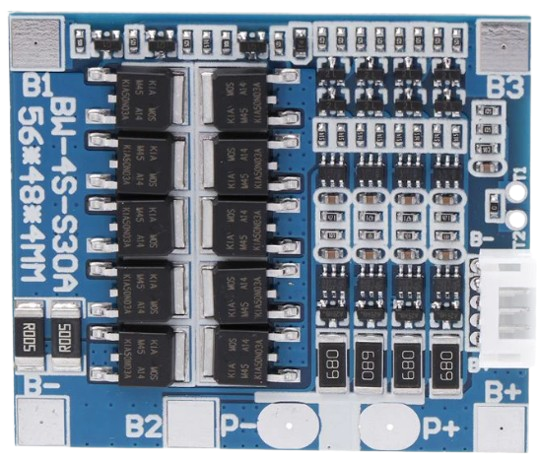

How to Use 4S 30A BMS: Examples, Pinouts, and Specs

Design with 4S 30A BMS in Cirkit Designer

Design with 4S 30A BMS in Cirkit DesignerIntroduction

The 4S 30A Battery Management System (BMS) is a critical component for managing and protecting lithium-ion battery packs consisting of four series-connected cells. It ensures the safe operation of the battery pack by monitoring individual cell voltages, temperatures, and current flow. Additionally, the BMS balances the cells during charging and discharging, which helps to extend the overall lifespan of the battery pack.

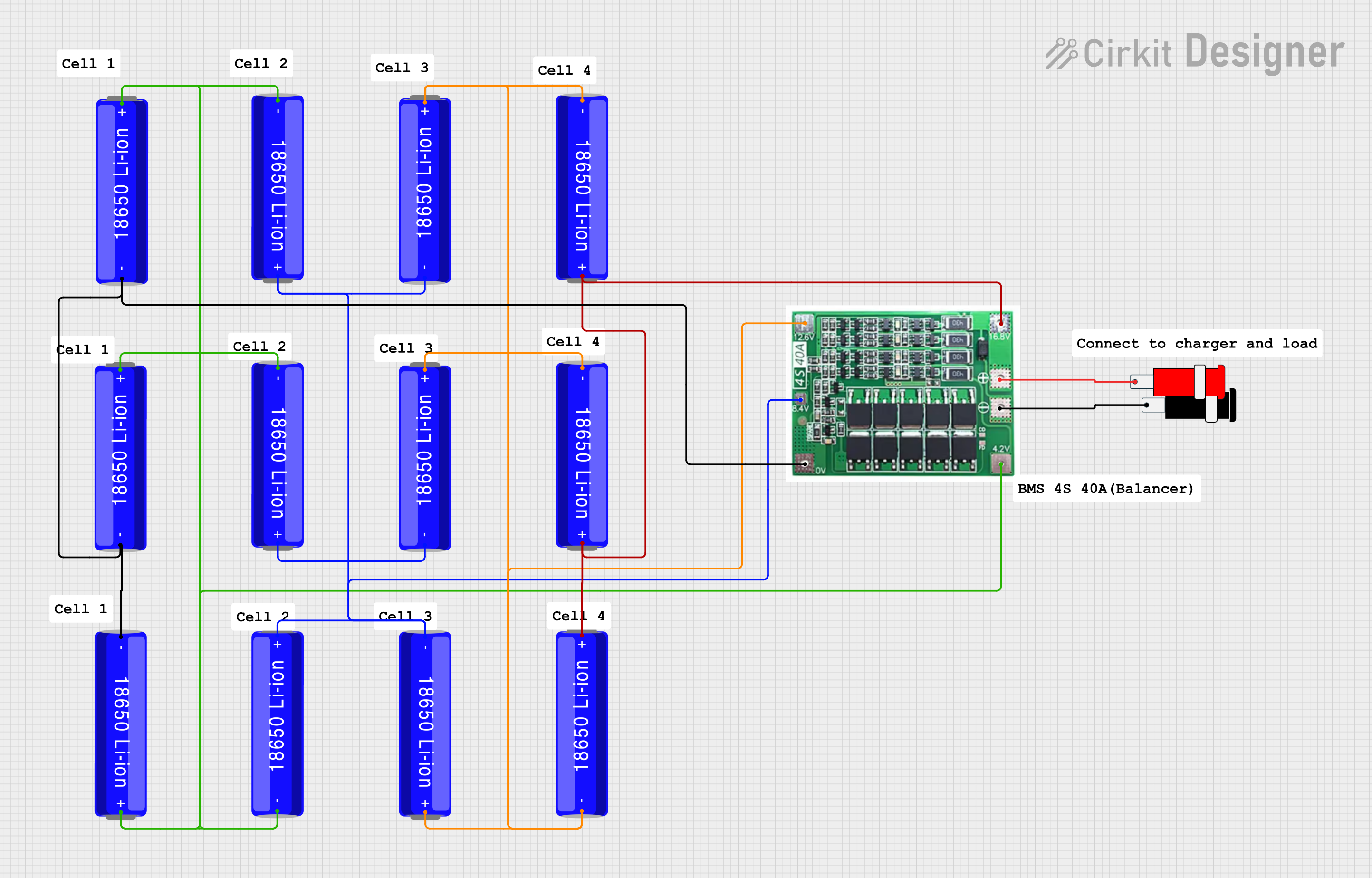

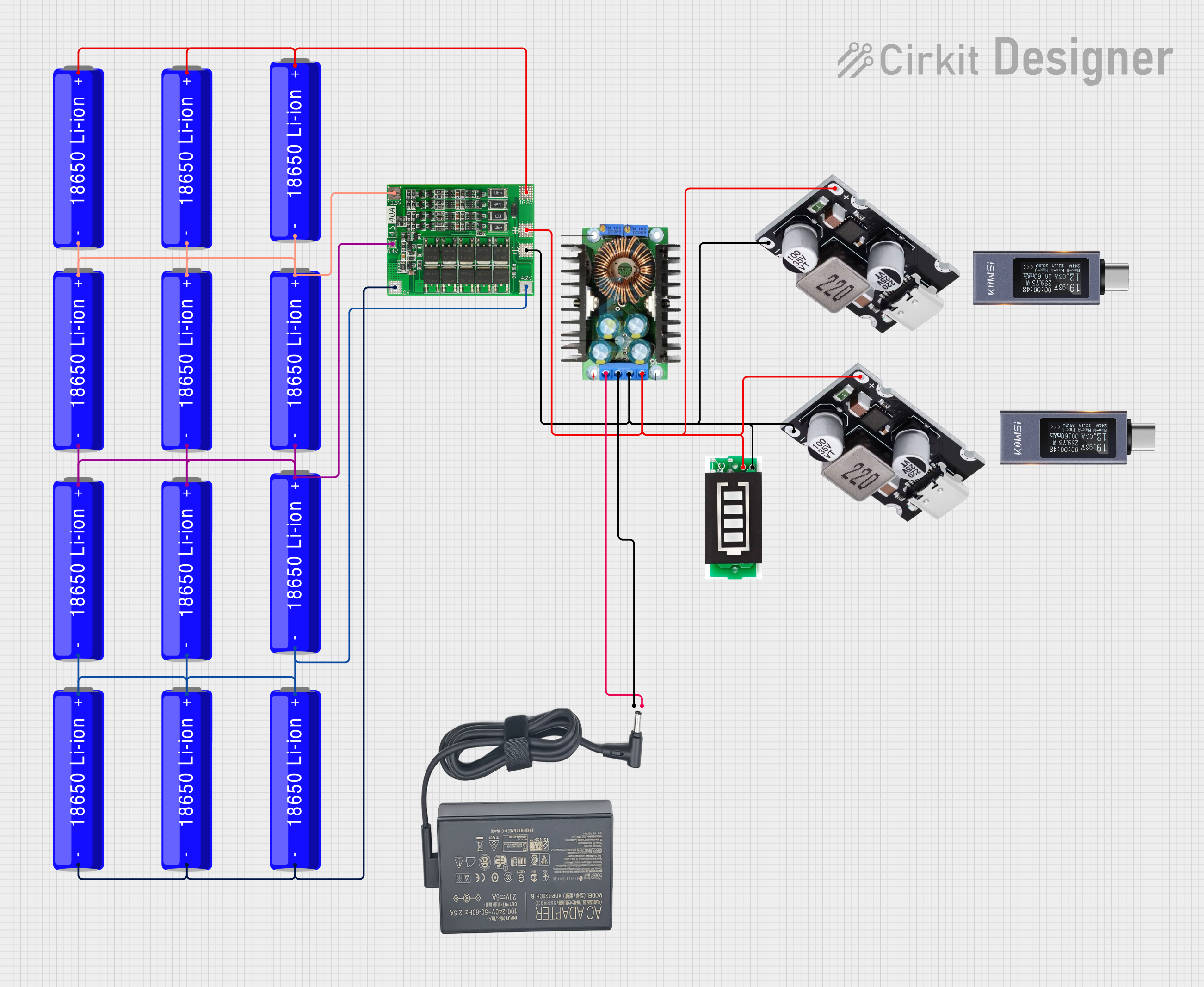

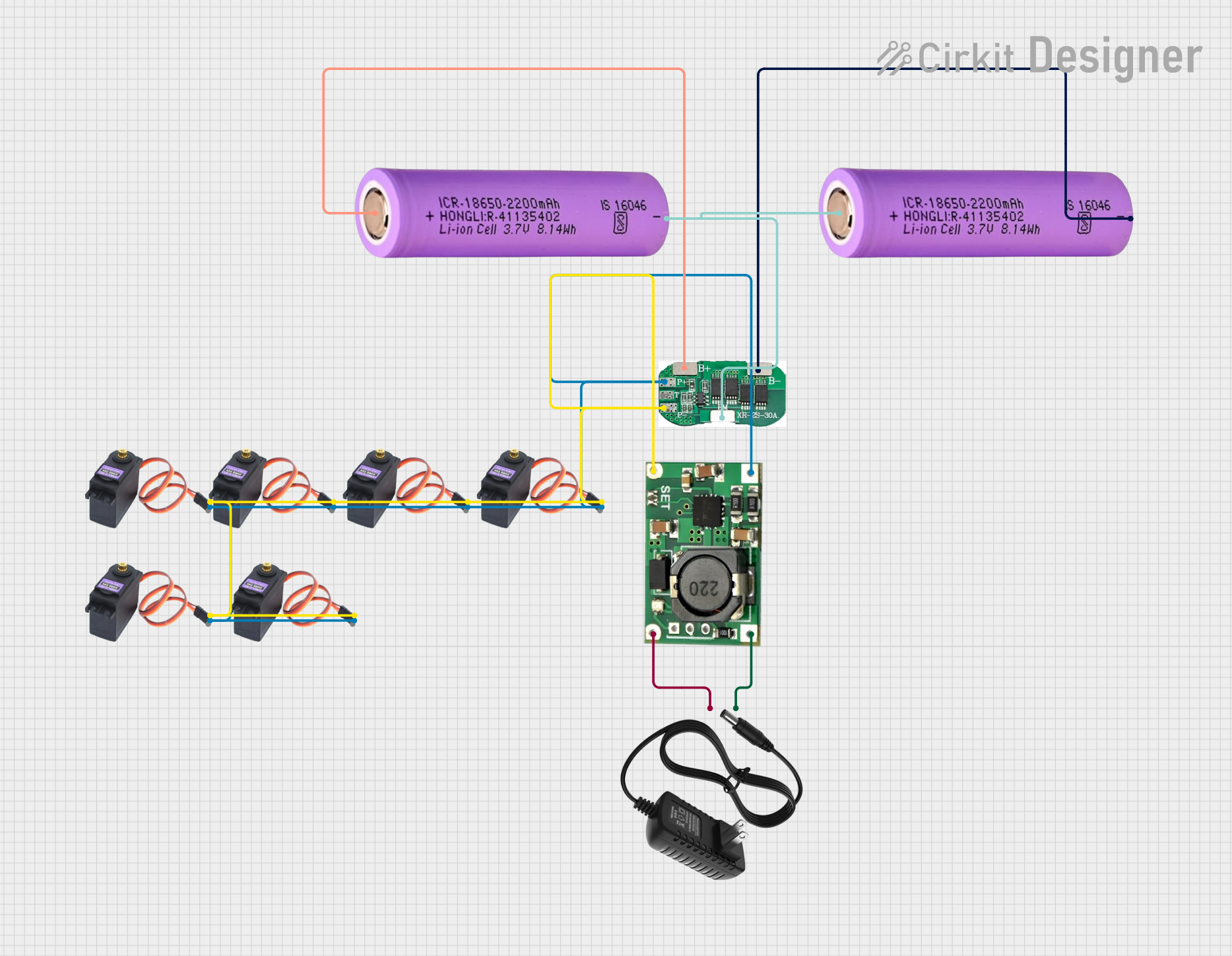

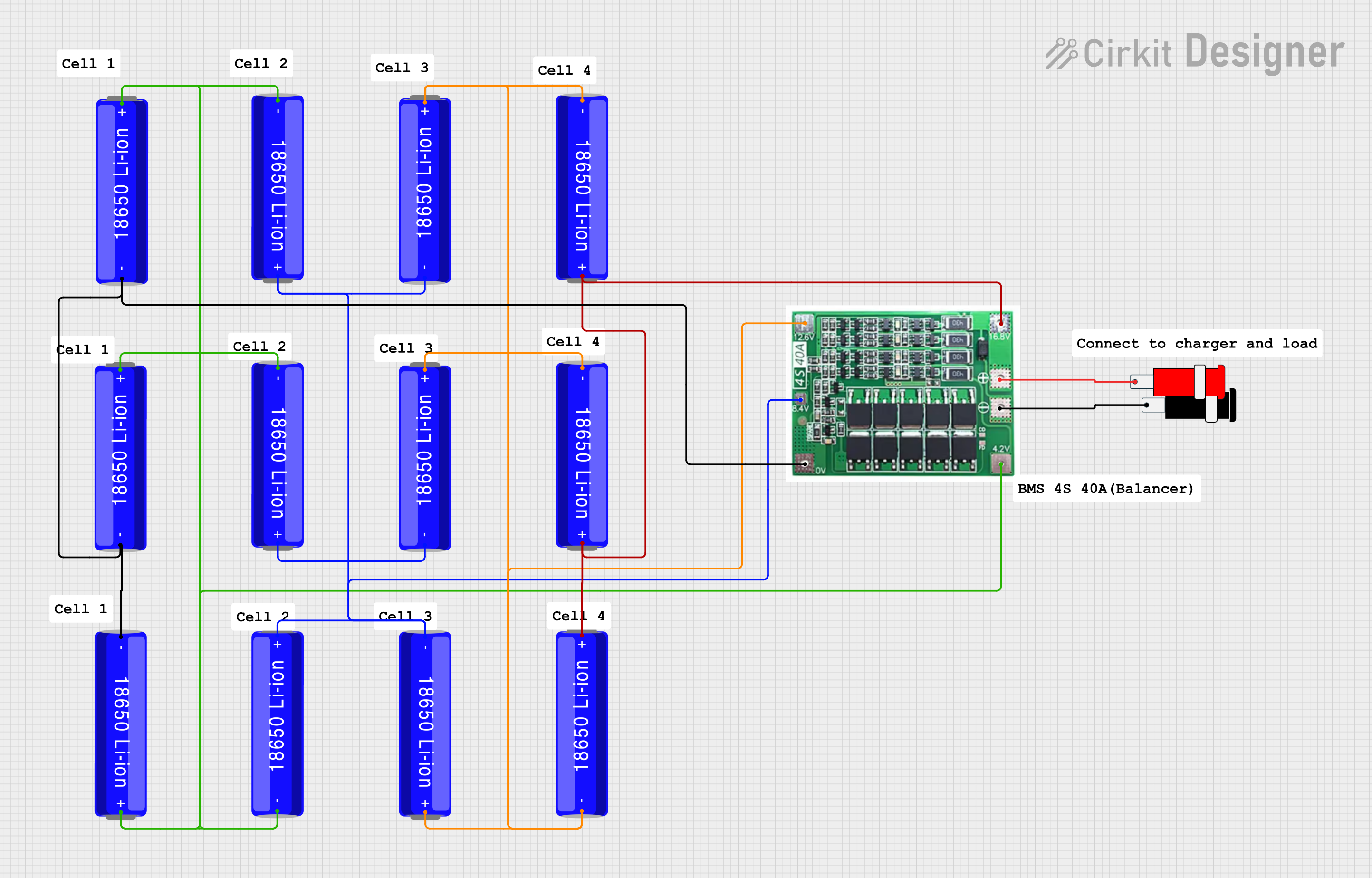

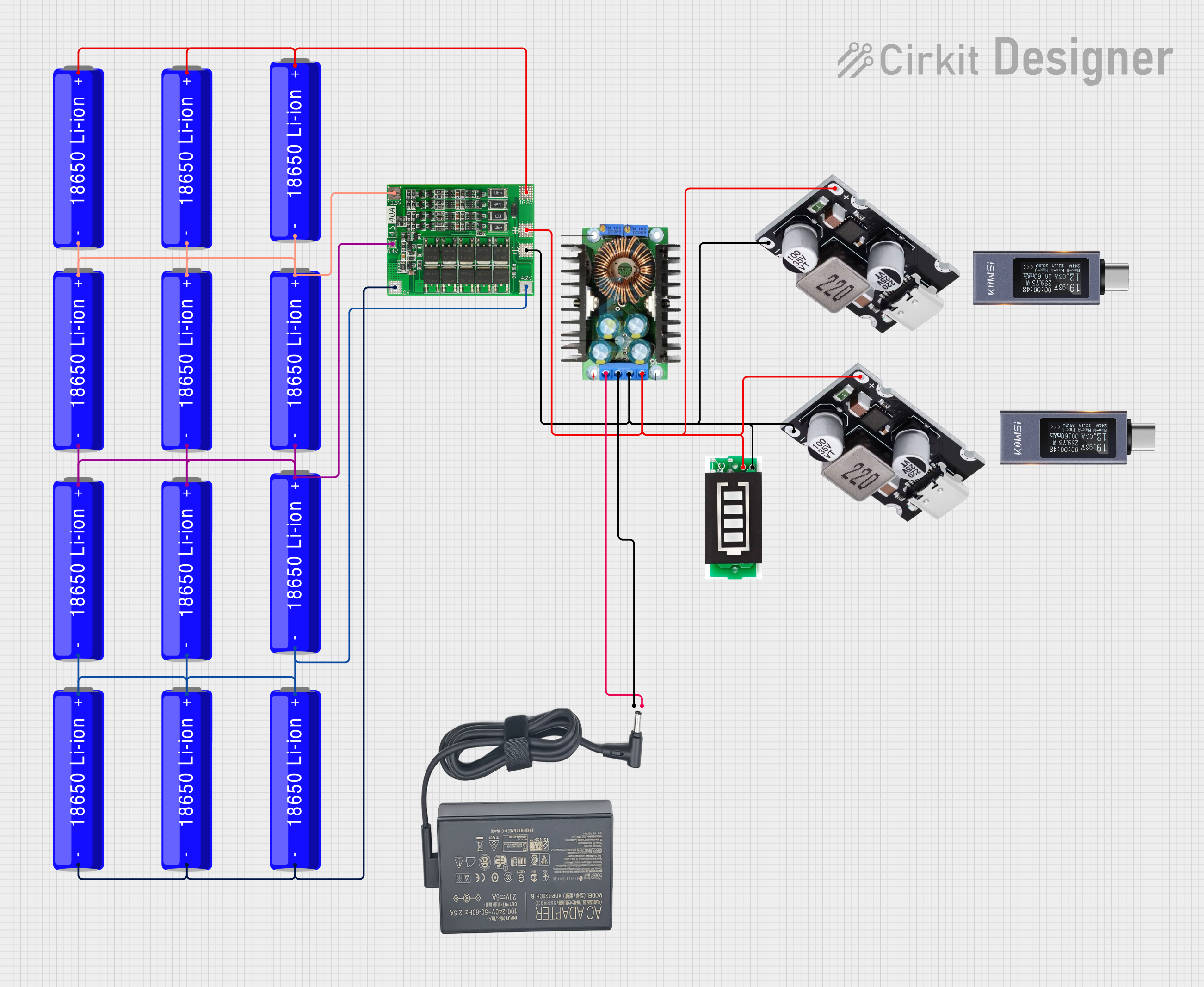

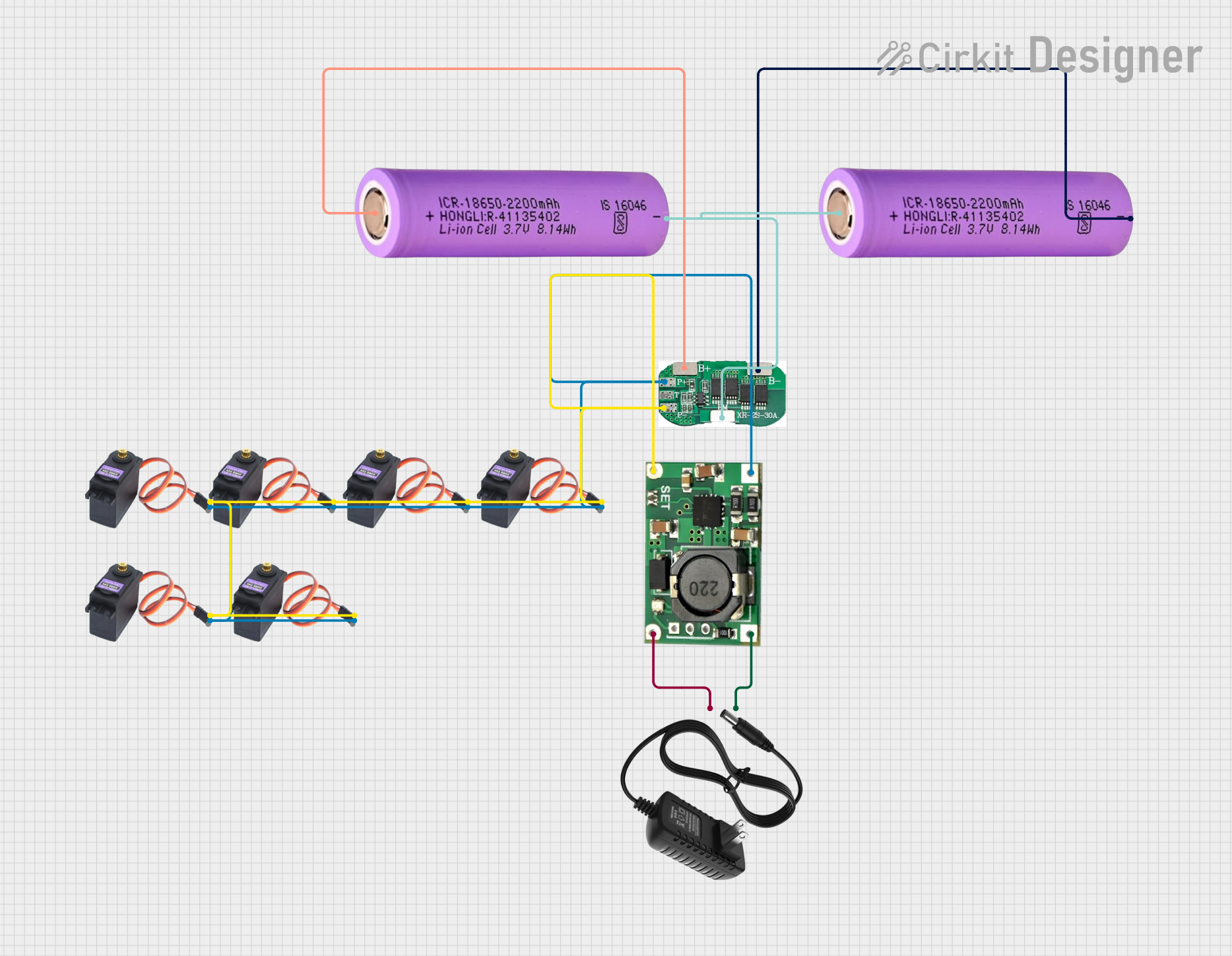

Explore Projects Built with 4S 30A BMS

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 4S 30A BMS

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Electric bicycles and scooters

- Portable power banks

- Solar energy storage systems

- Uninterruptible Power Supplies (UPS)

- Robotics and DIY electronics projects

Technical Specifications

The following table outlines the key technical details of the 4S 30A BMS:

| Parameter | Value |

|---|---|

| Battery Configuration | 4 series-connected lithium-ion cells (4S) |

| Maximum Continuous Current | 30A |

| Overcharge Protection Voltage | 4.25V ± 0.05V per cell |

| Overdischarge Protection Voltage | 2.7V ± 0.05V per cell |

| Balancing Voltage | 4.2V ± 0.05V per cell |

| Balancing Current | 30mA |

| Operating Temperature | -20°C to 60°C |

| Dimensions | Varies by manufacturer (e.g., 60mm x 20mm) |

| Weight | ~20g |

Pin Configuration and Descriptions

The 4S 30A BMS typically has the following pin configuration:

| Pin Name | Description |

|---|---|

| B- | Battery pack negative terminal |

| B1 | Connection to the positive terminal of the first cell |

| B2 | Connection to the positive terminal of the second cell |

| B3 | Connection to the positive terminal of the third cell |

| B+ | Battery pack positive terminal |

| P- | Power output negative terminal (connects to the load or charger negative) |

| P+ | Power output positive terminal (connects to the load or charger positive) |

Usage Instructions

How to Use the 4S 30A BMS in a Circuit

Connect the Battery Pack:

- Ensure the battery pack consists of four series-connected lithium-ion cells.

- Connect the B- pin to the negative terminal of the battery pack.

- Connect the B1, B2, and B3 pins to the positive terminals of the first, second, and third cells, respectively.

- Connect the B+ pin to the positive terminal of the battery pack.

Connect the Load and Charger:

- Connect the P- pin to the negative terminal of the load or charger.

- Connect the P+ pin to the positive terminal of the load or charger.

Verify Connections:

- Double-check all connections to ensure they are secure and correctly aligned with the pin configuration.

Power On:

- Once all connections are verified, the BMS will begin monitoring and managing the battery pack.

Important Considerations and Best Practices

- Cell Matching: Use cells with similar capacities, internal resistances, and charge levels to ensure proper balancing and operation.

- Heat Dissipation: Ensure adequate ventilation or heat sinking for the BMS, especially when operating near the maximum current rating.

- Avoid Overloading: Do not exceed the 30A maximum continuous current rating to prevent damage to the BMS.

- Wiring: Use appropriately rated wires for the current to avoid overheating or voltage drops.

- Testing: Before connecting the BMS to a load, test the voltage of each cell to ensure they are within the safe operating range.

Arduino Integration Example

The 4S 30A BMS can be used with an Arduino to monitor the battery pack's voltage. Below is an example code snippet for reading the total pack voltage using a voltage divider:

// Arduino code to monitor battery pack voltage using a voltage divider

// Ensure the voltage divider output does not exceed 5V for Arduino's analog input

const int voltagePin = A0; // Analog pin connected to the voltage divider

const float resistorRatio = 5.7; // Ratio of the voltage divider resistors

// (e.g., R1 = 47k, R2 = 10k -> 5.7)

void setup() {

Serial.begin(9600); // Initialize serial communication

}

void loop() {

int rawValue = analogRead(voltagePin); // Read the analog input

float voltage = (rawValue * 5.0 / 1023.0) * resistorRatio;

// Convert raw ADC value to voltage

Serial.print("Battery Pack Voltage: ");

Serial.print(voltage);

Serial.println(" V");

delay(1000); // Wait 1 second before the next reading

}

Note: Use a voltage divider to scale down the battery pack voltage to a safe level for the Arduino's analog input (0-5V).

Troubleshooting and FAQs

Common Issues and Solutions

BMS Not Powering On:

- Cause: Incorrect wiring or loose connections.

- Solution: Verify all connections, especially the B- and B+ terminals.

Cells Not Balancing:

- Cause: Significant mismatch in cell capacities or internal resistances.

- Solution: Replace mismatched cells with ones of similar specifications.

Overheating:

- Cause: Exceeding the maximum current rating or poor ventilation.

- Solution: Reduce the load current or improve heat dissipation.

Load Not Receiving Power:

- Cause: Overcharge or overdischarge protection triggered.

- Solution: Check individual cell voltages and recharge or replace cells as needed.

FAQs

Q: Can I use the 4S 30A BMS with other battery chemistries?

A: No, this BMS is specifically designed for lithium-ion cells. Using it with other chemistries may result in improper operation or damage.

Q: What happens if one cell is damaged?

A: The BMS will detect the abnormal voltage and may prevent the pack from operating. Replace the damaged cell to restore functionality.

Q: Can I use this BMS for parallel battery packs?

A: Yes, but ensure that each parallel group consists of balanced cells and is treated as a single "cell" in the series configuration.

Q: How do I know if the BMS is balancing the cells?

A: Measure the voltage of each cell. If they are close to 4.2V during charging, the BMS is actively balancing them.