How to Use Pitot Tube: Examples, Pinouts, and Specs

Design with Pitot Tube in Cirkit Designer

Design with Pitot Tube in Cirkit DesignerIntroduction

The TE Connectivity MS4525DO is a digital pressure sensor designed for applications requiring precise measurement of fluid flow velocity. It operates based on the principles of a Pitot tube, which measures the dynamic and static pressure of a fluid to calculate its velocity. This sensor integrates advanced MEMS technology and a digital output, making it ideal for modern electronic systems.

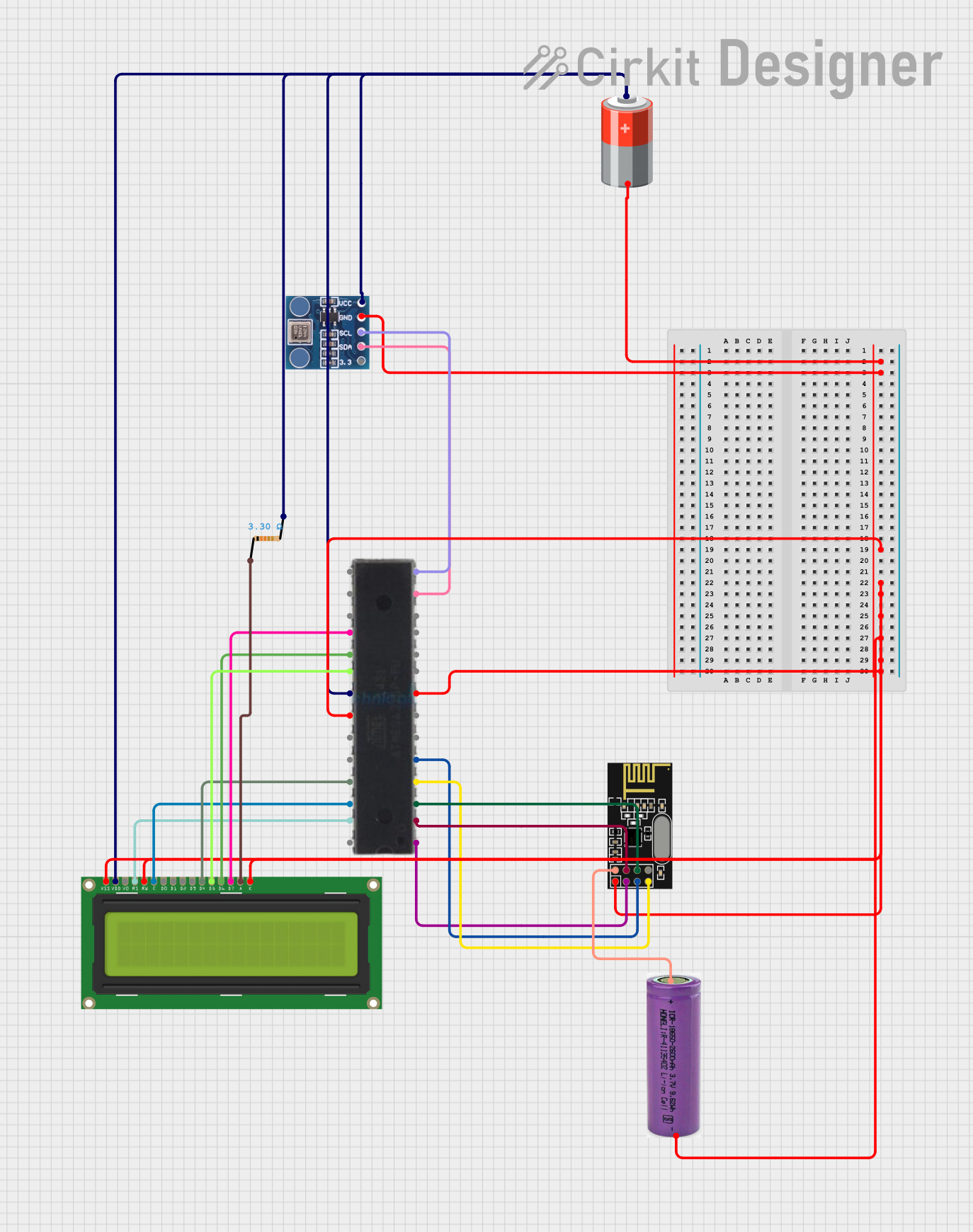

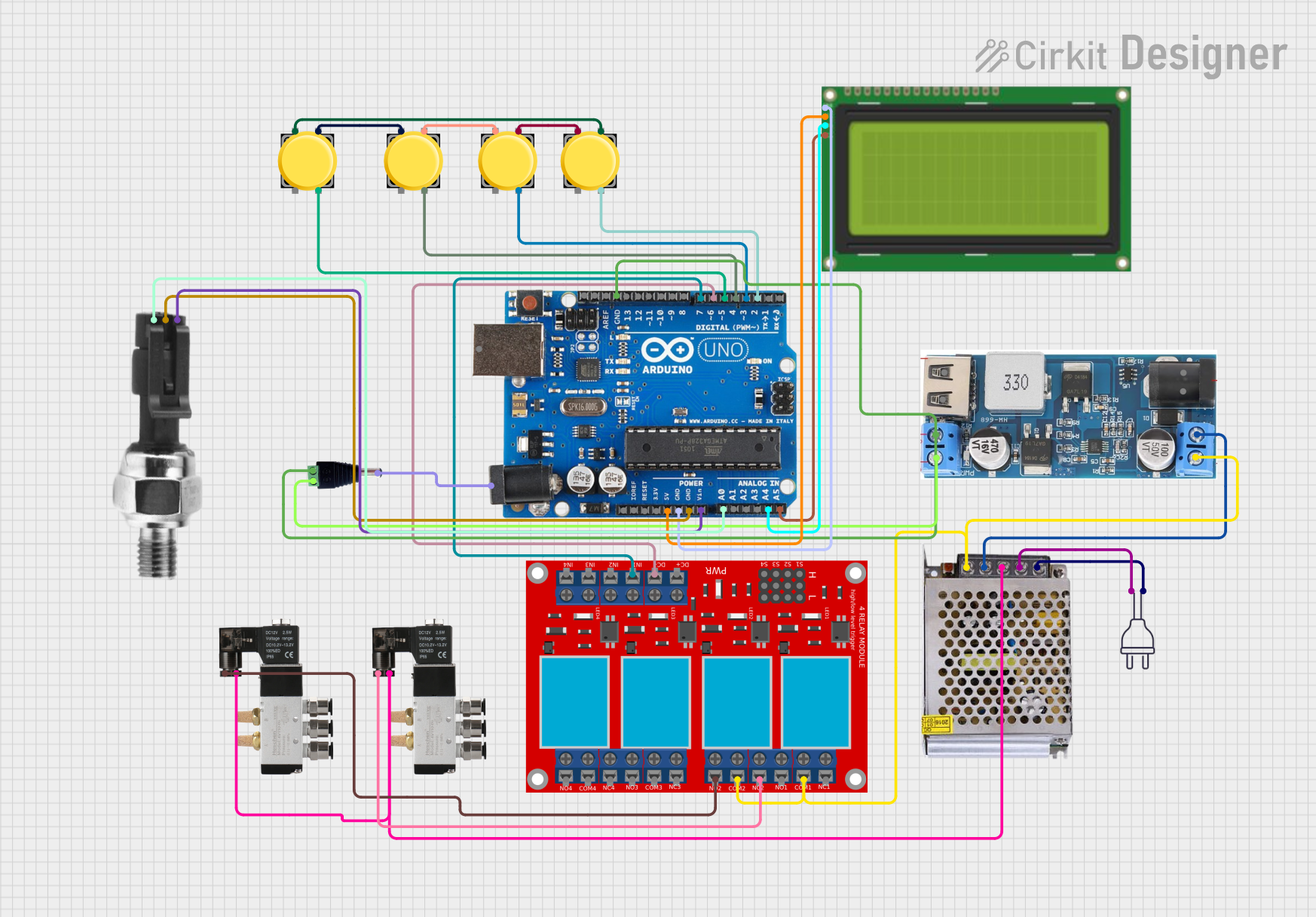

Explore Projects Built with Pitot Tube

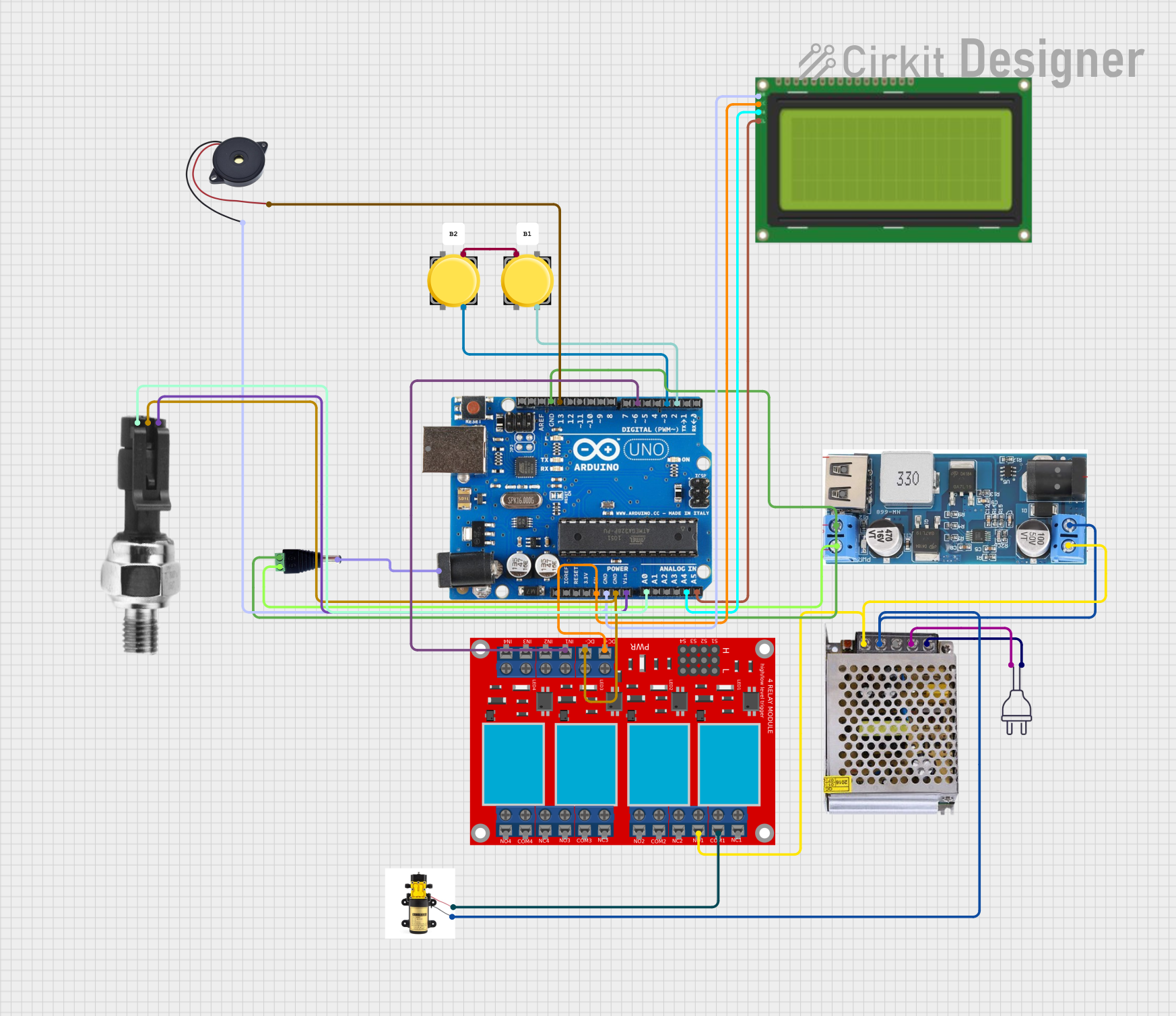

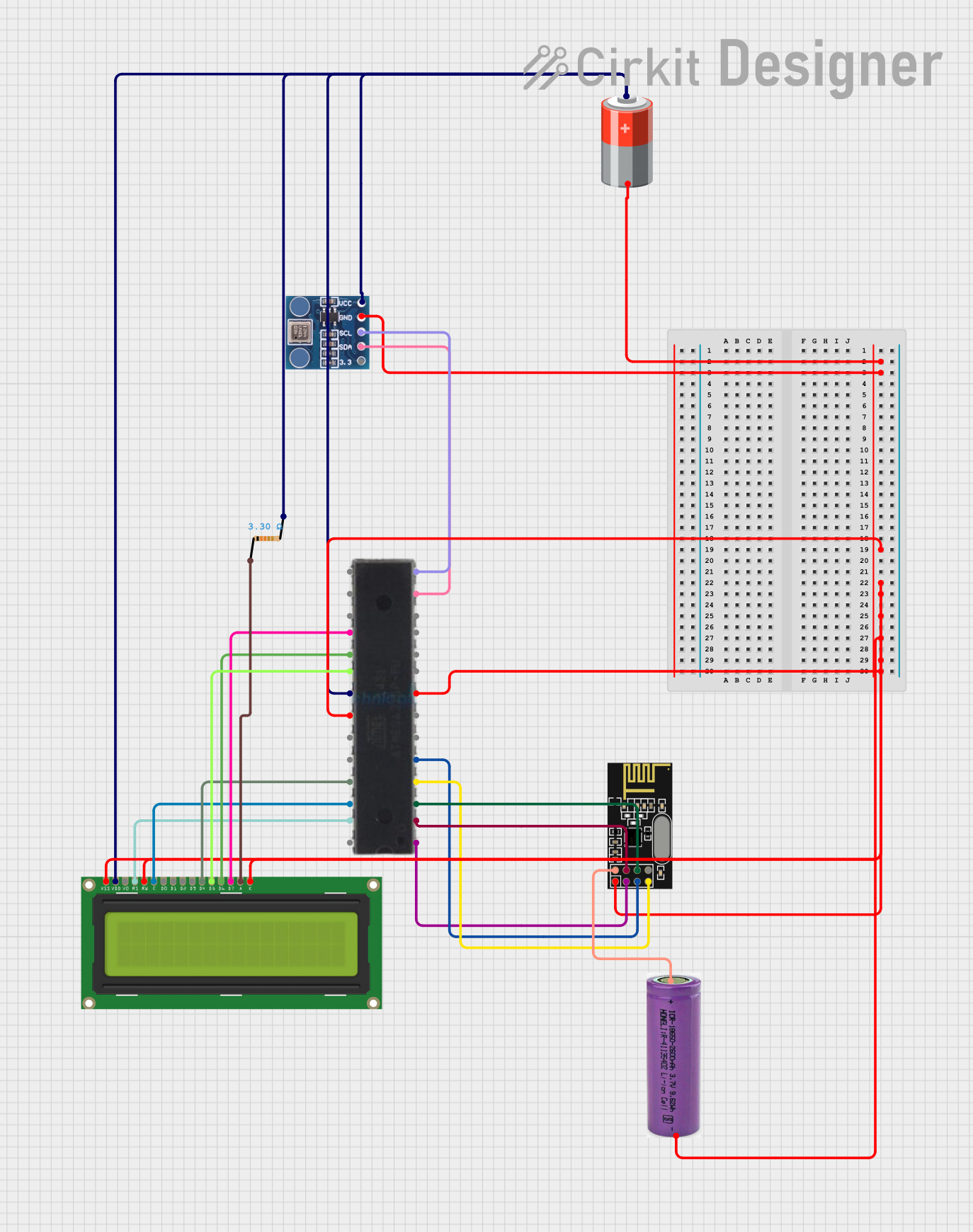

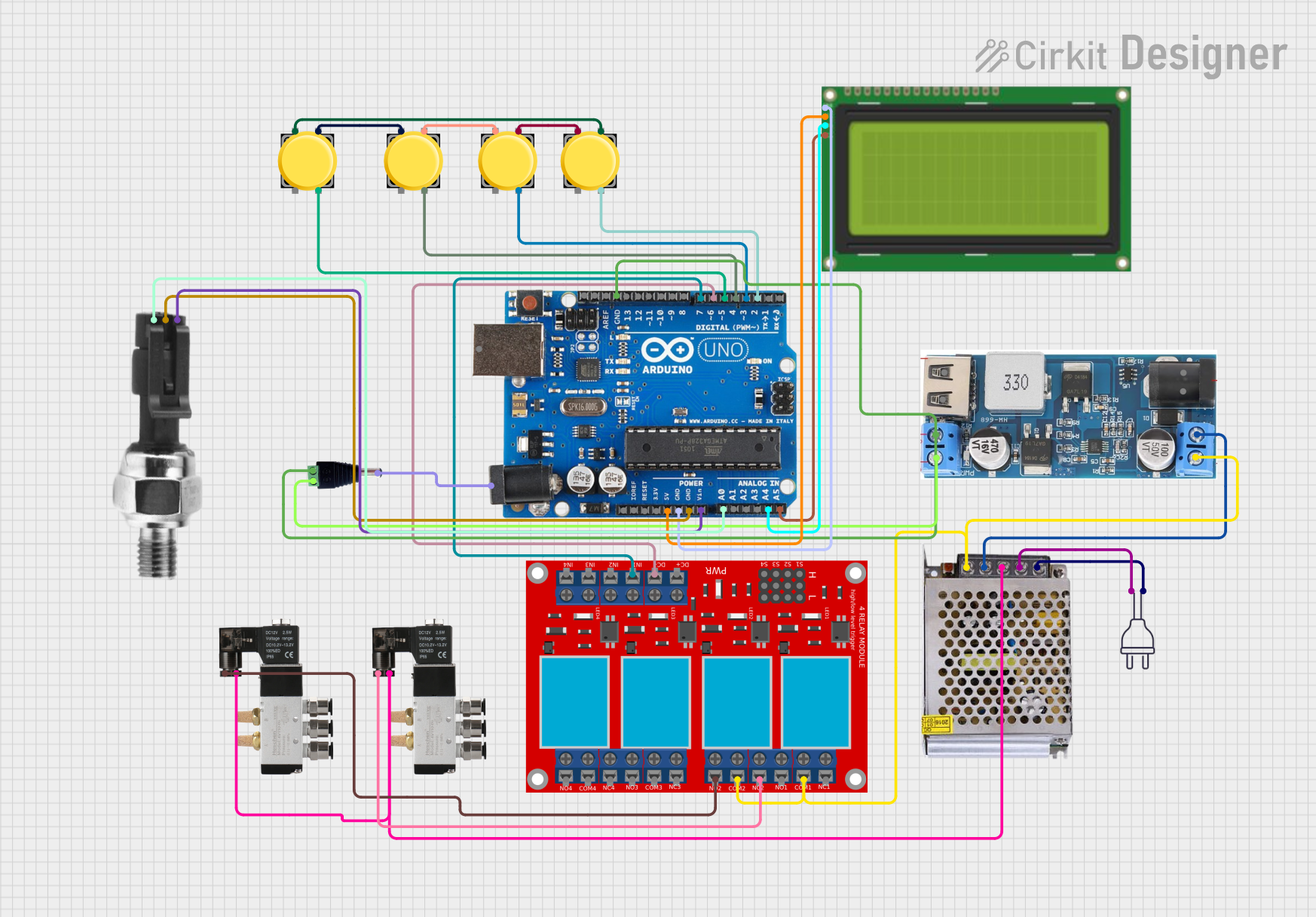

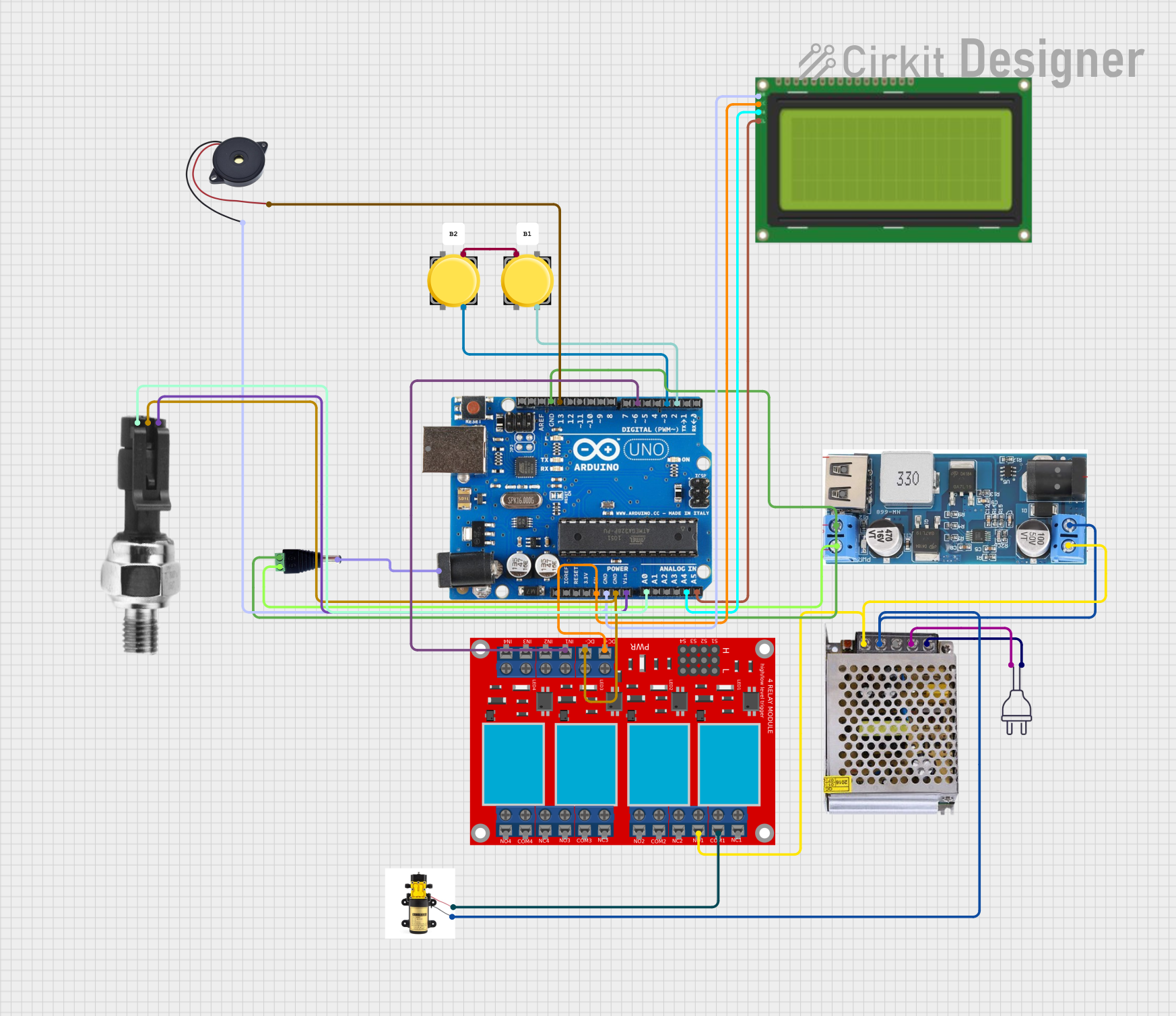

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Pitot Tube

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Aerospace: Airspeed measurement in aircraft

- Automotive: Airflow monitoring in engine systems

- Industrial: Fluid flow measurement in pipelines

- HVAC: Air velocity monitoring in ventilation systems

- Robotics: Environmental sensing for drones and autonomous vehicles

Technical Specifications

The MS4525DO is a high-performance digital pressure sensor with the following key specifications:

General Specifications

| Parameter | Value |

|---|---|

| Manufacturer | TE Connectivity |

| Part Number | MS4525DO |

| Pressure Range | ±1 psi to ±30 psi (varies by model) |

| Supply Voltage | 3.3V or 5V |

| Output Type | I²C or SPI (digital) |

| Accuracy | ±0.25% of full scale |

| Operating Temperature | -40°C to +125°C |

| Response Time | 1 ms |

Pin Configuration and Descriptions

The MS4525DO sensor typically comes in a 6-pin package. Below is the pinout and description:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VDD | Power supply (3.3V or 5V) |

| 2 | GND | Ground connection |

| 3 | SDA | I²C data line (or SPI MOSI) |

| 4 | SCL | I²C clock line (or SPI SCK) |

| 5 | ADDR/CS | I²C address select (or SPI chip select) |

| 6 | NC | No connection (leave unconnected) |

Usage Instructions

How to Use the MS4525DO in a Circuit

- Power Supply: Connect the VDD pin to a 3.3V or 5V power source and the GND pin to ground.

- Communication Interface: Choose between I²C or SPI communication. For I²C:

- Connect the SDA pin to the microcontroller's I²C data line.

- Connect the SCL pin to the microcontroller's I²C clock line.

- Use the ADDR pin to set the I²C address (pull high or low as needed). For SPI:

- Connect the SDA pin to the microcontroller's MOSI line.

- Connect the SCL pin to the microcontroller's SCK line.

- Use the ADDR/CS pin as the chip select line.

- Pressure Ports: Attach the Pitot tube to the sensor's pressure ports:

- The high-pressure port (P1) connects to the dynamic pressure source.

- The low-pressure port (P2) connects to the static pressure source.

- Initialization: Configure the microcontroller to communicate with the sensor using the chosen protocol. Refer to the datasheet for initialization commands.

Important Considerations and Best Practices

- Ensure the pressure range of the sensor matches your application requirements.

- Avoid exposing the sensor to pressures beyond its rated range to prevent damage.

- Use proper tubing and fittings to minimize leaks and ensure accurate measurements.

- If using I²C, ensure pull-up resistors are present on the SDA and SCL lines.

- Calibrate the sensor periodically for optimal accuracy.

Example Code for Arduino UNO (I²C)

#include <Wire.h>

// Define the I²C address of the MS4525DO sensor

#define MS4525DO_ADDRESS 0x28

void setup() {

Wire.begin(); // Initialize I²C communication

Serial.begin(9600); // Start serial communication for debugging

}

void loop() {

Wire.beginTransmission(MS4525DO_ADDRESS); // Start communication with sensor

Wire.write(0x00); // Request data from the sensor

Wire.endTransmission(false); // End transmission but keep I²C active

Wire.requestFrom(MS4525DO_ADDRESS, 4); // Request 4 bytes of data

if (Wire.available() == 4) {

uint8_t byte1 = Wire.read(); // Read first byte

uint8_t byte2 = Wire.read(); // Read second byte

uint8_t byte3 = Wire.read(); // Read third byte

uint8_t byte4 = Wire.read(); // Read fourth byte

// Combine bytes to calculate pressure and temperature

int16_t pressure = ((byte1 & 0x3F) << 8) | byte2;

int16_t temperature = ((byte3 << 8) | byte4) >> 5;

// Convert raw values to meaningful units

float pressure_psi = (pressure - 8192) * 0.00390625; // Example conversion

float temperature_c = (temperature * 0.0977) - 50; // Example conversion

// Print results to the serial monitor

Serial.print("Pressure (psi): ");

Serial.print(pressure_psi);

Serial.print(" | Temperature (°C): ");

Serial.println(temperature_c);

}

delay(1000); // Wait 1 second before next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Data from Sensor

- Cause: Incorrect wiring or communication protocol mismatch.

- Solution: Double-check the connections and ensure the correct protocol (I²C or SPI) is configured.

Inaccurate Readings

- Cause: Calibration drift or leaks in the pressure tubing.

- Solution: Recalibrate the sensor and inspect the tubing for leaks.

Sensor Not Responding

- Cause: Incorrect power supply voltage.

- Solution: Verify that the VDD pin is supplied with 3.3V or 5V as required.

Fluctuating Measurements

- Cause: Electrical noise or unstable pressure source.

- Solution: Add decoupling capacitors near the sensor and stabilize the pressure source.

FAQs

Q: Can the MS4525DO measure both positive and negative pressures?

A: Yes, the sensor supports differential pressure measurement, allowing it to measure both positive and negative pressures within its specified range.

Q: Is the MS4525DO waterproof?

A: No, the sensor is not waterproof. Avoid exposing it to liquids or high humidity environments.

Q: Can I use the MS4525DO with a 5V microcontroller?

A: Yes, the sensor is compatible with both 3.3V and 5V systems. Ensure the I²C or SPI logic levels match the microcontroller.

Q: How often should I calibrate the sensor?

A: Calibration frequency depends on the application. For critical measurements, calibrate every 6-12 months or as needed.