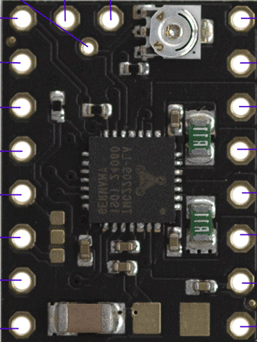

How to Use TMC2209 Stepper motor Driver: Examples, Pinouts, and Specs

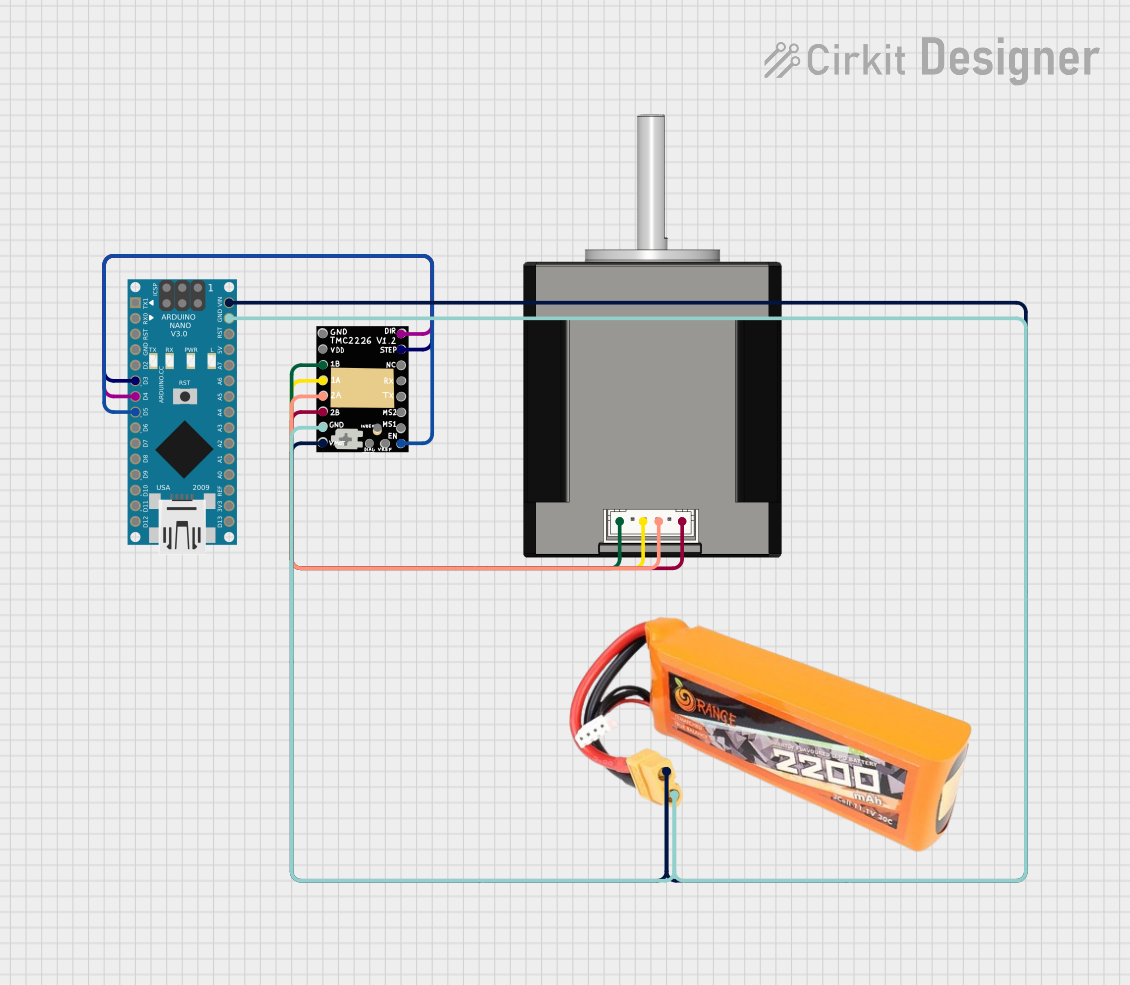

Design with TMC2209 Stepper motor Driver in Cirkit Designer

Design with TMC2209 Stepper motor Driver in Cirkit DesignerIntroduction

The TMC2209 is a high-performance stepper motor driver designed for precise and efficient control of stepper motors. Manufactured by Trinamic, this driver is widely used in applications requiring silent operation, smooth motion, and advanced motor control. It supports features such as StealthChop2 for quiet operation, SpreadCycle for high-speed performance, and configurable microstepping up to 1/256 steps. The TMC2209 is ideal for 3D printers, CNC machines, robotics, and other motion control systems.

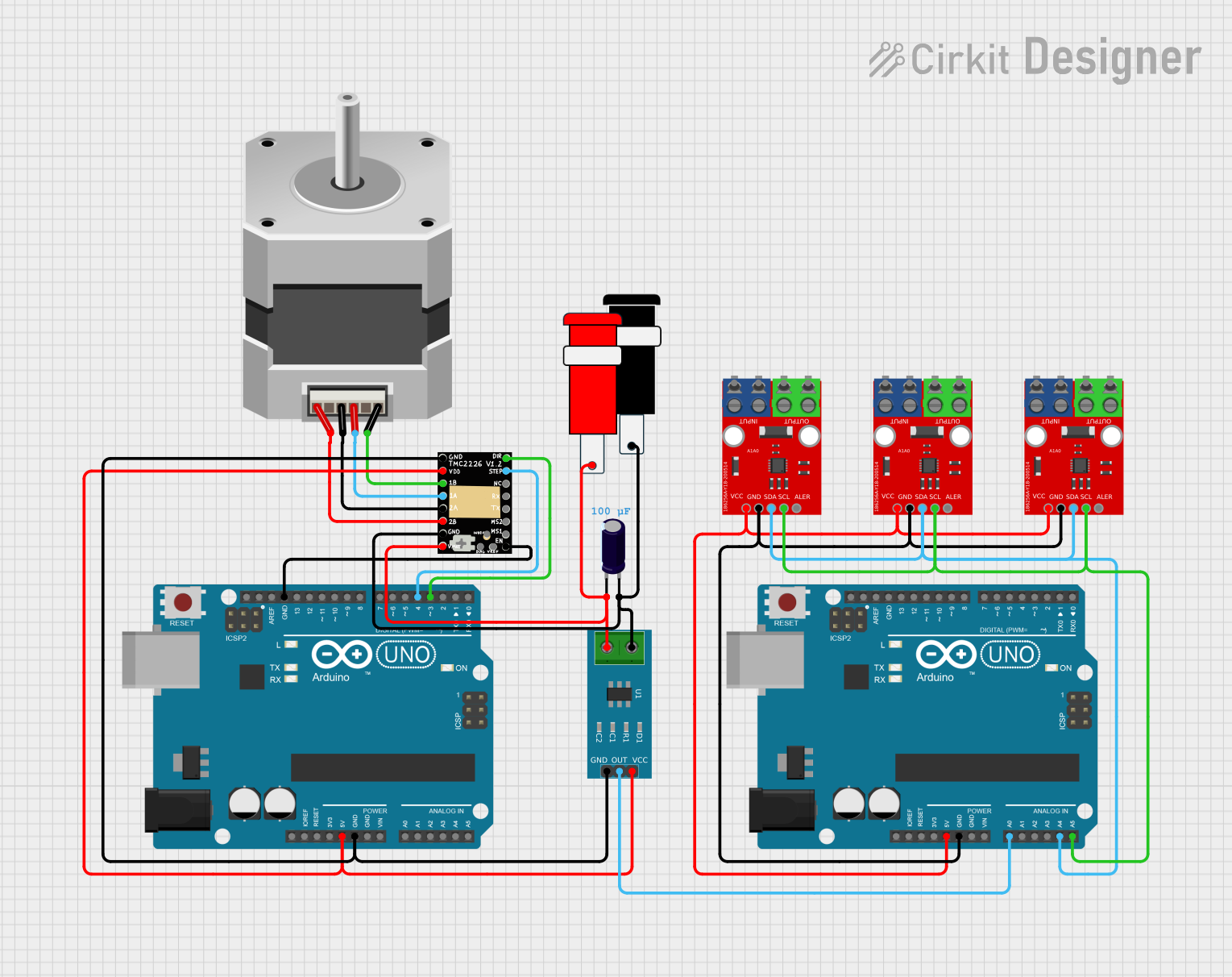

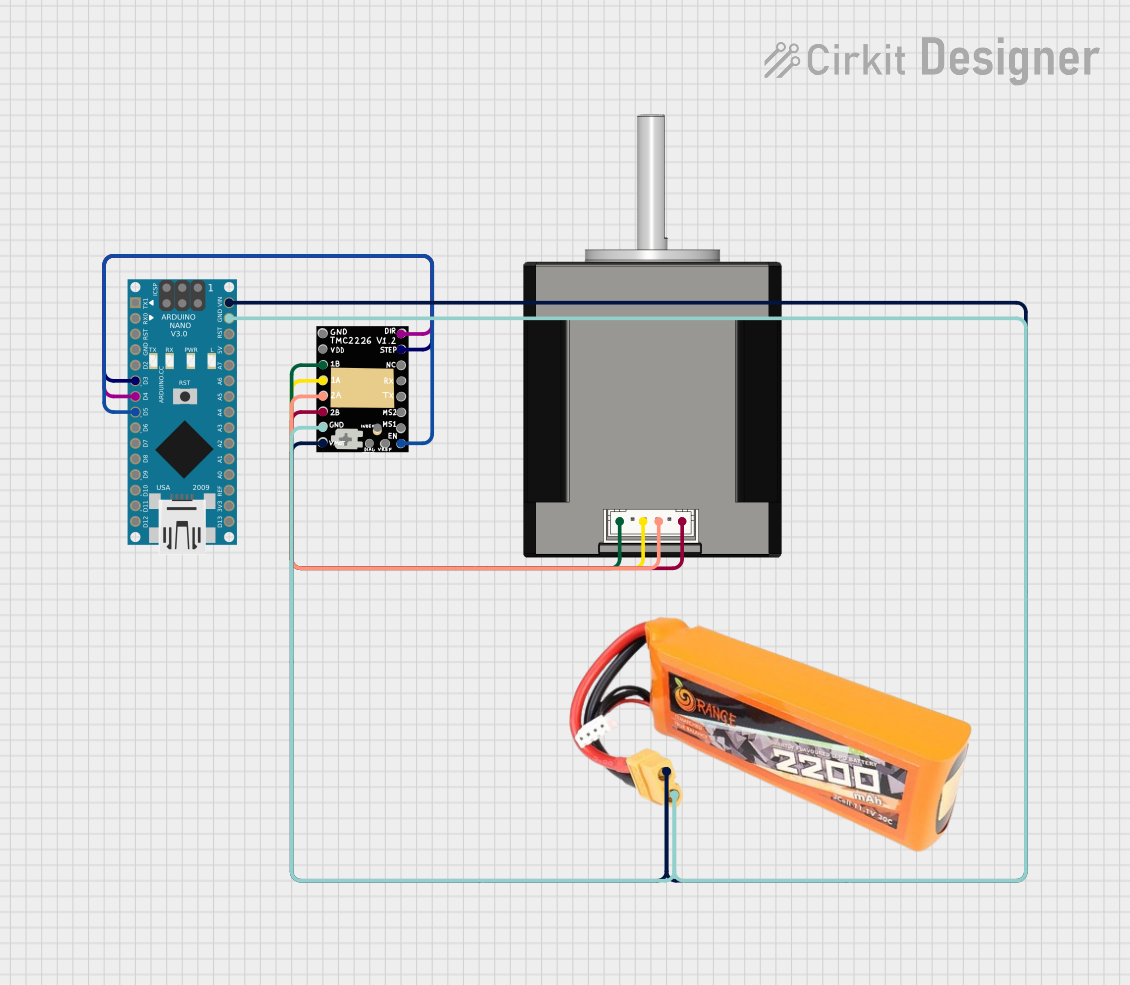

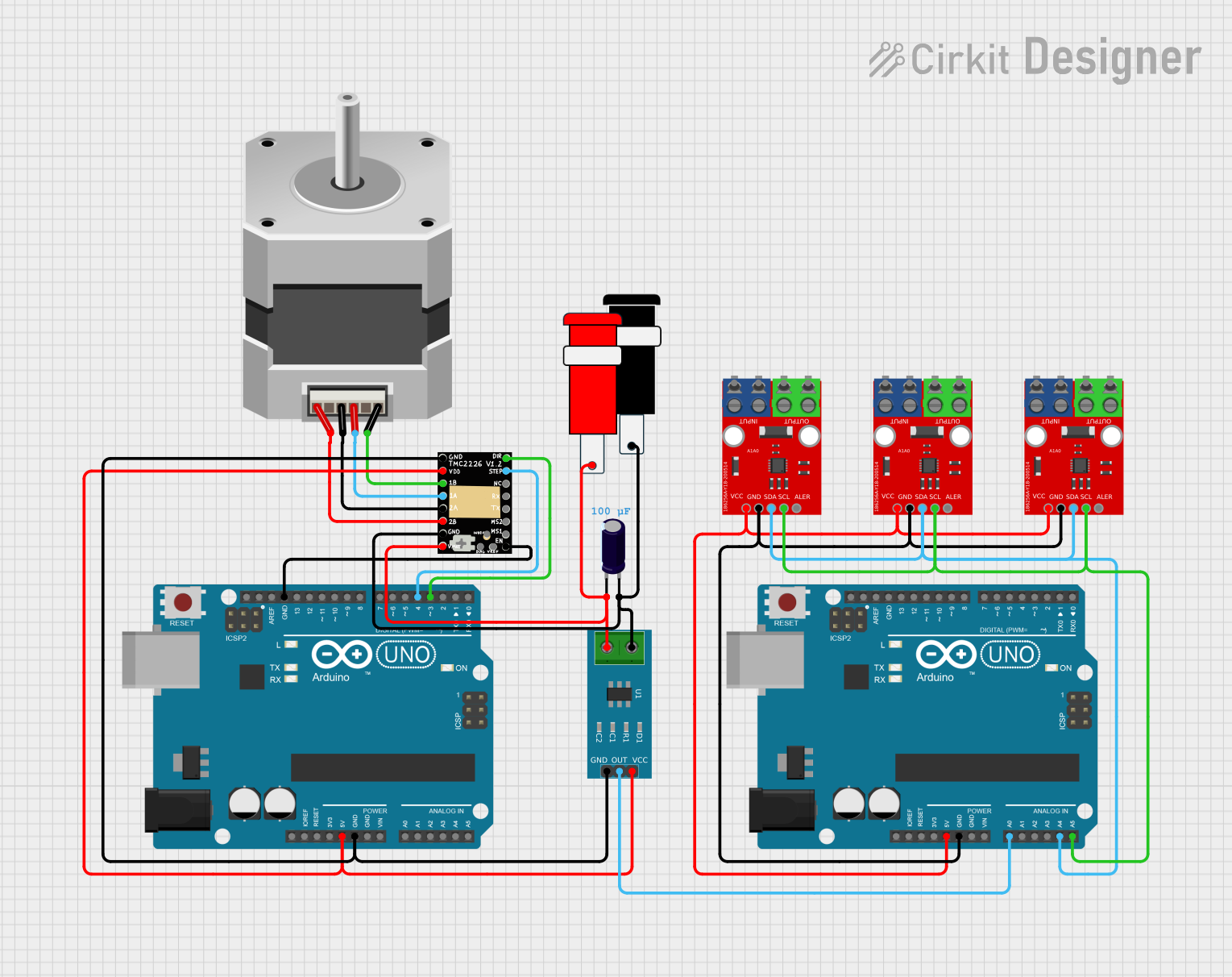

Explore Projects Built with TMC2209 Stepper motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with TMC2209 Stepper motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- 3D printers for precise and quiet motor control

- CNC machines for smooth and accurate motion

- Robotics for efficient and silent operation

- Automated systems requiring advanced stepper motor control

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Operating Voltage (VIO) | 3.3V or 5V |

| Motor Supply Voltage (VM) | 4.75V to 29V |

| Maximum Motor Current | 2.0A RMS (2.8A peak) |

| Microstepping Modes | Up to 1/256 steps |

| Communication Interface | UART |

| Logic Levels | 3.3V or 5V compatible |

| Features | StealthChop2, SpreadCycle, CoolStep, StallGuard4 |

Pin Configuration and Descriptions

The TMC2209 is typically available in a 28-pin package. Below is the pin configuration:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | GND | Ground connection |

| 2 | VM | Motor power supply (4.75V to 29V) |

| 3 | VIO | Logic voltage input (3.3V or 5V) |

| 4 | EN | Enable pin (active low) |

| 5 | DIR | Direction control input |

| 6 | STEP | Step pulse input |

| 7 | UART | UART communication pin for configuration and diagnostics |

| 8 | MS1 | Microstepping resolution selection |

| 9 | MS2 | Microstepping resolution selection |

| 10 | DIAG | Diagnostic output (e.g., stall detection) |

| 11 | INDEX | Index output for step position |

| 12 | CFG1 | Configuration pin 1 |

| 13 | CFG2 | Configuration pin 2 |

| 14 | NC | Not connected |

| 15-28 | Motor Pins | Connections for motor coils (A1, A2, B1, B2) |

Usage Instructions

How to Use the TMC2209 in a Circuit

- Power Supply: Connect the motor power supply (VM) to a voltage source between 4.75V and 29V. Ensure the logic voltage (VIO) matches your microcontroller's logic level (3.3V or 5V).

- Motor Connections: Connect the stepper motor coils to the motor pins (A1, A2, B1, B2). Ensure proper wiring to avoid incorrect motor operation.

- Control Pins: Use the STEP and DIR pins to control the motor's movement and direction. Optionally, configure microstepping using the MS1 and MS2 pins.

- UART Configuration: For advanced features like StealthChop2 or CoolStep, connect the UART pin to your microcontroller for communication and configuration.

- Enable Pin: Use the EN pin to enable or disable the driver. Pull it low to enable the driver.

Important Considerations

- Heat Dissipation: The TMC2209 can generate heat during operation. Use a heatsink or active cooling if necessary.

- Current Limiting: Adjust the motor current using the onboard potentiometer or via UART to prevent overheating or motor damage.

- Microstepping: Configure the microstepping mode based on your application's precision and speed requirements.

- Stall Detection: Use the StallGuard4 feature for sensorless homing or stall detection.

Example Code for Arduino UNO

Below is an example of how to control the TMC2209 using an Arduino UNO:

// Example code to control a stepper motor with the TMC2209 driver

// Connect STEP to pin 2, DIR to pin 3, and EN to pin 4 on the Arduino UNO

#define STEP_PIN 2 // Pin connected to STEP

#define DIR_PIN 3 // Pin connected to DIR

#define EN_PIN 4 // Pin connected to EN

void setup() {

pinMode(STEP_PIN, OUTPUT); // Set STEP pin as output

pinMode(DIR_PIN, OUTPUT); // Set DIR pin as output

pinMode(EN_PIN, OUTPUT); // Set EN pin as output

digitalWrite(EN_PIN, LOW); // Enable the driver (active low)

digitalWrite(DIR_PIN, HIGH); // Set direction (HIGH or LOW)

}

void loop() {

// Generate step pulses to move the motor

digitalWrite(STEP_PIN, HIGH); // Set STEP pin HIGH

delayMicroseconds(500); // Wait for 500 microseconds

digitalWrite(STEP_PIN, LOW); // Set STEP pin LOW

delayMicroseconds(500); // Wait for 500 microseconds

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Check the power supply connections (VM and VIO).

- Ensure the STEP and DIR signals are being sent correctly.

- Verify motor coil connections (A1, A2, B1, B2).

Overheating:

- Reduce the motor current using the potentiometer or UART.

- Add a heatsink or active cooling to the driver.

Noisy Operation:

- Enable StealthChop2 mode via UART for silent operation.

- Check for loose motor connections.

Stall Detection Not Working:

- Ensure StallGuard4 is enabled and properly configured via UART.

- Verify the motor current is set correctly for your application.

FAQs

Can the TMC2209 be used with 12V or 24V motors? Yes, the TMC2209 supports motor supply voltages between 4.75V and 29V, making it compatible with 12V and 24V motors.

How do I configure microstepping? Use the MS1 and MS2 pins or configure it via UART for finer control.

Is the TMC2209 compatible with 3.3V logic? Yes, the TMC2209 supports both 3.3V and 5V logic levels.

What is the maximum current the TMC2209 can handle? The TMC2209 can handle up to 2.0A RMS (2.8A peak) per phase.