Cirkit Designer

Your all-in-one circuit design IDE

Home /

Component Documentation

How to Use degasing pump: Examples, Pinouts, and Specs

Design with degasing pump in Cirkit Designer

Design with degasing pump in Cirkit DesignerIntroduction

A degassing pump is a specialized device designed to remove dissolved gases from liquids. This process is crucial in various applications to ensure the purity and effectiveness of the liquid. Common use cases include water treatment, chemical processing, and laboratory equipment. By eliminating dissolved gases, the degassing pump helps prevent issues such as oxidation, foaming, and inaccurate measurements in sensitive applications.

Explore Projects Built with degasing pump

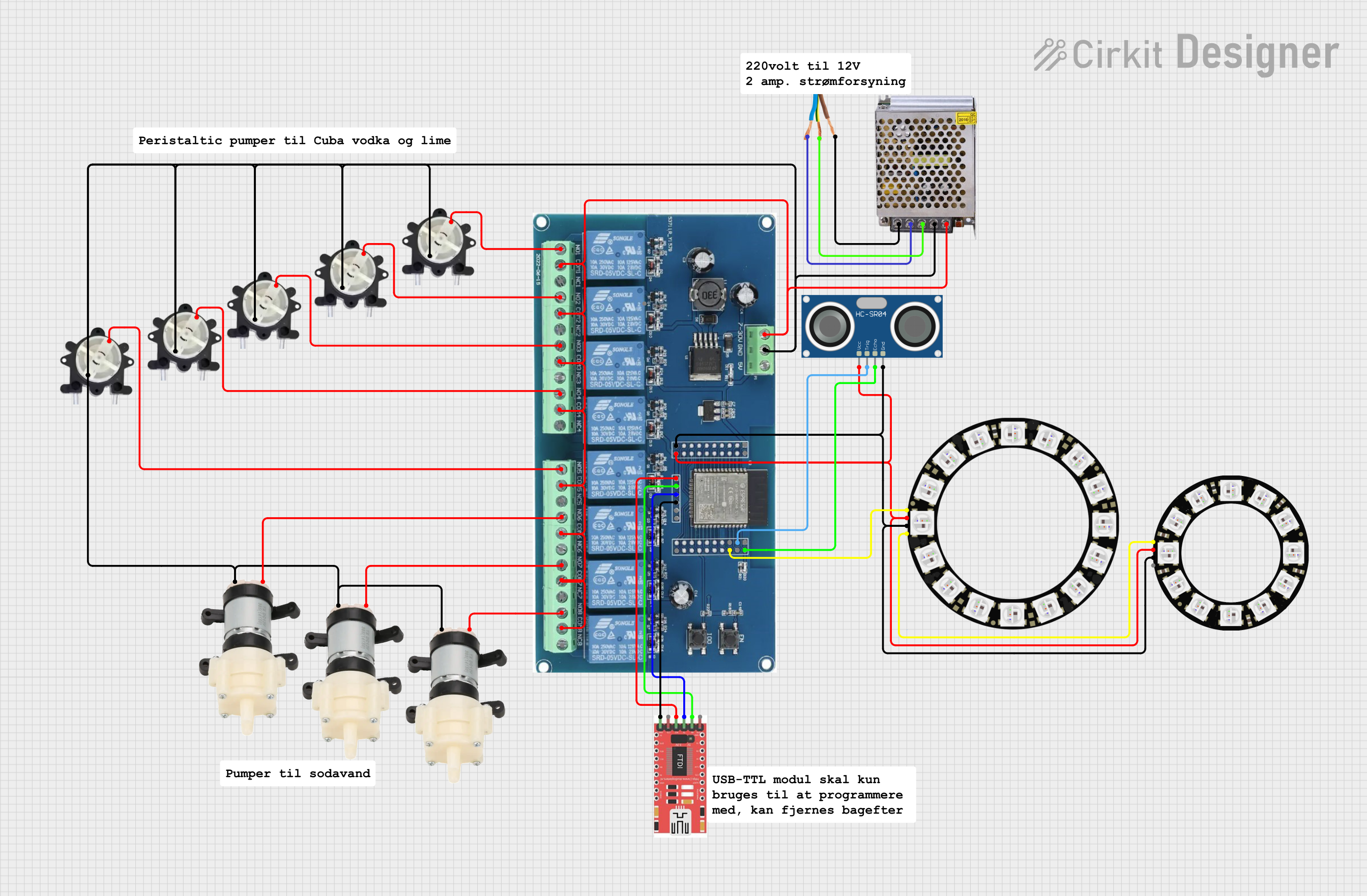

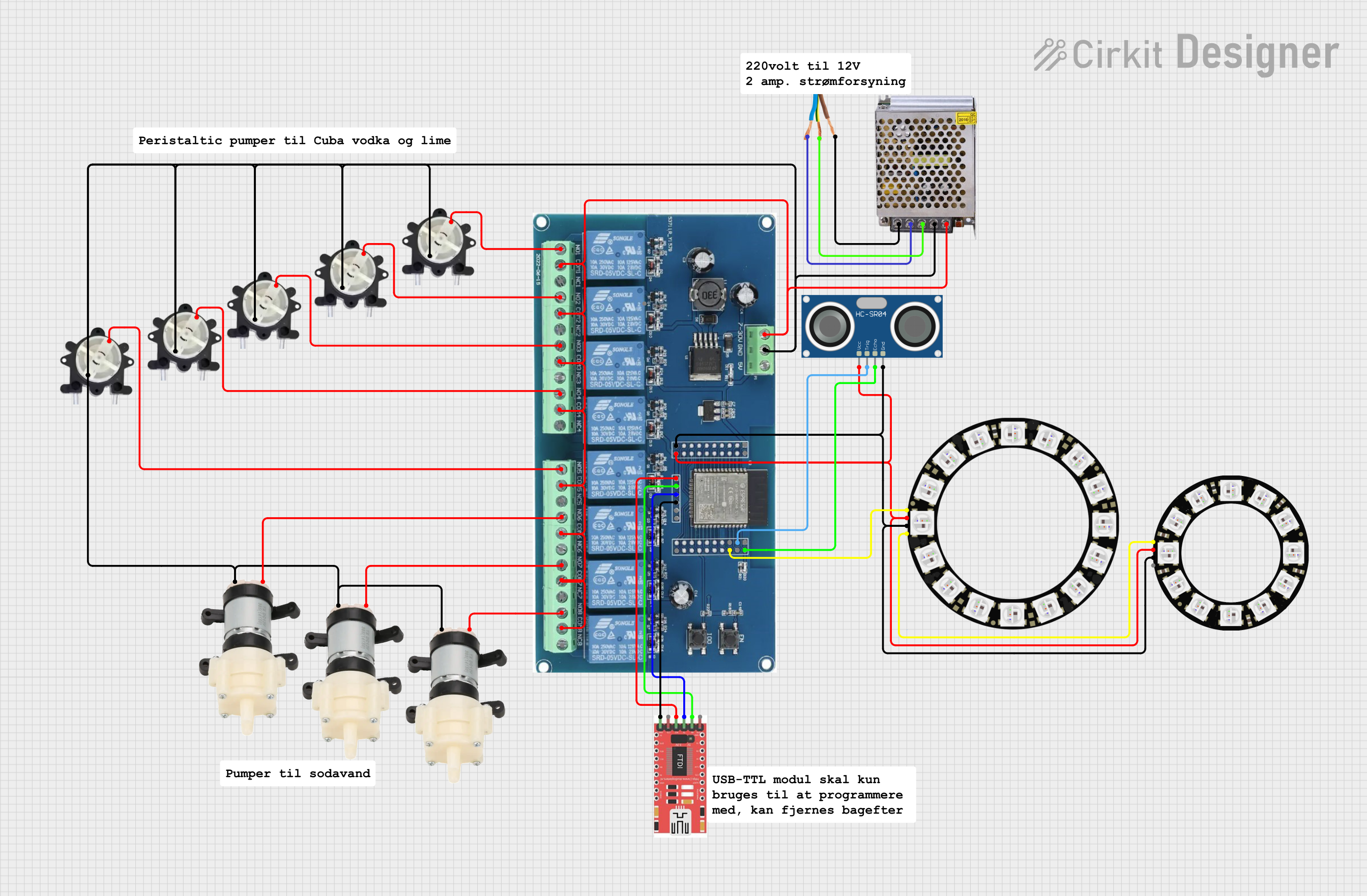

ESP32-Based Bluetooth-Controlled Cocktail Drink Mixer with Peristaltic and Diaphragm Pumps

This circuit is an automated cocktail drink mixer controlled by an ESP32 microcontroller. It uses multiple peristaltic and diaphragm pumps to dispense various liquids, an ultrasonic sensor to detect the presence of a glass, and LED rings for visual feedback. The system is operated via Bluetooth commands sent from a mobile app.

Open Project in Cirkit Designer

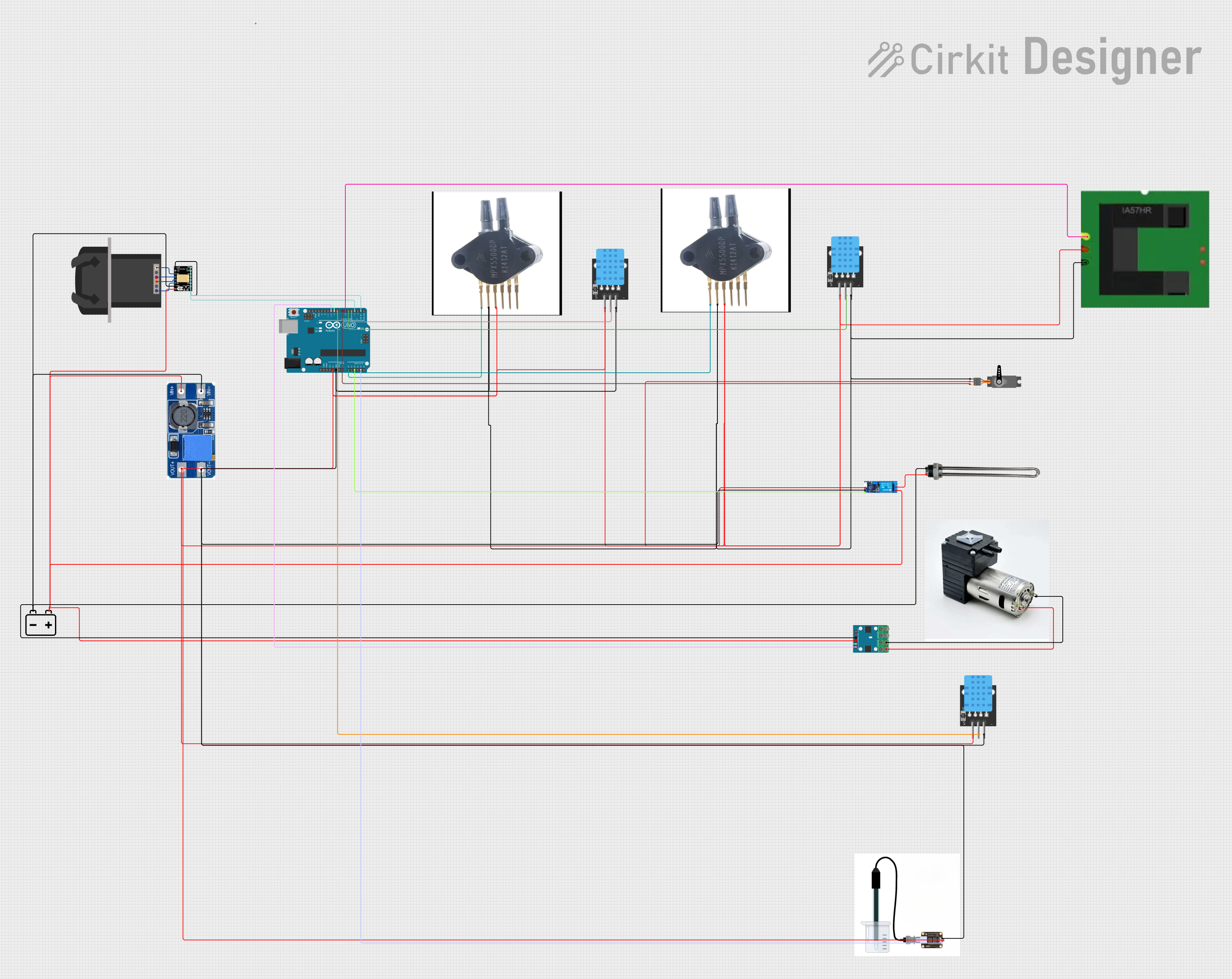

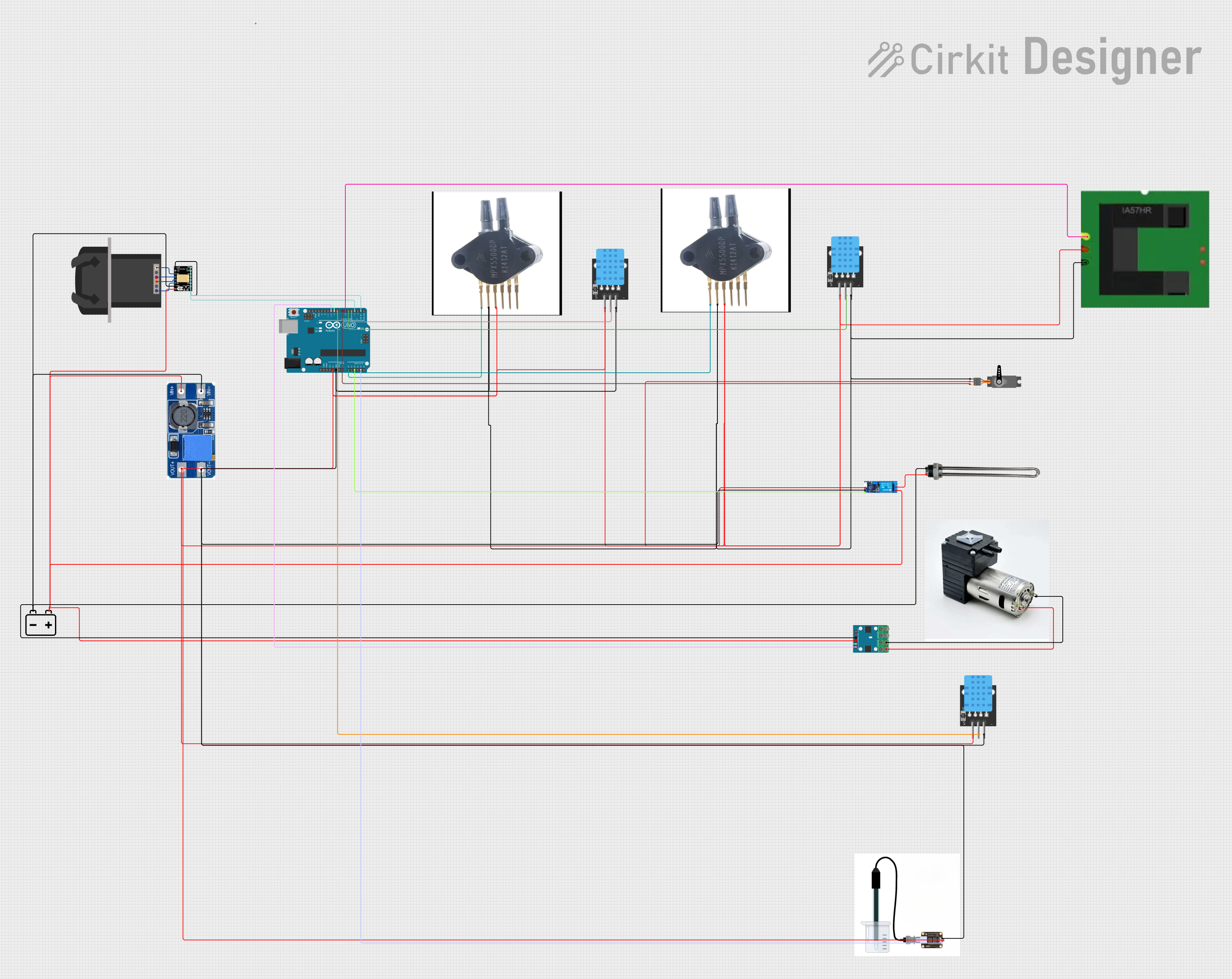

Open Project in Cirkit DesignerArduino UNO Controlled Peristaltic Pump System with Temperature and Pressure Monitoring

This circuit is designed to control a KPCS200 peristaltic pump using a TMC2226 stepper driver, powered by a 12V battery and regulated by a step-up boost converter. An Arduino UNO microcontroller manages various sensors, including temperature, pressure, and conductivity sensors, as well as a servo and a relay module for a water heater, enabling precise control and monitoring of fluid flow and environmental conditions.

Open Project in Cirkit Designer

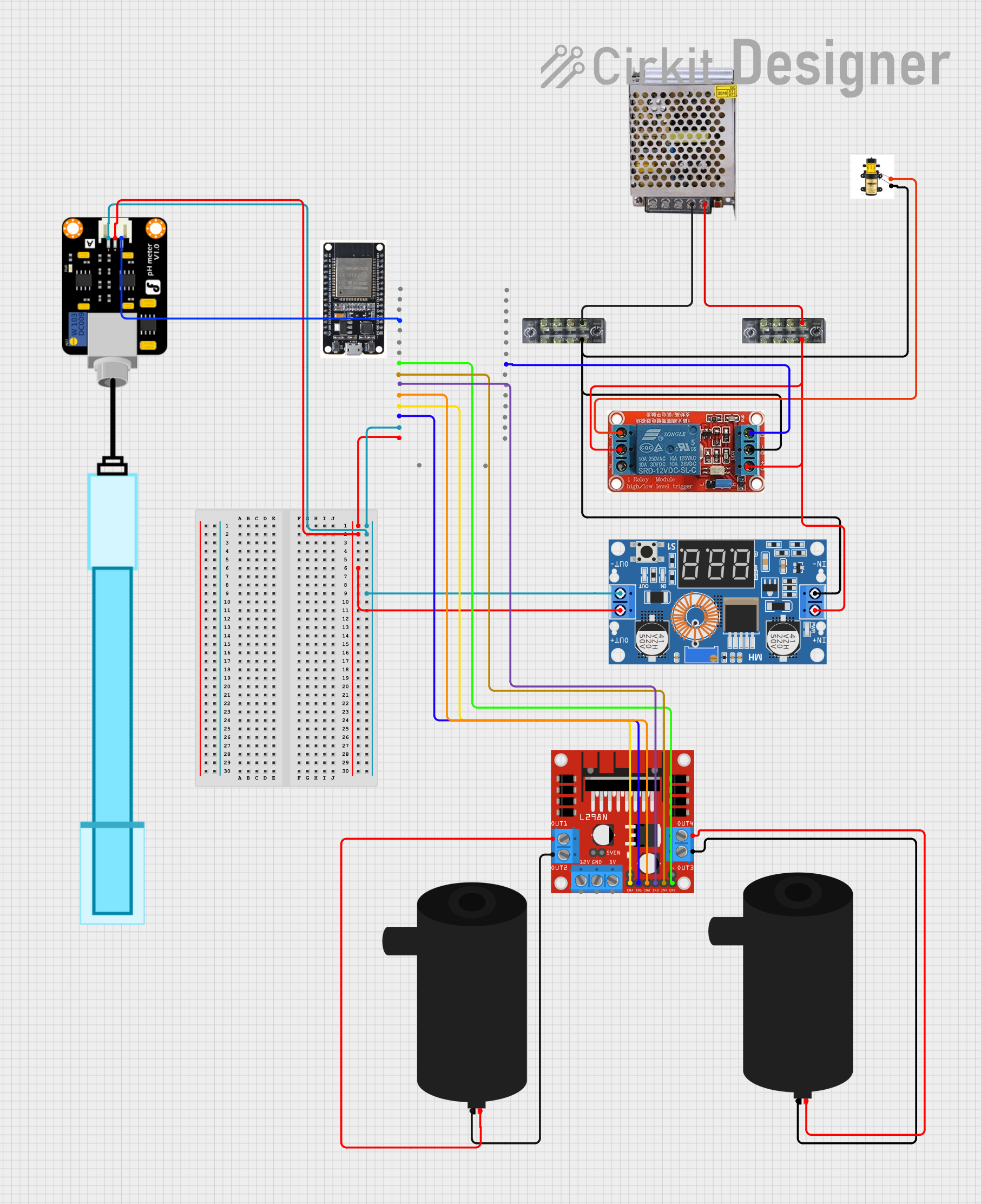

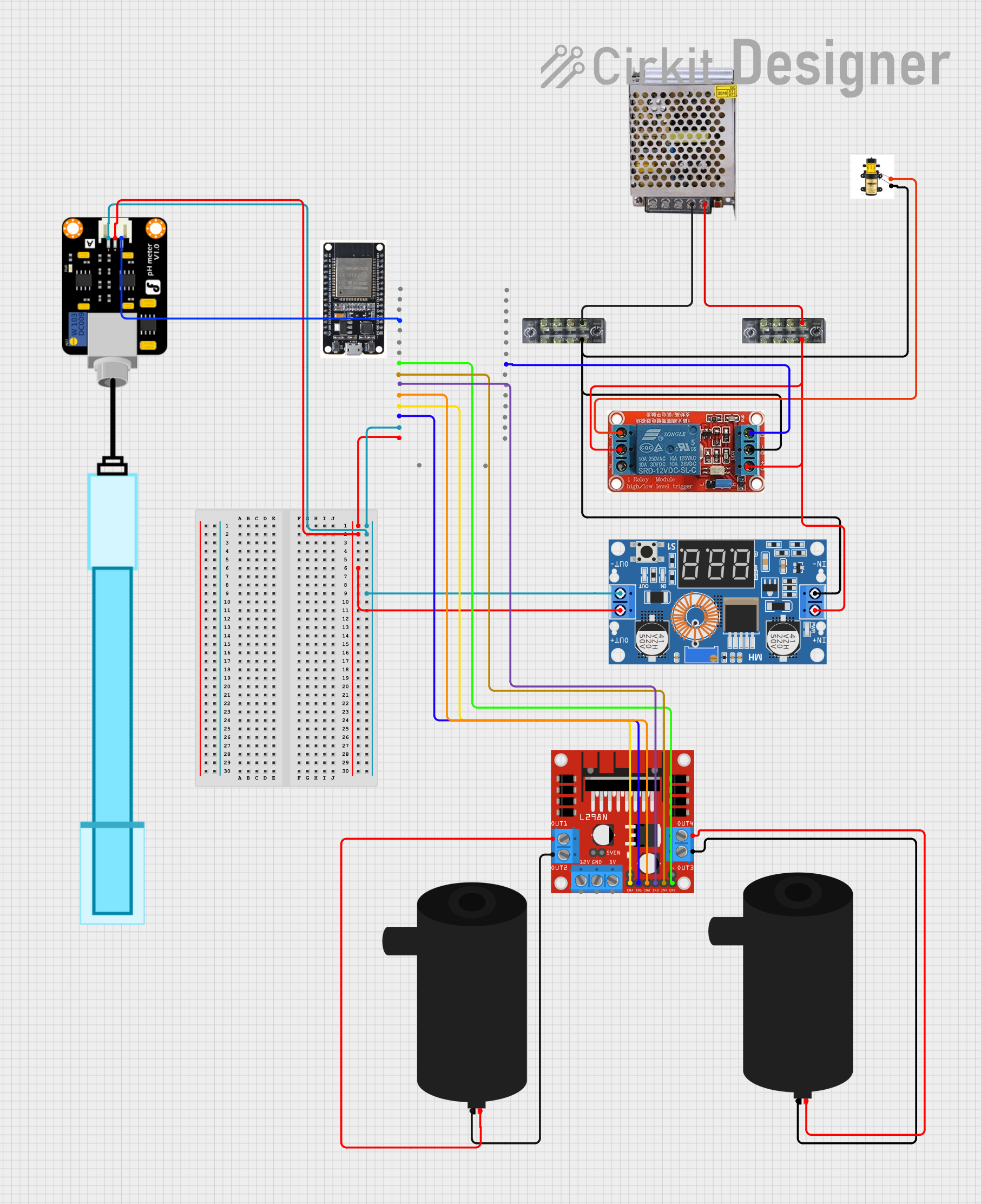

Open Project in Cirkit DesignerESP32-Based Automated pH Monitoring and Water Pump Control System

This circuit is a water management system controlled by an ESP32 microcontroller. It includes a pH meter for monitoring water quality, a relay to control a pump, and an L298N motor driver to manage multiple water pumps. The system is powered by a 5V power supply and uses a DC buck converter to step down voltage as needed.

Open Project in Cirkit Designer

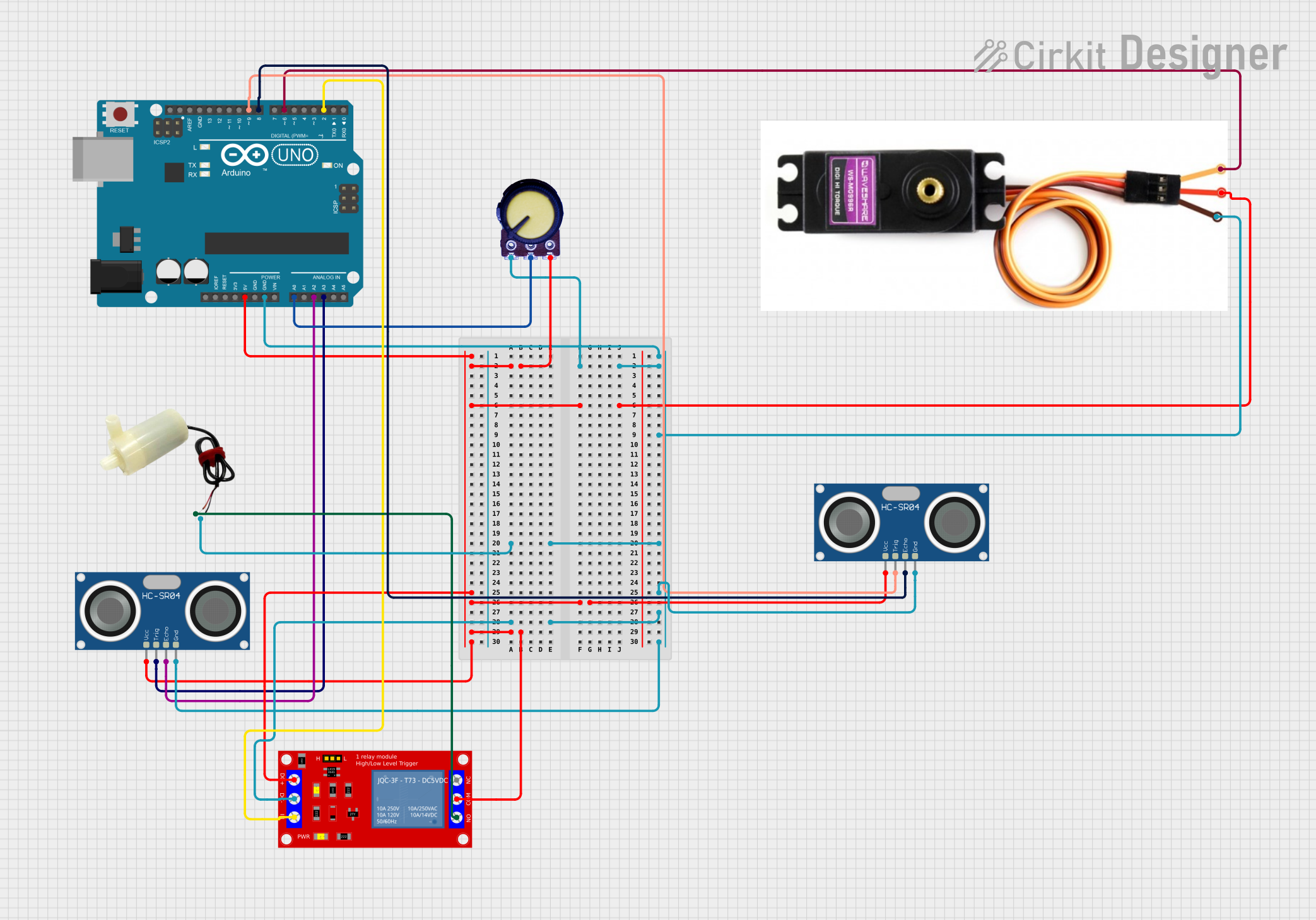

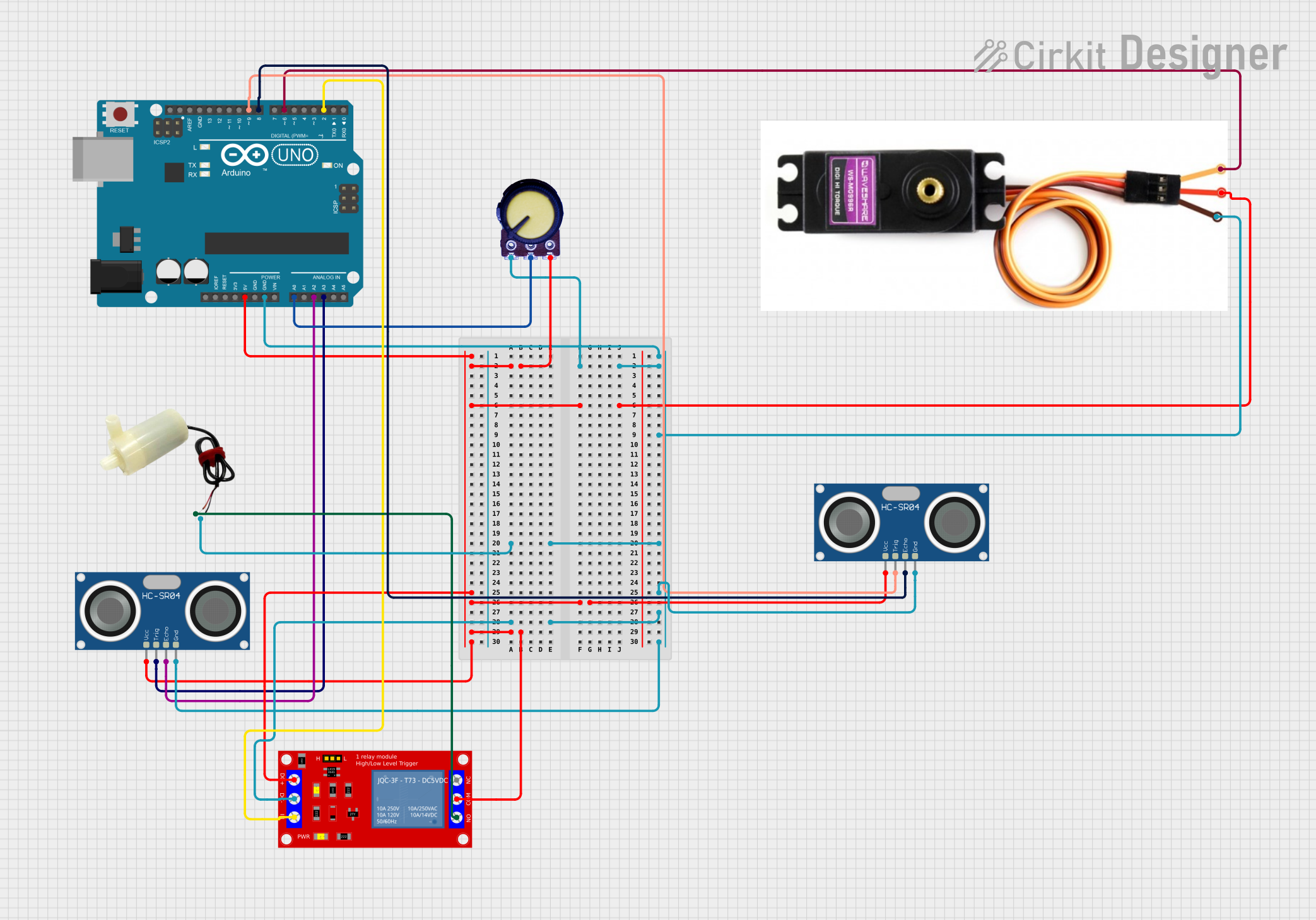

Open Project in Cirkit DesignerArduino UNO-Based Automatic Liquid Hand Sanitizer and Soap Dispenser

This circuit is an Arduino UNO-based automatic liquid hand sanitizer dispenser system. It uses two HC-SR04 ultrasonic sensors to detect the presence of a hand: one sensor controls a 5V mini water pump through a relay for dispensing hand sanitizer, and the other sensor controls a MG996R servo motor for a soap dispenser mechanism. A potentiometer is likely used for adjusting the sensitivity or operational parameters of the system.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with degasing pump

ESP32-Based Bluetooth-Controlled Cocktail Drink Mixer with Peristaltic and Diaphragm Pumps

This circuit is an automated cocktail drink mixer controlled by an ESP32 microcontroller. It uses multiple peristaltic and diaphragm pumps to dispense various liquids, an ultrasonic sensor to detect the presence of a glass, and LED rings for visual feedback. The system is operated via Bluetooth commands sent from a mobile app.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Arduino UNO Controlled Peristaltic Pump System with Temperature and Pressure Monitoring

This circuit is designed to control a KPCS200 peristaltic pump using a TMC2226 stepper driver, powered by a 12V battery and regulated by a step-up boost converter. An Arduino UNO microcontroller manages various sensors, including temperature, pressure, and conductivity sensors, as well as a servo and a relay module for a water heater, enabling precise control and monitoring of fluid flow and environmental conditions.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

ESP32-Based Automated pH Monitoring and Water Pump Control System

This circuit is a water management system controlled by an ESP32 microcontroller. It includes a pH meter for monitoring water quality, a relay to control a pump, and an L298N motor driver to manage multiple water pumps. The system is powered by a 5V power supply and uses a DC buck converter to step down voltage as needed.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Arduino UNO-Based Automatic Liquid Hand Sanitizer and Soap Dispenser

This circuit is an Arduino UNO-based automatic liquid hand sanitizer dispenser system. It uses two HC-SR04 ultrasonic sensors to detect the presence of a hand: one sensor controls a 5V mini water pump through a relay for dispensing hand sanitizer, and the other sensor controls a MG996R servo motor for a soap dispenser mechanism. A potentiometer is likely used for adjusting the sensitivity or operational parameters of the system.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the key technical details and pin configuration for the degassing pump:

Key Technical Details

| Parameter | Value |

|---|---|

| Manufacturer | pump |

| Part ID | pump |

| Operating Voltage | 12V DC |

| Operating Current | 500mA |

| Power Rating | 6W |

| Flow Rate | 0.5 L/min |

| Maximum Pressure | 0.2 MPa |

| Inlet/Outlet Size | 6mm |

| Operating Temperature Range | 0°C to 50°C |

| Weight | 150g |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply (12V DC) |

| 2 | GND | Ground |

| 3 | IN | Liquid Inlet |

| 4 | OUT | Liquid Outlet |

| 5 | CTRL | Control Signal (PWM for speed control) |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the VCC pin to a 12V DC power supply and the GND pin to the ground.

- Liquid Connections: Attach the liquid inlet to the source of the liquid to be degassed and the outlet to the destination container.

- Control Signal: If speed control is required, connect the CTRL pin to a PWM signal from a microcontroller like an Arduino UNO.

Important Considerations and Best Practices

- Ensure Proper Sealing: Make sure all connections are properly sealed to prevent leaks.

- Avoid Dry Running: Do not run the pump without liquid as it may damage the internal components.

- Temperature Range: Operate the pump within the specified temperature range (0°C to 50°C) to avoid overheating.

- Flow Rate: Monitor the flow rate to ensure it does not exceed the specified 0.5 L/min.

Example Arduino UNO Code

Below is an example code to control the degassing pump using an Arduino UNO:

// Define the control pin for the pump

const int pumpControlPin = 9;

void setup() {

// Initialize the control pin as an output

pinMode(pumpControlPin, OUTPUT);

}

void loop() {

// Set the pump speed using PWM (0-255)

analogWrite(pumpControlPin, 128); // 50% speed

// Run the pump for 10 seconds

delay(10000);

// Stop the pump

analogWrite(pumpControlPin, 0);

// Wait for 5 seconds before restarting

delay(5000);

}

Troubleshooting and FAQs

Common Issues Users Might Face

- Pump Not Starting: Ensure the power supply is connected correctly and providing 12V DC.

- Low Flow Rate: Check for blockages in the inlet or outlet and ensure the liquid source is sufficient.

- Overheating: Verify that the pump is operating within the specified temperature range and not running dry.

Solutions and Tips for Troubleshooting

- Check Connections: Ensure all electrical and liquid connections are secure and correct.

- Monitor Power Supply: Use a stable power supply to avoid voltage fluctuations.

- Regular Maintenance: Clean the pump and check for wear and tear regularly to maintain optimal performance.

By following this documentation, users can effectively utilize the degassing pump in their applications, ensuring reliable and efficient operation.