How to Use ESC Basic: Examples, Pinouts, and Specs

Design with ESC Basic in Cirkit Designer

Design with ESC Basic in Cirkit DesignerIntroduction

The ESC Basic by Bluerobotics is an Electronic Speed Controller designed to regulate the speed, direction, and braking of brushless DC motors. It is a critical component in electric vehicles, drones, and other motor-driven systems, enabling precise control of motor performance. The ESC Basic interprets input signals from a receiver or microcontroller and adjusts the motor's power output accordingly, ensuring smooth and efficient operation.

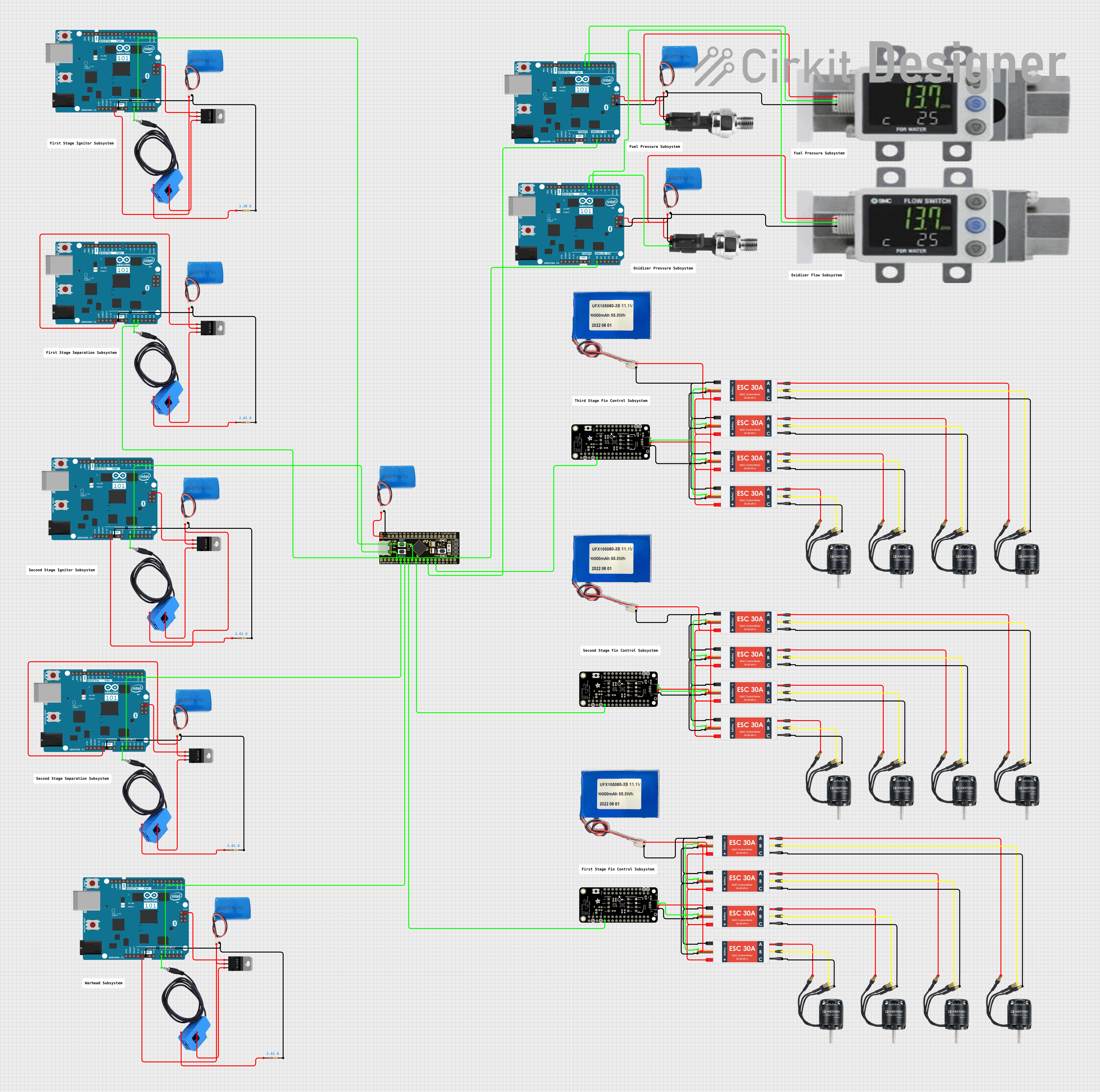

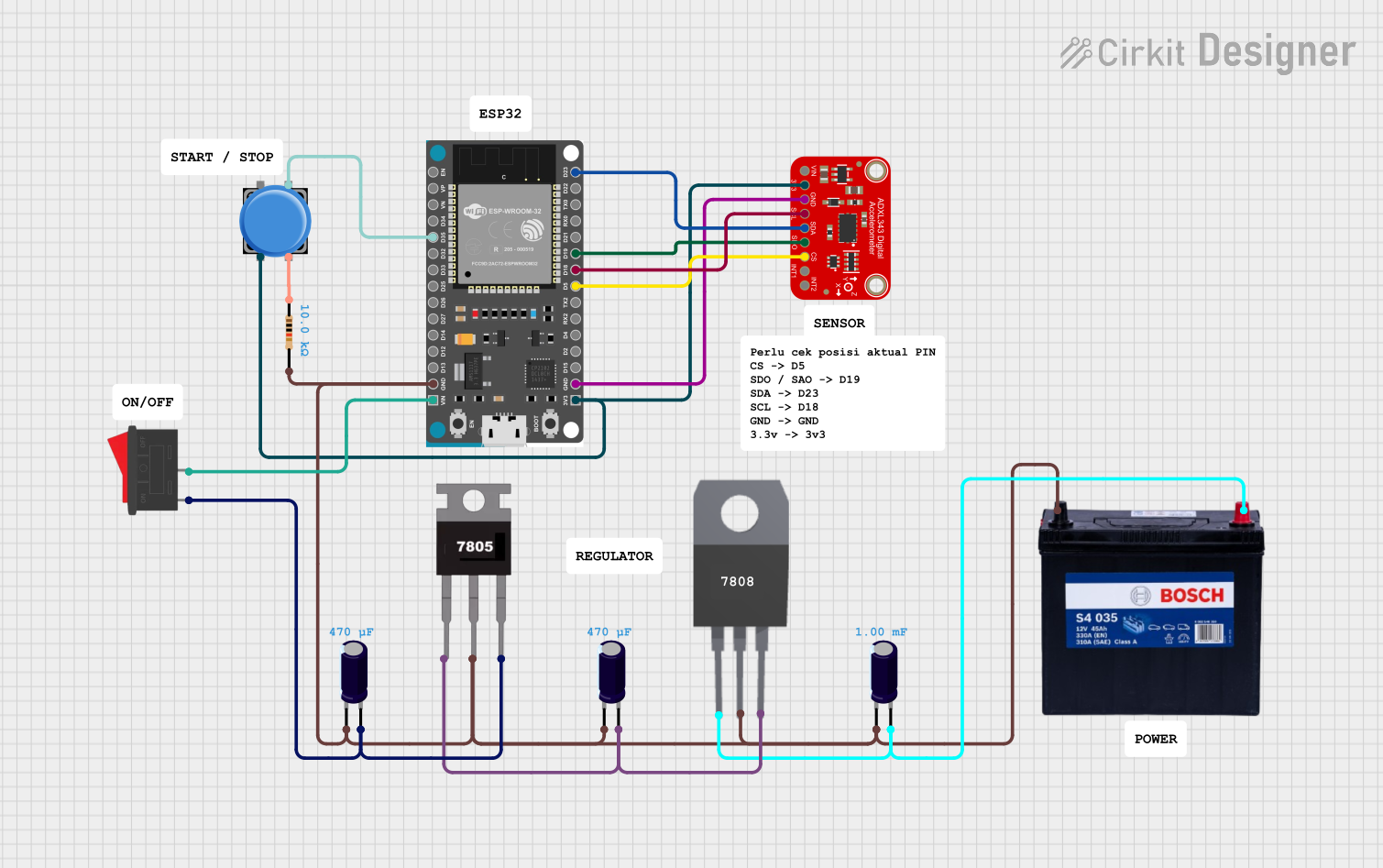

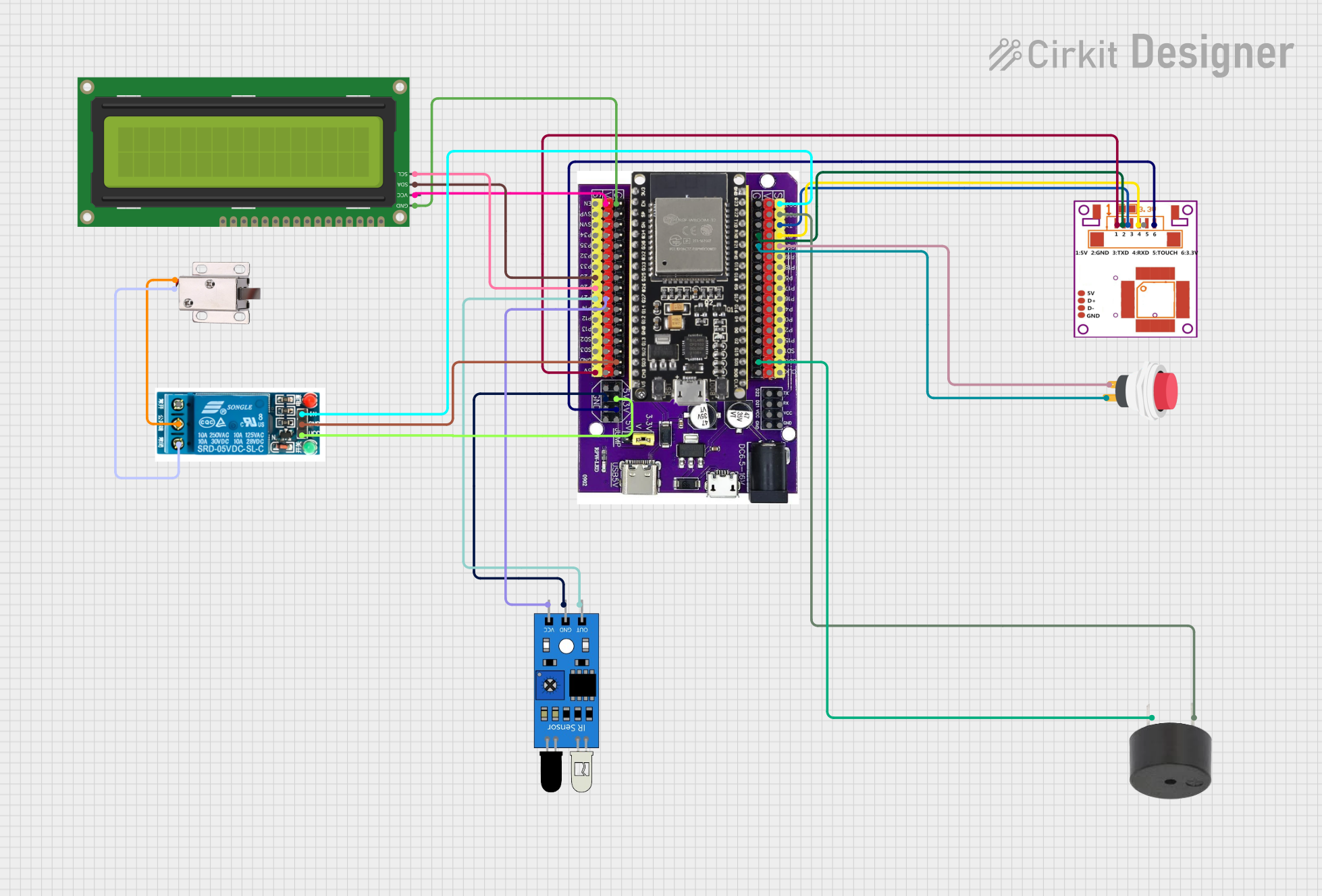

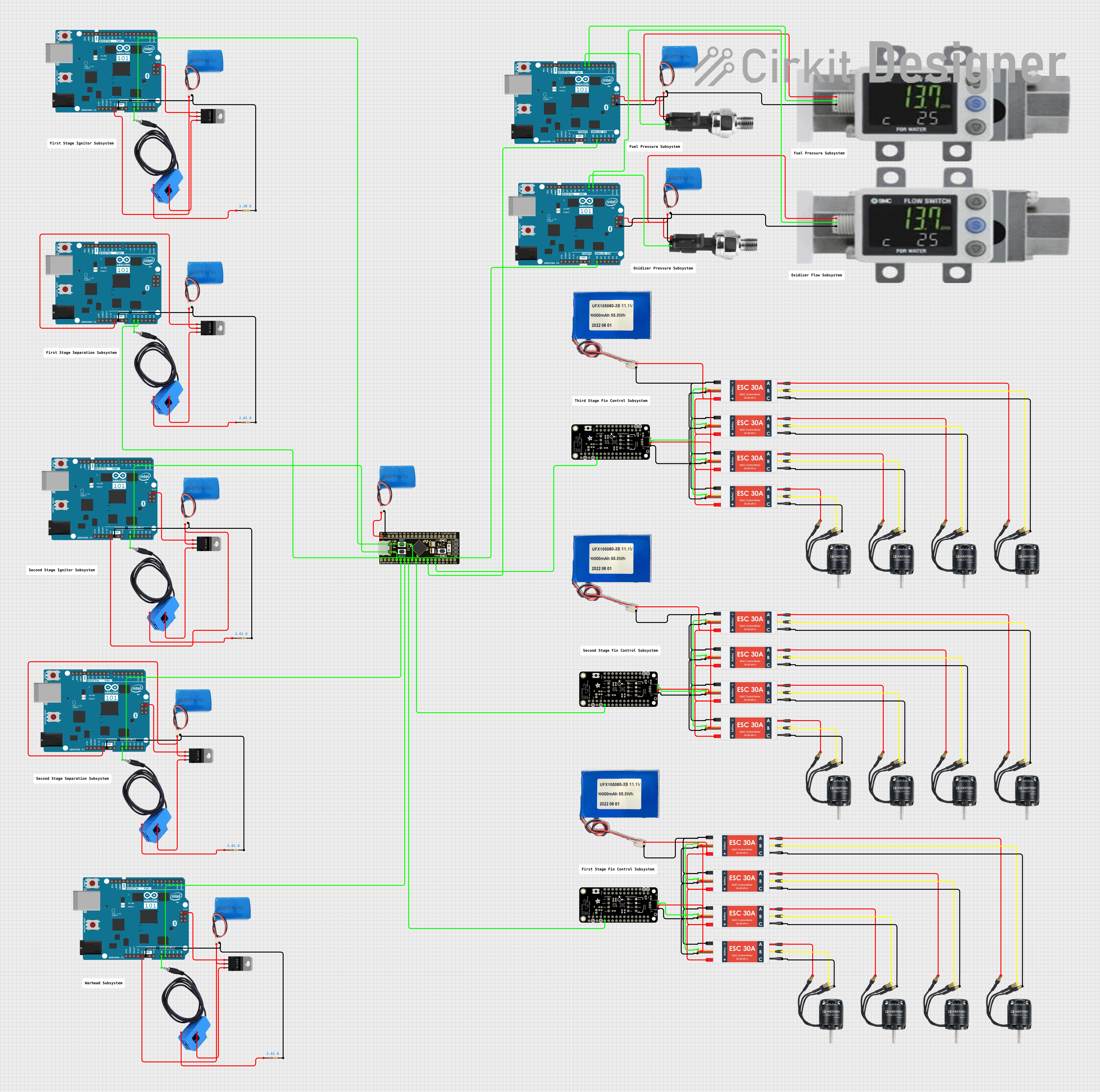

Explore Projects Built with ESC Basic

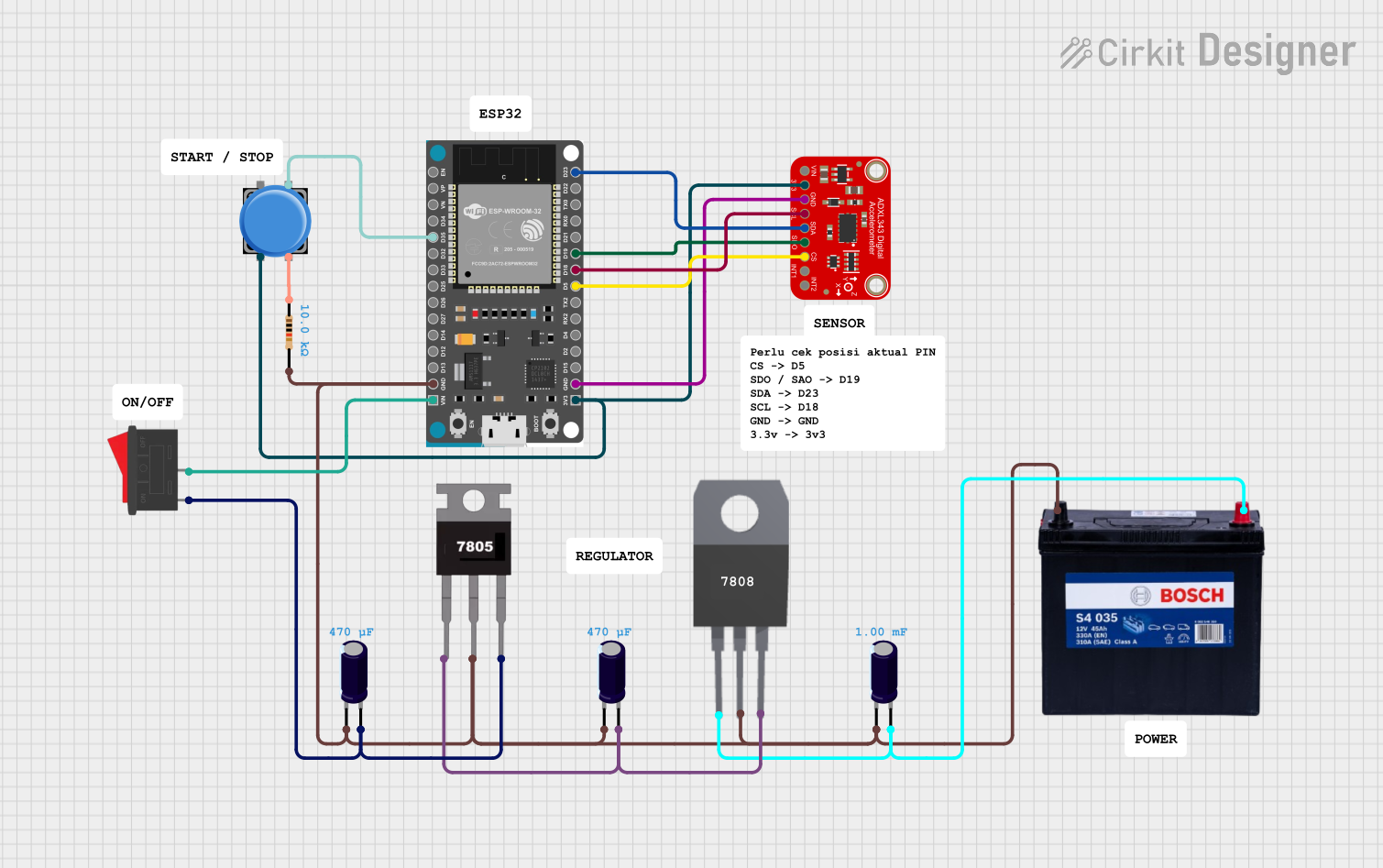

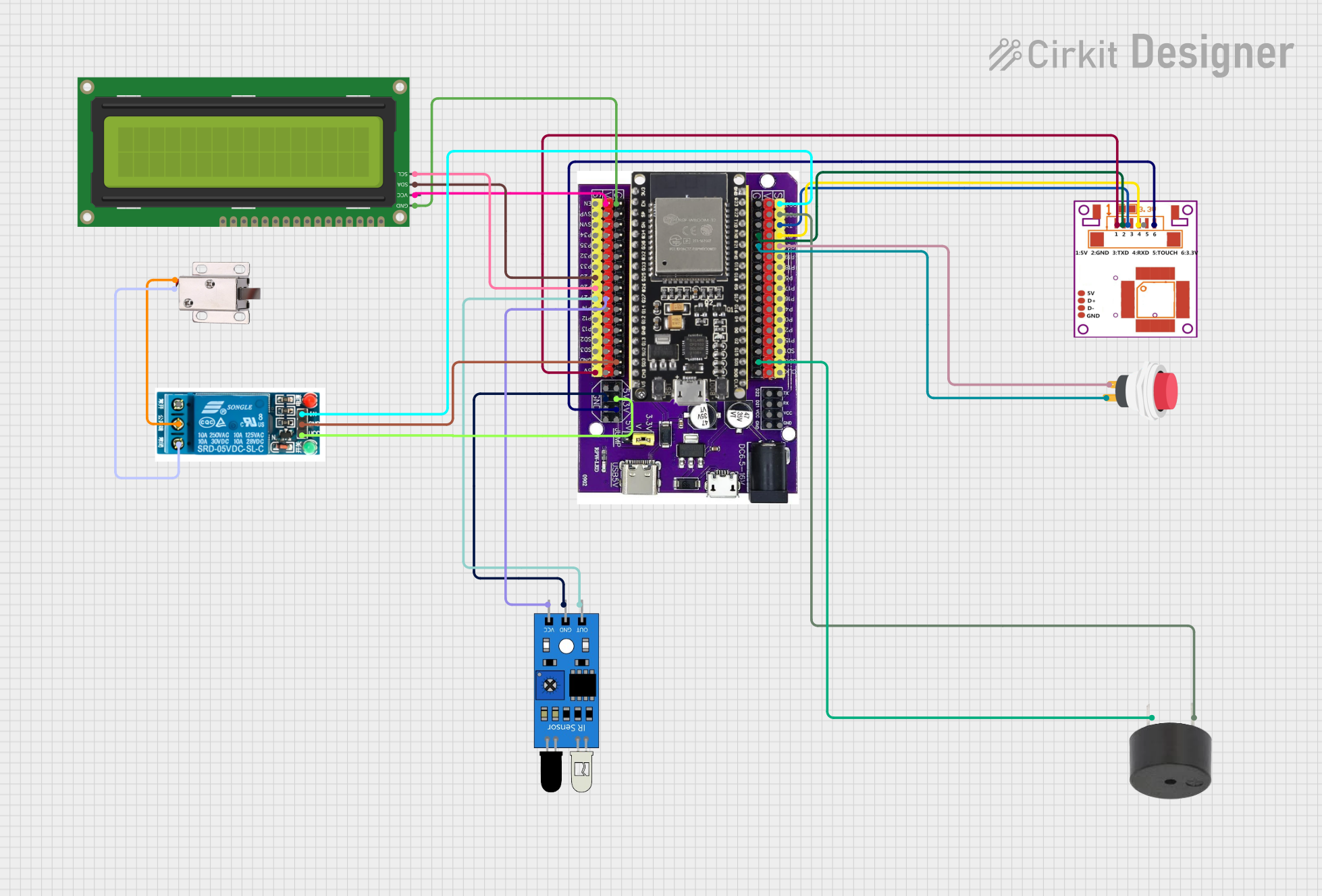

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with ESC Basic

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Drones and UAVs: For controlling brushless motors in quadcopters and other aerial vehicles.

- Electric Vehicles: Used in e-bikes, scooters, and small electric cars.

- Robotics: Provides motor control for robotic arms, rovers, and other automated systems.

- RC Models: Powers motors in remote-controlled cars, boats, and planes.

Technical Specifications

The ESC Basic is designed for reliability and performance in a variety of applications. Below are its key technical details:

General Specifications

| Parameter | Value |

|---|---|

| Input Voltage Range | 6V - 26V (2S to 6S LiPo) |

| Continuous Current | 30A |

| Peak Current | 40A (for 10 seconds) |

| Motor Compatibility | Brushless DC motors |

| Signal Input Type | PWM (Pulse Width Modulation) |

| Operating Temperature | -20°C to 60°C |

| Dimensions | 45mm x 25mm x 11mm |

| Weight | 25g |

Pin Configuration and Descriptions

The ESC Basic has three main connection interfaces: power input, motor output, and signal input. Below is the pin configuration:

Power Input and Motor Output

| Pin Name | Description |

|---|---|

| + (Red) | Positive terminal for power input (6V-26V) |

| - (Black) | Negative terminal for power input (GND) |

| A (Blue) | Motor phase A |

| B (Yellow) | Motor phase B |

| C (Green) | Motor phase C |

Signal Input

| Pin Name | Description |

|---|---|

| Signal | PWM signal input from receiver or MCU |

| GND | Ground connection for signal input |

| +5V | 5V output for powering external devices (optional) |

Usage Instructions

How to Use the ESC Basic in a Circuit

- Connect the Power Supply: Attach the positive (+) and negative (-) terminals of the ESC to a compatible power source (e.g., a 2S-6S LiPo battery).

- Connect the Motor: Connect the three motor wires (A, B, C) to the corresponding motor phases. If the motor spins in the wrong direction, swap any two of the motor wires.

- Connect the Signal Input:

- Attach the signal wire to the PWM output pin of your receiver or microcontroller.

- Connect the GND pin to the ground of your control system.

- Optionally, use the +5V pin to power external devices if needed.

- Calibrate the ESC: Follow the calibration procedure provided by Bluerobotics to ensure the ESC correctly interprets the PWM signal range.

- Test the Setup: Gradually increase the throttle signal to verify motor operation.

Important Considerations and Best Practices

- Signal Range: Ensure the PWM signal range matches the ESC's supported range (typically 1000µs to 2000µs).

- Cooling: Avoid overheating by ensuring proper ventilation or adding a heatsink if necessary.

- Battery Compatibility: Use a battery within the specified voltage range to prevent damage.

- Startup Safety: Always start with the throttle at the lowest position to avoid sudden motor activation.

Example: Using ESC Basic with Arduino UNO

Below is an example of how to control the ESC Basic using an Arduino UNO:

#include <Servo.h> // Include the Servo library for PWM signal generation

Servo esc; // Create a Servo object to control the ESC

void setup() {

esc.attach(9); // Attach the ESC signal wire to pin 9

esc.writeMicroseconds(1000); // Set throttle to minimum (1000µs)

delay(2000); // Wait for 2 seconds to initialize the ESC

}

void loop() {

esc.writeMicroseconds(1500); // Set throttle to mid-range (1500µs)

delay(5000); // Run motor at mid-speed for 5 seconds

esc.writeMicroseconds(1000); // Set throttle to minimum (stop motor)

delay(5000); // Wait for 5 seconds before repeating

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Spin:

- Cause: Incorrect wiring or no signal input.

- Solution: Verify all connections, ensure the PWM signal is being sent, and check the power supply.

Motor Spins in the Wrong Direction:

- Cause: Motor phase wires are incorrectly connected.

- Solution: Swap any two of the motor phase wires (A, B, or C).

ESC Overheats:

- Cause: Excessive current draw or poor ventilation.

- Solution: Ensure the motor is within the ESC's current rating and improve cooling.

No Response from ESC:

- Cause: Incorrect PWM signal range or calibration issue.

- Solution: Recalibrate the ESC and verify the PWM signal range (1000µs to 2000µs).

FAQs

Can the ESC Basic be used with brushed motors? No, the ESC Basic is designed specifically for brushless DC motors.

What happens if I exceed the voltage range? Exceeding the voltage range can permanently damage the ESC. Always use a compatible power source.

Can I use the ESC Basic for bidirectional motor control? No, the ESC Basic is designed for unidirectional control. For bidirectional control, use an ESC with reverse functionality.

Is the ESC waterproof? No, the ESC Basic is not waterproof. Protect it from water exposure during use.

By following this documentation, users can effectively integrate the ESC Basic into their projects and troubleshoot common issues with ease.