How to Use DC Motor with Encoder: Examples, Pinouts, and Specs

Design with DC Motor with Encoder in Cirkit Designer

Design with DC Motor with Encoder in Cirkit DesignerIntroduction

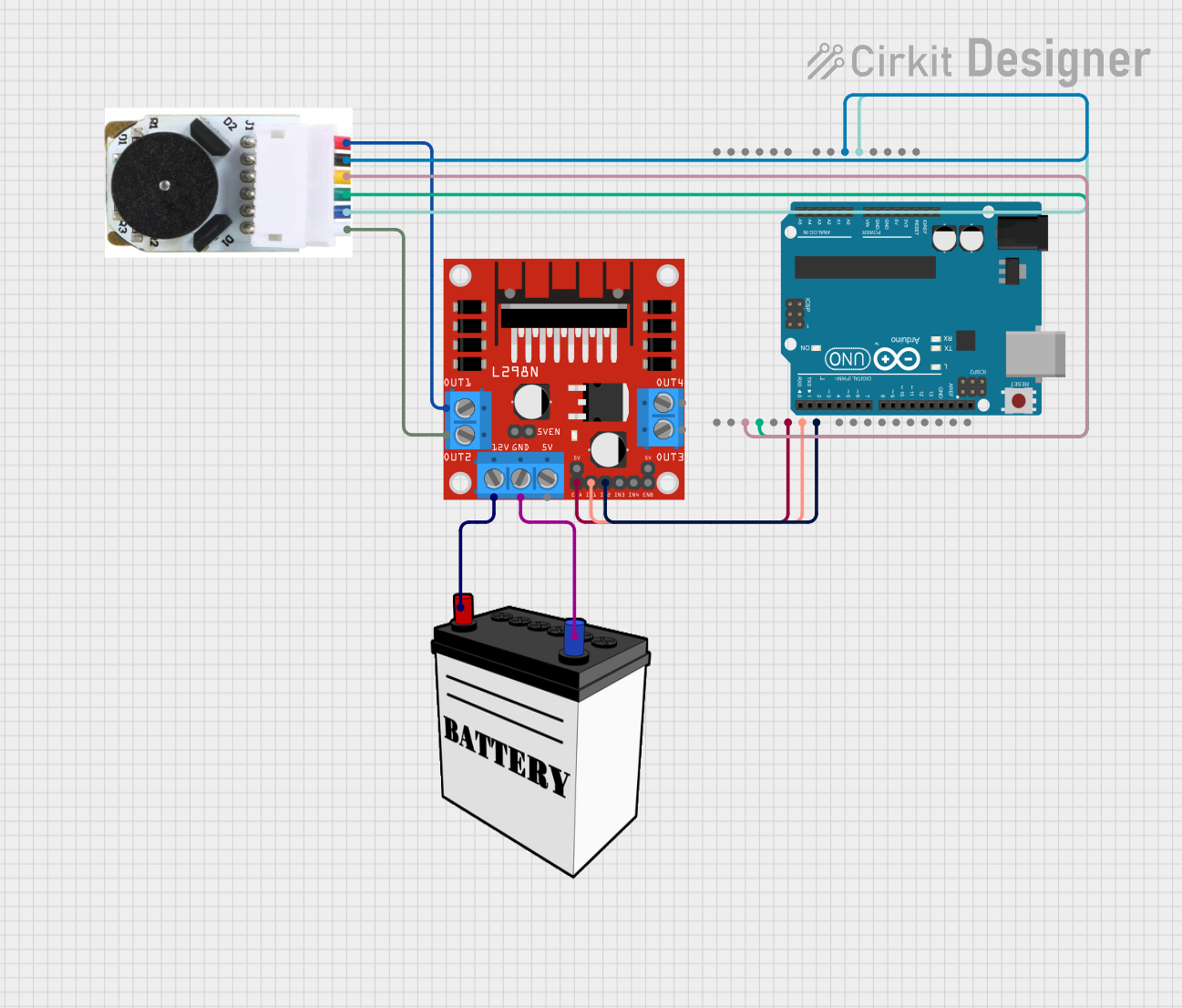

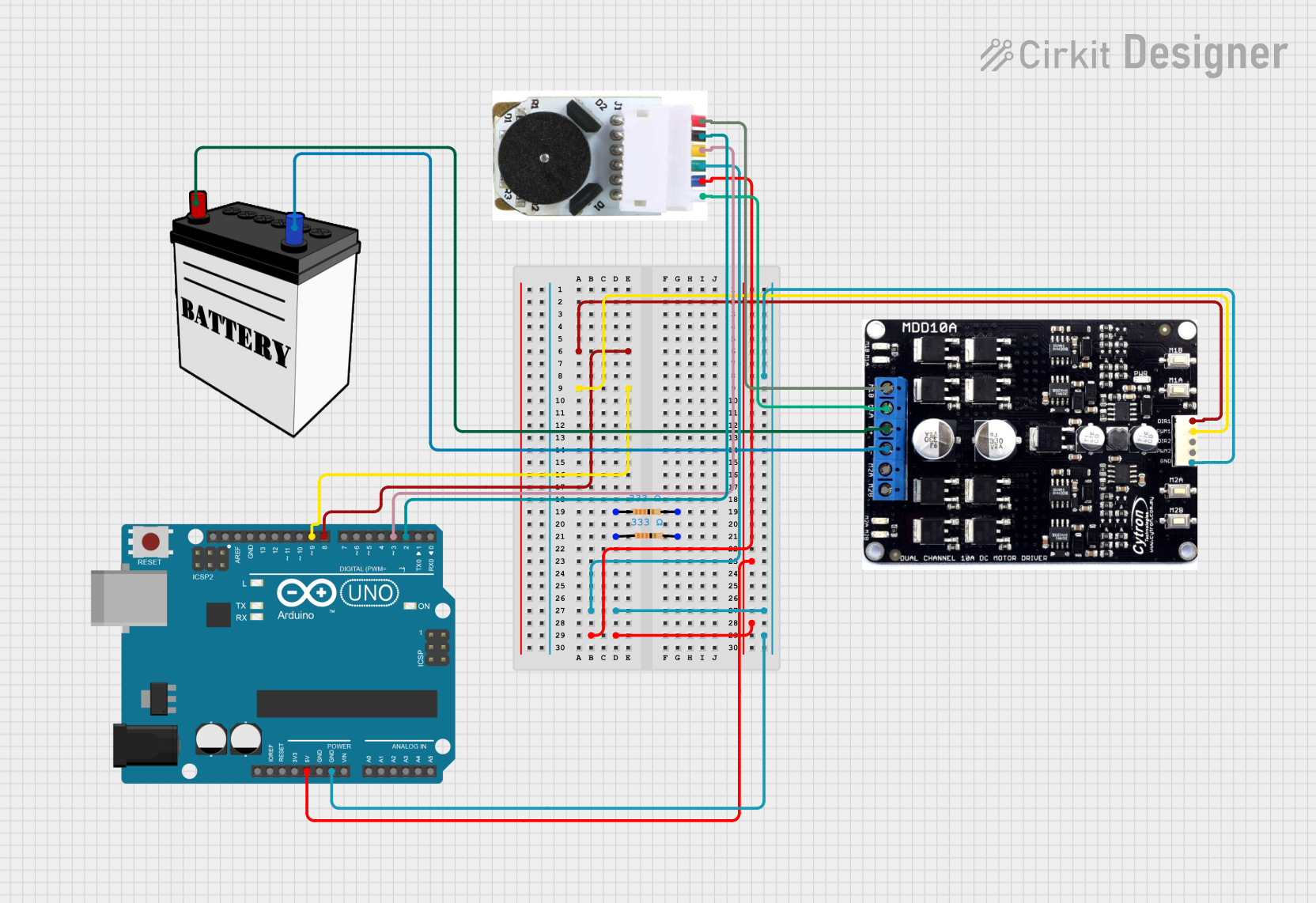

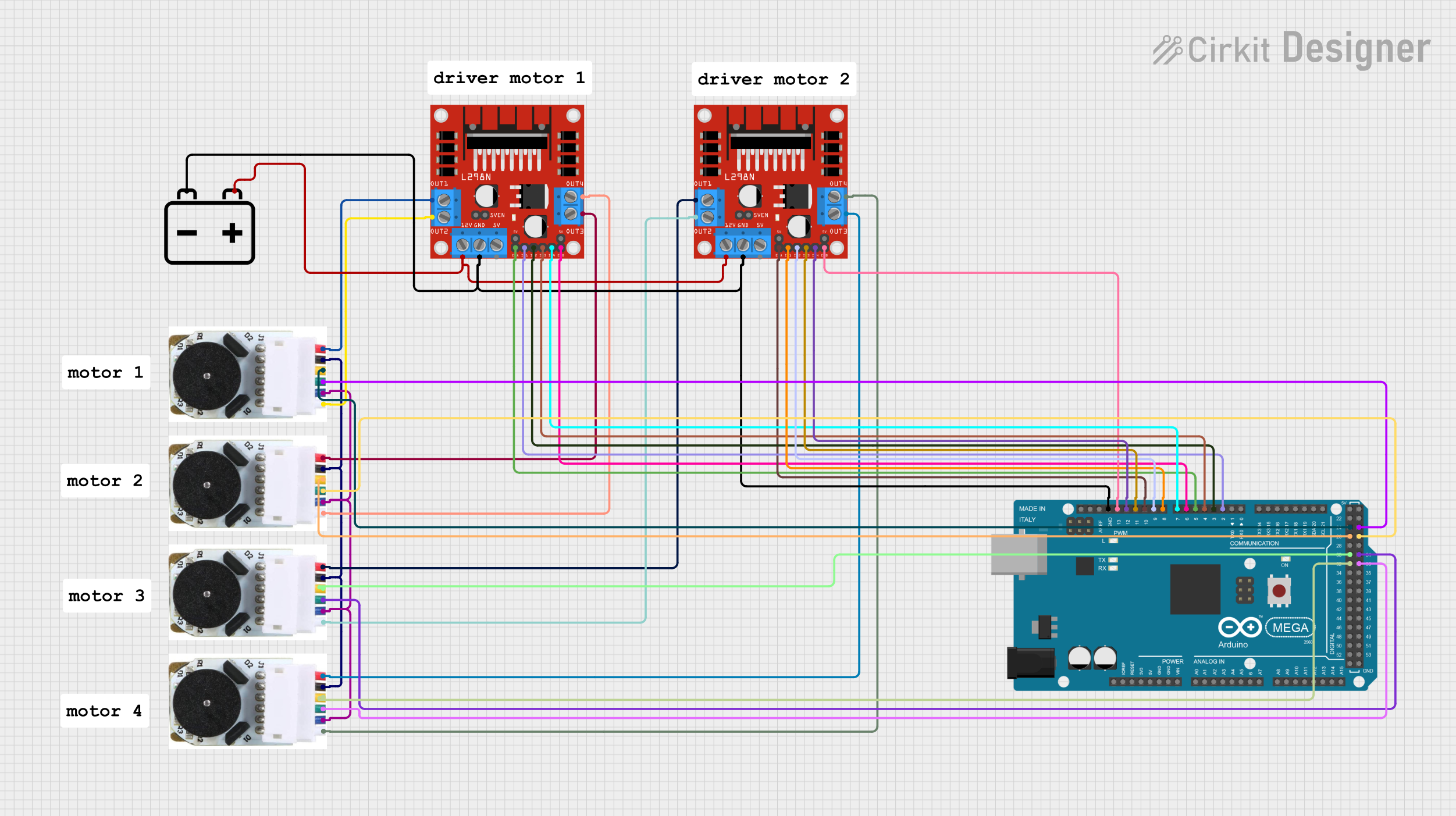

A DC motor with an encoder is a vital component in robotics and automation, allowing for precise control over position and speed. The encoder provides feedback that can be used to adjust the motor's input and achieve the desired motion. This type of motor is commonly used in applications such as robotic arms, conveyor belts, and any system requiring controlled movement.

Explore Projects Built with DC Motor with Encoder

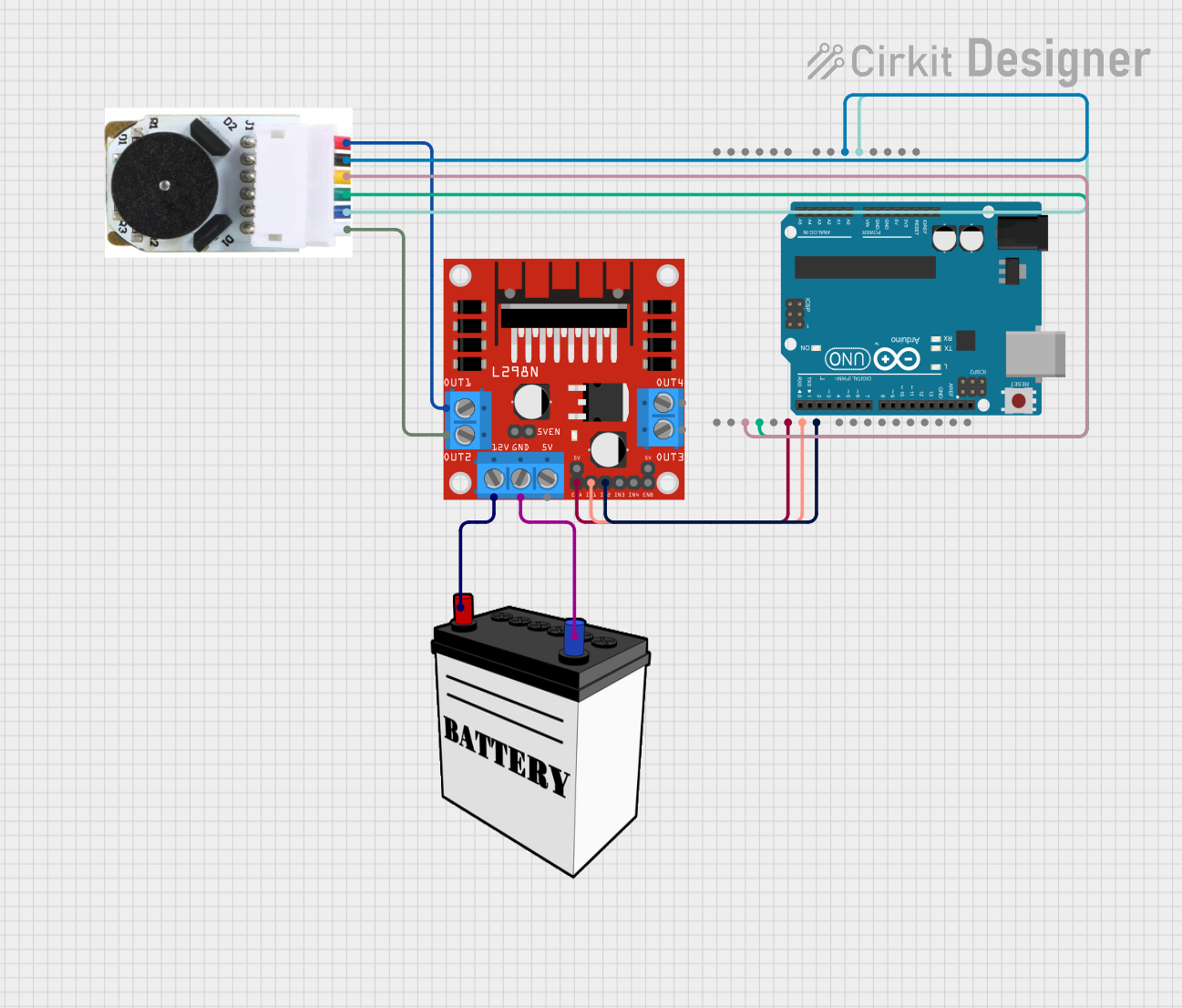

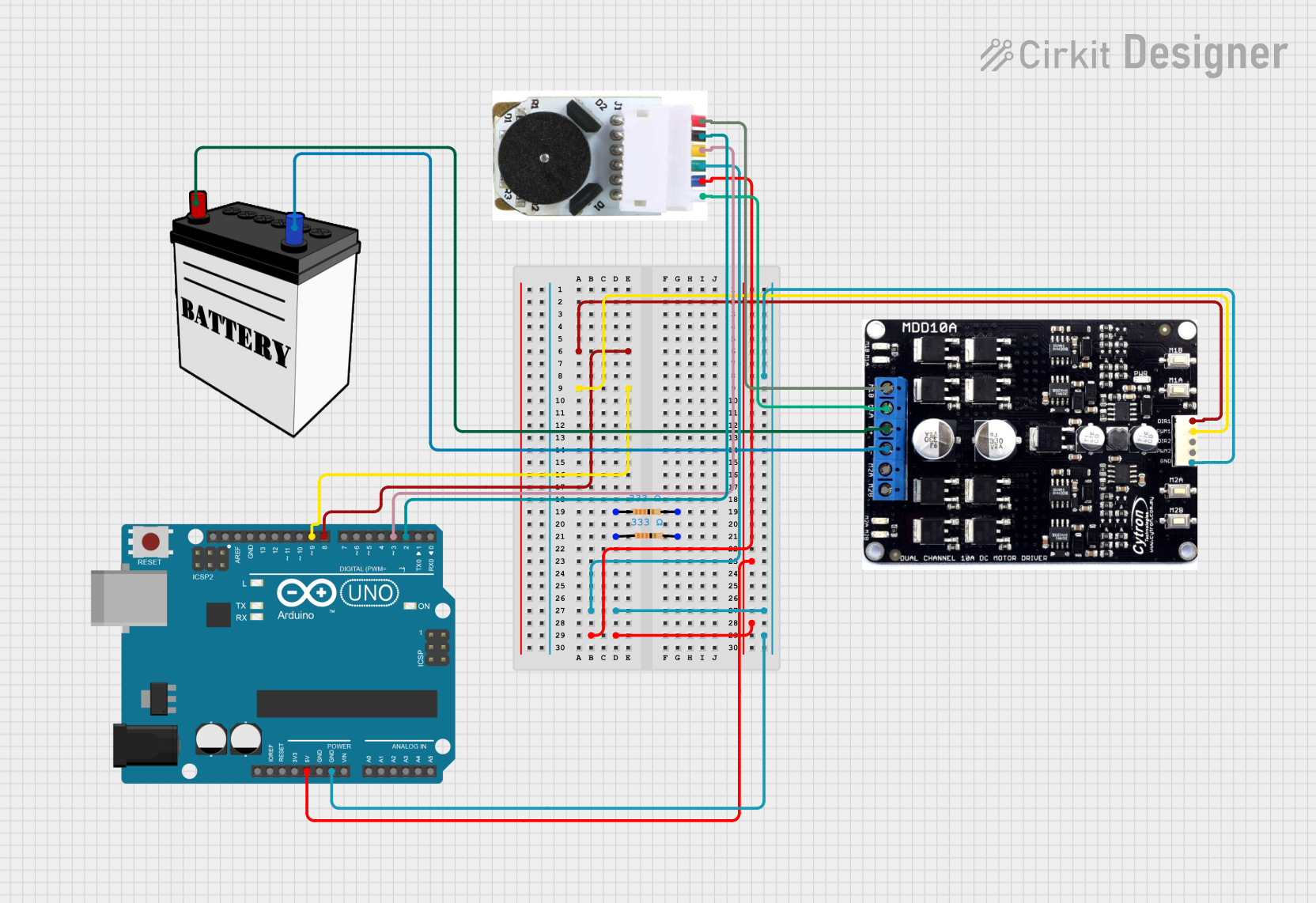

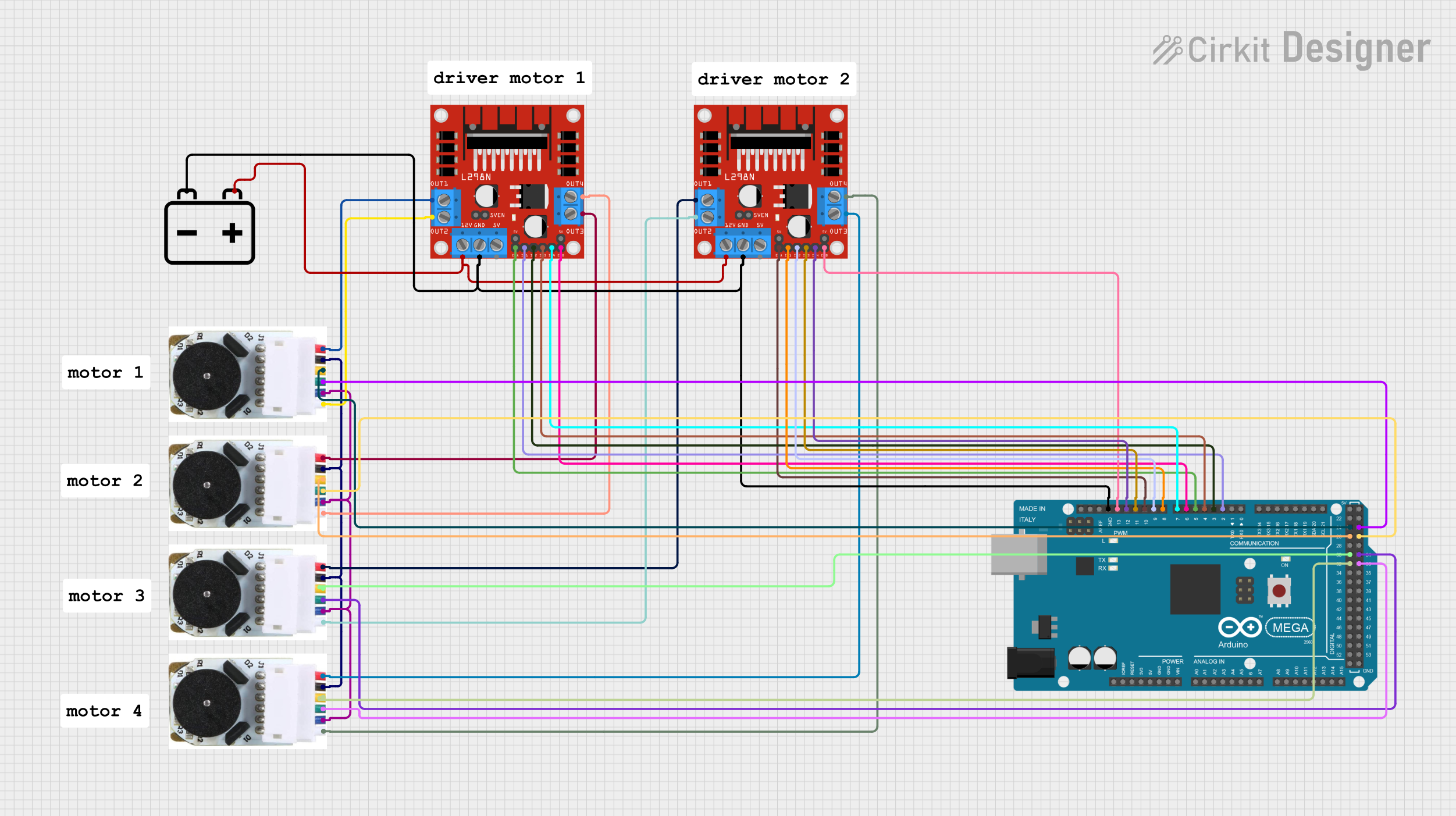

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DC Motor with Encoder

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Specifications

- Motor Type: Brushed DC Motor

- Encoder Type: Quadrature Encoder

- Supply Voltage: Typically 6V to 12V DC

- Rated Speed: Varies, e.g., 1000 RPM at 12V

- Rated Torque: Varies, e.g., 1 Nm at 12V

- Gear Ratio: Often included, e.g., 50:1

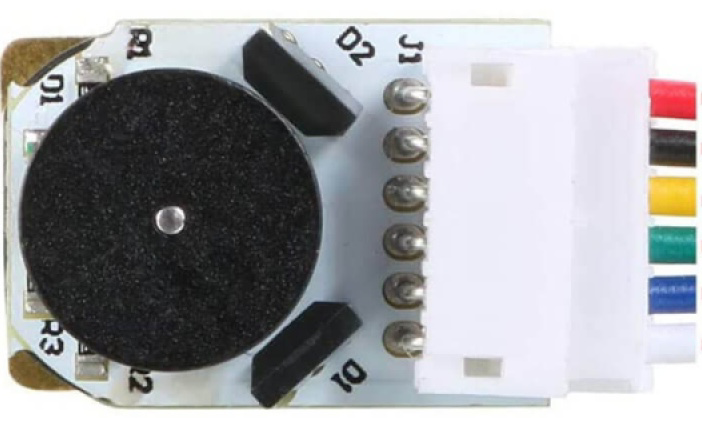

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Motor Power (+) | Connect to positive voltage |

| 2 | Motor Power (-) | Connect to ground |

| 3 | Encoder Vcc | Encoder power supply (3.3V-5V) |

| 4 | Encoder GND | Encoder ground |

| 5 | Encoder Channel A | Outputs pulses for speed/position |

| 6 | Encoder Channel B | Outputs pulses for direction |

Usage Instructions

Connecting the Motor

- Connect the motor power pins to your power supply, ensuring the voltage is within the motor's rated specifications.

- Connect the encoder Vcc to a 3.3V or 5V supply from your microcontroller (e.g., Arduino UNO).

- Connect the encoder GND to the ground of your microcontroller.

Interfacing with a Microcontroller

To use the motor with an Arduino UNO, you'll need to connect the encoder output pins to two digital input pins on the Arduino. You can use the attachInterrupt() function to count the pulses from the encoder, which represent the motor's rotation.

Sample Arduino Code

// Define the encoder pins

const int encoderPinA = 2; // Interrupt pin for encoder A

const int encoderPinB = 3; // Interrupt pin for encoder B

volatile long encoderTicks = 0;

// Interrupt service routine for encoder A

void encoderISR() {

if (digitalRead(encoderPinB) == HIGH) {

encoderTicks++;

} else {

encoderTicks--;

}

}

void setup() {

pinMode(encoderPinA, INPUT);

pinMode(encoderPinB, INPUT);

// Attach interrupt on a rising edge of encoder A (to call encoderISR)

attachInterrupt(digitalPinToInterrupt(encoderPinA), encoderISR, RISING);

Serial.begin(9600);

}

void loop() {

Serial.println(encoderTicks);

delay(1000); // Update every second

}

Important Considerations and Best Practices

- Ensure the power supply does not exceed the motor's voltage rating to prevent damage.

- Use a motor driver or H-bridge to control the motor's direction and speed.

- Implement debounce logic in software or hardware to ensure accurate encoder readings.

- Consider using a pull-up or pull-down resistor on the encoder outputs to stabilize the signal.

Troubleshooting and FAQs

Common Issues

- Motor not turning: Check power supply connections and voltage levels.

- Inaccurate encoder readings: Verify the encoder connections and ensure there are no loose wires. Implement debounce logic if necessary.

- Motor turning erratically: Ensure that the motor driver is functioning correctly and that the PWM signal is stable.

FAQs

Q: How do I reverse the motor's direction? A: Use an H-bridge or motor driver to reverse the polarity of the voltage applied to the motor.

Q: Can I use this motor at a voltage lower than the rated voltage? A: Yes, but the motor will run slower and with less torque.

Q: How do I calculate the motor's position from the encoder? A: Count the number of encoder pulses and consider the encoder's resolution and the motor's gear ratio to determine the position.

Q: What is the purpose of having two channels on the encoder? A: Two channels allow for detecting the direction of rotation by comparing the phase of the signals.

For further assistance, consult the manufacturer's datasheet or contact technical support.