How to Use DKC-1A(Stepper_Motor_Controllers): Examples, Pinouts, and Specs

Design with DKC-1A(Stepper_Motor_Controllers) in Cirkit Designer

Design with DKC-1A(Stepper_Motor_Controllers) in Cirkit DesignerIntroduction

The DKC-1A Stepper Motor Controller is a versatile and reliable electronic device designed to drive stepper motors with precision and ease. Stepper motors are commonly used in applications requiring controlled, precise movements such as 3D printers, CNC machines, robotics, and automated manufacturing systems. The DKC-1A controller allows users to command a stepper motor to move to specific positions or at certain speeds without the need for constant feedback about the motor's position.

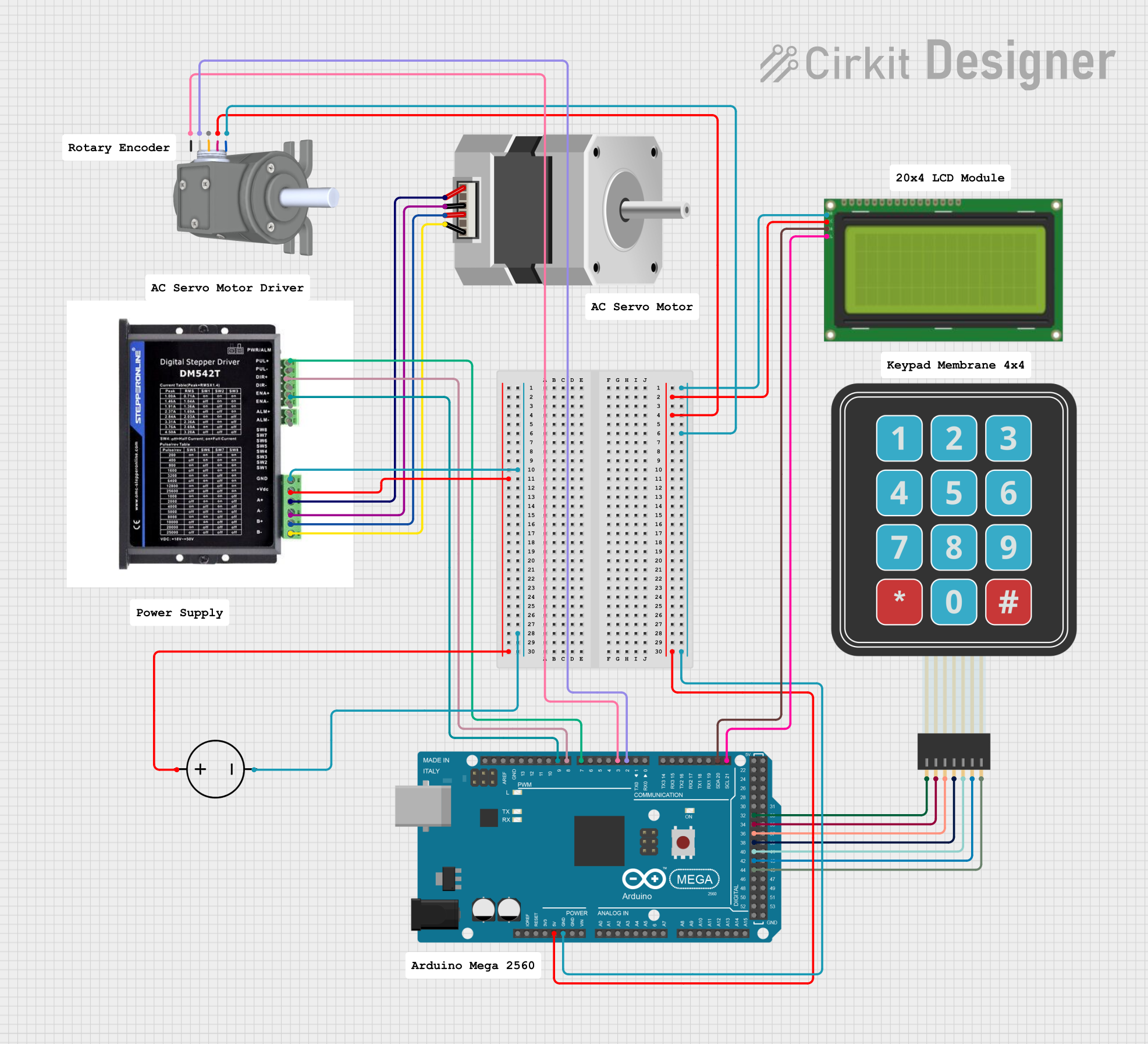

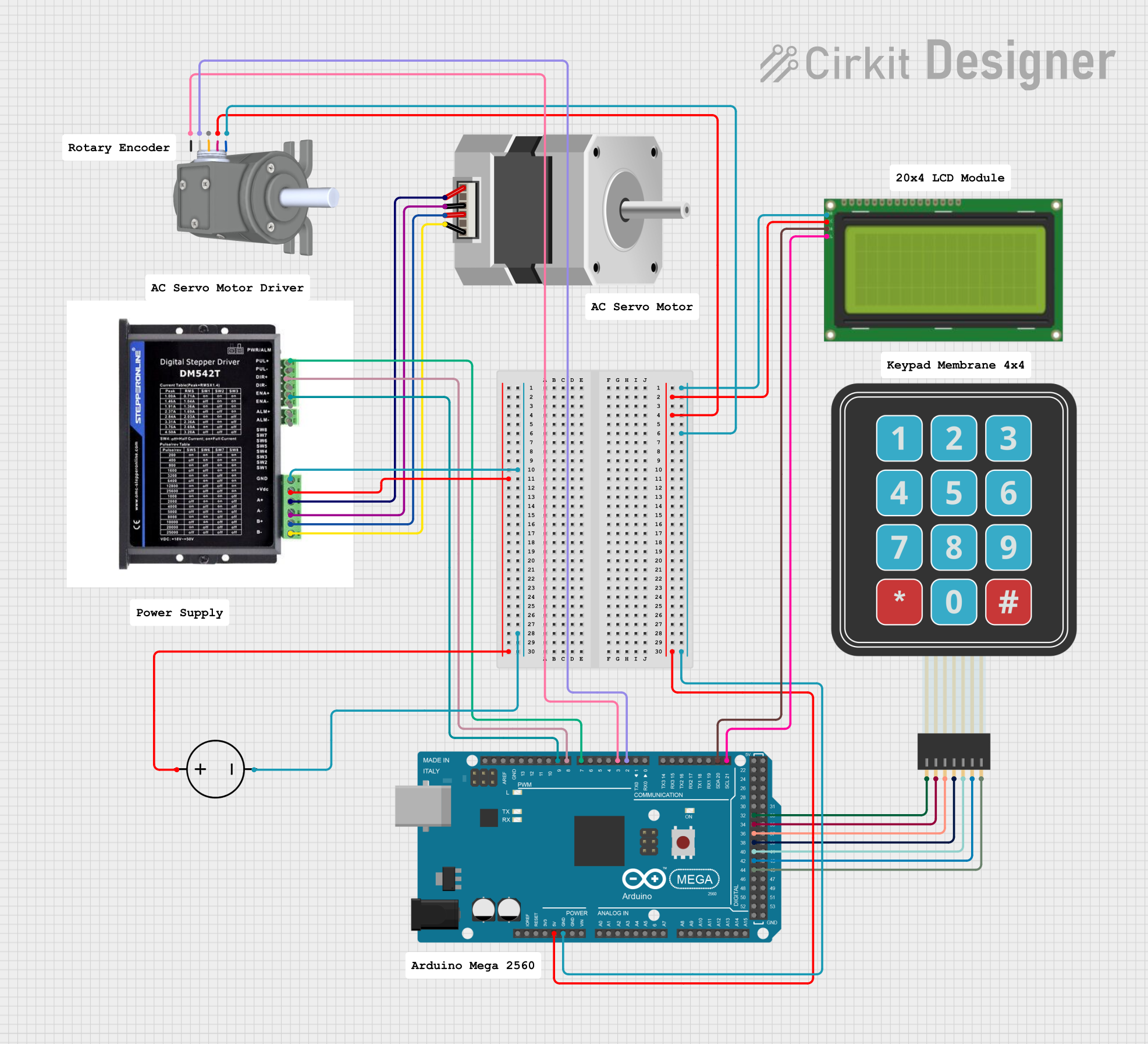

Explore Projects Built with DKC-1A(Stepper_Motor_Controllers)

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DKC-1A(Stepper_Motor_Controllers)

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Operating Voltage: 12-24V DC

- Output Current: Adjustable up to 3A per phase

- Microstepping: Full, 1/2, 1/4, 1/8, 1/16 steps

- Input Signal Voltage: 5V (TTL compatible)

- Control Method: Step and Direction

- Dimensions: 75mm x 50mm x 35mm (L x W x H)

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | VDD | Logic supply voltage (5V) |

| 2 | GND | Ground connection |

| 3 | PUL+ | Pulse signal input: controls step rate |

| 4 | PUL- | Pulse signal ground |

| 5 | DIR+ | Direction signal input |

| 6 | DIR- | Direction signal ground |

| 7 | ENA+ | Enable motor output |

| 8 | ENA- | Enable signal ground |

Usage Instructions

Connecting the DKC-1A to a Stepper Motor

- Power Supply: Connect a 12-24V DC power supply to the motor power inputs on the DKC-1A.

- Motor Connections: Connect the stepper motor wires to the appropriate outputs on the DKC-1A, ensuring correct phase alignment.

- Control Signals: Connect the PUL+, PUL-, DIR+, DIR-, ENA+, and ENA- to the control signals from your microcontroller or pulse generator.

Best Practices

- Always ensure the power supply is turned off before making any connections.

- Use a current limit setting appropriate for your stepper motor to prevent overheating.

- For optimal performance, use shielded cables for control signals to minimize electrical noise.

- Configure microstepping settings according to the precision required for your application.

Example Code for Arduino UNO

// Define the connections to the Arduino

const int dirPin = 2; // DIR+ to digital pin 2

const int stepPin = 3; // PUL+ to digital pin 3

const int enablePin = 4; // ENA+ to digital pin 4

void setup() {

// Set the pin modes

pinMode(dirPin, OUTPUT);

pinMode(stepPin, OUTPUT);

pinMode(enablePin, OUTPUT);

// Enable the motor

digitalWrite(enablePin, LOW);

}

void loop() {

// Set the direction

digitalWrite(dirPin, HIGH); // Set to LOW to change direction

// Move the motor with a simple square wave

digitalWrite(stepPin, HIGH);

delayMicroseconds(500); // Set the speed with delay duration

digitalWrite(stepPin, LOW);

delayMicroseconds(500);

}

Troubleshooting and FAQs

Common Issues

- Motor does not move: Check power supply and connections. Ensure the enable pin is set to the correct state.

- Erratic movement: Verify that the control signals are not affected by noise. Use shorter cables or shielded wires.

- Overheating: Ensure the current limit is set correctly for your motor. Provide adequate cooling if necessary.

FAQs

Q: Can I use the DKC-1A with a 5V stepper motor? A: No, the DKC-1A is designed for 12-24V motors. Using a 5V motor may damage the controller or the motor.

Q: How do I change the microstepping settings? A: Microstepping is typically set by DIP switches or jumpers on the controller board. Refer to the specific product manual for details.

Q: What is the maximum stepping frequency for the DKC-1A? A: The maximum stepping frequency depends on the motor and power supply, but the controller can typically handle up to several kHz.

Remember to always refer to the DKC-1A Stepper Motor Controller's manual for detailed information and safety guidelines.