How to Use pcb_2: Examples, Pinouts, and Specs

Design with pcb_2 in Cirkit Designer

Design with pcb_2 in Cirkit DesignerIntroduction

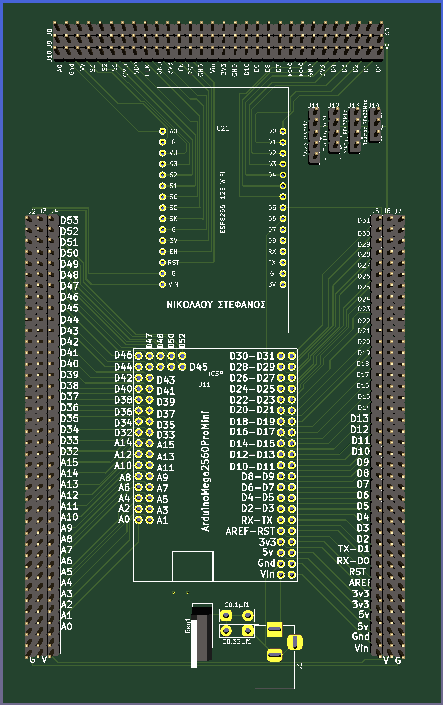

The PCB_2, manufactured by Νικολάου Νίκος (Part ID: Πλακέτα), is a high-quality printed circuit board designed for mounting electronic components. It provides both electrical connections and mechanical support, making it an essential component in electronic circuit design. The PCB_2 is versatile and suitable for a wide range of applications, from prototyping to industrial-grade electronics.

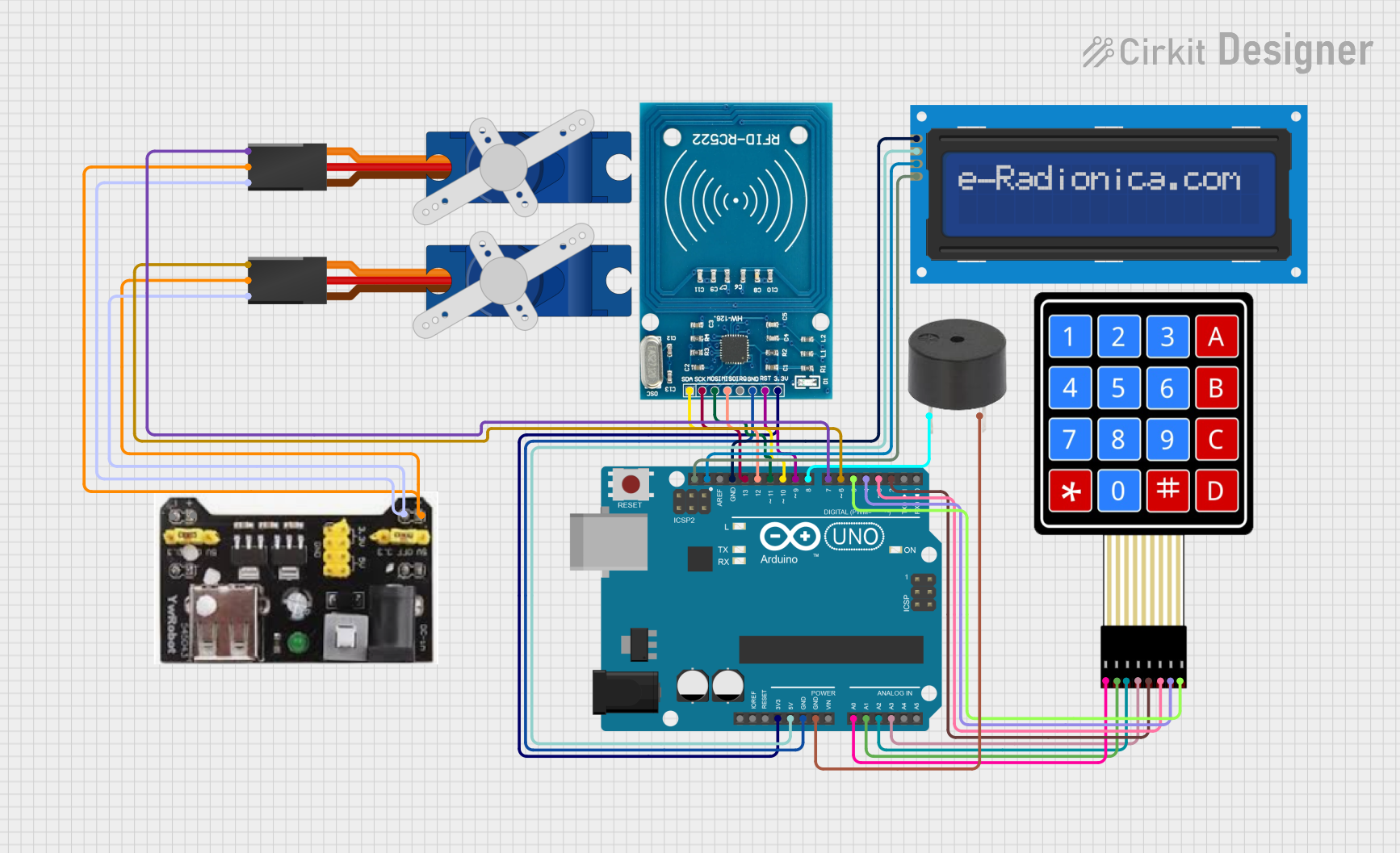

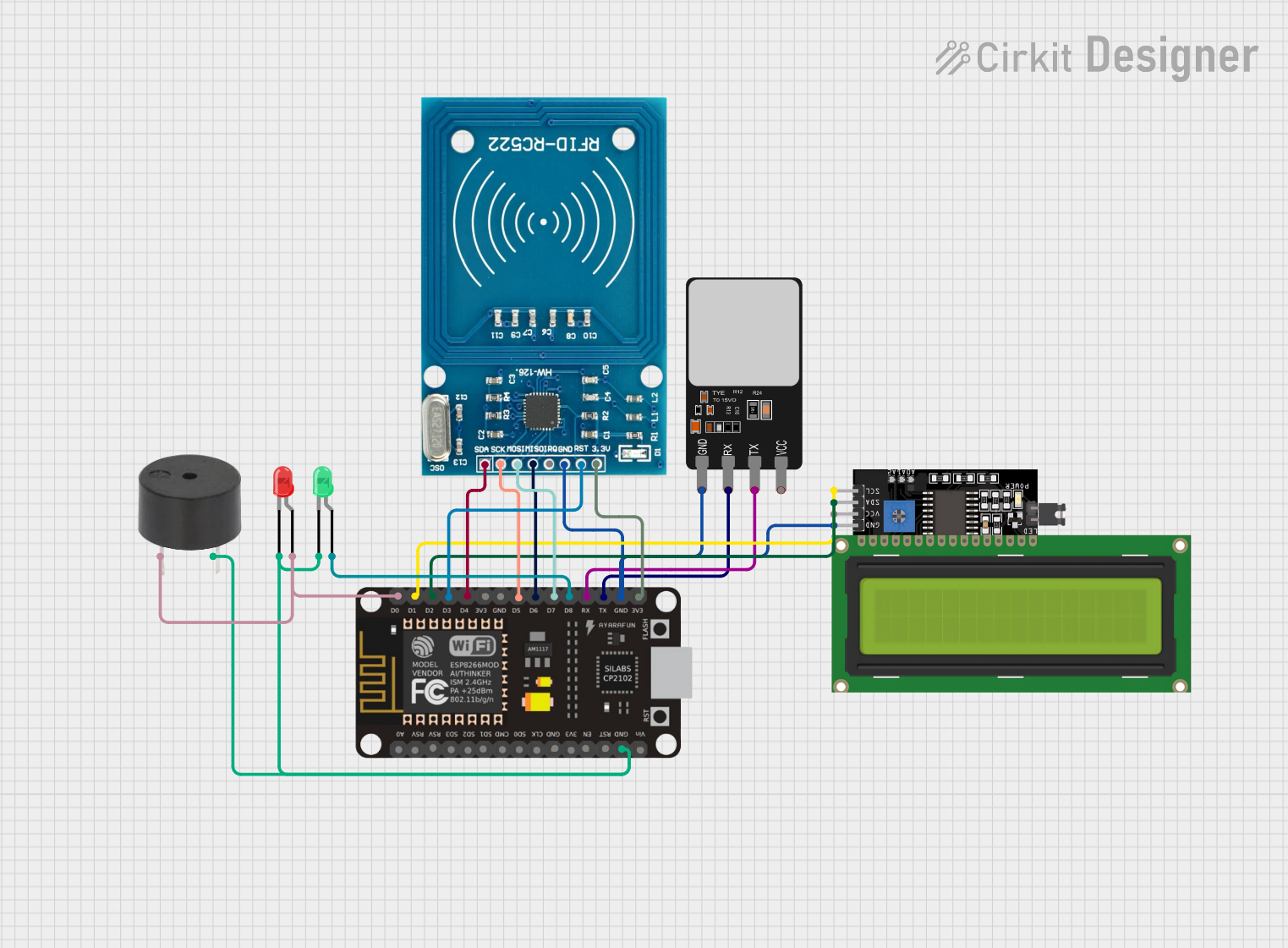

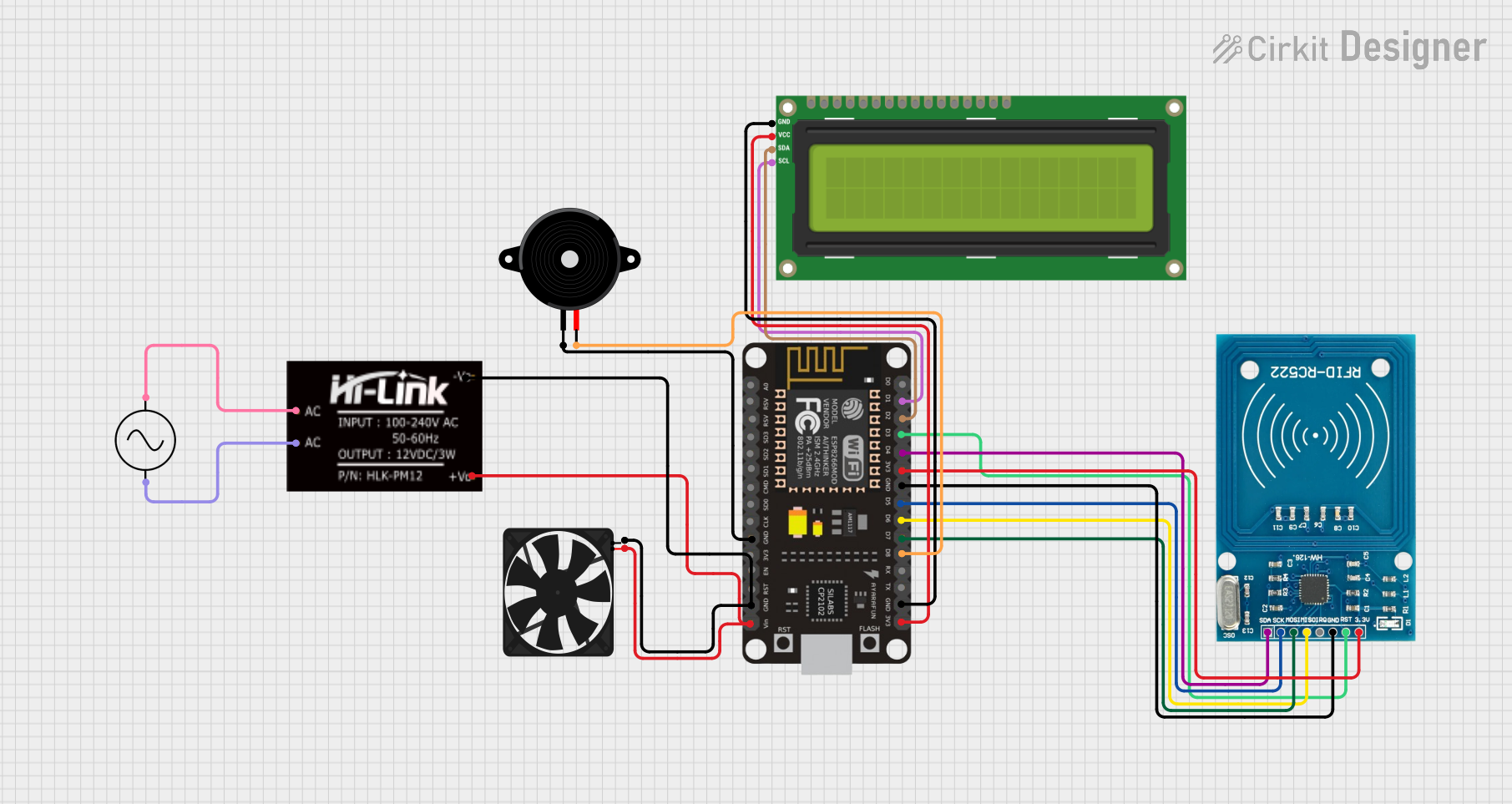

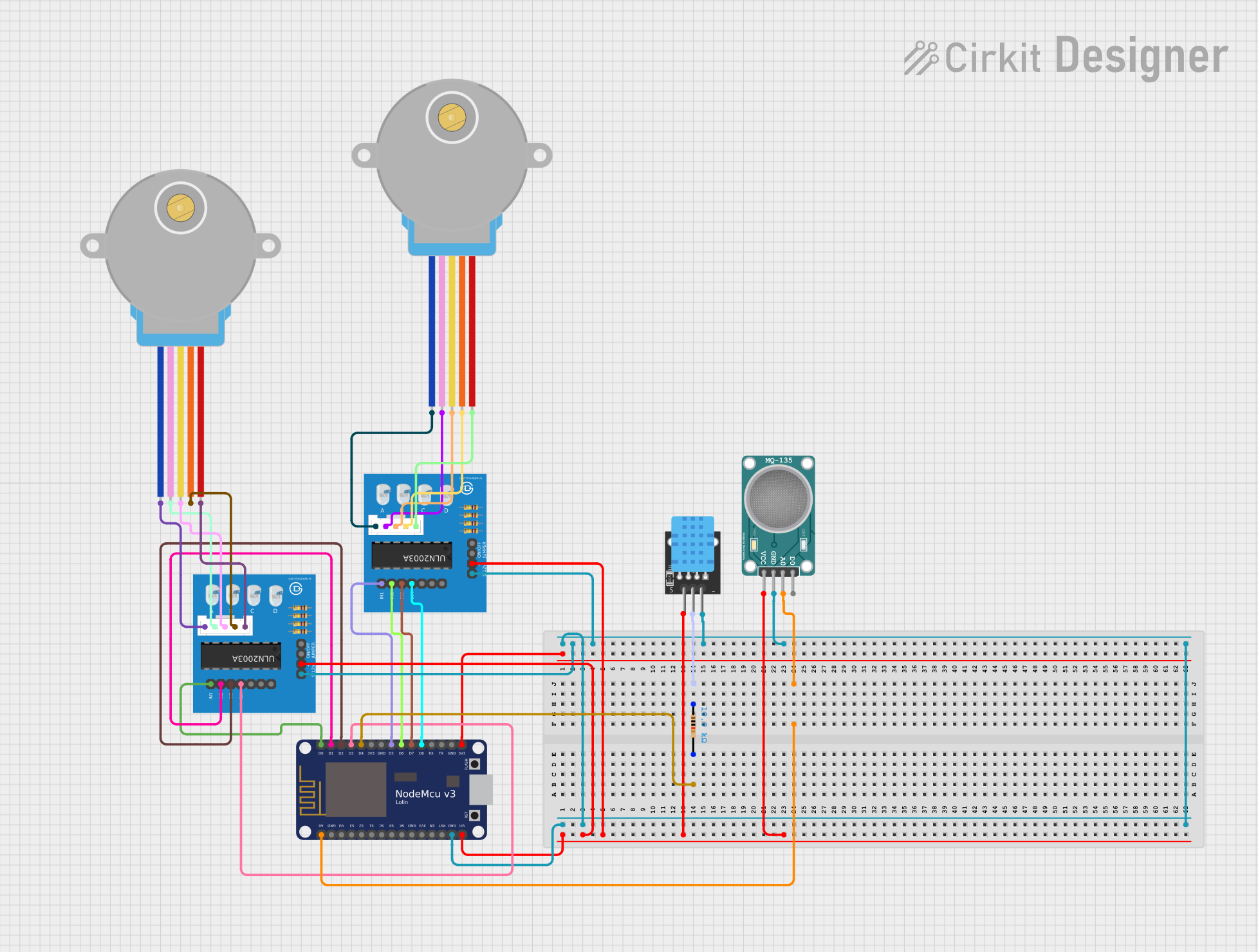

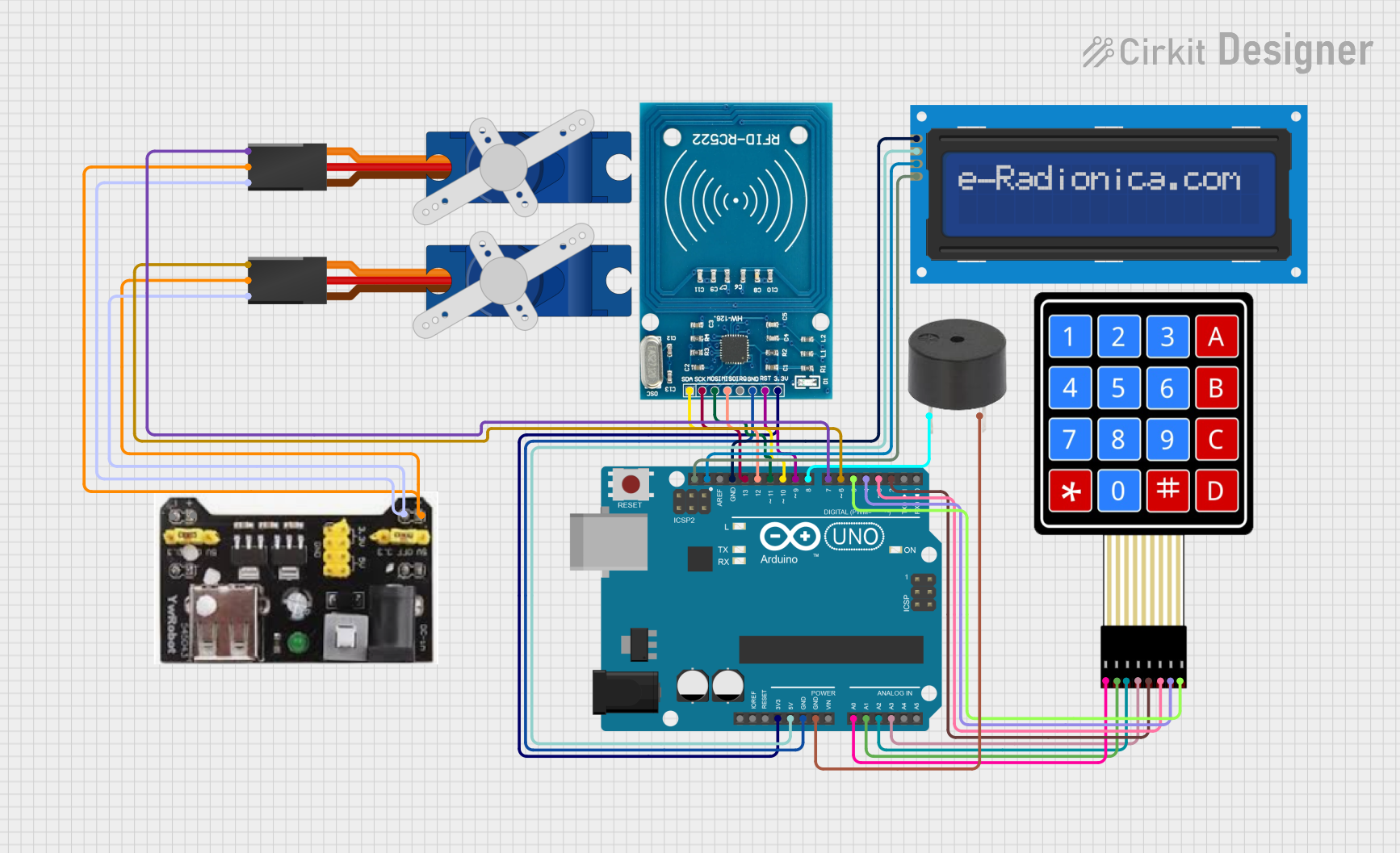

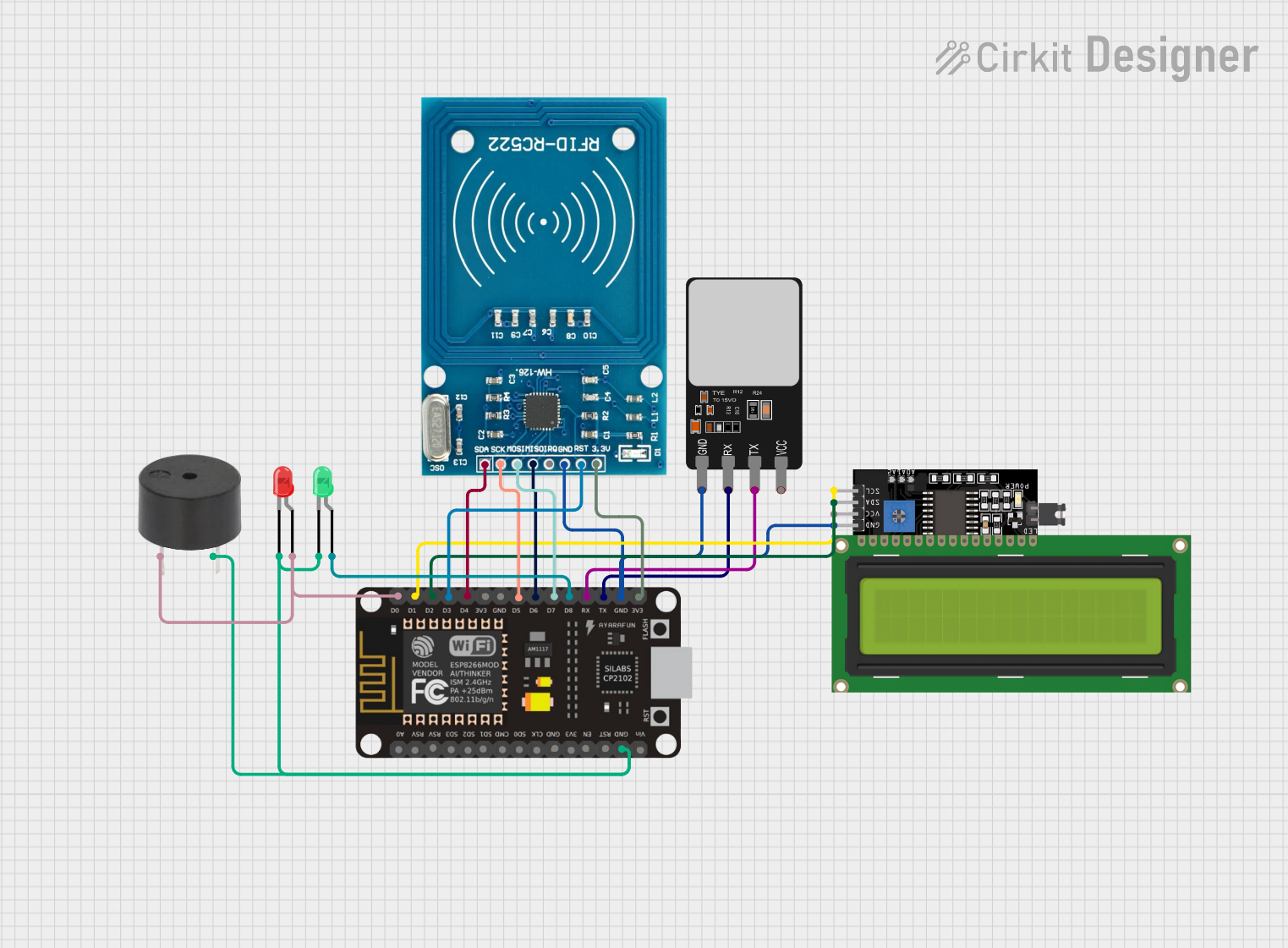

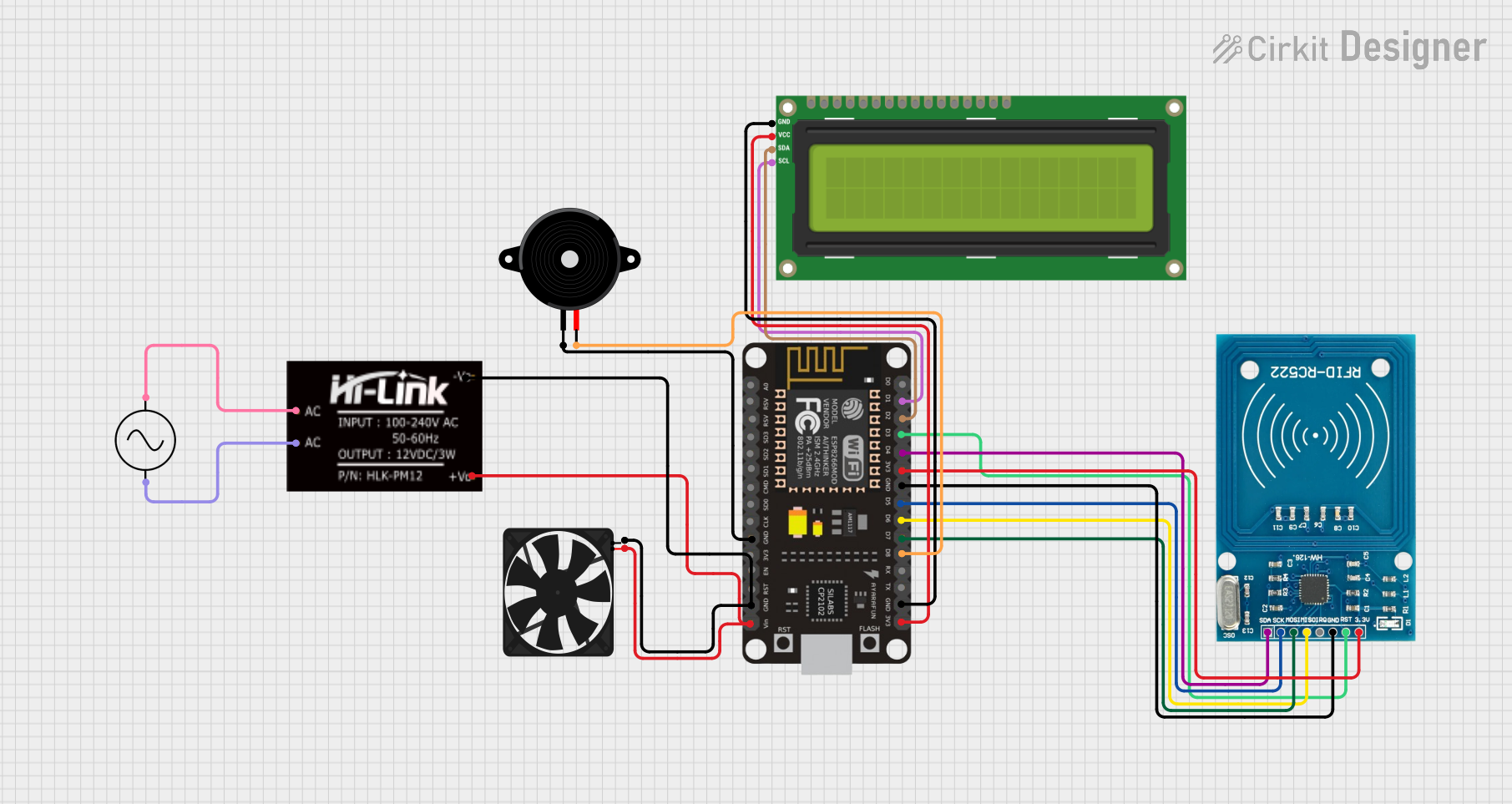

Explore Projects Built with pcb_2

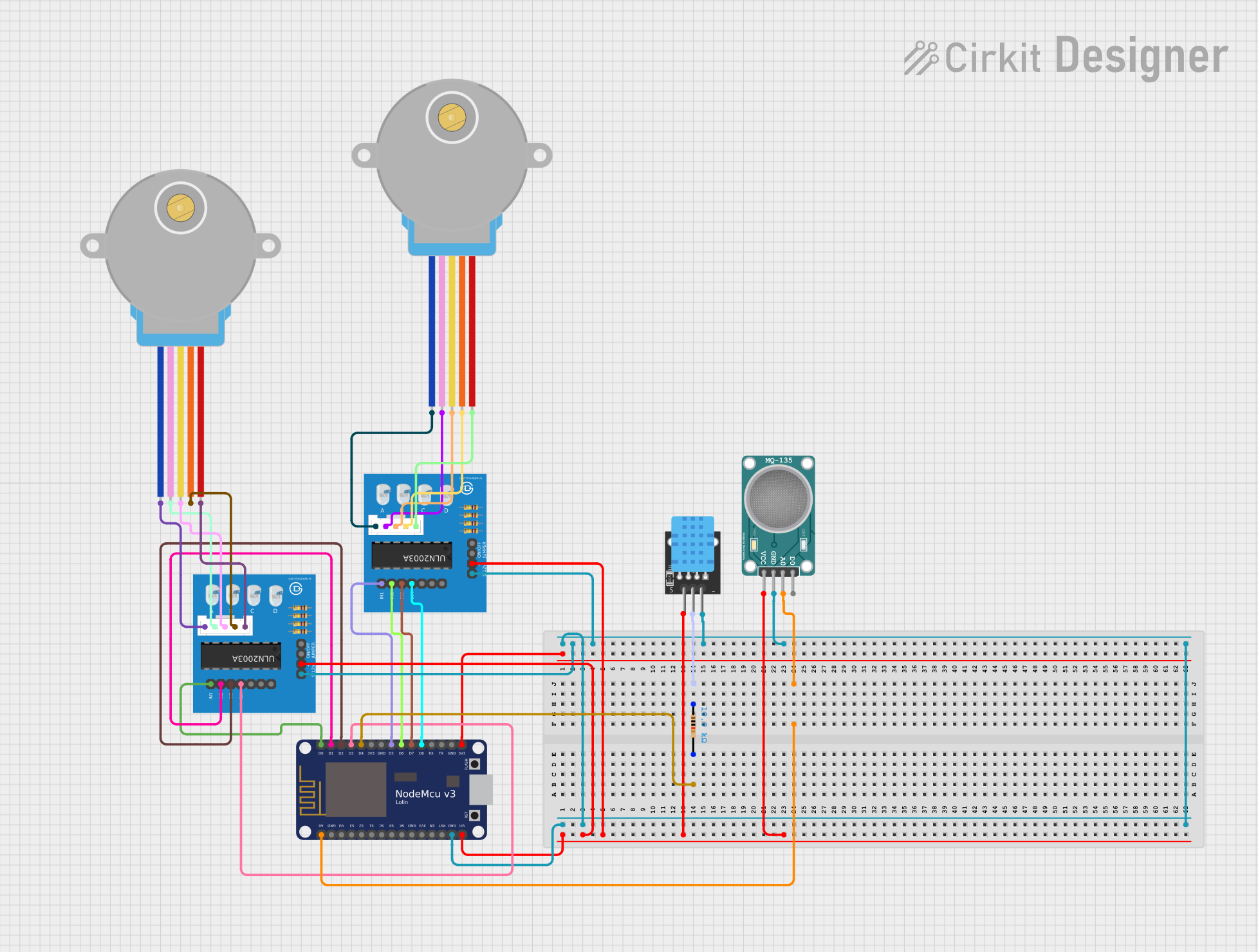

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with pcb_2

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Prototyping and development of electronic circuits

- Mounting and interconnecting components in consumer electronics

- Industrial control systems and automation

- Educational projects and DIY electronics

- Embedded systems and IoT devices

Technical Specifications

The PCB_2 is designed to meet the needs of both hobbyists and professionals. Below are its key technical specifications:

General Specifications

| Parameter | Value |

|---|---|

| Manufacturer | Νικολάου Νίκος |

| Part ID | Πλακέτα |

| Material | FR4 (Flame Retardant 4) |

| Layers | 2 |

| Board Thickness | 1.6 mm |

| Copper Thickness | 35 µm (1 oz/ft²) |

| Surface Finish | HASL (Hot Air Solder Leveling) |

| Solder Mask Color | Green |

| Silkscreen Color | White |

| Operating Temperature | -40°C to +85°C |

Electrical Specifications

| Parameter | Value |

|---|---|

| Maximum Voltage | 50 V |

| Maximum Current | 2 A per trace (depending on width) |

| Dielectric Constant | 4.5 |

| Insulation Resistance | >10⁶ MΩ |

Pin Configuration and Descriptions

The PCB_2 does not have predefined pins, as it is a customizable board for mounting components. However, it includes the following features:

- Through-Hole Pads: For mounting components with leads.

- Surface-Mount Pads: For SMD (Surface-Mount Device) components.

- Power and Ground Planes: Dedicated layers for power distribution and grounding.

- Vias: For interconnecting layers.

Usage Instructions

The PCB_2 is straightforward to use and can be adapted for various circuit designs. Follow these steps and best practices to ensure optimal performance:

How to Use the PCB_2 in a Circuit

Design the Circuit Layout:

- Use PCB design software (e.g., KiCad, Eagle, or Altium) to create the schematic and layout.

- Ensure proper trace width for current-carrying paths and adequate spacing between traces.

Prepare the PCB:

- Print the design onto the PCB_2 using a suitable fabrication method (e.g., etching or CNC milling).

- Apply solder mask and silkscreen if required.

Mount Components:

- Solder through-hole or surface-mount components onto the board.

- Use flux to ensure clean and reliable solder joints.

Test the Circuit:

- Verify connections using a multimeter.

- Power the circuit and test its functionality.

Important Considerations and Best Practices

- Trace Width: Use a trace width calculator to ensure traces can handle the required current.

- Thermal Management: For high-power circuits, include thermal vias and heat sinks.

- Grounding: Use a solid ground plane to reduce noise and improve signal integrity.

- Component Placement: Place components logically to minimize trace lengths and avoid interference.

- Safety: Ensure the board operates within its voltage and current limits.

Example: Connecting PCB_2 to an Arduino UNO

The PCB_2 can be used to create custom shields or circuits for the Arduino UNO. Below is an example of a simple LED circuit:

Circuit Description

- An LED is connected to pin 13 of the Arduino UNO via a 220-ohm resistor.

- The PCB_2 is used to mount the LED and resistor.

Arduino Code

// Simple LED Blink Example

// This code blinks an LED connected to pin 13 of the Arduino UNO.

// Define the LED pin

const int ledPin = 13;

void setup() {

// Set the LED pin as an output

pinMode(ledPin, OUTPUT);

}

void loop() {

// Turn the LED on

digitalWrite(ledPin, HIGH);

delay(1000); // Wait for 1 second

// Turn the LED off

digitalWrite(ledPin, LOW);

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues

Poor Solder Joints:

- Cause: Insufficient heat or flux during soldering.

- Solution: Use a soldering iron with the correct temperature and apply flux.

Short Circuits:

- Cause: Traces or solder bridges touching unintentionally.

- Solution: Inspect the board under a magnifying glass and remove excess solder.

Broken Traces:

- Cause: Excessive mechanical stress or overheating.

- Solution: Repair the trace using a wire or conductive ink.

Component Misplacement:

- Cause: Incorrect orientation or placement of components.

- Solution: Double-check the schematic and component markings before soldering.

FAQs

Q1: Can the PCB_2 handle high-frequency signals?

A1: Yes, the PCB_2 is suitable for high-frequency signals, but proper trace design and impedance matching are required.

Q2: What is the maximum number of components I can mount?

A2: The number of components depends on the size of the board and the layout design.

Q3: Can I use the PCB_2 for power circuits?

A3: Yes, but ensure the traces are wide enough to handle the required current, and use thermal management techniques.

Q4: Is the PCB_2 compatible with SMD components?

A4: Yes, the PCB_2 includes surface-mount pads for SMD components.

By following this documentation, users can effectively utilize the PCB_2 for a variety of electronic projects.