How to Use 4A Stepper Phidget: Examples, Pinouts, and Specs

Design with 4A Stepper Phidget in Cirkit Designer

Design with 4A Stepper Phidget in Cirkit DesignerIntroduction

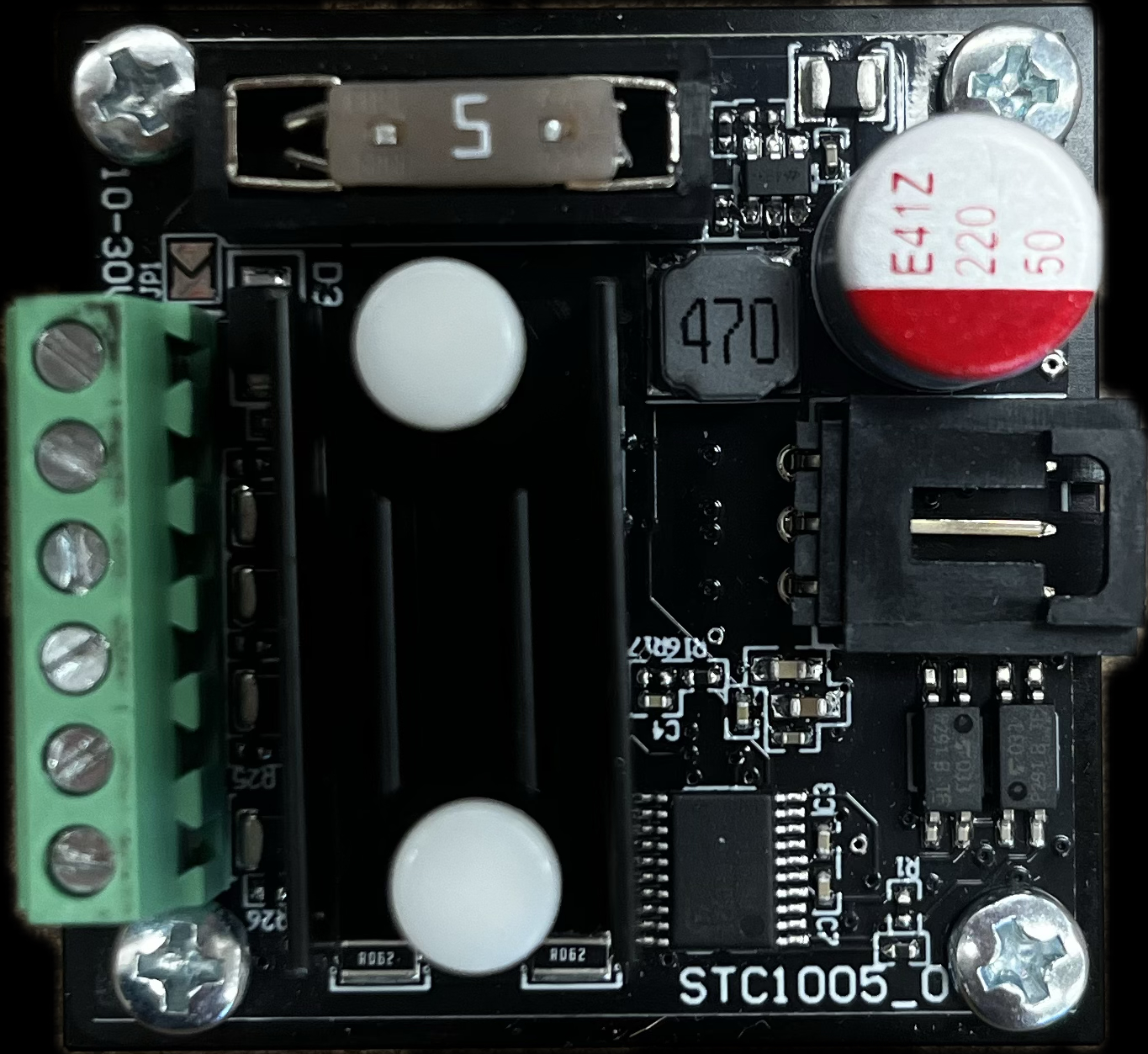

The 4A Stepper Phidget (STC1005_0) is a high-power stepper motor controller designed to precisely control the motion of a stepper motor. It is capable of delivering up to 4A of current, making it suitable for a wide range of applications that require precise positioning and speed control. Common applications include CNC machines, 3D printers, robotics, and automated manufacturing systems.

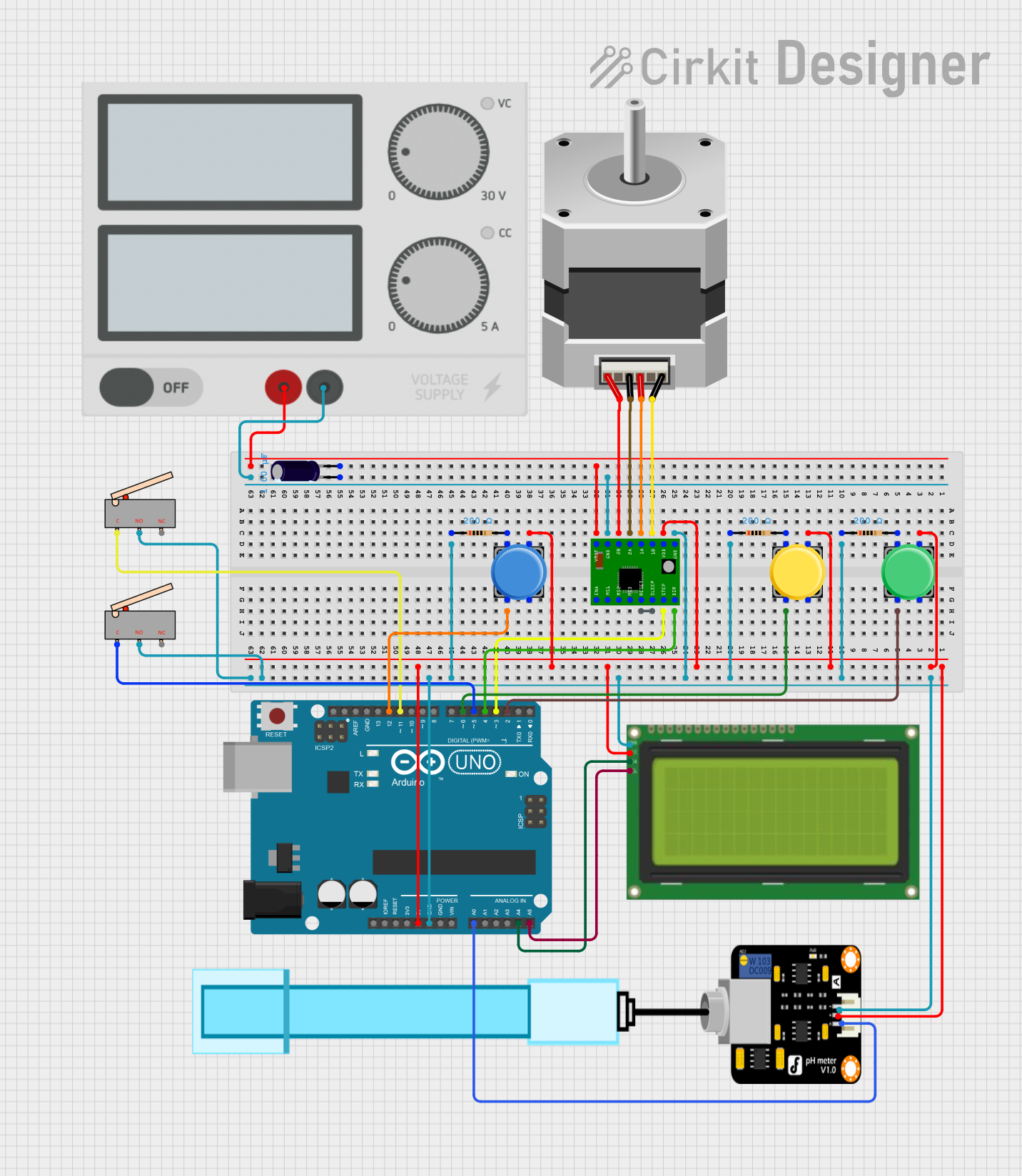

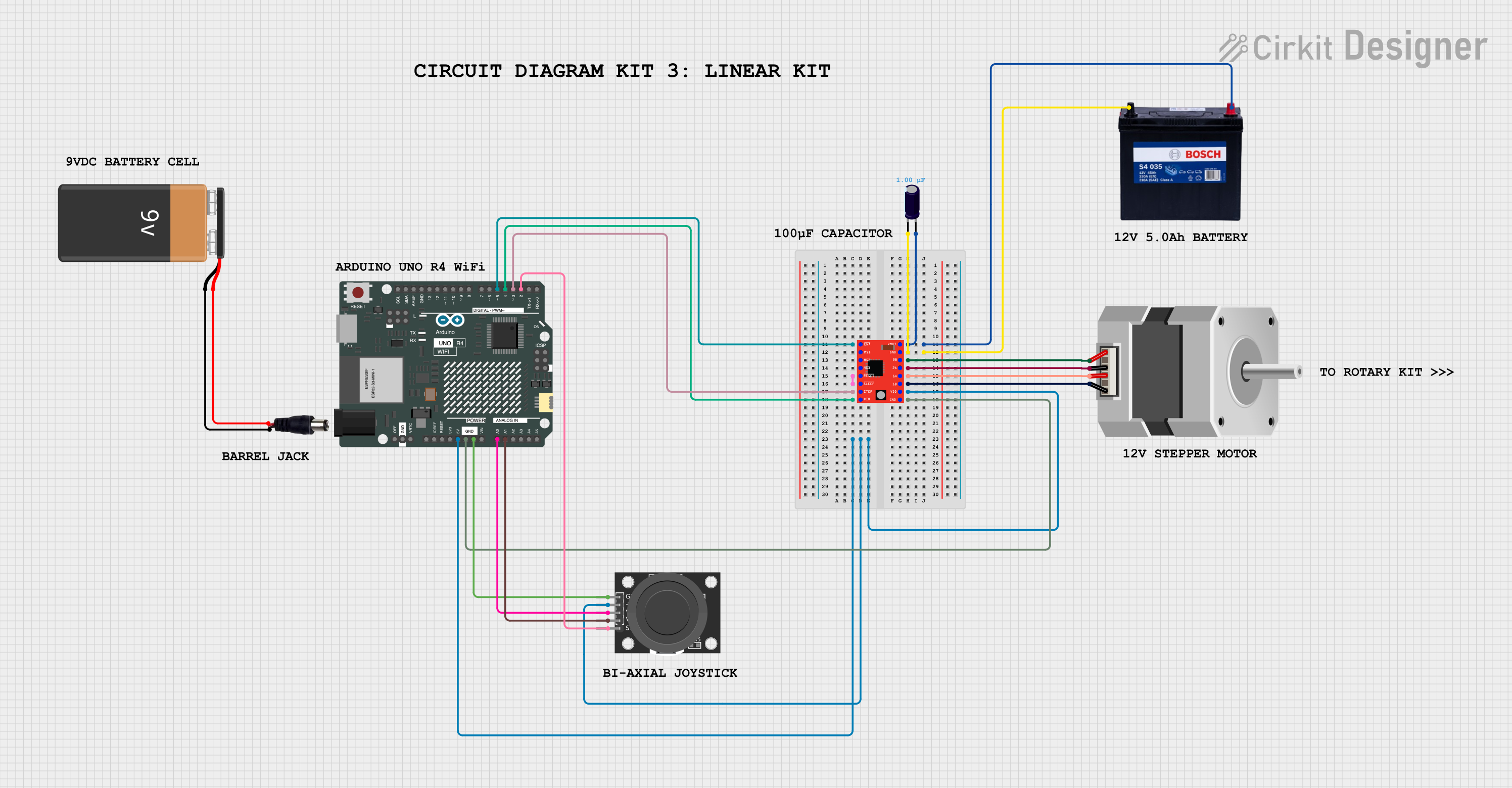

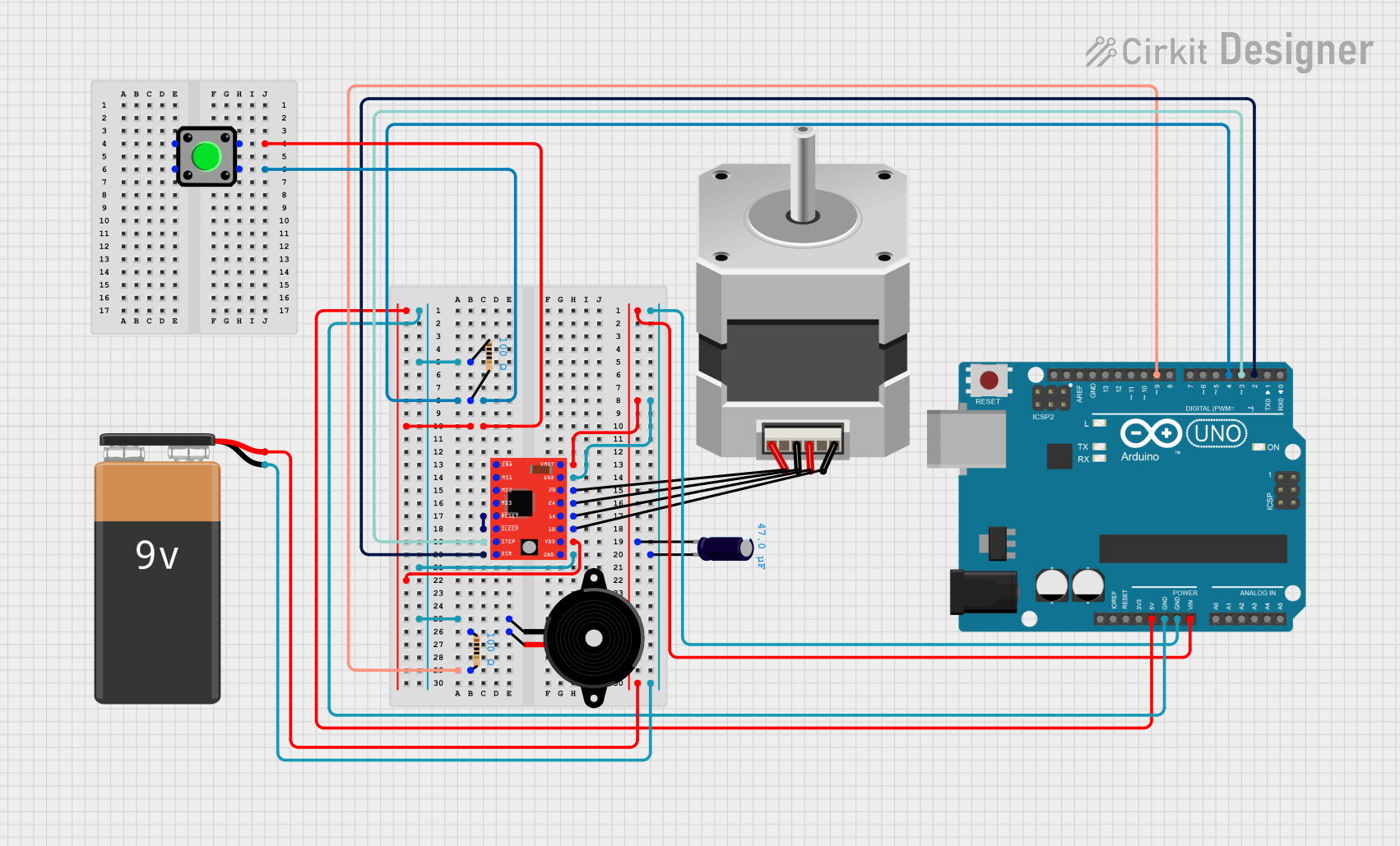

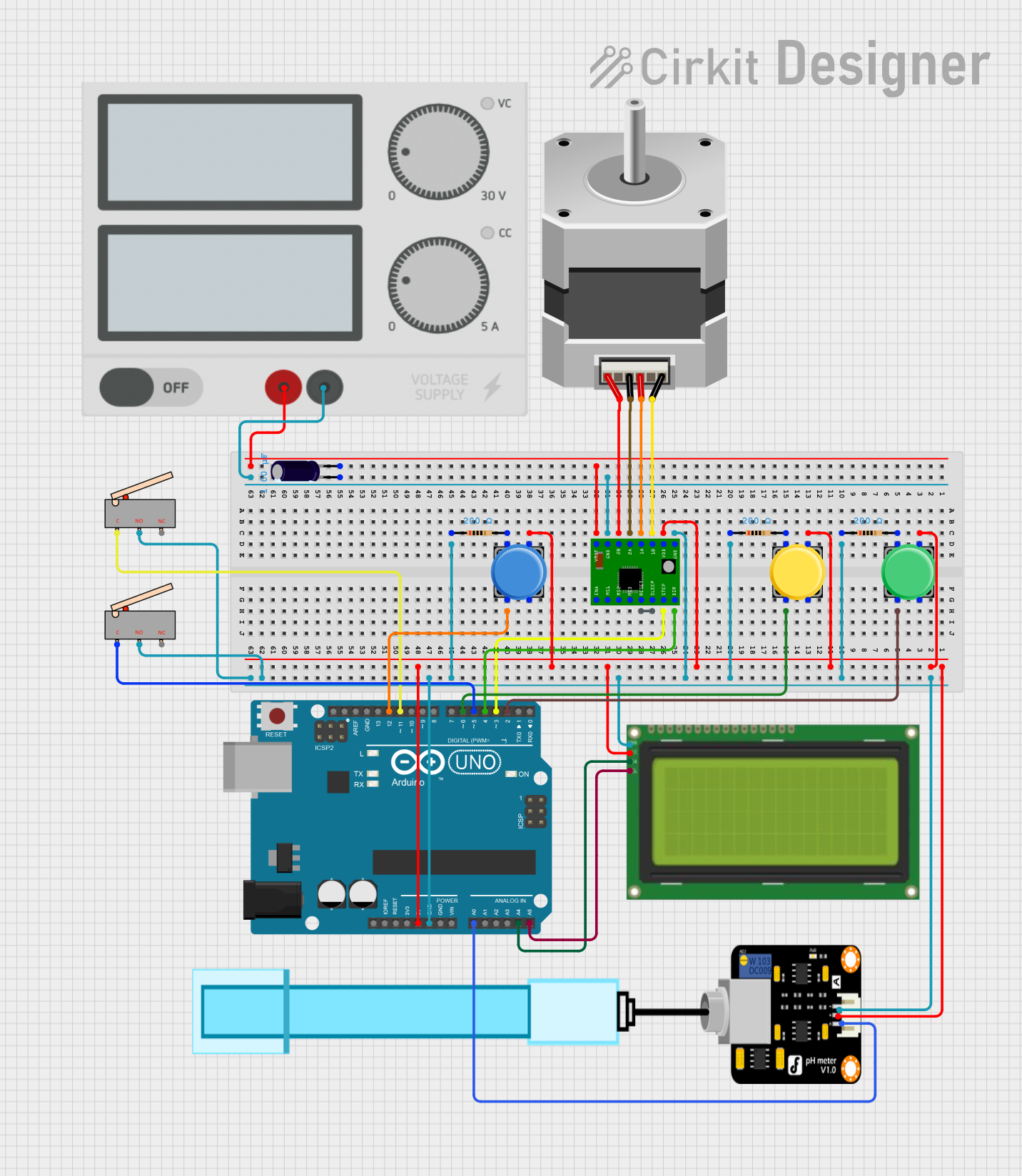

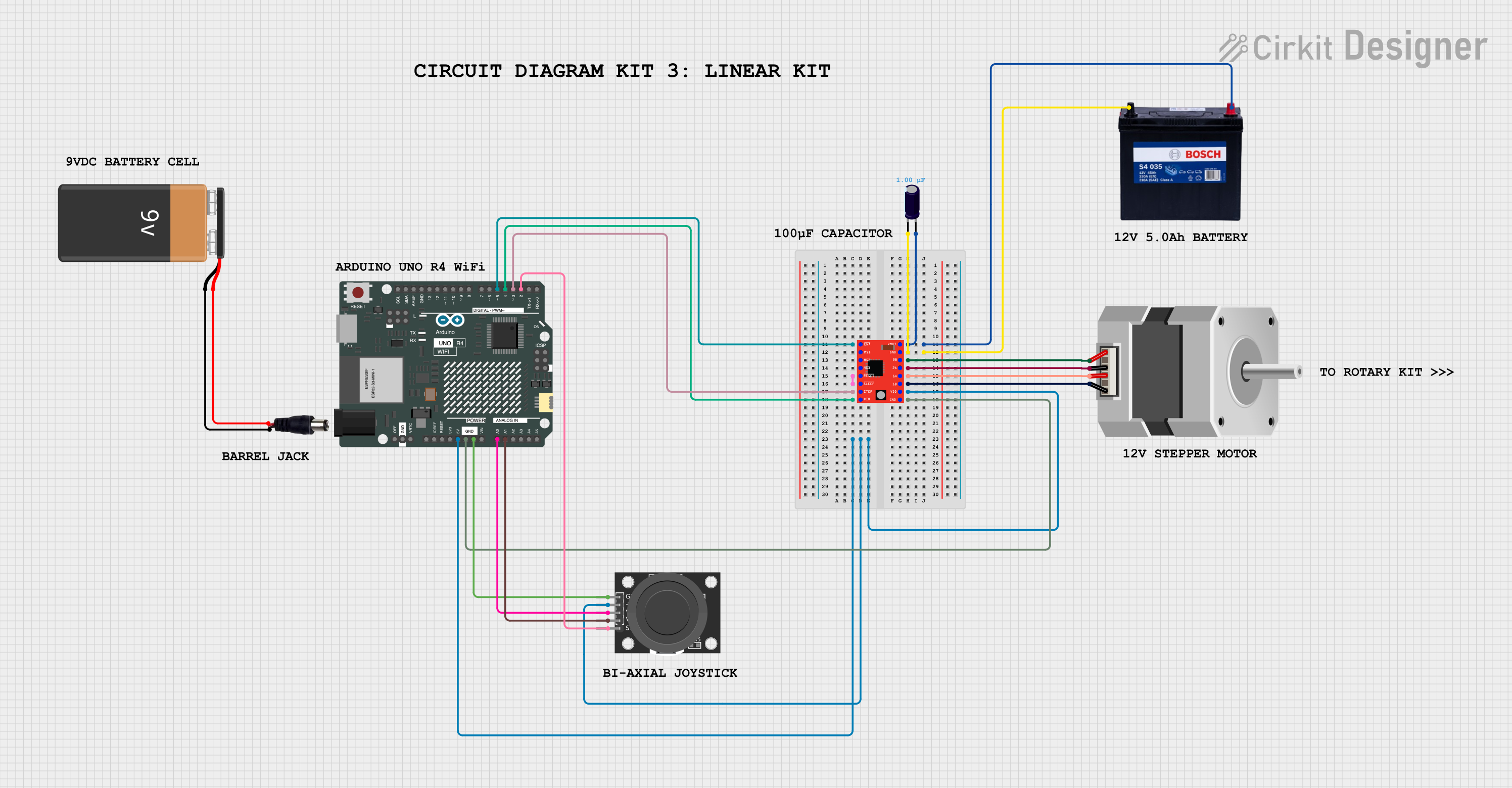

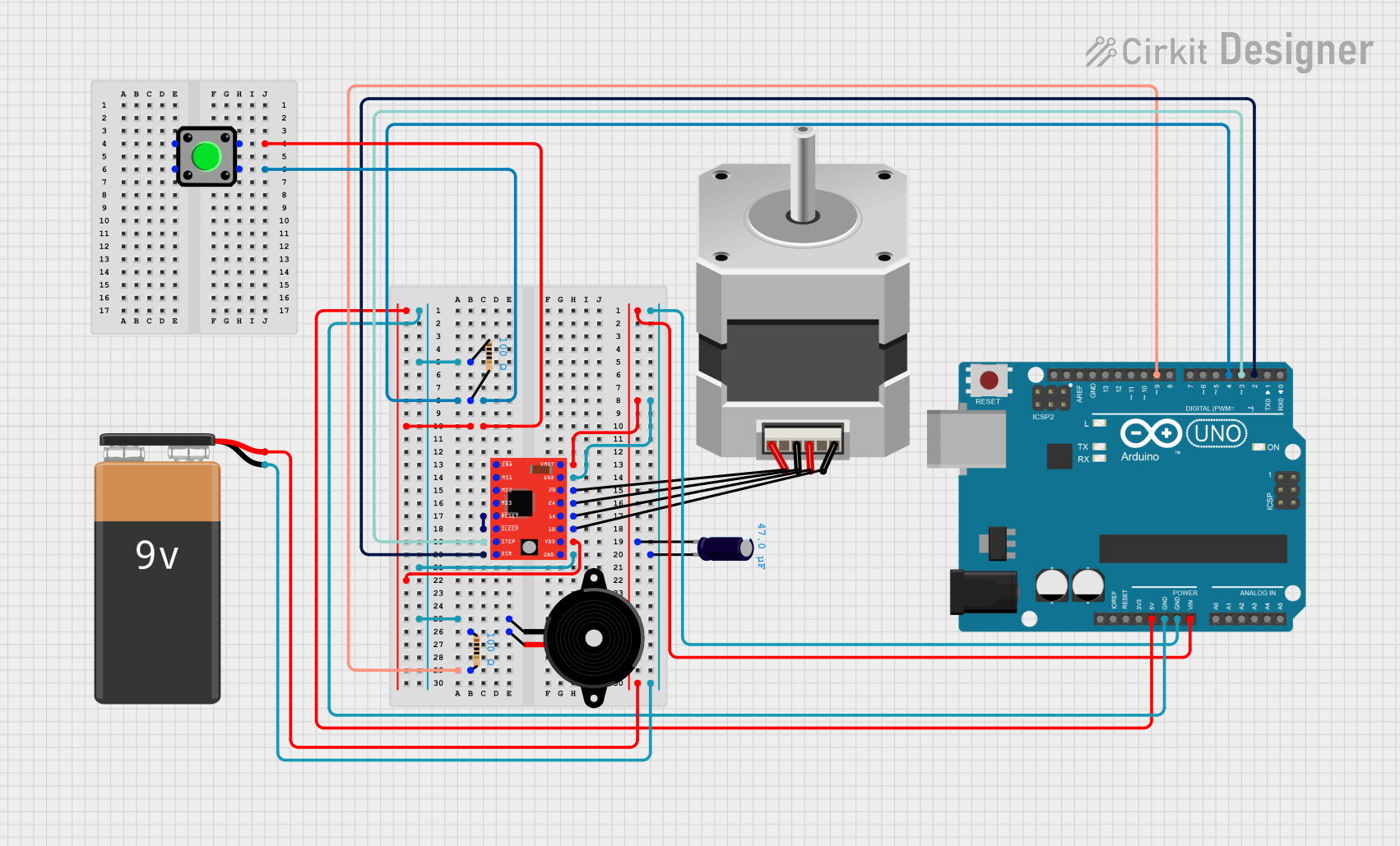

Explore Projects Built with 4A Stepper Phidget

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 4A Stepper Phidget

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Specifications

- Manufacturer: Phidgets Inc.

- Part Number: STC1005_0

- Controlled By: VINT

- API Object Name: Stepper

- Current Consumption (VINT): 500 μA

- Motor Current Max: 4 A

- Motor Voltage Min/Max: 8 - 30 V DC

Pin Configuration and Descriptions

| Pin Number | Description |

|---|---|

| 1 | Ground |

| 2 | VINT (Voltage Input) |

| 3 | Digital Input |

| 4 | Digital Output |

| 5 | Encoder Input A |

| 6 | Encoder Input B |

| 7 | Motor Coil A+ |

| 8 | Motor Coil A- |

| 9 | Motor Coil B+ |

| 10 | Motor Coil B- |

Usage Instructions

Connecting the Stepper Motor

- Power Supply: Connect a suitable power supply to the Phidget, ensuring that the voltage is within the specified range (8 - 30 V DC).

- Motor Connection: Connect the stepper motor coils to the appropriate pins on the Phidget. Ensure that the polarity is correct for each coil.

- VINT Hub: Connect the Phidget to a VINT Hub using the VINT port. The VINT Hub should be connected to your computer or another control device.

Programming with Arduino

To control the 4A Stepper Phidget with an Arduino UNO, you will need to use the Phidget22 library. Below is an example code snippet to initialize and control the stepper motor:

#include <Phidget22.h>

PhidgetStepperHandle stepper;

void setup() {

PhidgetStepper_create(&stepper);

Phidget_setDeviceSerialNumber((PhidgetHandle)stepper, 12345); // Replace with your device's serial number

Phidget_openWaitForAttachment((PhidgetHandle)stepper, 5000);

PhidgetStepper_setControlMode(stepper, CONTROL_MODE_STEP);

PhidgetStepper_setTargetPosition(stepper, 10000); // Set target position

PhidgetStepper_setEngaged(stepper, 1); // Engage the motor

}

void loop() {

// Your code here to control the stepper motor

}

Important Considerations and Best Practices

- Current Limit: Always set the current limit to match the specifications of your stepper motor to prevent damage.

- Heat Dissipation: Ensure adequate heat dissipation for the Phidget, as high currents can generate significant heat.

- Microstepping: Utilize microstepping for smoother motion and higher resolution control if required by your application.

Troubleshooting and FAQs

Common Issues

- Motor Not Moving: Check connections and ensure that the power supply is within the specified range. Verify that the current limit is set correctly.

- Inaccurate Positioning: Ensure that the motor is not overloaded and that the steps per revolution setting matches the motor's specifications.

FAQs

Q: Can I control multiple stepper motors with one 4A Stepper Phidget? A: No, the STC1005_0 is designed to control one stepper motor. To control multiple motors, you will need additional Phidgets.

Q: What is the maximum step rate for the 4A Stepper Phidget? A: The maximum step rate depends on the motor and power supply used. Refer to the Phidgets documentation for detailed specifications.

Q: How do I set the microstepping resolution? A: Microstepping can be set through the Phidget22 API. Refer to the Phidget22 programming guide for detailed instructions.

For further assistance, consult the Phidgets support resources or contact their technical support team.