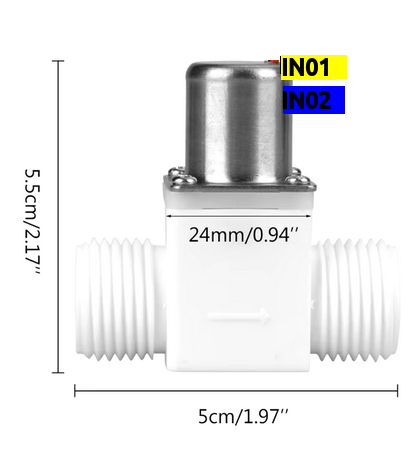

How to Use valve solenoid water: Examples, Pinouts, and Specs

Design with valve solenoid water in Cirkit Designer

Design with valve solenoid water in Cirkit DesignerIntroduction

The AFU 211B Valve Solenoid Water is an electromechanical valve designed for controlling the flow of water within a system. It operates by receiving an electrical signal that activates a solenoid, which in turn opens or closes the valve. This component is commonly used in irrigation systems, home appliances, and industrial machines where precise control of water flow is necessary.

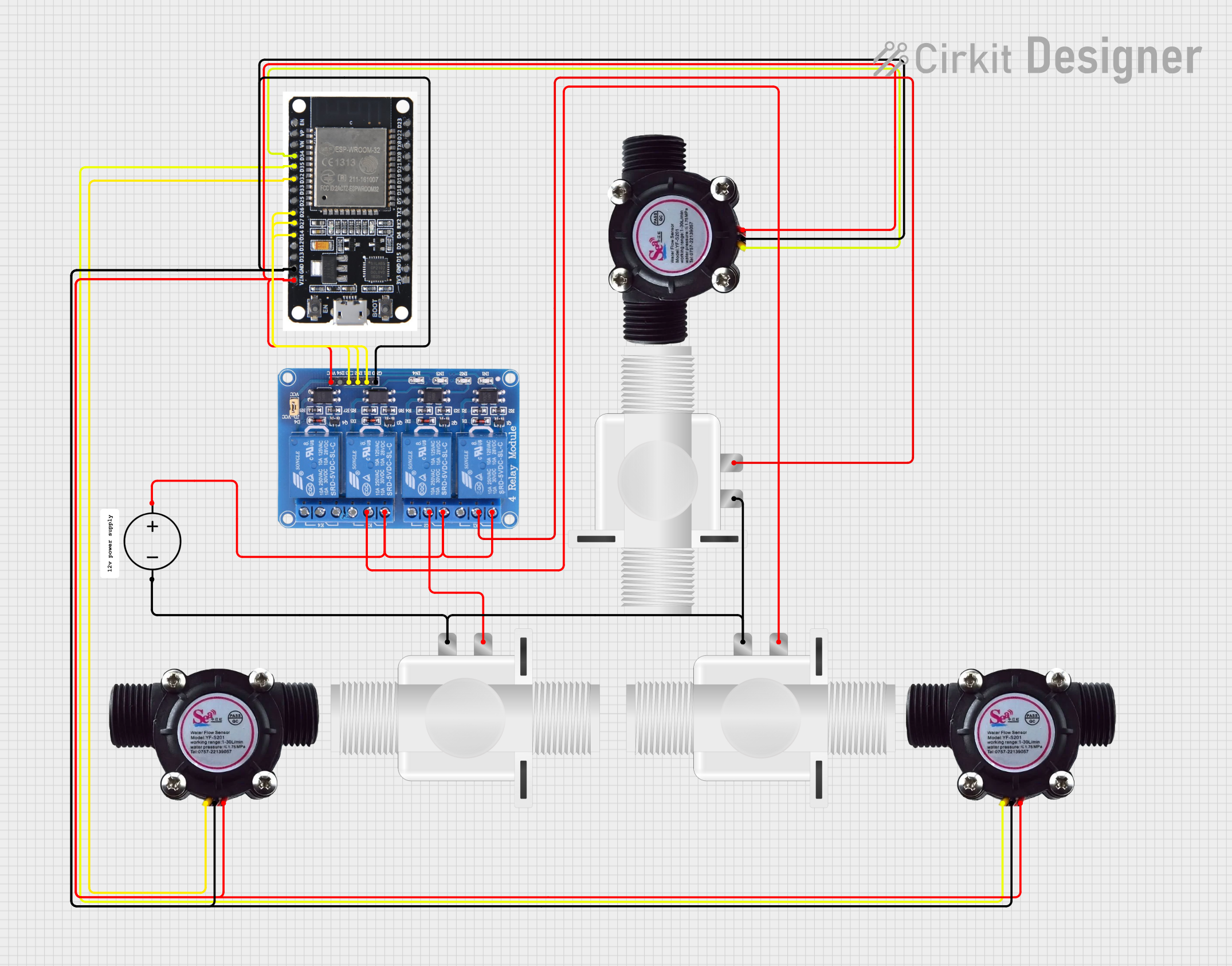

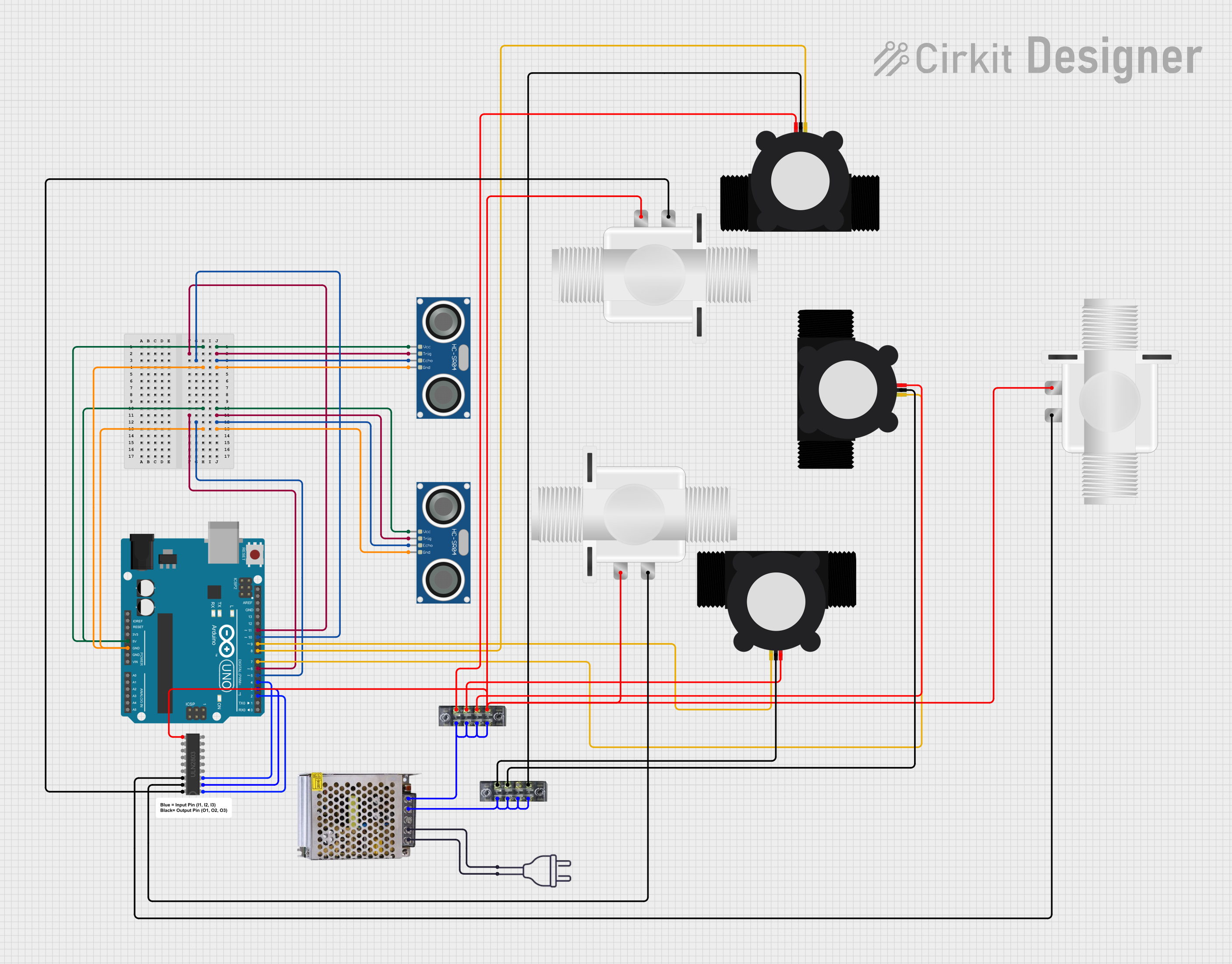

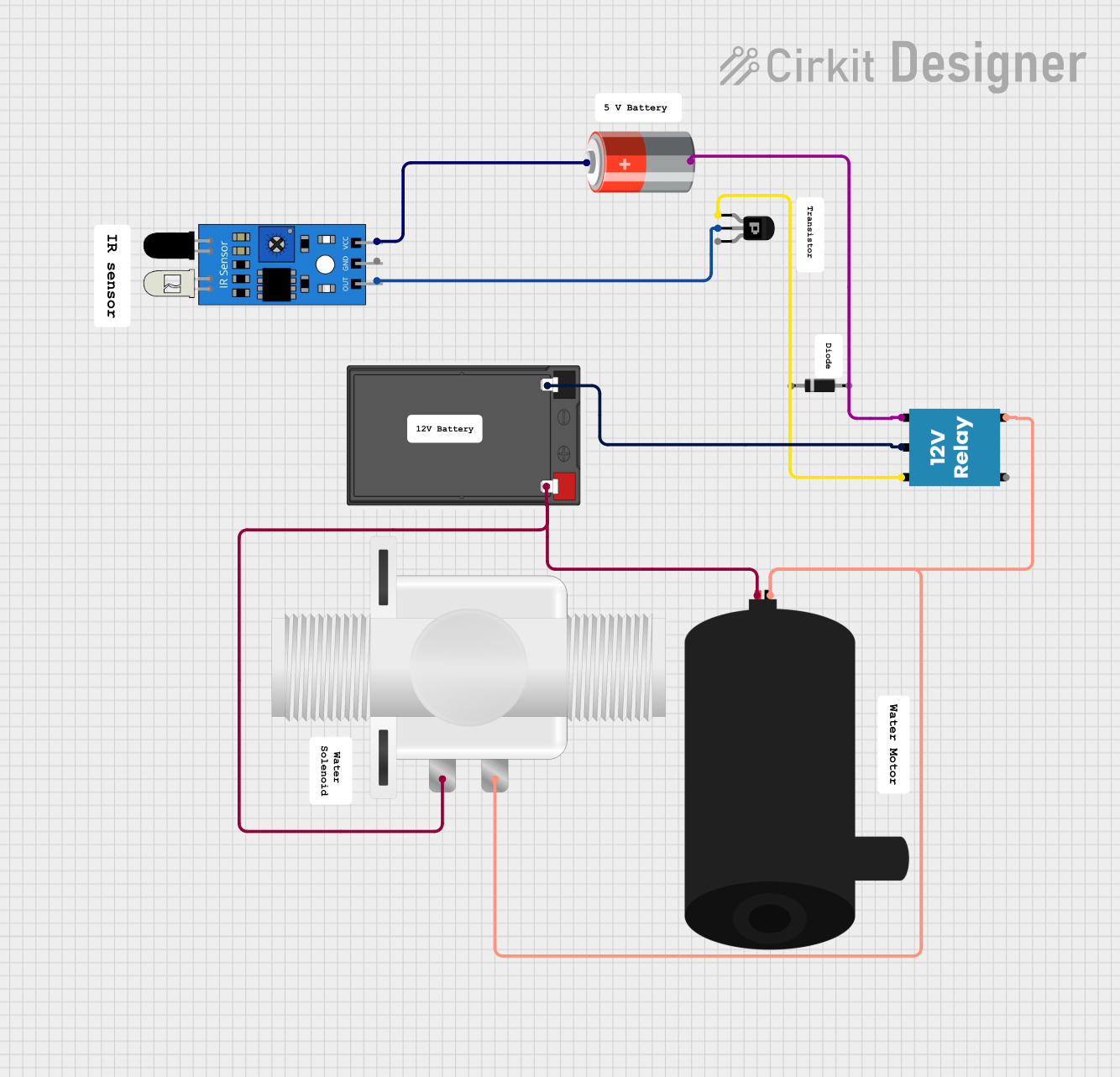

Explore Projects Built with valve solenoid water

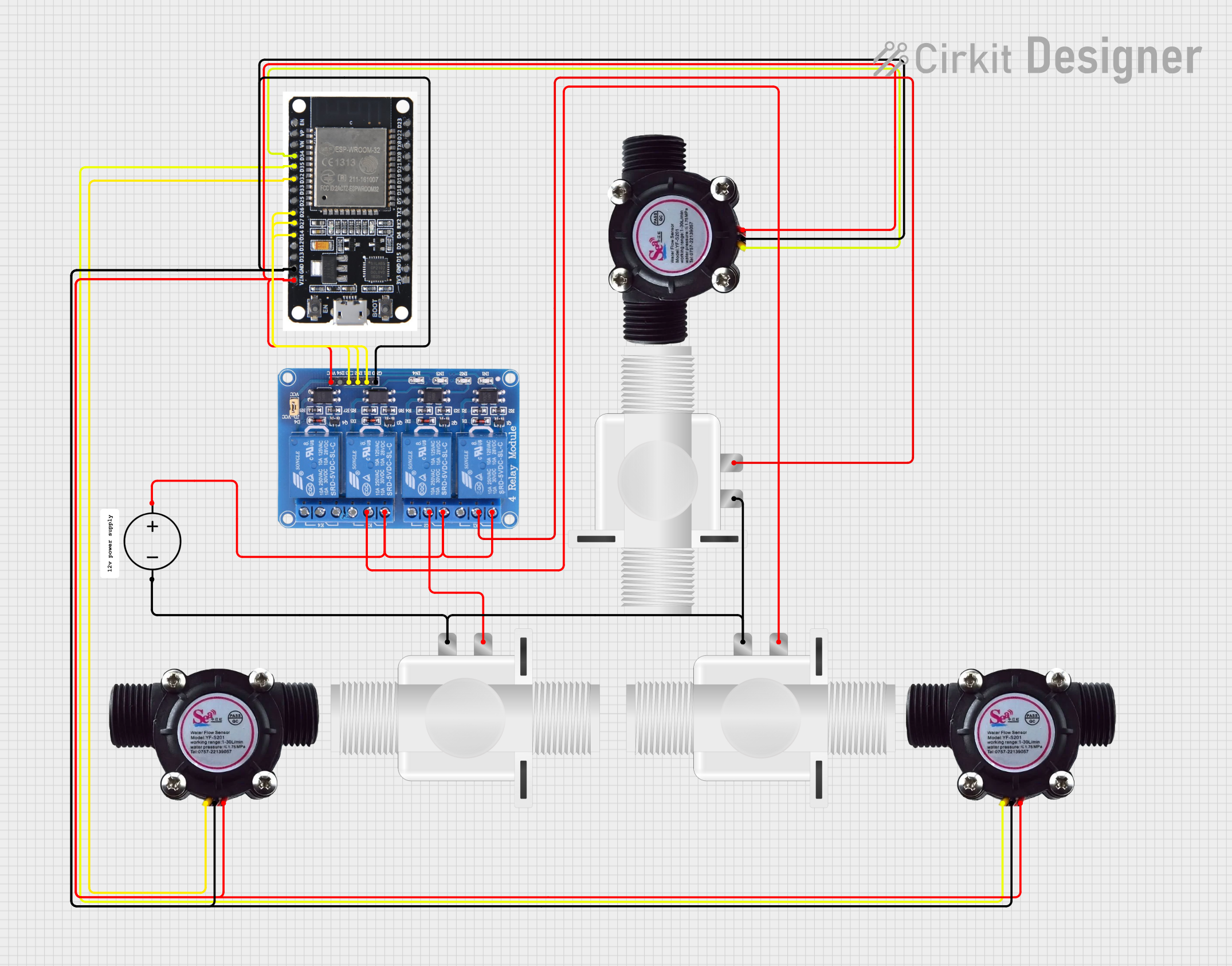

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

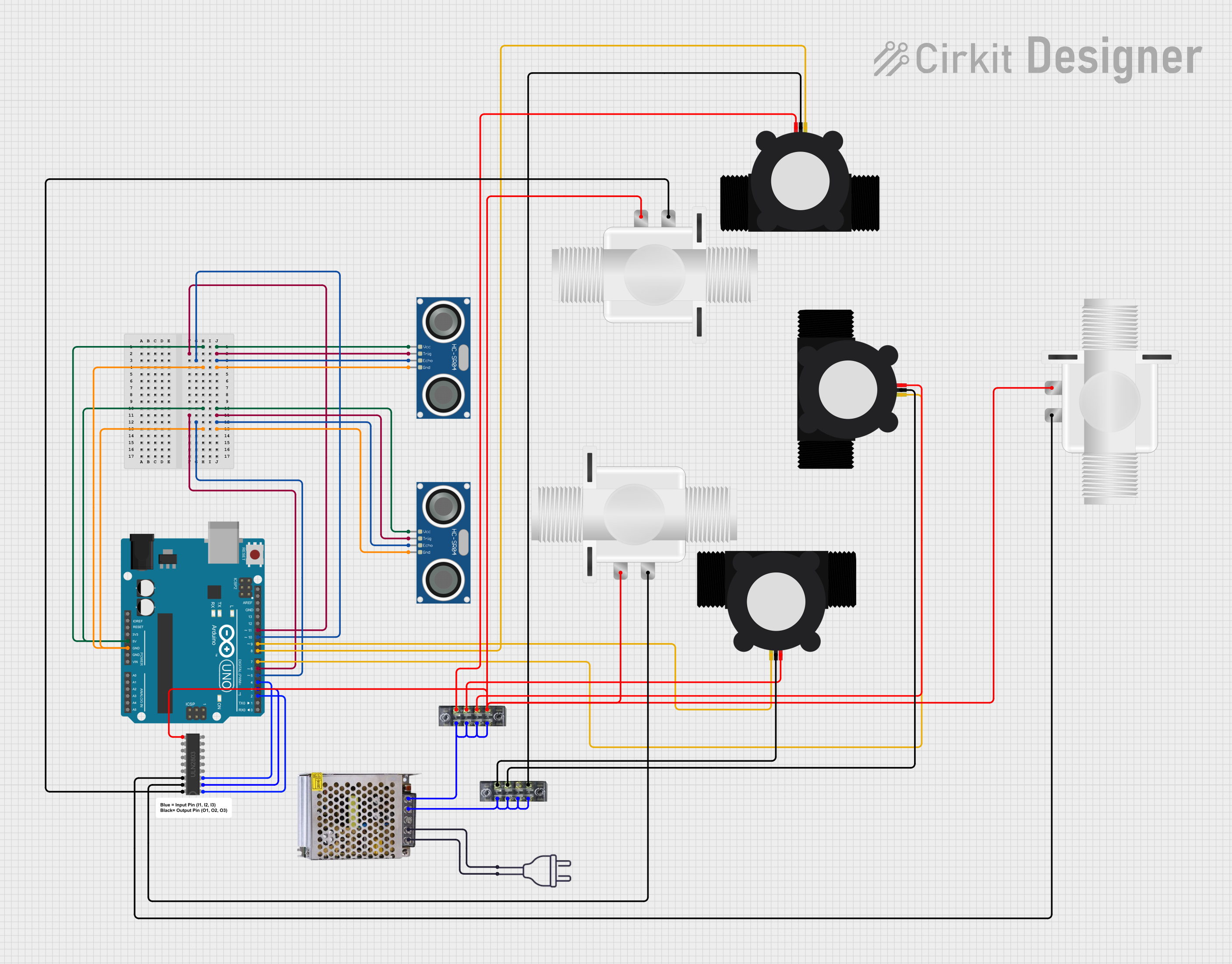

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

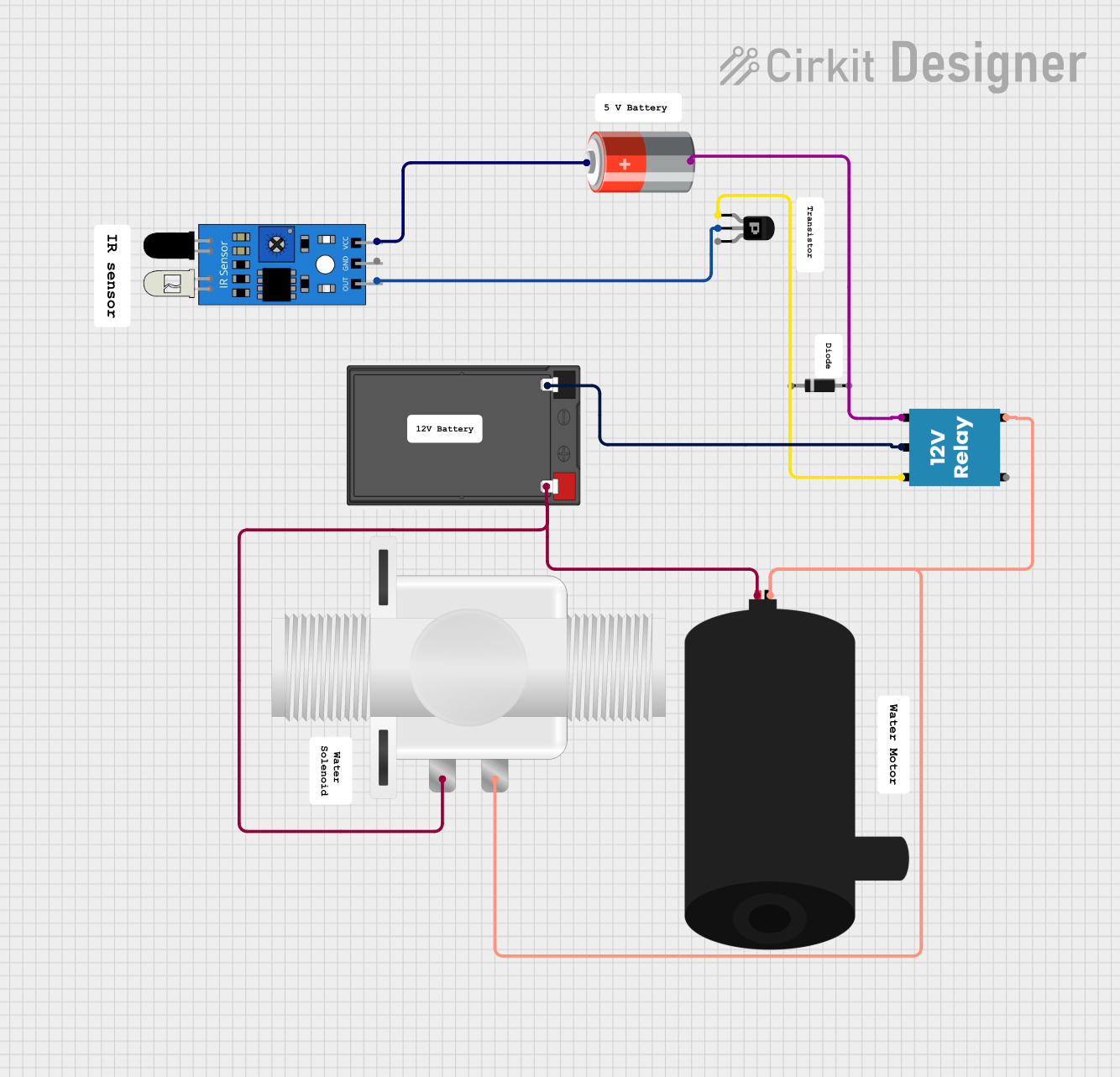

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with valve solenoid water

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Automated irrigation systems

- Washing machines and dishwashers

- Fluid control in industrial processes

- Water dispensing systems

Technical Specifications

General Specifications

| Parameter | Value |

|---|---|

| Operating Voltage | 12V DC |

| Current | 500mA |

| Power Rating | 6W |

| Pressure Range | 0.02-0.8MPa |

| Response Time | <20ms |

| Life Expectancy | 100,000 cycles |

Pin Configuration and Descriptions

| Pin Number | Description |

|---|---|

| 1 | Solenoid Positive (+) |

| 2 | Solenoid Negative (-) |

Usage Instructions

Integration with a Circuit

To use the AFU 211B Valve Solenoid Water in a circuit:

- Connect the positive pin (Pin 1) to the positive output of a power supply or a controlling device like an Arduino.

- Connect the negative pin (Pin 2) to the ground of the power supply or the controlling device.

Best Practices

- Ensure the power supply matches the operating voltage and current requirements.

- Use a flyback diode across the solenoid coil to prevent voltage spikes.

- Install the valve with the flow direction according to the arrow on the valve body.

- Avoid applying pressure that exceeds the specified range to prevent damage.

Example Code for Arduino UNO

// Define the solenoid valve control pin

const int solenoidPin = 7;

void setup() {

// Set the solenoid pin as an output

pinMode(solenoidPin, OUTPUT);

}

void loop() {

// Open the solenoid valve

digitalWrite(solenoidPin, HIGH);

delay(1000); // Keep the valve open for 1 second

// Close the solenoid valve

digitalWrite(solenoidPin, LOW);

delay(1000); // Keep the valve closed for 1 second

}

Note: This code assumes that the solenoid is connected to digital pin 7 on the Arduino UNO. Adjust the pin number as necessary for your setup.

Troubleshooting and FAQs

Common Issues

- Valve does not operate: Check the power supply and connections. Ensure the voltage and current are within specified limits.

- Valve leaks: Verify that the pressure is within the specified range and that there are no obstructions or damage to the valve.

FAQs

Q: Can the valve be operated with AC power? A: No, the AFU 211B is designed for DC power operation only.

Q: Is it necessary to use a flyback diode? A: Yes, to protect the controlling device from voltage spikes caused by the collapsing magnetic field of the solenoid.

Q: How can I control the valve with a microcontroller? A: Use a digital output pin to send a HIGH signal to open the valve and a LOW signal to close it. Ensure the microcontroller can handle the current required by the solenoid or use a relay or transistor.

Q: What is the maximum fluid temperature the valve can handle? A: Refer to the manufacturer's datasheet for temperature ratings as it may vary based on the model.

For further assistance, contact AFU customer support or refer to the detailed manufacturer's datasheet.