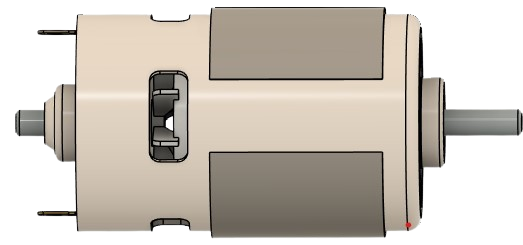

How to Use RS 775 DC MOTOR: Examples, Pinouts, and Specs

Design with RS 775 DC MOTOR in Cirkit Designer

Design with RS 775 DC MOTOR in Cirkit DesignerIntroduction

The RS 775 DC Motor is a high-power, brushed DC motor manufactured by Generic. It is known for its high torque and speed capabilities, making it a popular choice in various applications. This motor operates at 12V and can achieve speeds up to 3000 RPM. It is commonly used in robotics, industrial machinery, and other applications requiring reliable and powerful motor performance.

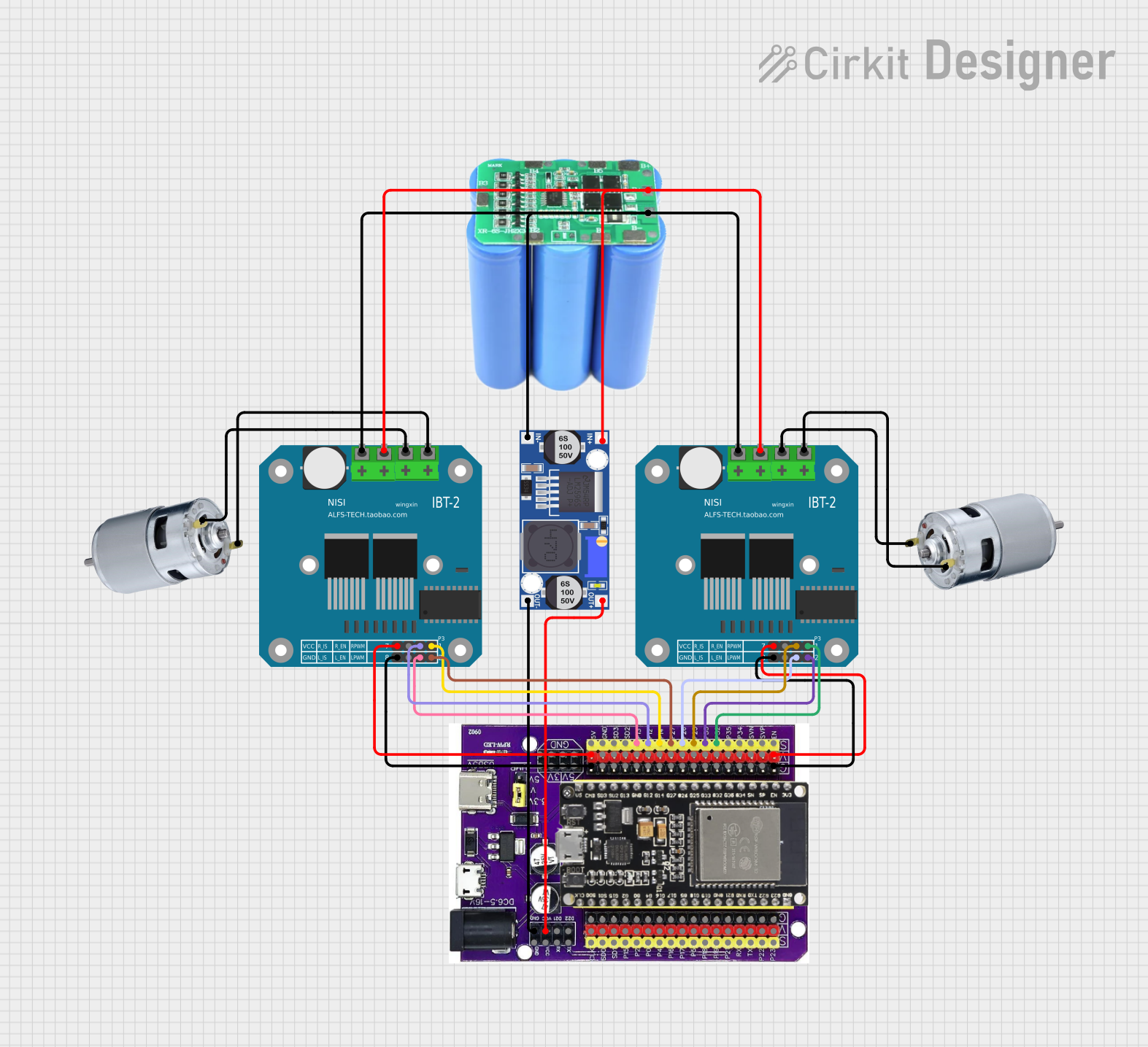

Explore Projects Built with RS 775 DC MOTOR

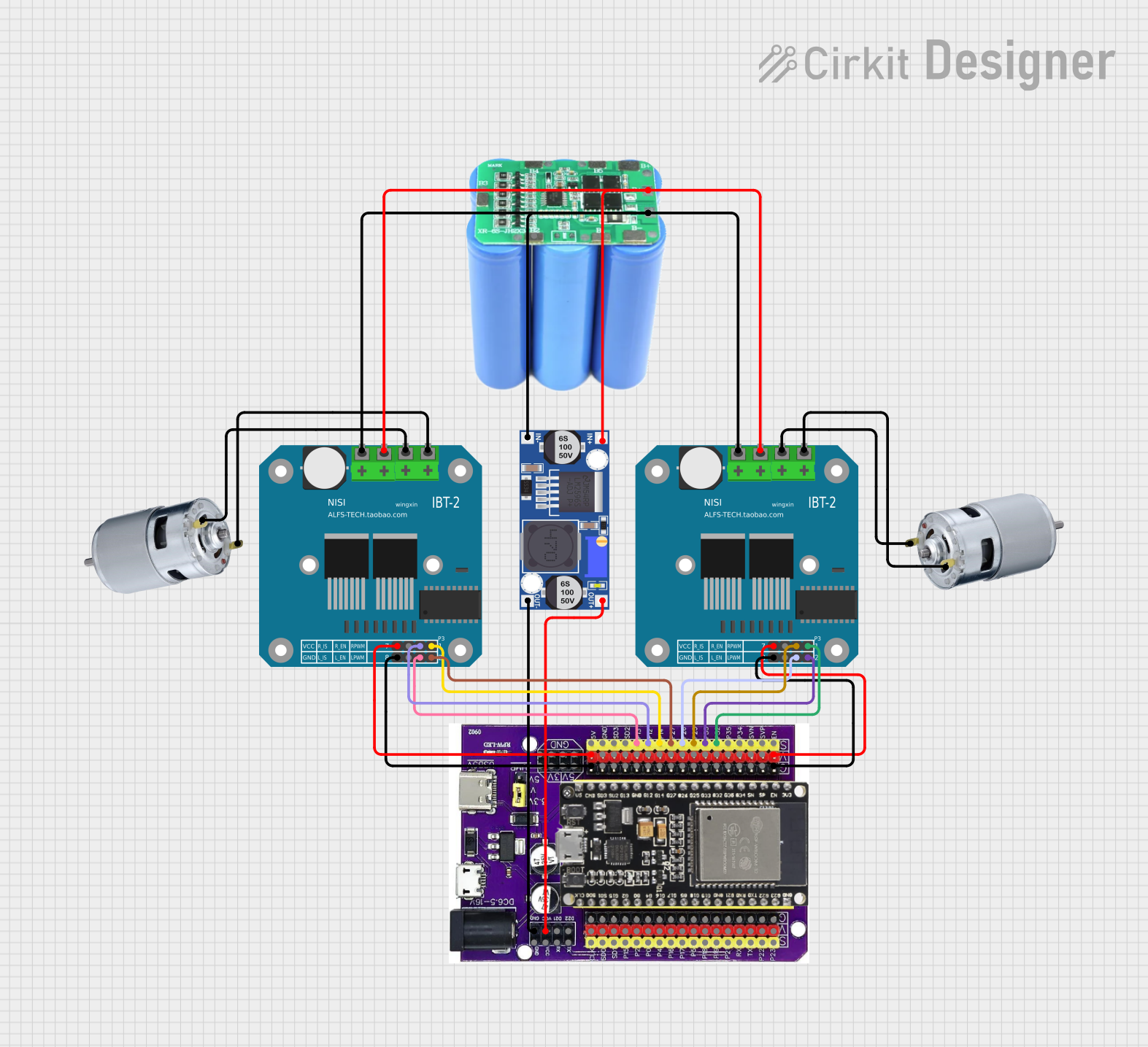

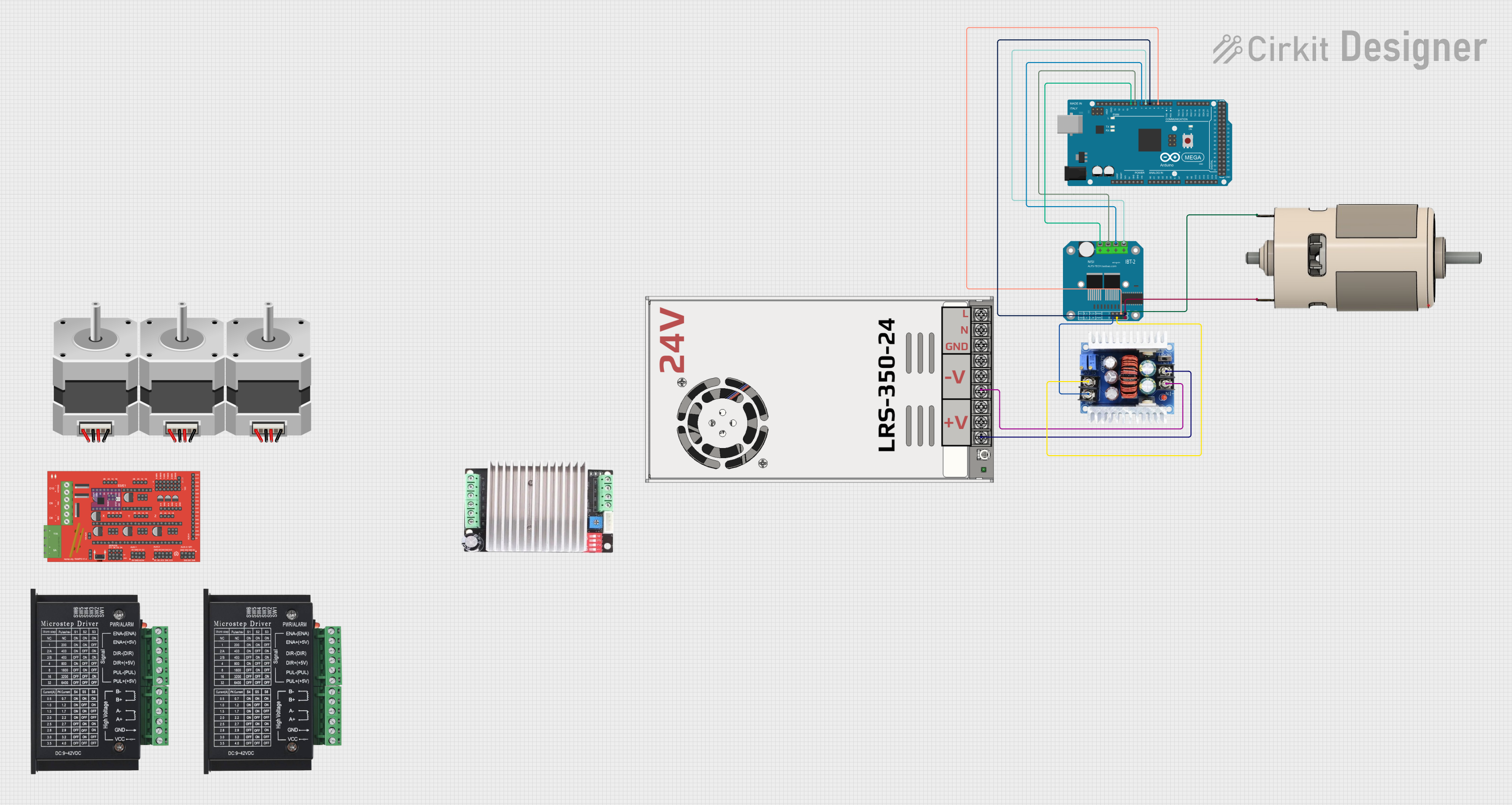

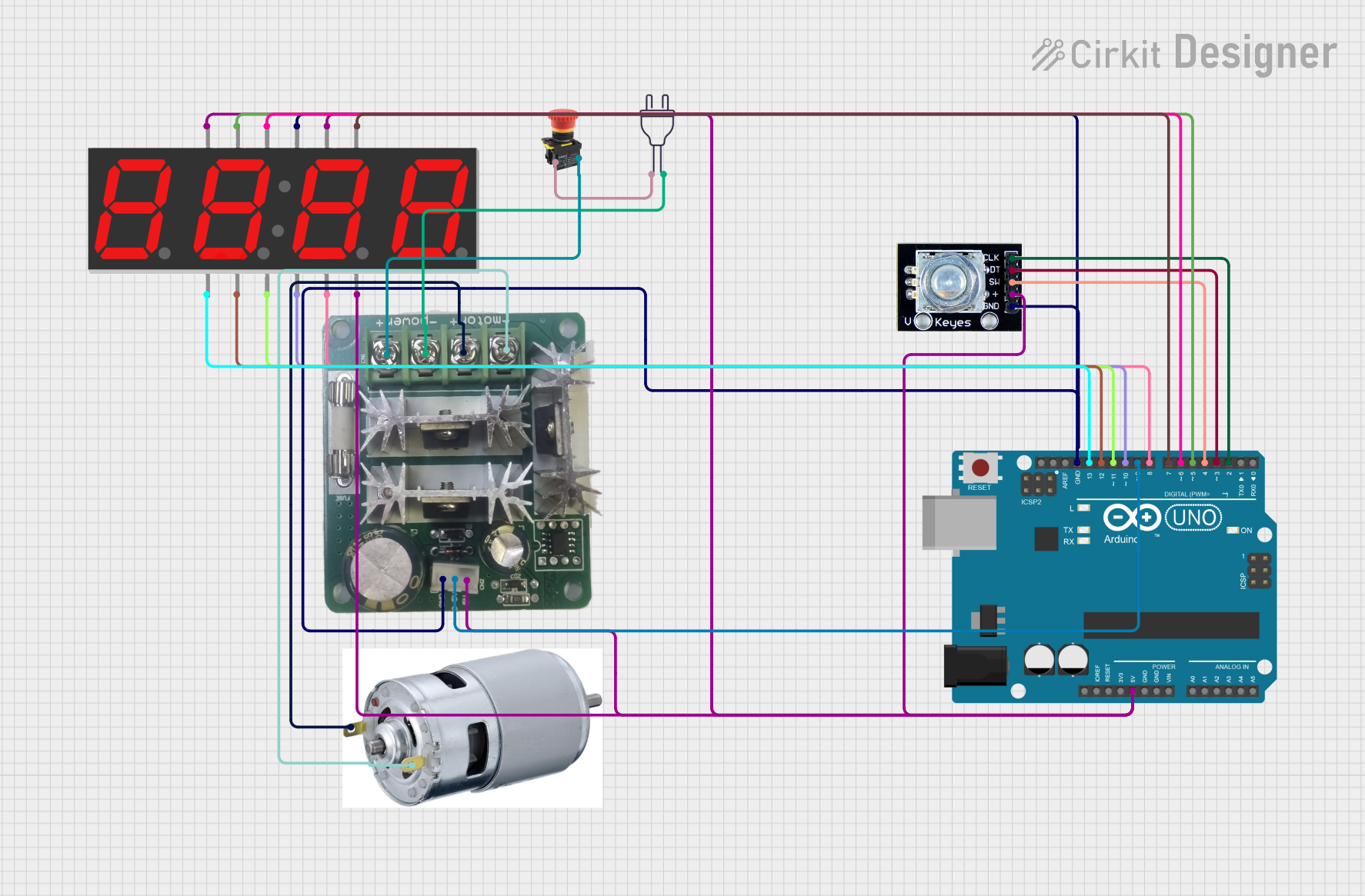

Open Project in Cirkit Designer

Open Project in Cirkit Designer

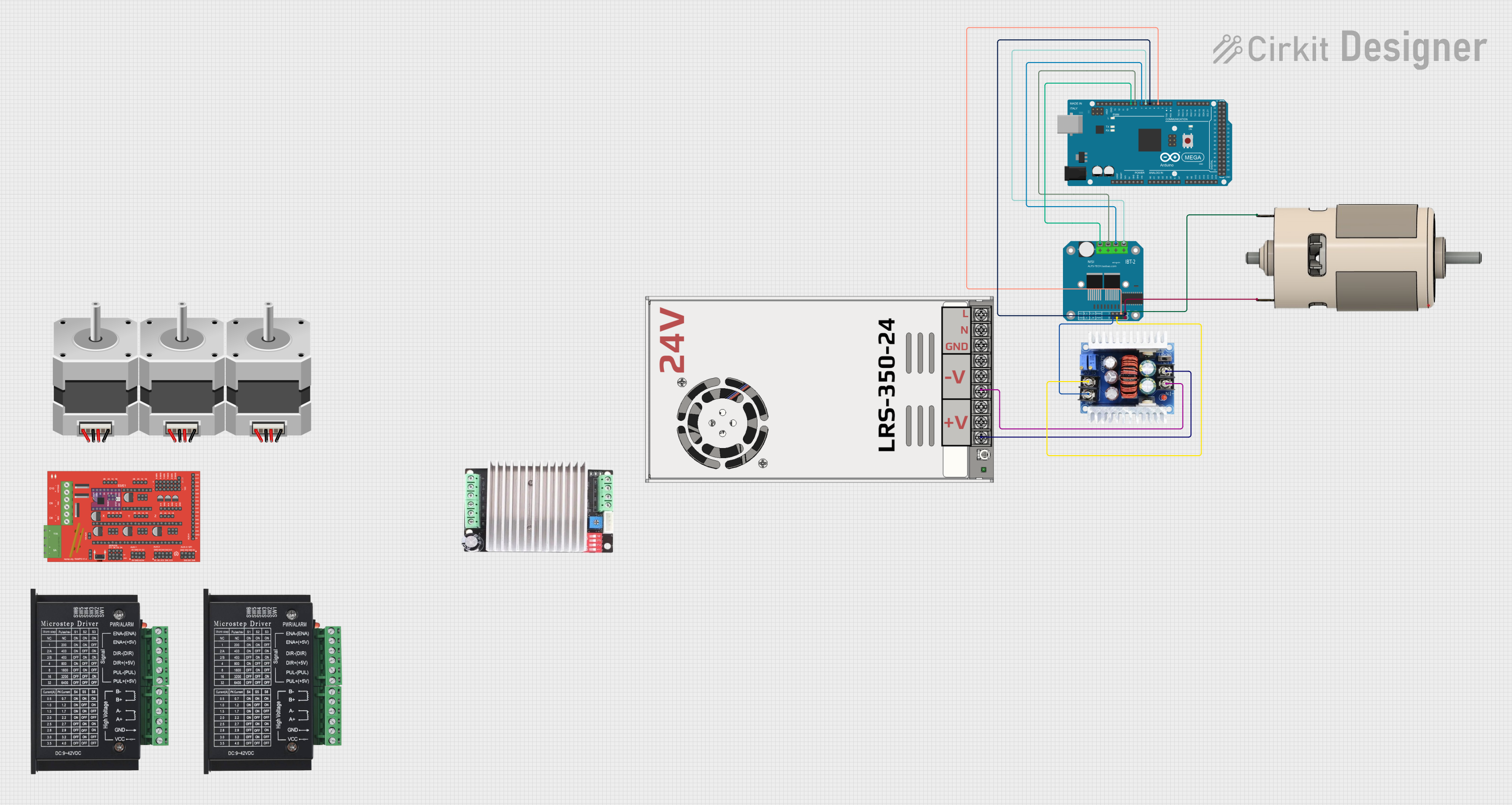

Open Project in Cirkit Designer

Open Project in Cirkit Designer

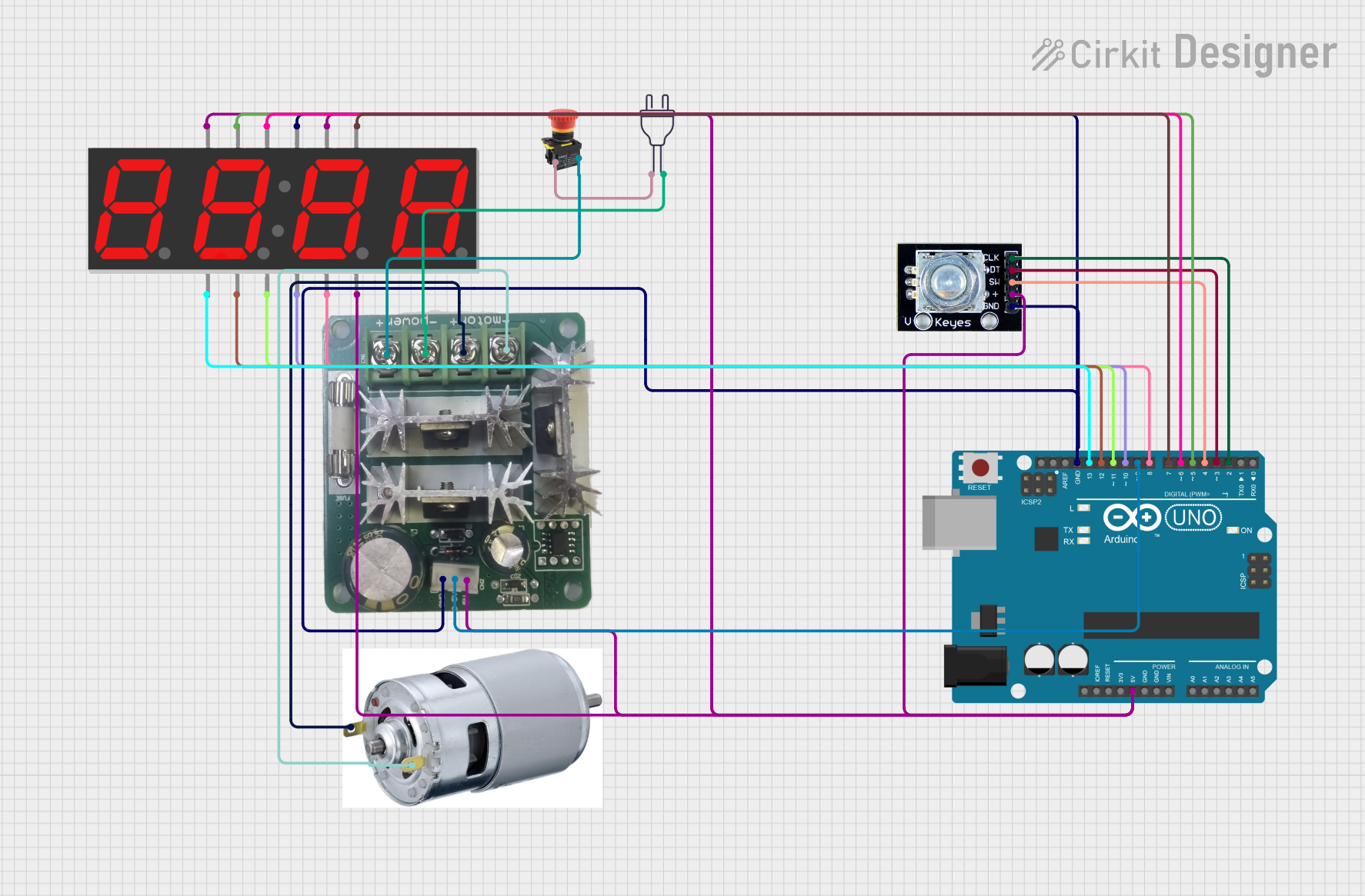

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with RS 775 DC MOTOR

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Used for driving wheels, arms, and other moving parts.

- Industrial Machinery: Employed in conveyor belts, drills, and other equipment.

- DIY Projects: Ideal for hobbyists building custom machines or vehicles.

- Electric Vehicles: Utilized in small electric vehicles for propulsion.

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Voltage Rating | 12V |

| Speed | 3000 RPM |

| Current Rating | 1.2A (no load) |

| Stall Current | 12A |

| Power Output | 30W |

| Torque | 0.5 Nm |

| Shaft Diameter | 5 mm |

| Motor Diameter | 42 mm |

| Motor Length | 66 mm |

| Weight | 320 g |

Pin Configuration and Descriptions

| Pin Number | Description |

|---|---|

| 1 | Positive Terminal (+) |

| 2 | Negative Terminal (-) |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the positive terminal of the power supply to the positive terminal of the motor (Pin 1) and the negative terminal of the power supply to the negative terminal of the motor (Pin 2).

- Motor Driver: For better control, use a motor driver like the L298N. Connect the motor terminals to the output pins of the driver.

- Control with Arduino: Connect the motor driver to an Arduino UNO for precise control. Use PWM (Pulse Width Modulation) to control the speed of the motor.

Important Considerations and Best Practices

- Heat Dissipation: Ensure proper ventilation or heat sinks to prevent overheating.

- Current Limiting: Use a current-limiting resistor or a fuse to protect the motor from overcurrent.

- Power Supply: Use a stable power supply to avoid voltage fluctuations that could damage the motor.

- Mounting: Securely mount the motor to prevent vibrations and ensure smooth operation.

Example Code for Arduino UNO

// Example code to control RS 775 DC Motor with Arduino UNO and L298N motor driver

const int enA = 9; // PWM pin to control speed

const int in1 = 8; // Control pin 1

const int in2 = 7; // Control pin 2

void setup() {

pinMode(enA, OUTPUT); // Set PWM pin as output

pinMode(in1, OUTPUT); // Set control pin 1 as output

pinMode(in2, OUTPUT); // Set control pin 2 as output

}

void loop() {

// Rotate motor clockwise

digitalWrite(in1, HIGH); // Set control pin 1 high

digitalWrite(in2, LOW); // Set control pin 2 low

analogWrite(enA, 255); // Set speed to maximum (255)

delay(2000); // Run motor for 2 seconds

// Stop motor

digitalWrite(in1, LOW); // Set control pin 1 low

digitalWrite(in2, LOW); // Set control pin 2 low

analogWrite(enA, 0); // Set speed to 0

delay(1000); // Wait for 1 second

// Rotate motor counterclockwise

digitalWrite(in1, LOW); // Set control pin 1 low

digitalWrite(in2, HIGH); // Set control pin 2 high

analogWrite(enA, 255); // Set speed to maximum (255)

delay(2000); // Run motor for 2 seconds

// Stop motor

digitalWrite(in1, LOW); // Set control pin 1 low

digitalWrite(in2, LOW); // Set control pin 2 low

analogWrite(enA, 0); // Set speed to 0

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues Users Might Face

Motor Not Spinning:

- Solution: Check the power supply connections and ensure the voltage is correct. Verify that the motor driver is functioning properly.

Overheating:

- Solution: Ensure proper ventilation and consider adding a heat sink. Check for overcurrent conditions and use a current-limiting resistor if necessary.

Inconsistent Speed:

- Solution: Use a stable power supply and ensure the PWM signal from the Arduino is consistent. Check for loose connections.

Excessive Noise:

- Solution: Securely mount the motor and check for any mechanical obstructions. Lubricate the motor bearings if needed.

FAQs

Q: Can I run the RS 775 DC Motor at a voltage higher than 12V?

- A: It is not recommended to exceed the rated voltage of 12V as it may damage the motor.

Q: How can I reverse the direction of the motor?

- A: Swap the connections of the positive and negative terminals or use a motor driver to control the direction programmatically.

Q: What is the maximum current the motor can handle?

- A: The stall current is 12A. Ensure your power supply and motor driver can handle this current to avoid damage.

Q: Can I control the speed of the motor?

- A: Yes, you can use PWM (Pulse Width Modulation) to control the speed of the motor.

This documentation provides a comprehensive guide to using the RS 775 DC Motor. Whether you are a beginner or an experienced user, following these instructions and best practices will help you achieve optimal performance and longevity from your motor.