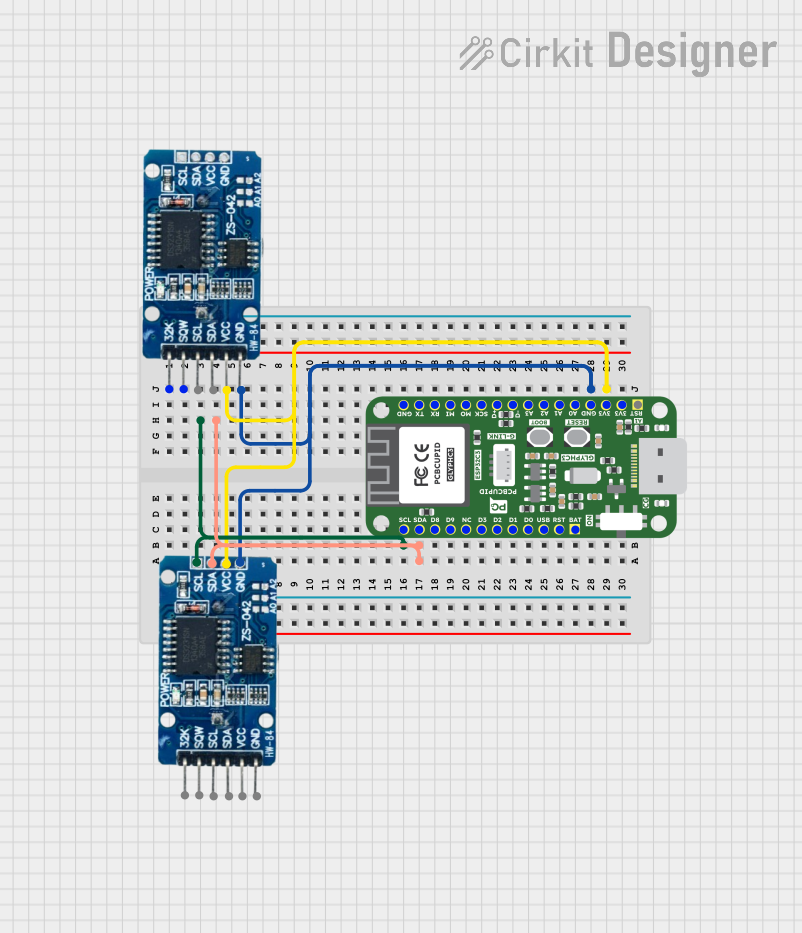

Explore Projects Built with CT Close

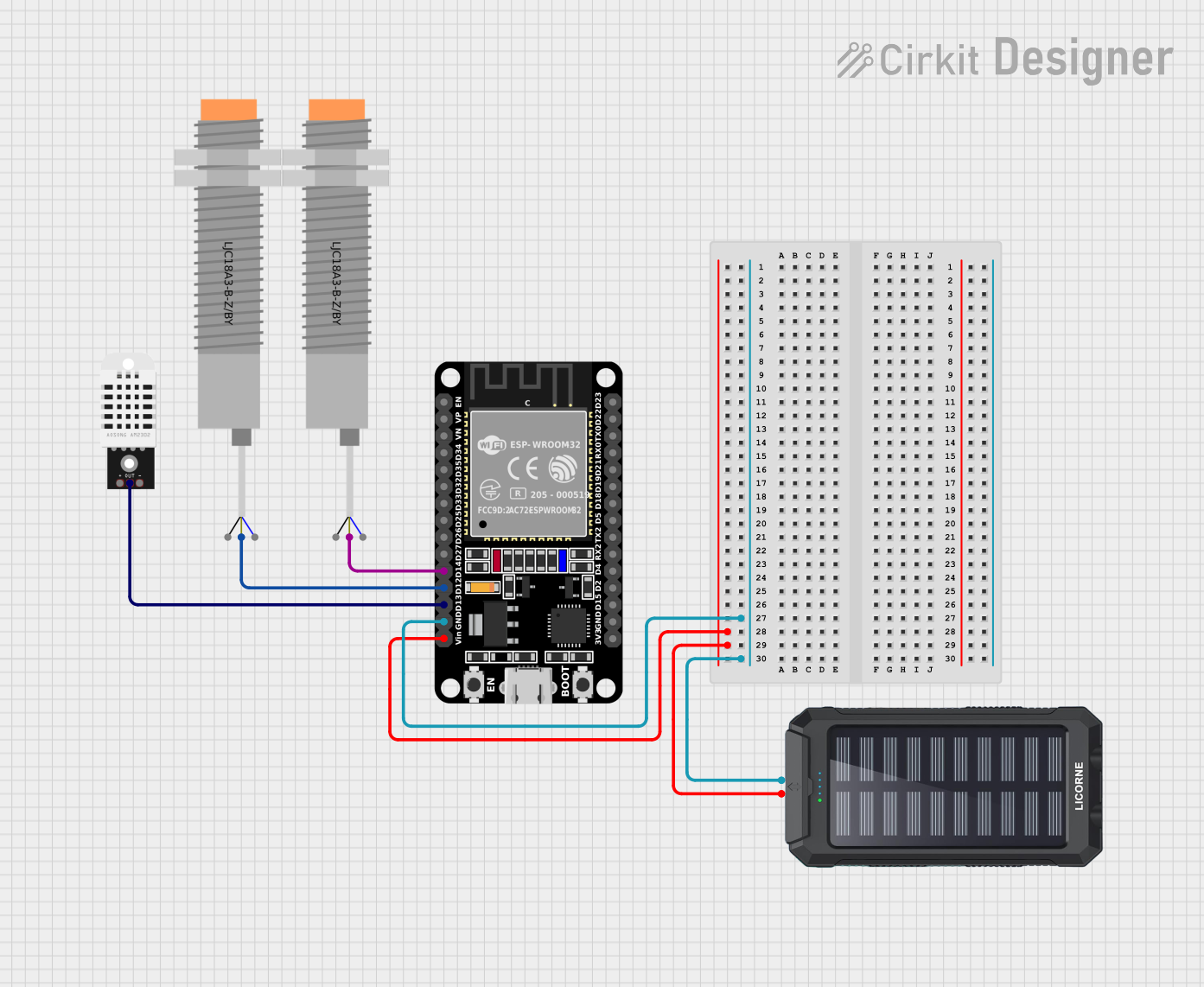

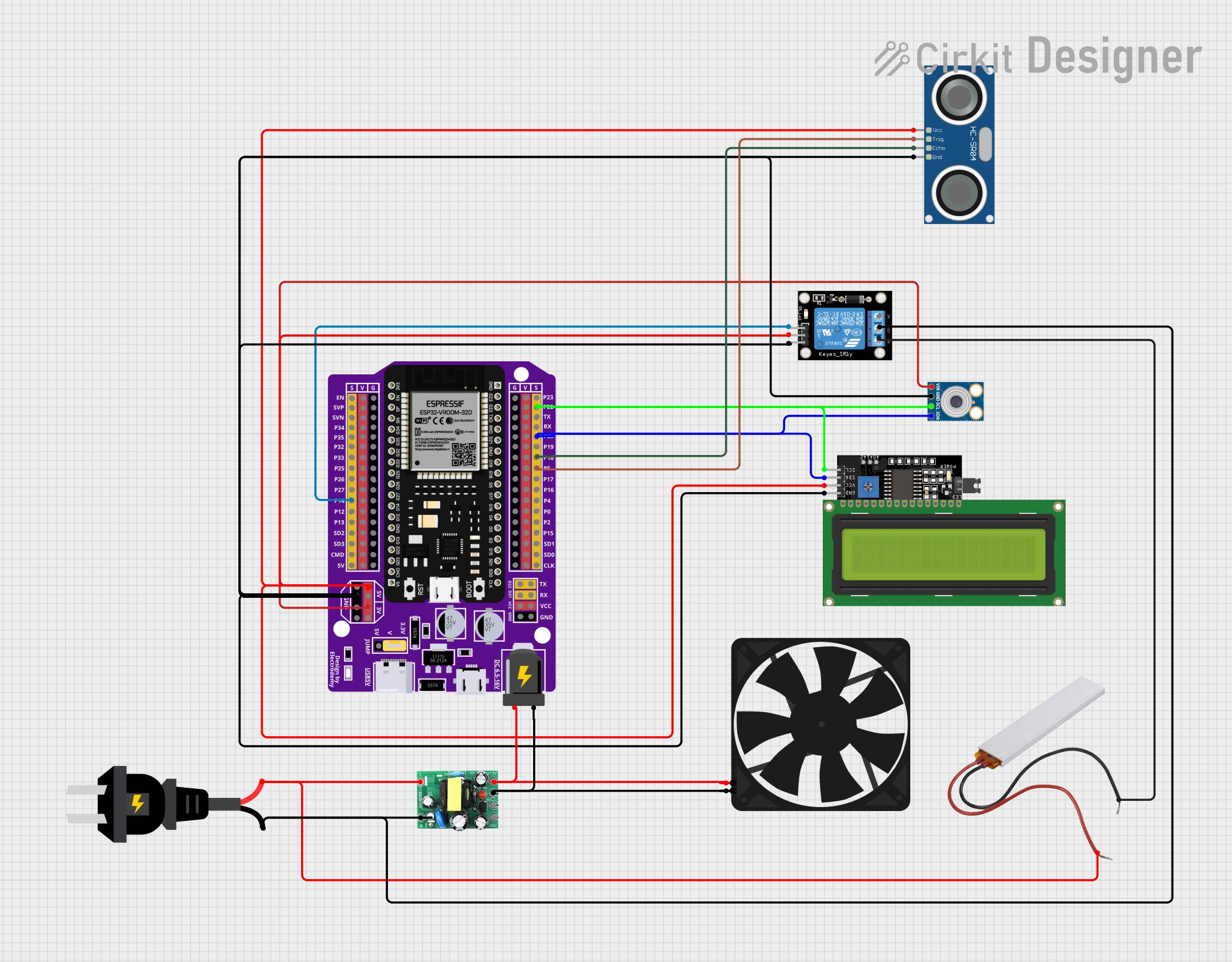

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with CT Close

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Manufacturer | 1 |

| Part ID | 2 |

| Voltage Rating | 24V DC |

| Current Rating | 10A |

| Power Rating | 240W |

| Contact Resistance | ≤ 100 mΩ |

| Insulation Resistance | ≥ 1000 MΩ @ 500V DC |

| Operating Temperature | -40°C to +85°C |

| Mechanical Life | 10^6 operations |

| Electrical Life | 10^5 operations |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | COM | Common terminal |

| 2 | NO | Normally Open contact |

| 3 | NC | Normally Closed contact |

| 4 | Coil+ | Positive terminal of the relay coil |

| 5 | Coil- | Negative terminal of the relay coil |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply Connection: Connect the positive terminal of the power supply to the Coil+ pin and the negative terminal to the Coil- pin to energize the relay coil.

- Load Connection: Connect the load between the COM and NO pins if you want the circuit to be closed when the relay is energized. Alternatively, connect the load between the COM and NC pins if you want the circuit to be closed when the relay is de-energized.

- Current Transformer Connection: Connect the secondary winding of the current transformer to the COM and NO pins to allow current flow through the secondary winding when the relay is energized.

Important Considerations and Best Practices

- Voltage and Current Ratings: Ensure that the voltage and current ratings of the CT Close match the requirements of your application to prevent damage to the component or the circuit.

- Proper Insulation: Maintain proper insulation between the high voltage and low voltage sides of the circuit to ensure safety and prevent electrical hazards.

- Avoid Overloading: Do not exceed the specified current rating to avoid overheating and potential failure of the relay.

- Regular Maintenance: Periodically check the contact resistance and insulation resistance to ensure reliable operation and longevity of the component.

Troubleshooting and FAQs

Common Issues Users Might Face

- Relay Not Energizing: If the relay does not energize, check the power supply connections to the Coil+ and Coil- pins. Ensure that the voltage is within the specified range.

- No Current Flow Through Secondary Winding: If there is no current flow through the secondary winding of the CT, verify the connections between the COM and NO pins. Ensure that the relay is properly energized.

- High Contact Resistance: If the contact resistance is higher than specified, clean the contacts and check for any signs of wear or damage. Replace the relay if necessary.

Solutions and Tips for Troubleshooting

- Check Power Supply: Ensure that the power supply voltage is stable and within the specified range for the relay coil.

- Verify Connections: Double-check all connections to ensure they are secure and correctly wired.

- Inspect Relay Contacts: Periodically inspect the relay contacts for signs of wear, corrosion, or damage. Clean or replace the relay if needed.

- Test Insulation Resistance: Use a megohmmeter to test the insulation resistance between the relay contacts and the coil. Ensure it meets the specified value.

Example Code for Arduino UNO

Below is an example code to control the CT Close relay using an Arduino UNO:

// Define the pin connected to the relay coil

const int relayPin = 7;

void setup() {

// Initialize the relay pin as an output

pinMode(relayPin, OUTPUT);

}

void loop() {

// Energize the relay to close the circuit

digitalWrite(relayPin, HIGH);

delay(5000); // Keep the relay energized for 5 seconds

// De-energize the relay to open the circuit

digitalWrite(relayPin, LOW);

delay(5000); // Keep the relay de-energized for 5 seconds

}

This code will energize the relay for 5 seconds, allowing current to flow through the secondary winding of the CT, and then de-energize it for 5 seconds, stopping the current flow. Adjust the delay values as needed for your specific application.

By following this documentation, users can effectively utilize the CT Close component in their circuits, ensuring accurate current measurement and protection in various electrical systems.