How to Use TMC2208 Stepper driver: Examples, Pinouts, and Specs

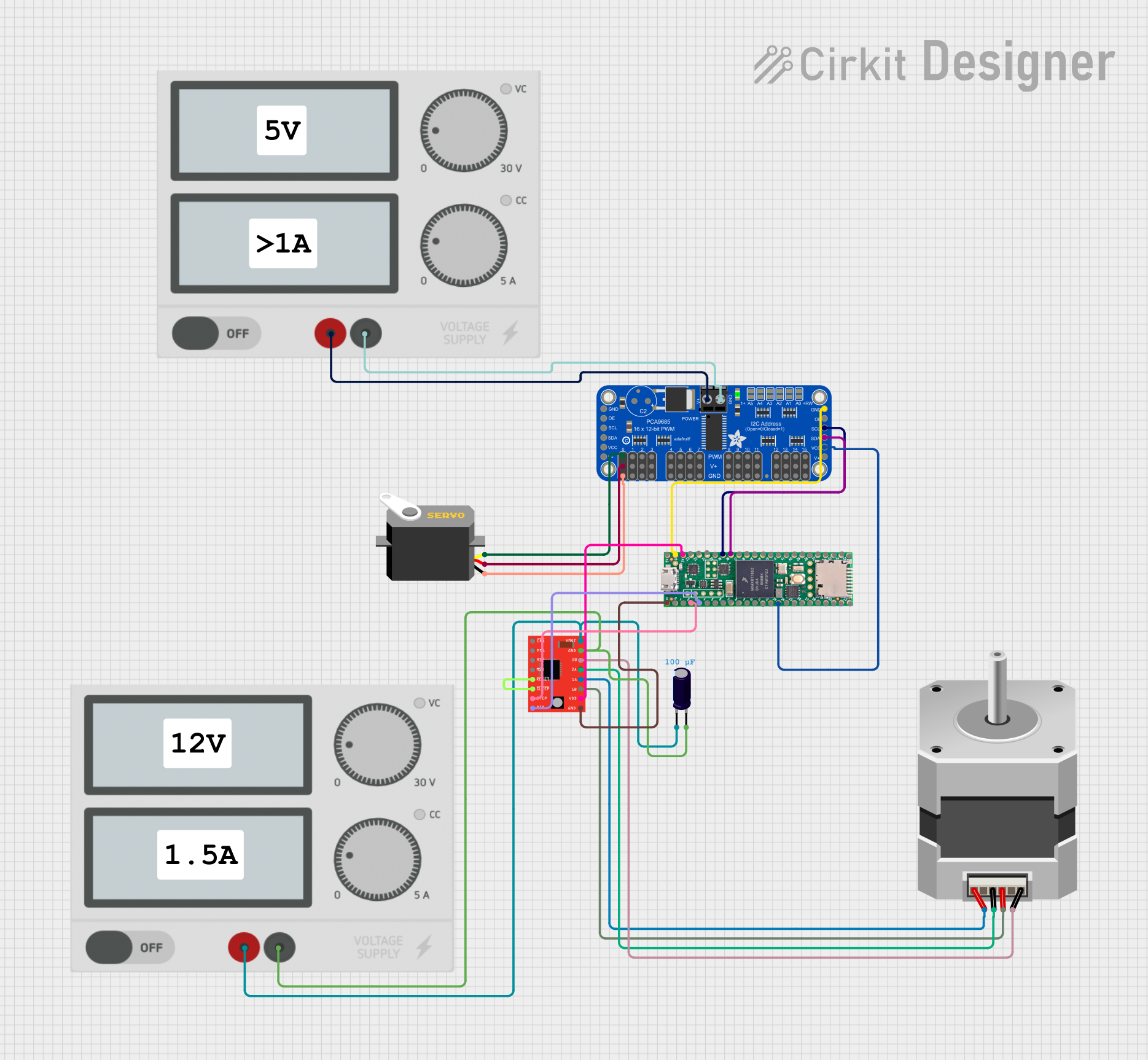

Design with TMC2208 Stepper driver in Cirkit Designer

Design with TMC2208 Stepper driver in Cirkit DesignerIntroduction

The TMC2208 is a high-performance stepper motor driver manufactured by Analog Devices Inc. It is designed to provide smooth and quiet operation for stepper motors, making it ideal for applications requiring precision and low noise. The TMC2208 features advanced technologies such as stealthChop for silent operation and coolStep for intelligent current control, ensuring efficient and reliable performance.

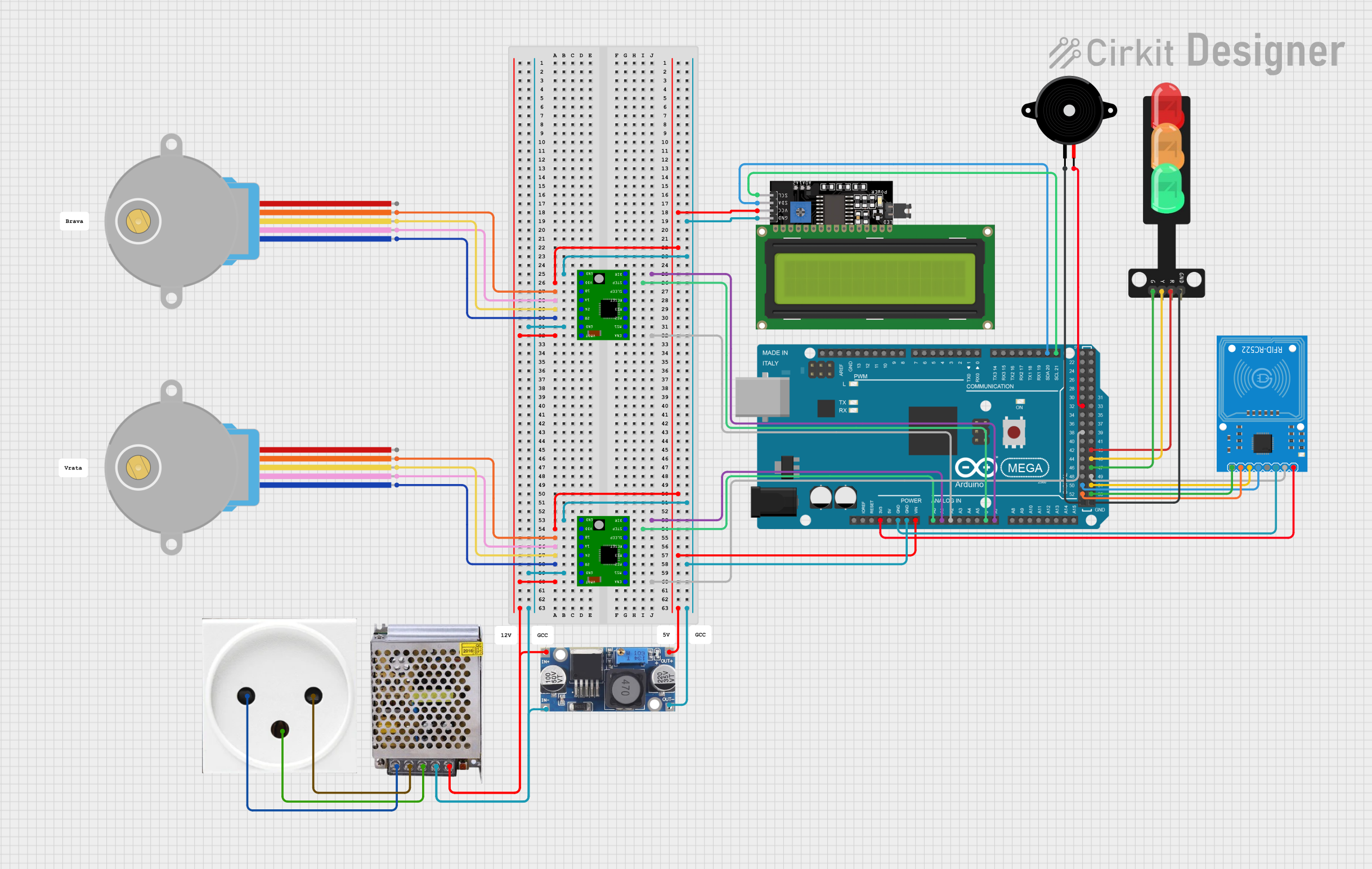

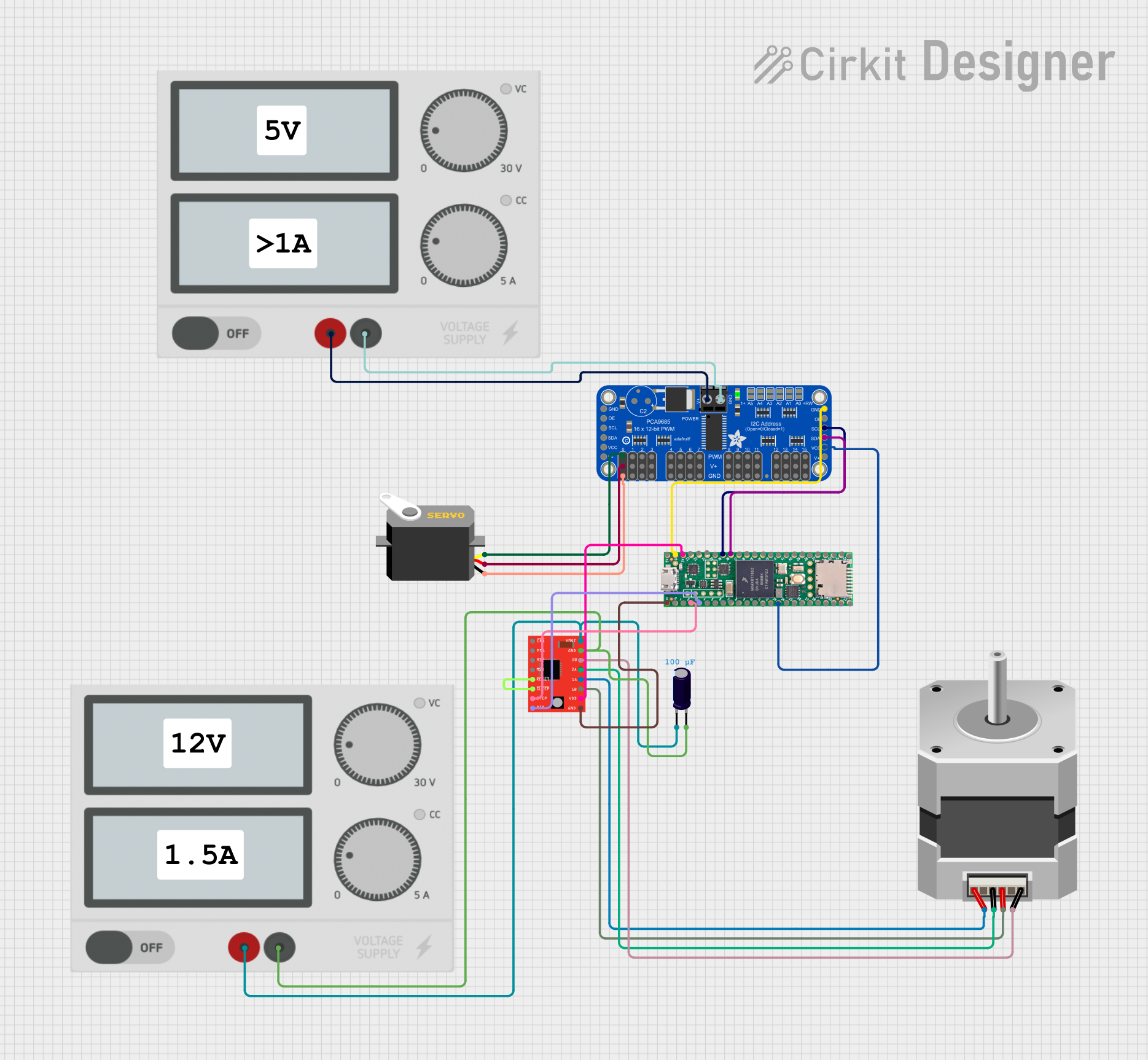

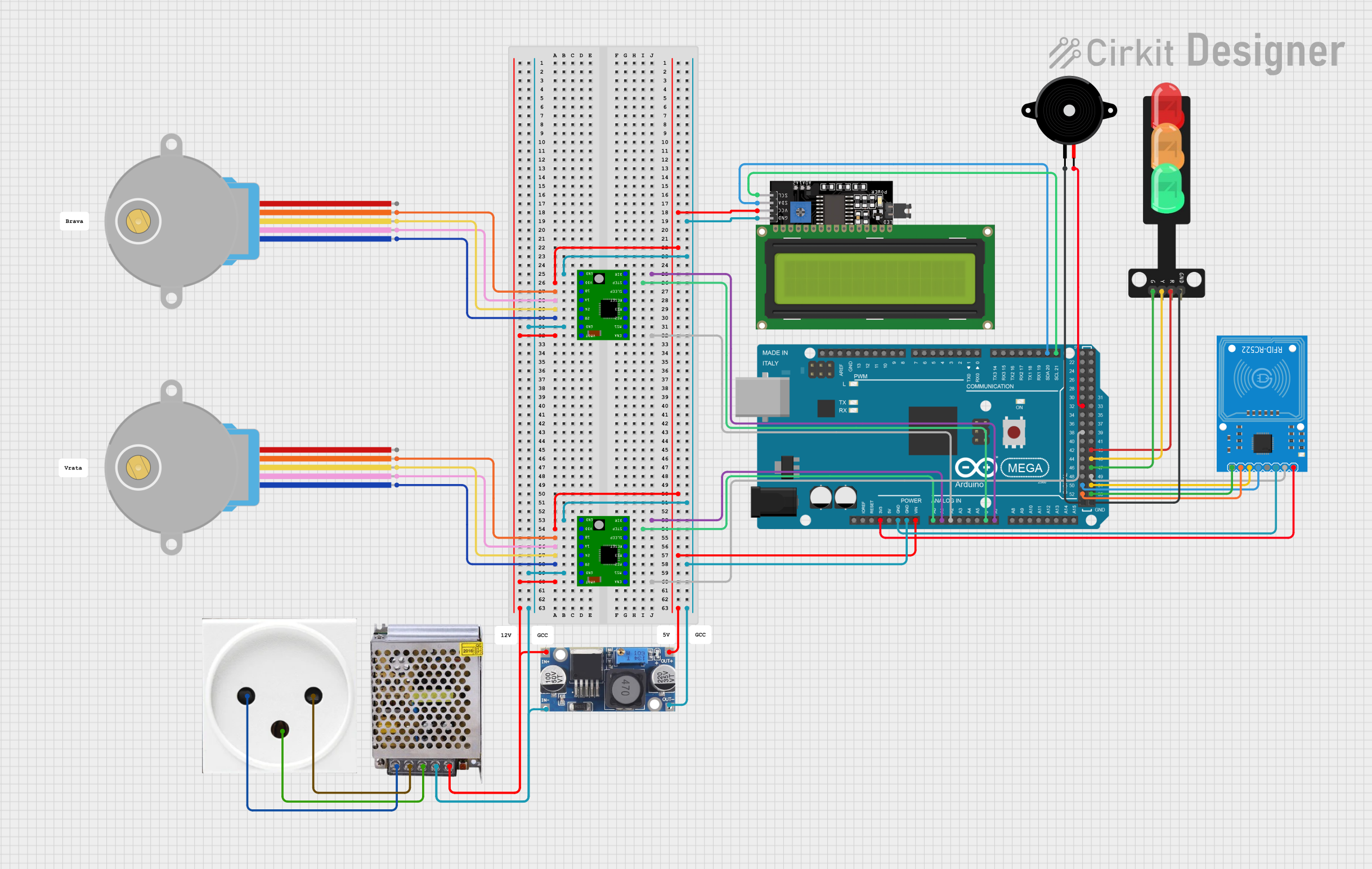

Explore Projects Built with TMC2208 Stepper driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with TMC2208 Stepper driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- 3D printers

- CNC machines

- Robotics

- Automated machinery

- Camera gimbals

- Precision motion control systems

Technical Specifications

The TMC2208 is a versatile and feature-rich stepper motor driver. Below are its key technical specifications:

| Parameter | Value |

|---|---|

| Supply Voltage (V_M) | 4.75V to 36V |

| Logic Voltage (V_IO) | 3.3V or 5V |

| Maximum Motor Current | 1.2A RMS (2.0A peak) |

| Microstepping Resolution | Up to 256 microsteps per full step |

| Communication Interface | UART |

| Operating Temperature | -40°C to +125°C |

| Features | stealthChop, coolStep, spreadCycle |

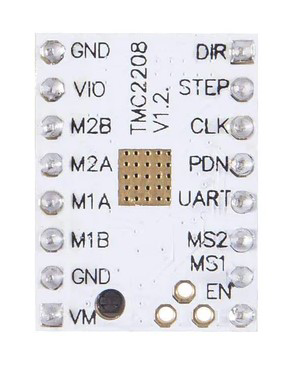

Pin Configuration and Descriptions

The TMC2208 comes in a compact package with the following pin configuration:

| Pin | Name | Description |

|---|---|---|

| 1 | GND | Ground connection |

| 2 | V_M | Motor power supply (4.75V to 36V) |

| 3 | V_IO | Logic voltage input (3.3V or 5V) |

| 4 | EN | Enable pin (active low) |

| 5 | DIR | Direction control input |

| 6 | STEP | Step pulse input |

| 7 | UART_TX | UART transmit pin for communication |

| 8 | UART_RX | UART receive pin for communication |

| 9 | MS1 | Microstepping resolution selection pin 1 |

| 10 | MS2 | Microstepping resolution selection pin 2 |

| 11 | NC | Not connected |

| 12 | OUT1A | Motor coil 1 output A |

| 13 | OUT1B | Motor coil 1 output B |

| 14 | OUT2A | Motor coil 2 output A |

| 15 | OUT2B | Motor coil 2 output B |

Usage Instructions

How to Use the TMC2208 in a Circuit

- Power Supply: Connect the motor power supply (V_M) to a voltage source between 4.75V and 36V. Ensure the logic voltage (V_IO) matches your microcontroller's logic level (3.3V or 5V).

- Motor Connection: Connect the stepper motor coils to the OUT1A, OUT1B, OUT2A, and OUT2B pins.

- Control Pins: Use the STEP and DIR pins to control the motor's movement. The STEP pin receives pulses to move the motor, while the DIR pin sets the rotation direction.

- Microstepping: Configure the microstepping resolution using the MS1 and MS2 pins or via UART communication.

- UART Communication: Connect the UART_TX and UART_RX pins to your microcontroller for advanced configuration and monitoring.

- Enable Pin: Use the EN pin to enable or disable the driver. Pull it low to enable the driver.

Important Considerations and Best Practices

- Use decoupling capacitors near the V_M and V_IO pins to stabilize the power supply.

- Ensure proper heat dissipation by using a heatsink or adequate ventilation, especially for high-current applications.

- Avoid exceeding the maximum current and voltage ratings to prevent damage to the driver.

- Use shielded cables for motor connections to minimize electromagnetic interference (EMI).

Example: Using the TMC2208 with an Arduino UNO

Below is an example of how to control a stepper motor using the TMC2208 and an Arduino UNO:

// Example: Controlling a stepper motor with TMC2208 and Arduino UNO

#define STEP_PIN 3 // Pin connected to STEP on TMC2208

#define DIR_PIN 4 // Pin connected to DIR on TMC2208

#define EN_PIN 5 // Pin connected to EN on TMC2208

void setup() {

pinMode(STEP_PIN, OUTPUT); // Set STEP pin as output

pinMode(DIR_PIN, OUTPUT); // Set DIR pin as output

pinMode(EN_PIN, OUTPUT); // Set EN pin as output

digitalWrite(EN_PIN, LOW); // Enable the TMC2208 driver

digitalWrite(DIR_PIN, HIGH); // Set initial direction (HIGH = clockwise)

}

void loop() {

// Generate step pulses to move the motor

digitalWrite(STEP_PIN, HIGH); // Step pulse HIGH

delayMicroseconds(500); // Wait 500 microseconds

digitalWrite(STEP_PIN, LOW); // Step pulse LOW

delayMicroseconds(500); // Wait 500 microseconds

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Ensure the EN pin is pulled low to enable the driver.

- Verify the STEP and DIR signals are being sent correctly.

- Check the motor connections to the OUT1A, OUT1B, OUT2A, and OUT2B pins.

Overheating:

- Use a heatsink or active cooling to dissipate heat.

- Reduce the motor current using the UART interface or configuration pins.

Noisy Operation:

- Enable stealthChop mode for silent operation.

- Check for loose connections or EMI interference.

UART Communication Issues:

- Verify the UART_TX and UART_RX connections.

- Ensure the baud rate matches the TMC2208's default or configured value.

FAQs

Q: Can the TMC2208 operate without UART communication?

A: Yes, the TMC2208 can operate in standalone mode using the STEP, DIR, and MS1/MS2 pins for basic control.

Q: How do I configure the microstepping resolution?

A: You can set the microstepping resolution using the MS1 and MS2 pins or via UART commands.

Q: What is the maximum current the TMC2208 can handle?

A: The TMC2208 supports up to 1.2A RMS (2.0A peak) per motor coil. Ensure proper cooling for high-current applications.