How to Use AC Synchronous Motor(5/6R/min): Examples, Pinouts, and Specs

Design with AC Synchronous Motor(5/6R/min) in Cirkit Designer

Design with AC Synchronous Motor(5/6R/min) in Cirkit DesignerIntroduction

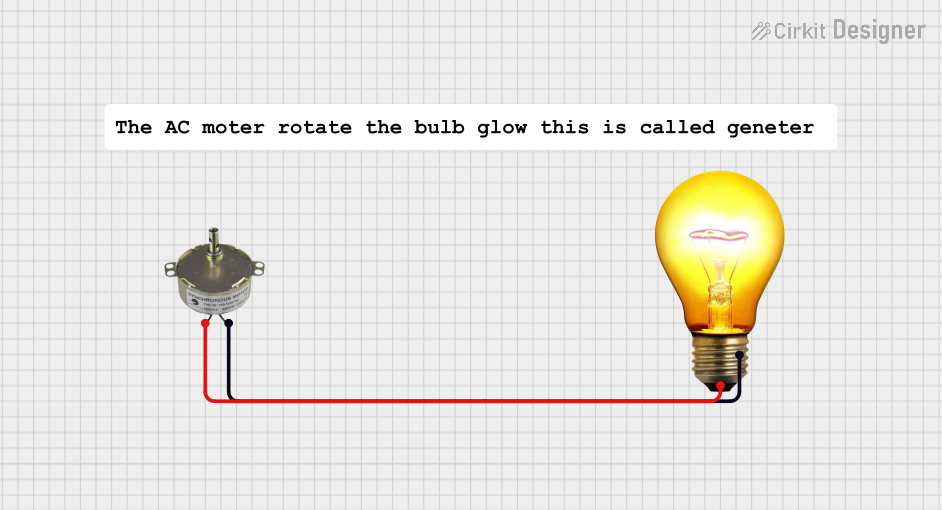

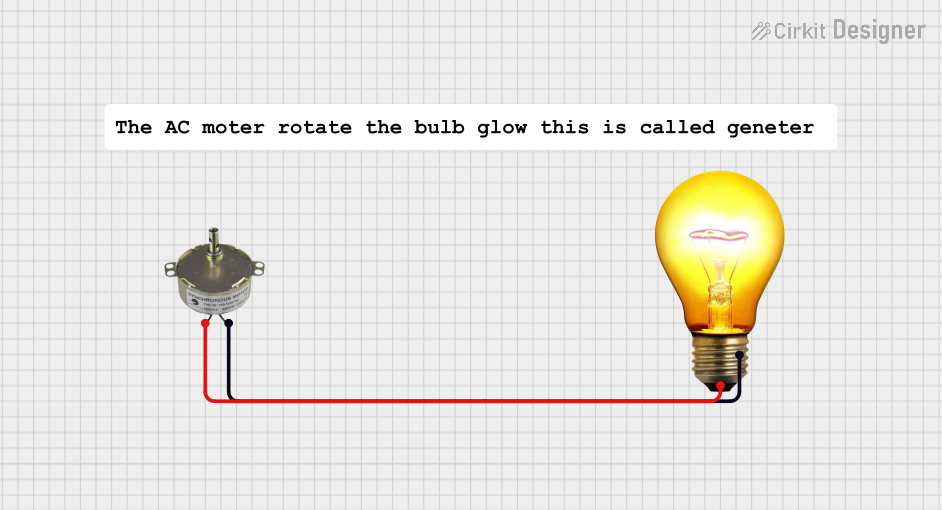

An AC Synchronous Motor is an electromechanical device that converts alternating current (AC) electrical energy into mechanical energy. This type of motor operates at a constant speed, which is synchronized with the frequency of the AC power supply. The 5/6 revolutions per minute (R/min) AC Synchronous Motor is specifically designed to rotate at a speed of 5 or 6 rotations per minute, depending on the frequency of the power source. Common applications include clock mechanisms, advertising displays, and any system requiring precise and constant low-speed rotation.

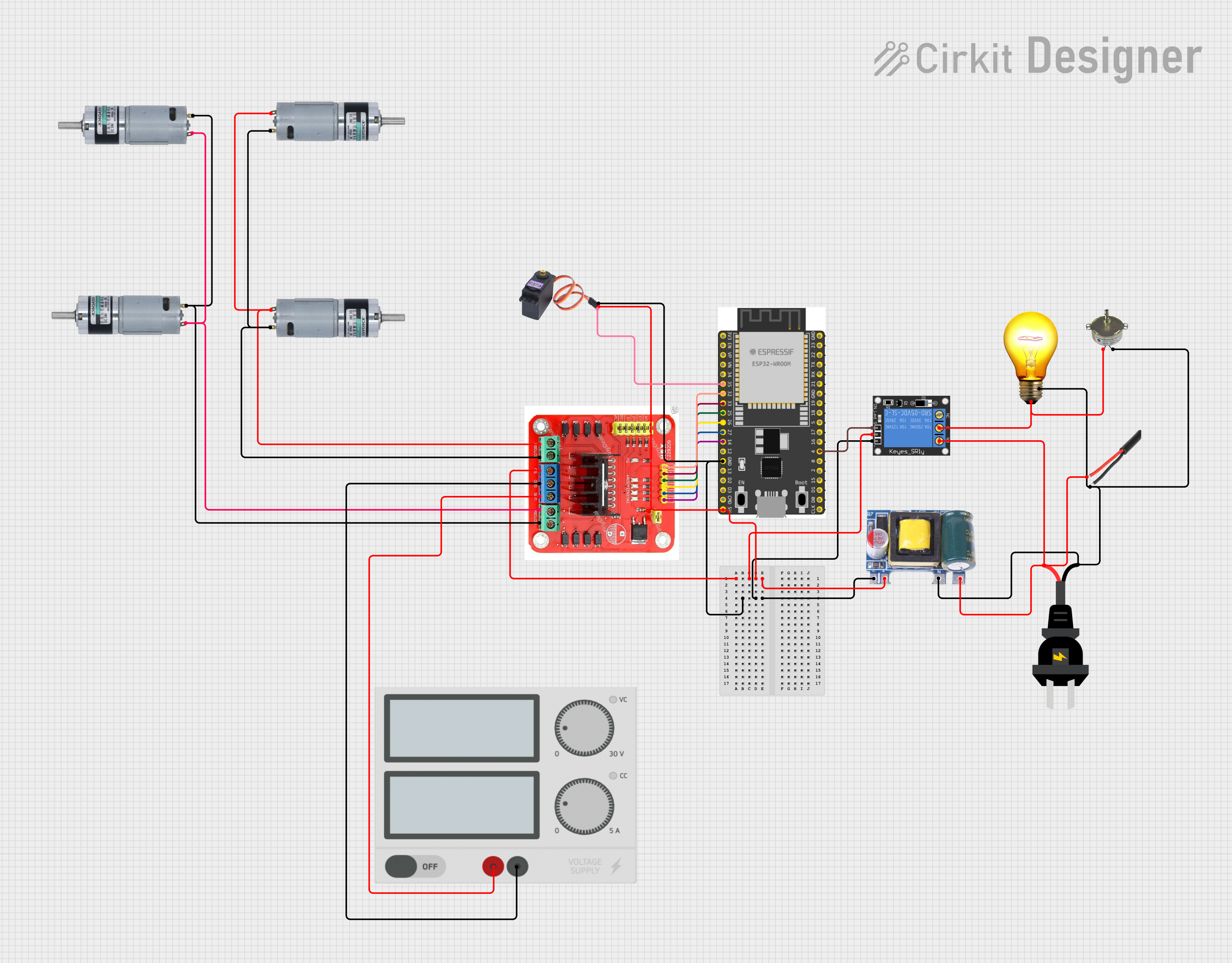

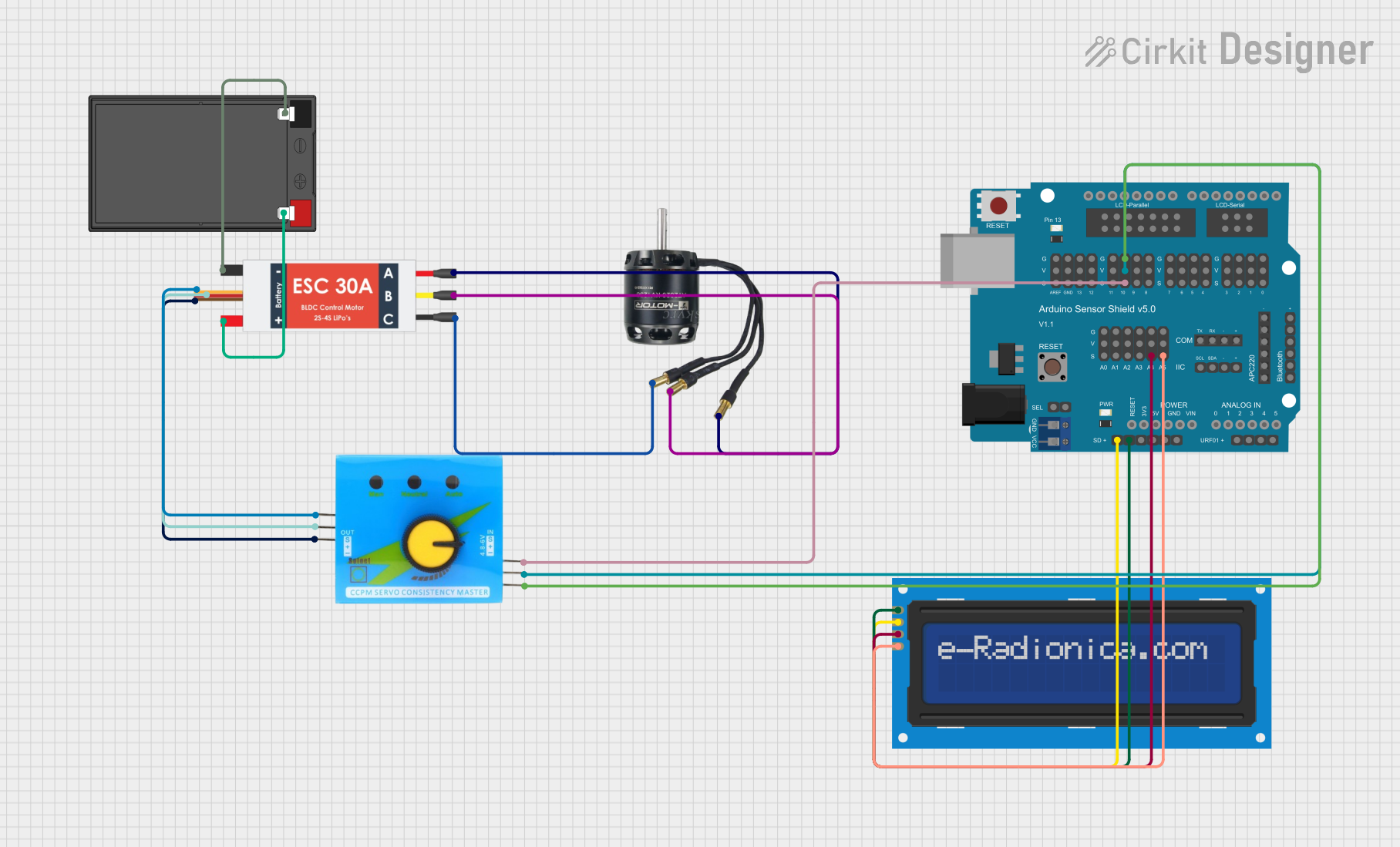

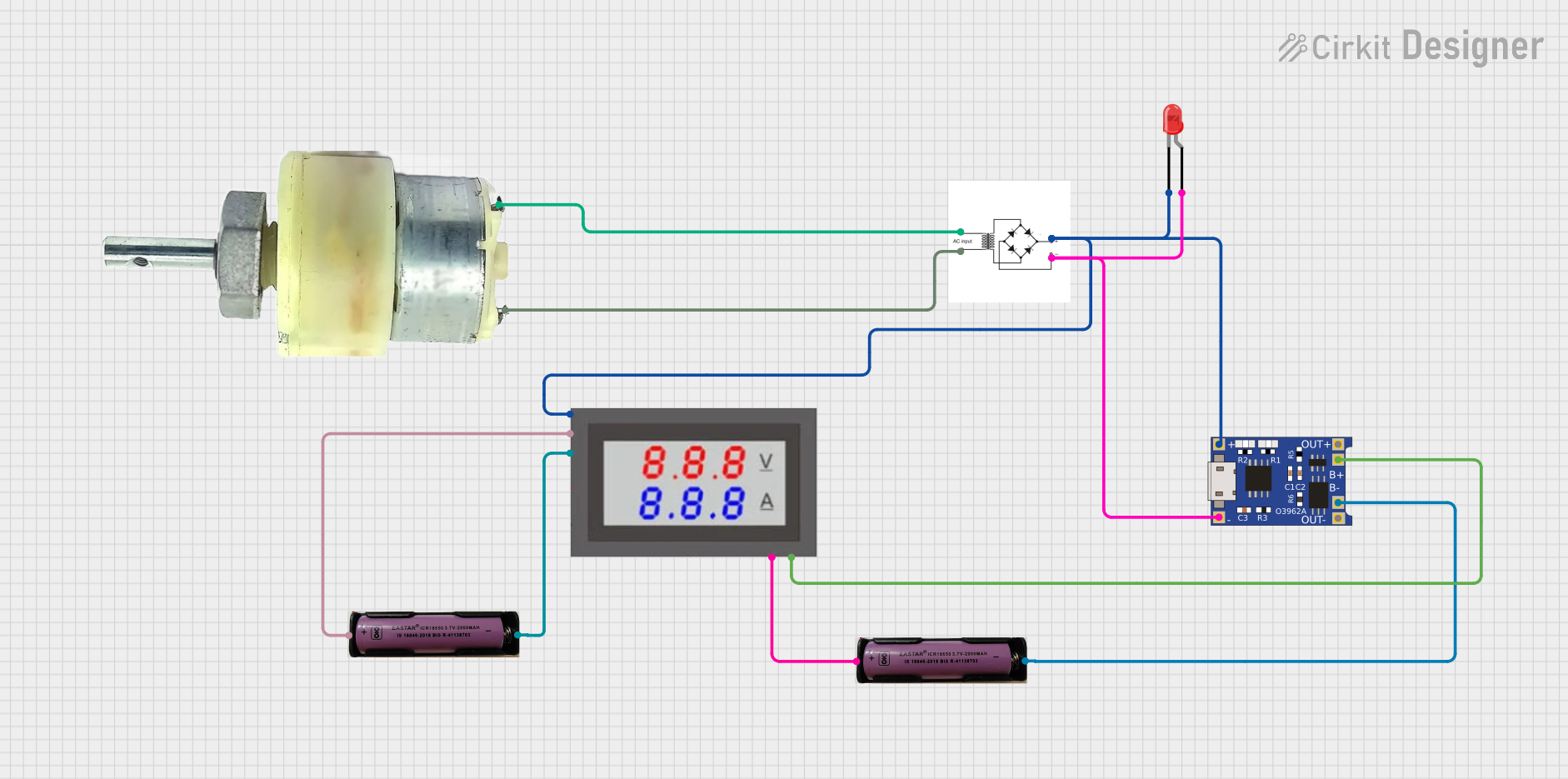

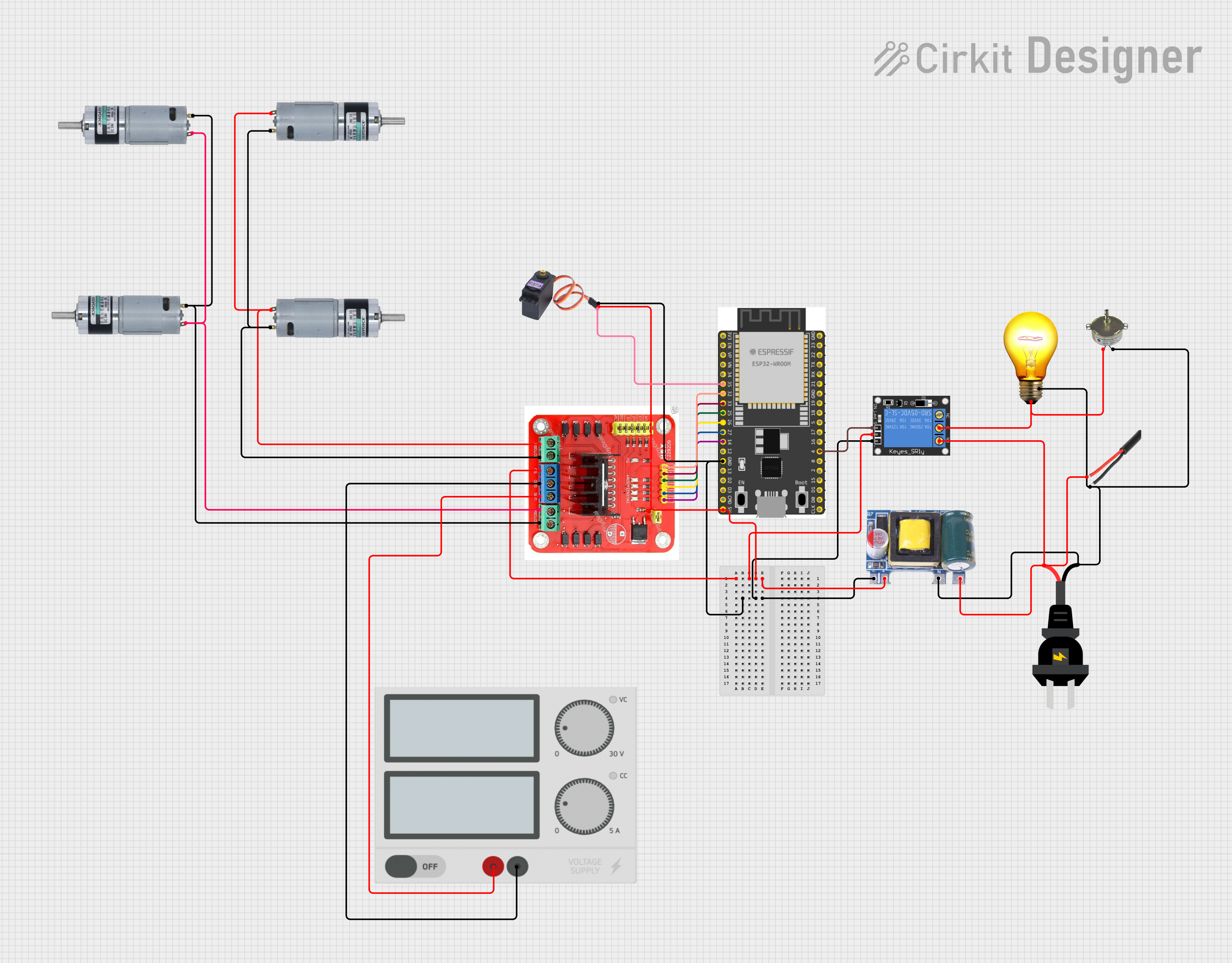

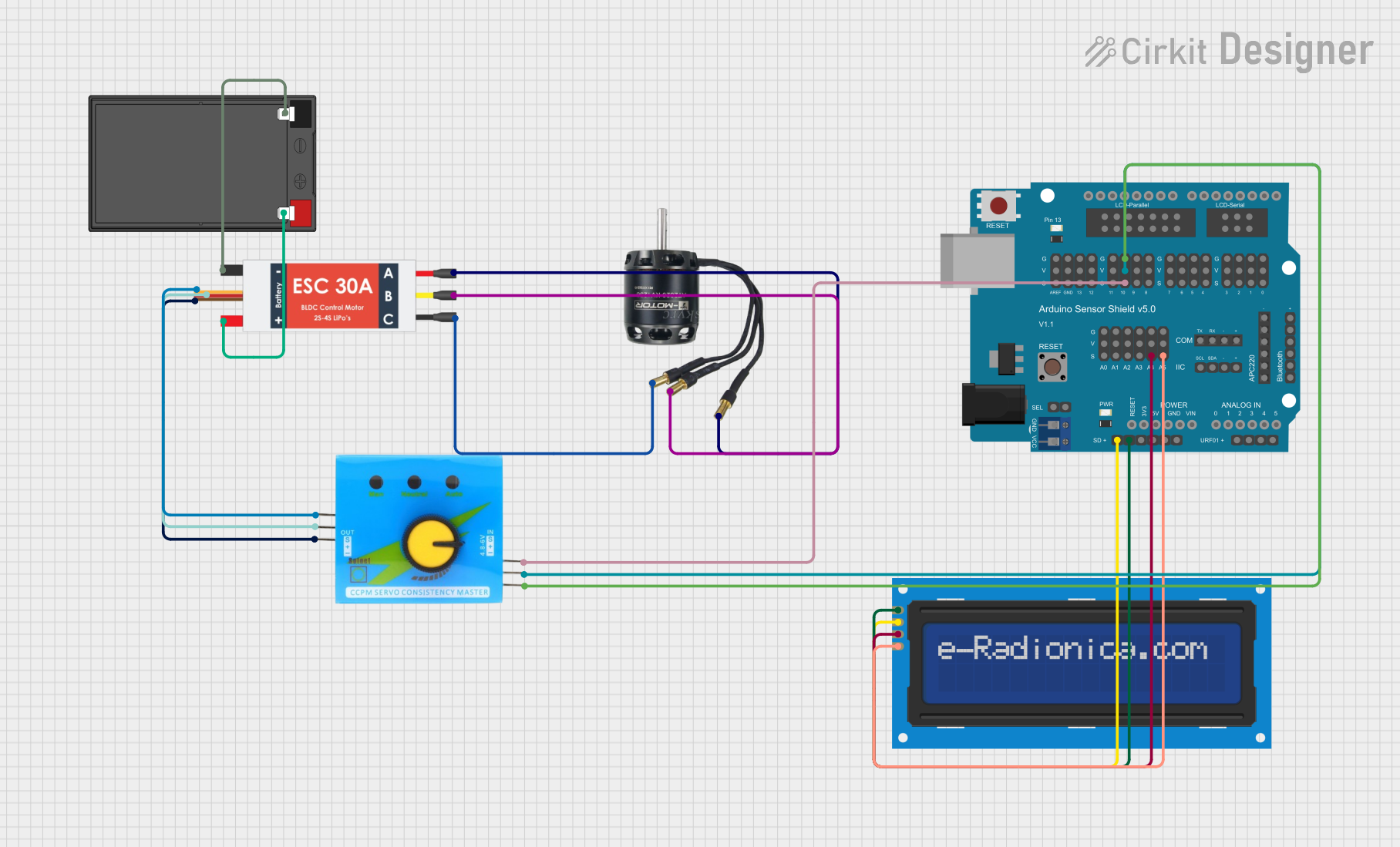

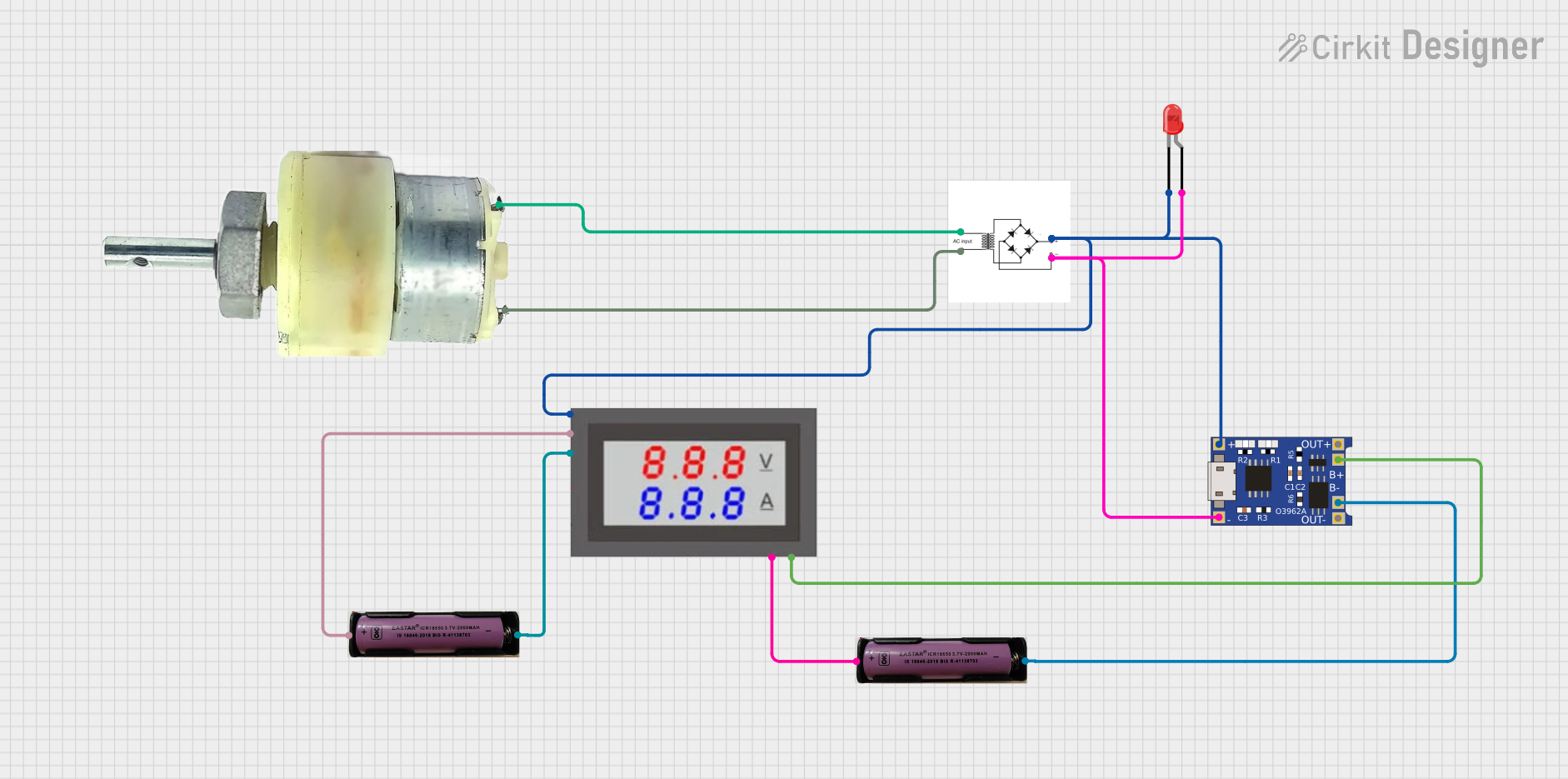

Explore Projects Built with AC Synchronous Motor(5/6R/min)

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with AC Synchronous Motor(5/6R/min)

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Characteristics

- Type: AC Synchronous Motor

- Speed: 5/6 R/min (fixed)

- Frequency: 50/60 Hz (depending on the region)

- Voltage Rating: Typically 110V or 220V AC (region-specific)

- Power Consumption: Varies with model (check datasheet)

- Torque: Specified in datasheet, sufficient for intended load

- Direction of Rotation: Typically clockwise (viewed from output shaft)

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Live (L) | Connect to phase of AC supply |

| 2 | Neutral (N) | Connect to neutral of AC supply |

Note: The motor may have additional wires or terminals for grounding or specific control features. Refer to the manufacturer's datasheet for exact pinout information.

Usage Instructions

Integration into a Circuit

- Power Supply Connection: Connect the live (L) and neutral (N) wires to the corresponding terminals of an appropriate AC power source. Ensure the voltage rating matches the motor's specification.

- Mounting: Secure the motor to a stable surface to prevent movement during operation.

- Load Attachment: Attach the load (e.g., gear, pulley) to the motor's shaft. Ensure it is firmly fixed to avoid slippage.

Important Considerations and Best Practices

- Voltage Matching: Always use the motor with an AC power supply that matches its voltage rating.

- Load Capacity: Do not exceed the motor's rated torque to prevent damage or reduced lifespan.

- Isolation: Use appropriate isolation techniques to prevent electrical shock.

- Overheating: Ensure adequate ventilation around the motor to prevent overheating.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Start:

- Check the power supply connections.

- Verify that the AC supply voltage matches the motor's rating.

- Inspect for any obstructions that may prevent the motor from rotating.

Motor Rotates Slowly or Irregularly:

- Ensure the load does not exceed the motor's torque capacity.

- Check for mechanical binding or friction in the attached load.

Motor Overheats:

- Confirm that the motor is not overloaded.

- Check for adequate ventilation around the motor.

FAQs

Q: Can I control the speed of the AC Synchronous Motor?

- A: No, the speed is fixed and determined by the frequency of the AC power supply.

Q: Can this motor run on a DC power supply?

- A: No, it requires an AC power supply to operate at its designed speed.

Q: Is it possible to reverse the direction of rotation?

- A: The direction of rotation is typically fixed. Some models may allow reversal by switching certain connections, but consult the manufacturer's datasheet for specific instructions.

Note: This documentation is a general guide and may not cover all aspects of the AC Synchronous Motor. For detailed information, always refer to the manufacturer's datasheet and safety guidelines.