How to Use Hot water pump: Examples, Pinouts, and Specs

Design with Hot water pump in Cirkit Designer

Design with Hot water pump in Cirkit DesignerIntroduction

The Grundfos UPS3 is a high-efficiency hot water pump designed for circulating hot water in heating systems. It is commonly used in residential and commercial applications to ensure efficient heating and a reliable hot water supply. The pump is known for its energy efficiency, quiet operation, and ease of installation, making it a popular choice for modern heating systems.

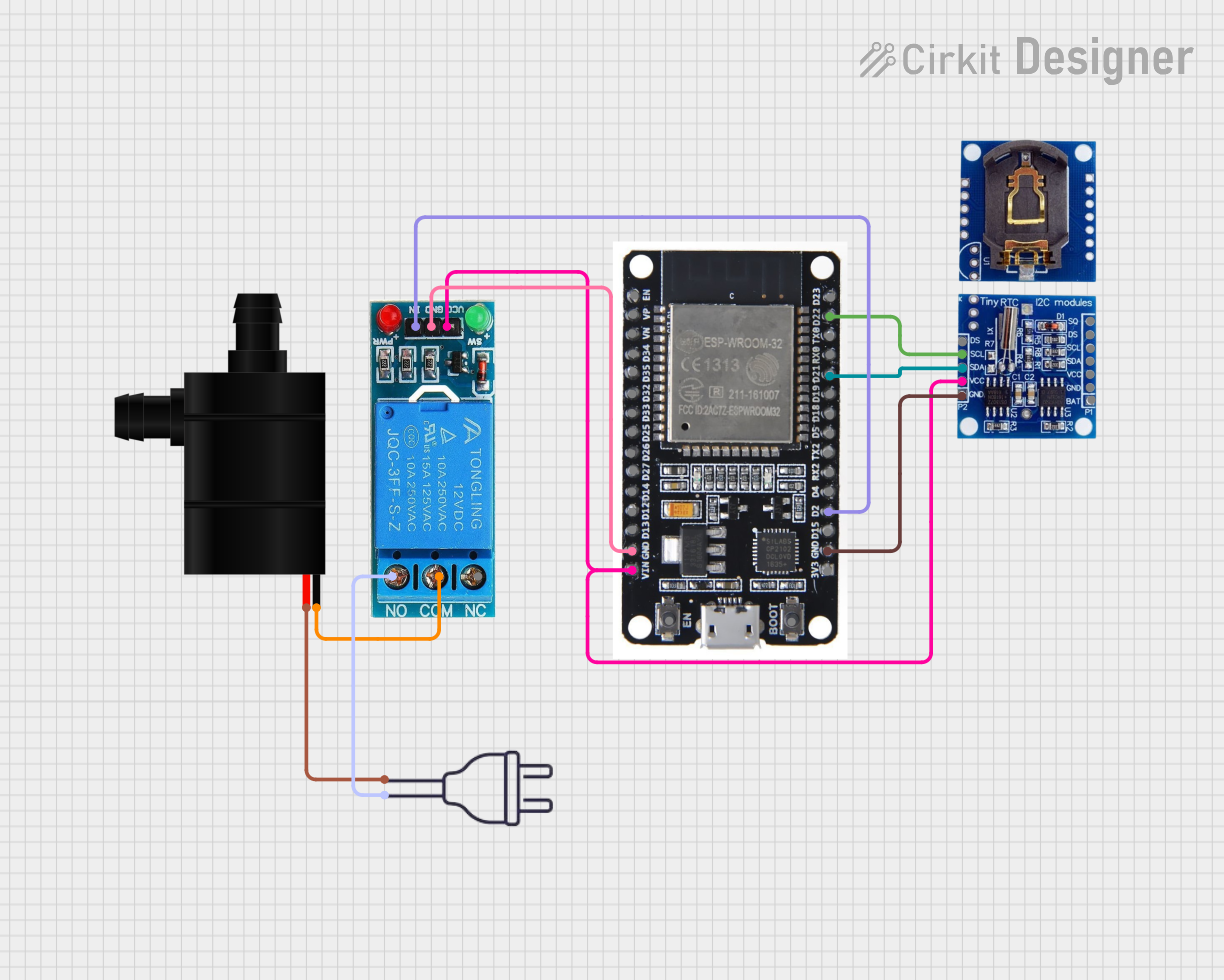

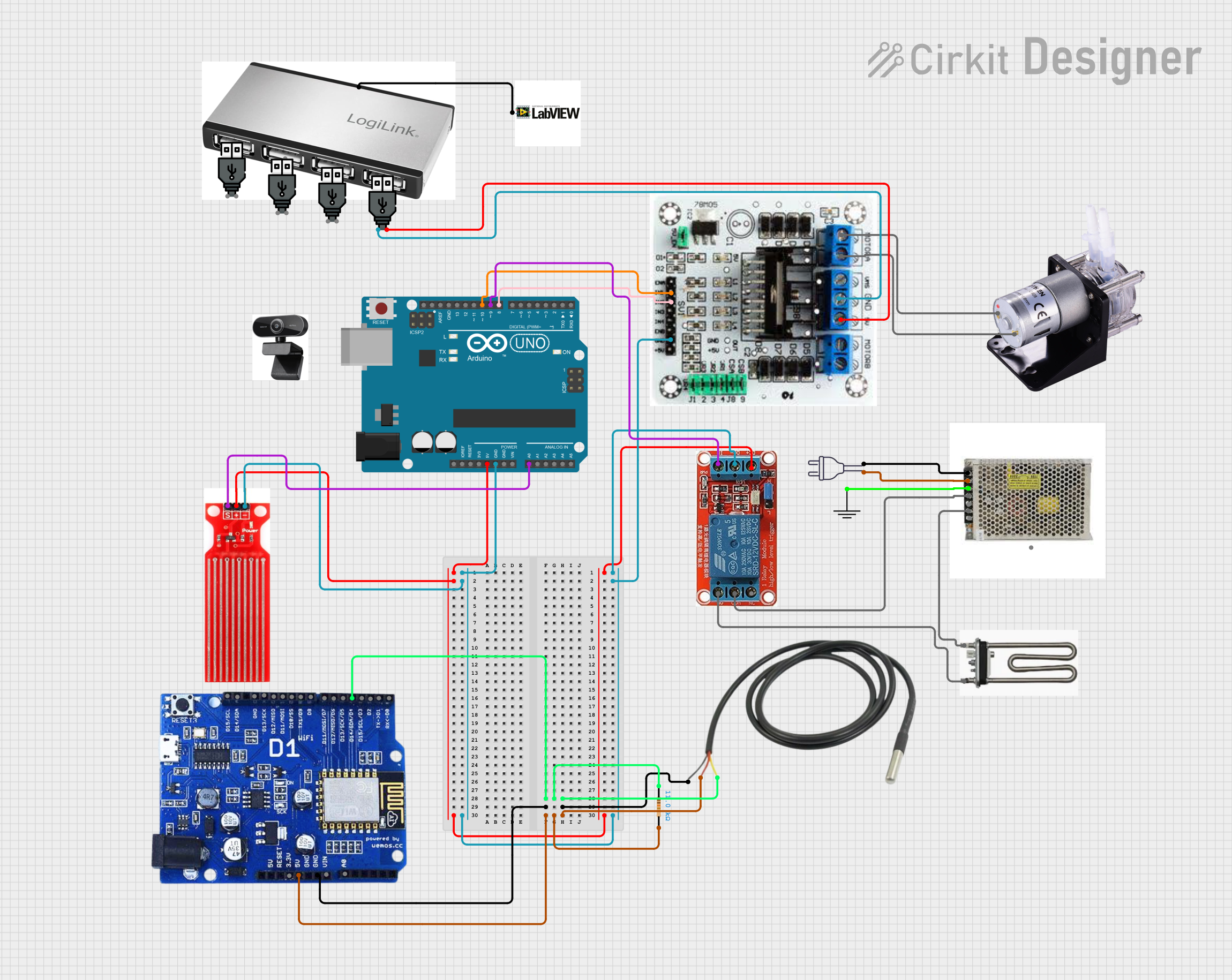

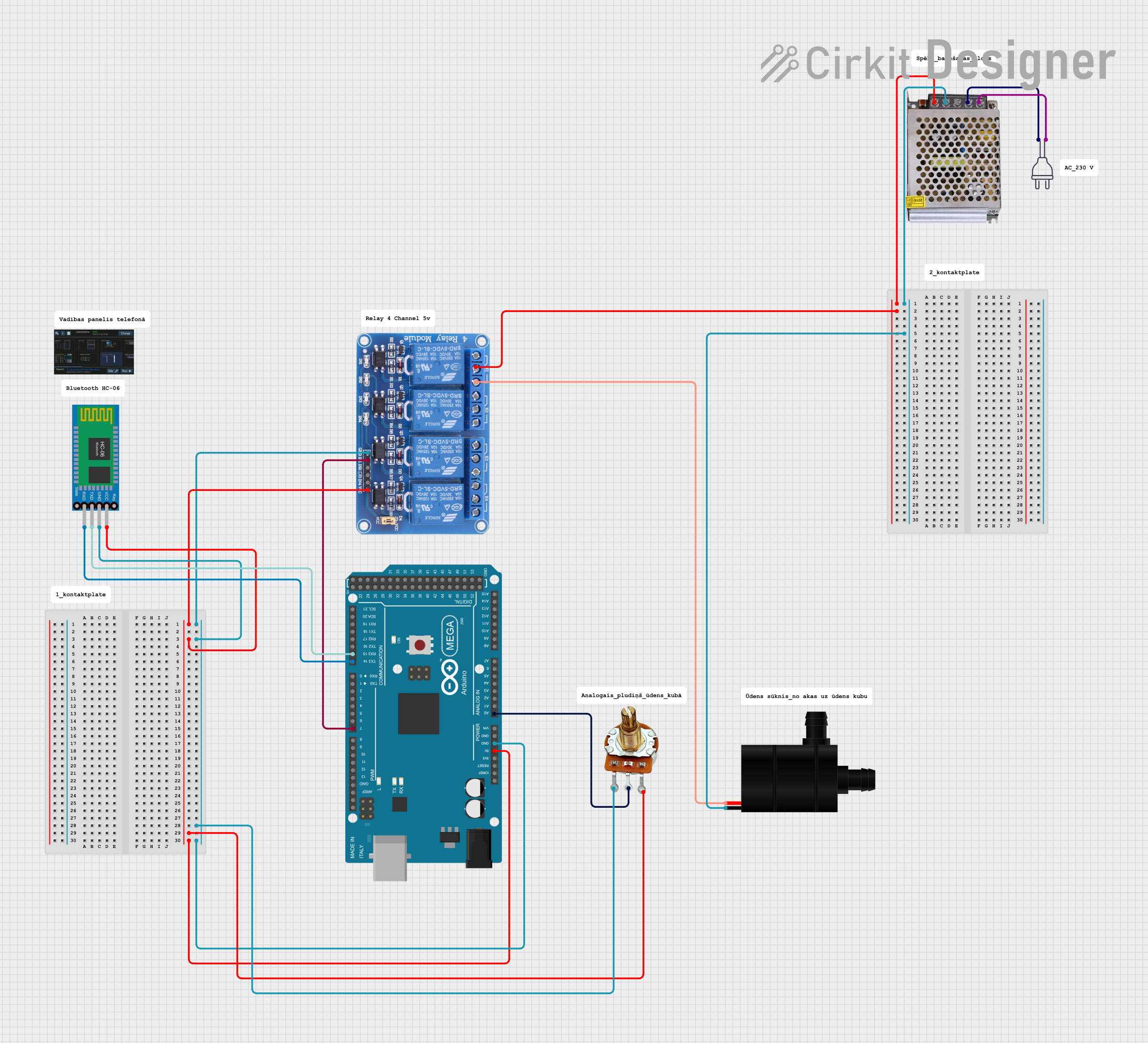

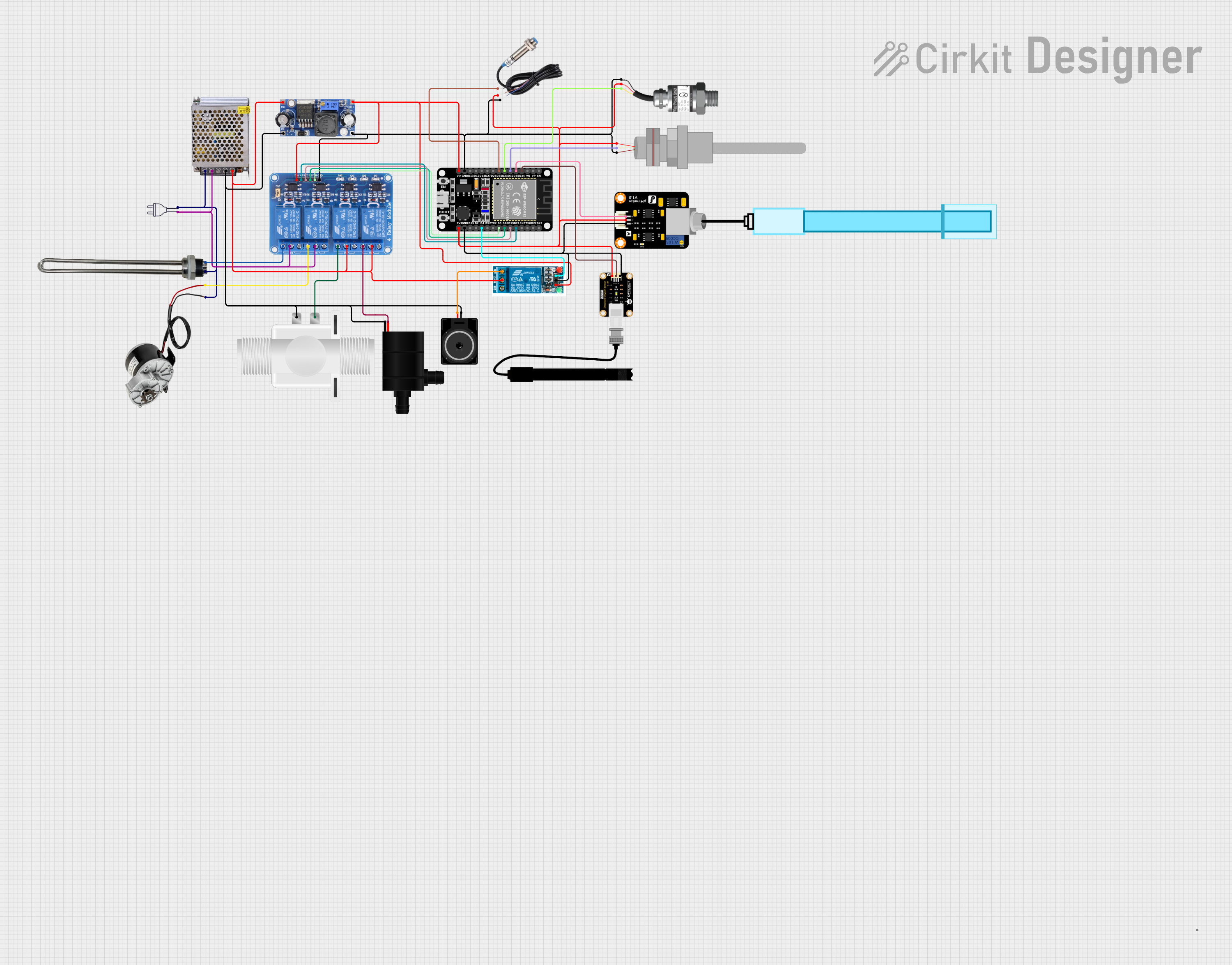

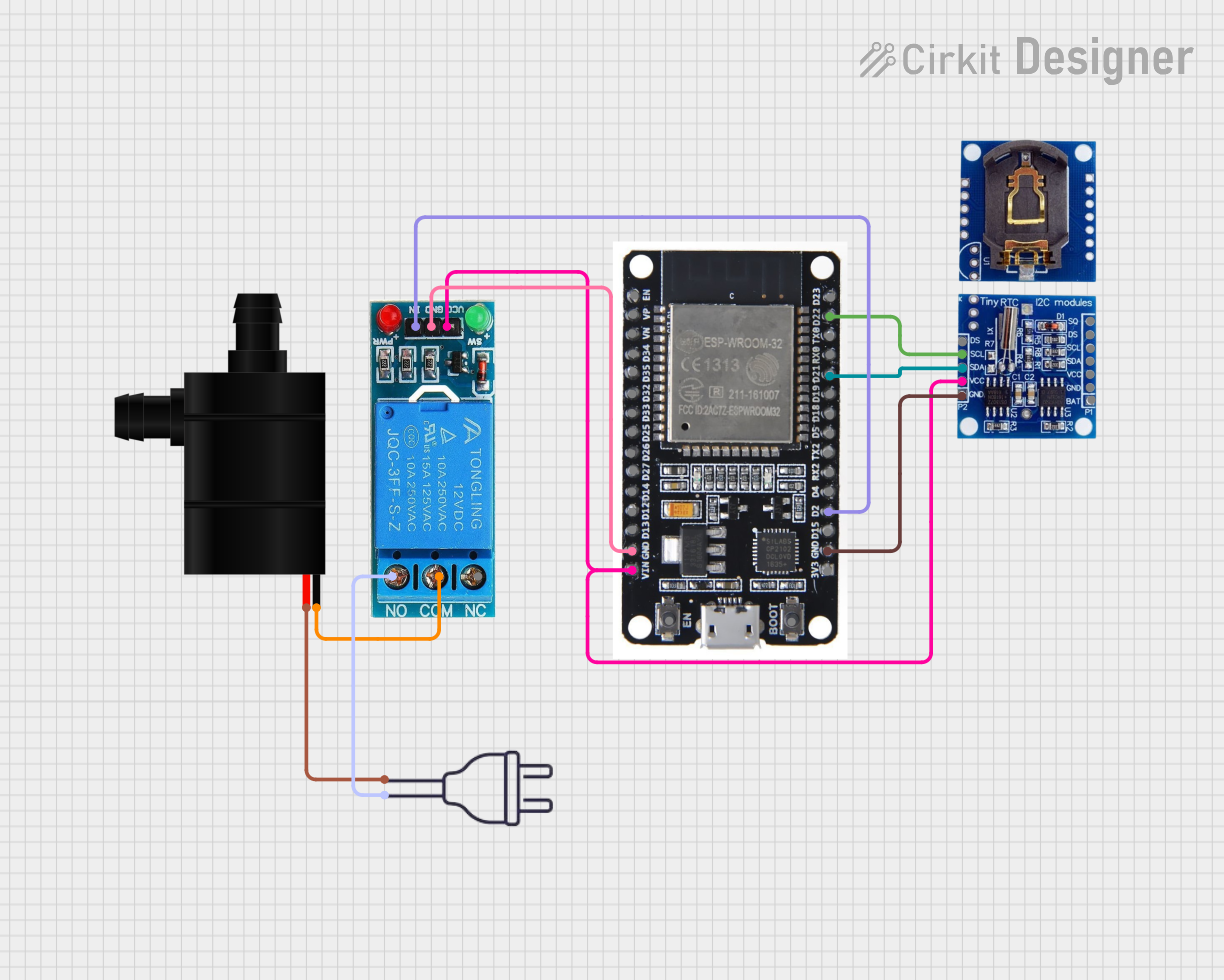

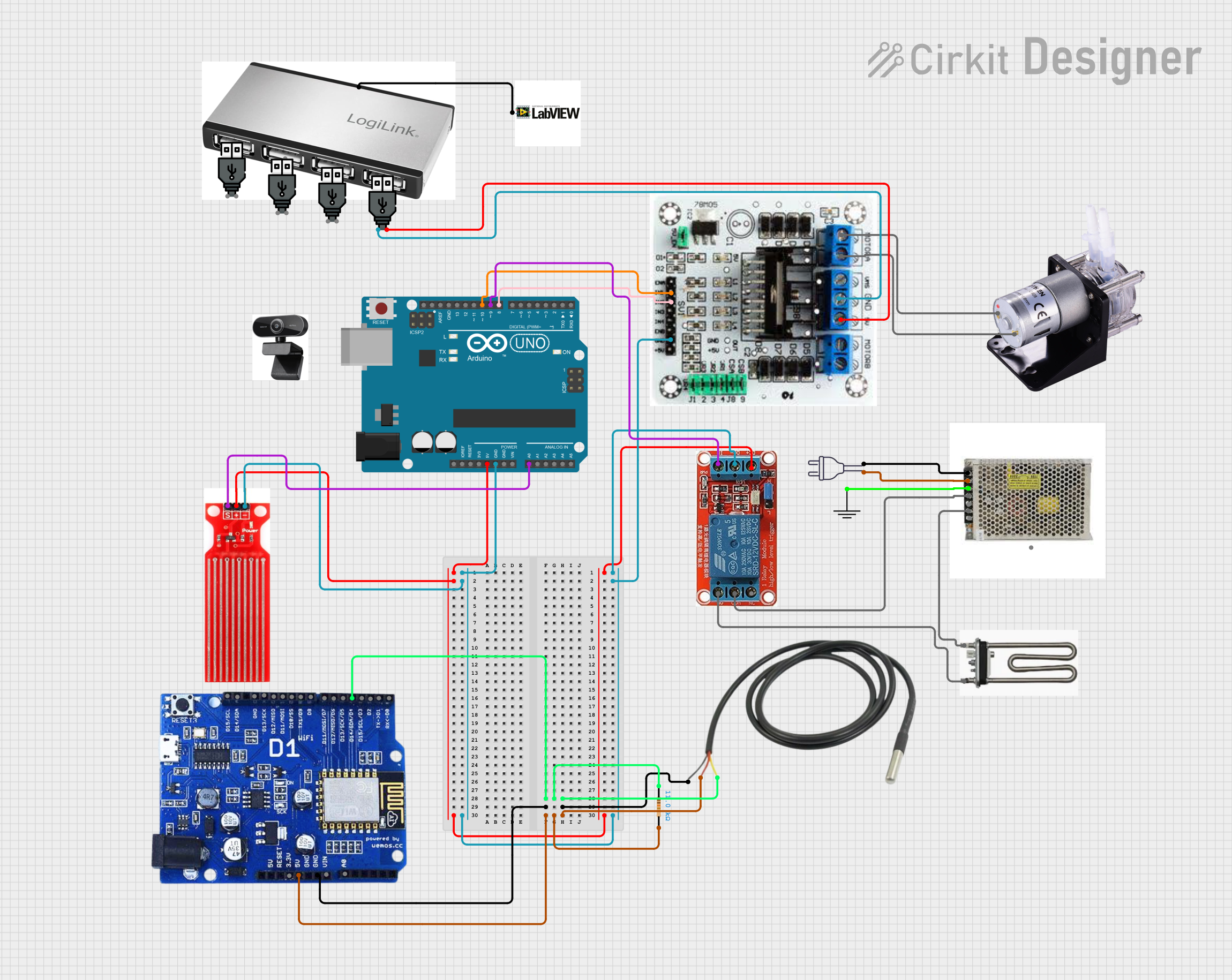

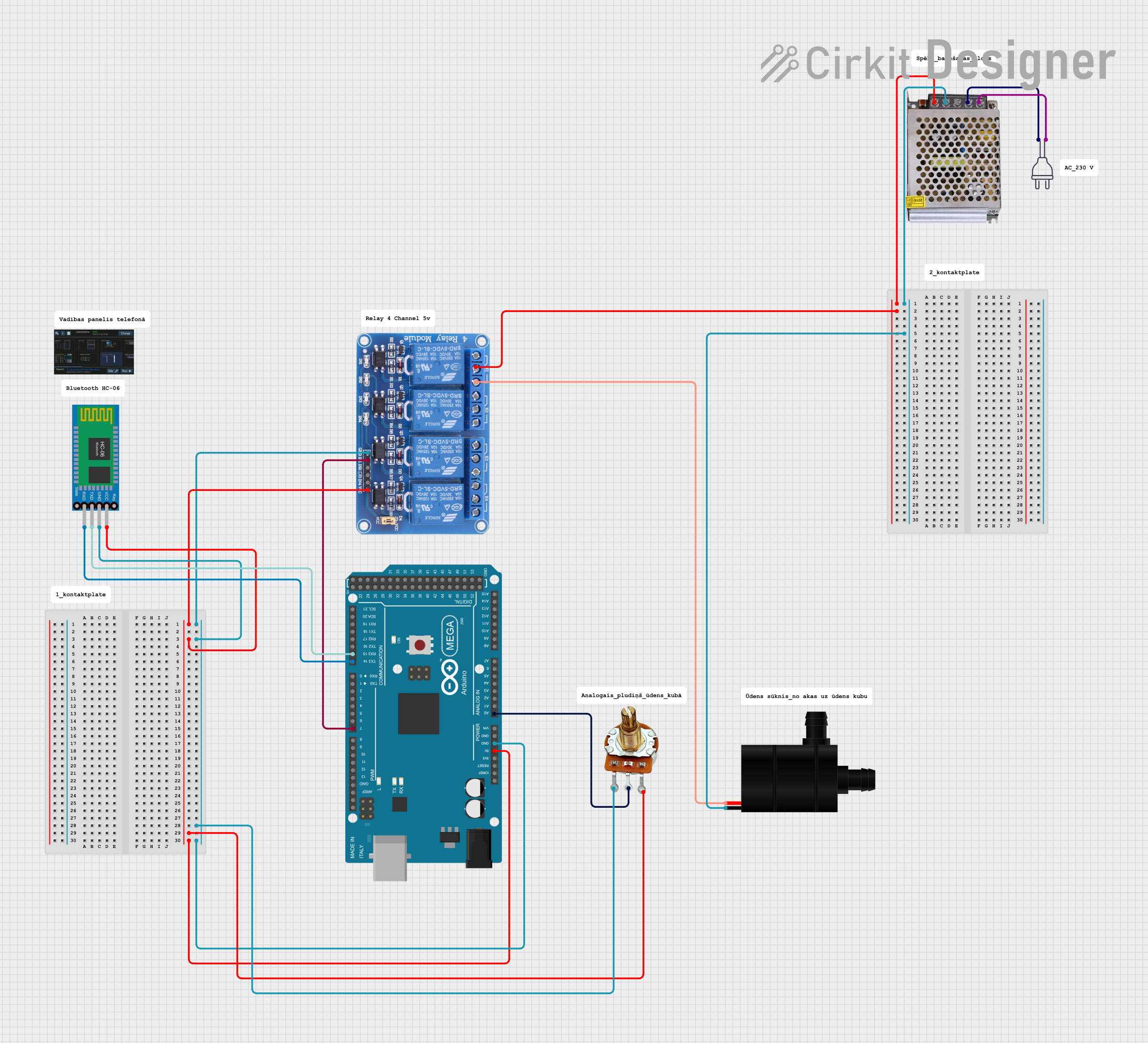

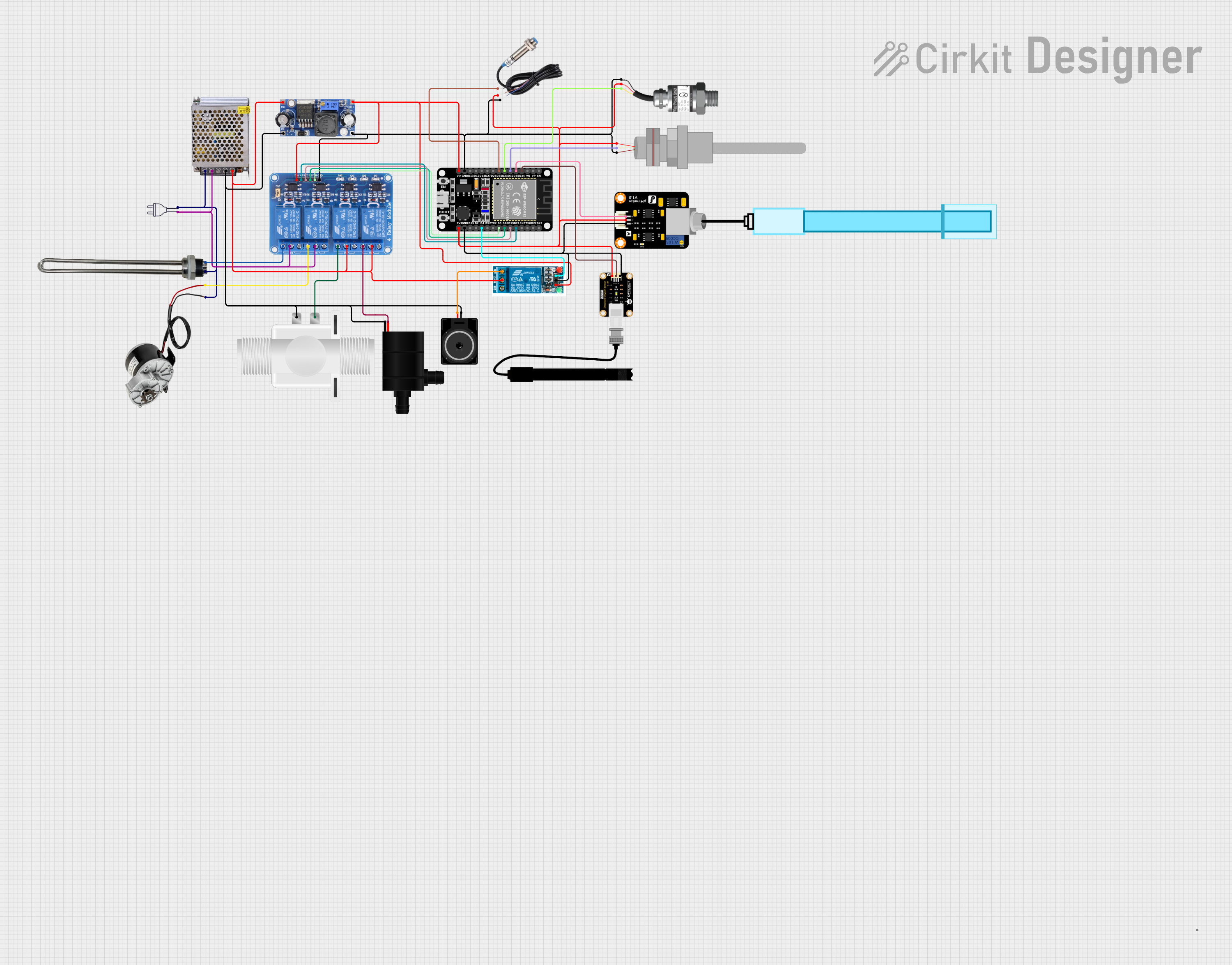

Explore Projects Built with Hot water pump

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Hot water pump

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Central heating systems in residential homes

- Hot water circulation in commercial buildings

- Underfloor heating systems

- Solar thermal heating systems

- Replacement for older Grundfos pumps in existing systems

Technical Specifications

The Grundfos UPS3 is engineered to meet the demands of modern heating systems. Below are its key technical details:

Key Technical Details

| Parameter | Value |

|---|---|

| Manufacturer | Grundfos |

| Part ID | UPS3 |

| Voltage | 230V AC |

| Frequency | 50/60 Hz |

| Power Consumption | 3W to 38W (depending on settings) |

| Maximum Head | 5.5 meters |

| Maximum Flow Rate | 3.4 m³/h |

| Temperature Range | +2°C to +95°C |

| Energy Efficiency Index | ≤ 0.20 |

| Protection Class | IP44 |

| Connection Size | G 1½" |

Pin Configuration and Descriptions

The Grundfos UPS3 does not have traditional "pins" like electronic components but instead features a terminal block for electrical connections. Below is a description of the terminal connections:

| Terminal Label | Description |

|---|---|

| L | Live (230V AC input) |

| N | Neutral (230V AC input) |

| PE | Protective Earth (Ground connection) |

Usage Instructions

The Grundfos UPS3 is straightforward to install and operate. Follow the steps below to integrate it into your heating system:

Installation Steps

Preparation:

- Ensure the power supply is turned off before installation.

- Verify that the pump's specifications match your system's requirements.

- Check that the pipe connections are clean and free of debris.

Mounting:

- Install the pump in the correct orientation (horizontal shaft position is recommended).

- Use the appropriate fittings to connect the pump to the pipework.

Electrical Connection:

- Connect the Live (L), Neutral (N), and Protective Earth (PE) wires to the terminal block.

- Ensure all connections are secure and comply with local electrical codes.

Operation:

- Turn on the power supply and select the desired pump setting (low, medium, or high speed).

- Monitor the pump for proper operation and check for leaks.

Important Considerations and Best Practices

- Always ensure the pump is filled with water before operation to prevent damage.

- Use the pump's built-in control panel to adjust settings for optimal performance.

- Regularly inspect the pump for signs of wear or blockages.

- If replacing an older pump, ensure compatibility with the existing system.

Arduino Integration

While the Grundfos UPS3 is not typically controlled by an Arduino, it is possible to monitor its operation using sensors (e.g., flow sensors or temperature sensors) connected to an Arduino. Below is an example of Arduino code to monitor a flow sensor:

// Example: Monitor water flow using a flow sensor with Arduino

// Connect the flow sensor's signal pin to Arduino pin 2

const int flowSensorPin = 2; // Pin connected to the flow sensor

volatile int pulseCount = 0; // Variable to store pulse count

void setup() {

pinMode(flowSensorPin, INPUT_PULLUP); // Set pin as input with pull-up

attachInterrupt(digitalPinToInterrupt(flowSensorPin), countPulse, RISING);

Serial.begin(9600); // Initialize serial communication

}

void loop() {

delay(1000); // Wait for 1 second

Serial.print("Flow pulses in last second: ");

Serial.println(pulseCount); // Print pulse count

pulseCount = 0; // Reset pulse count

}

// Interrupt service routine to count pulses

void countPulse() {

pulseCount++;

}

Troubleshooting and FAQs

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Pump not running | No power supply | Check electrical connections and fuse |

| No water circulation | Airlock in the system | Bleed the system to remove air |

| Unusual noise during operation | Debris in the pump or pipework | Clean the pump and pipe connections |

| Overheating | Insufficient water flow | Check for blockages or restrictions |

FAQs

Q: Can the UPS3 be used with solar heating systems?

A: Yes, the UPS3 is compatible with solar thermal systems, provided the temperature and flow requirements are within its specifications.

Q: How do I know if the pump is operating efficiently?

A: Monitor the pump's energy consumption and ensure the system is properly balanced. The built-in control panel can also provide performance feedback.

Q: Can I install the pump vertically?

A: The pump can be installed vertically, but the shaft must remain horizontal for optimal performance.

Q: How often should the pump be serviced?

A: Regular maintenance is recommended every 1-2 years, depending on usage and water quality.