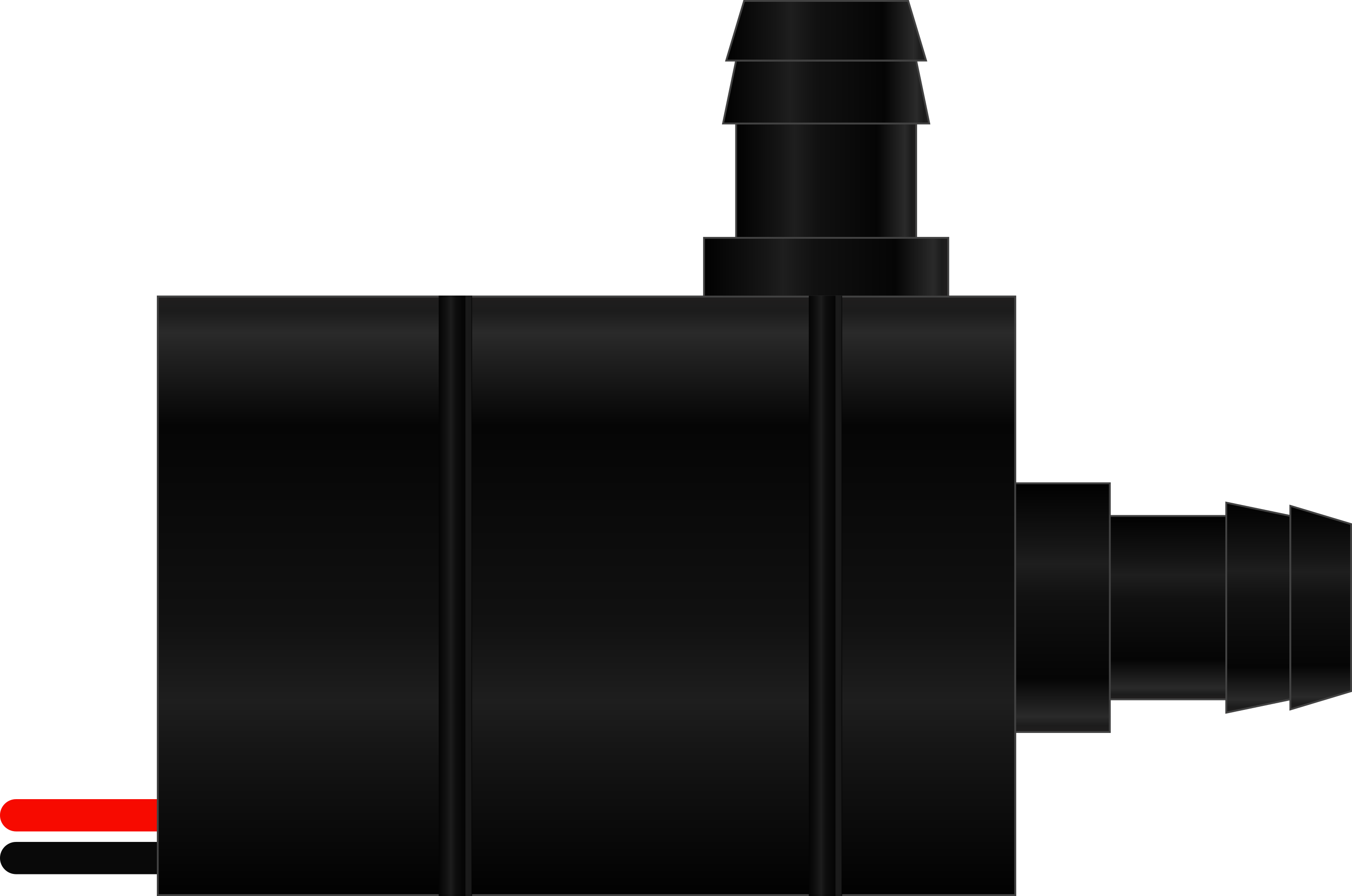

How to Use Water Pump: Examples, Pinouts, and Specs

Design with Water Pump in Cirkit Designer

Design with Water Pump in Cirkit DesignerIntroduction

A water pump is a device designed to move water from one location to another by converting mechanical energy into hydraulic energy. It is commonly used in a variety of applications, including irrigation systems, water circulation in aquariums, cooling systems, and household water supply systems. Water pumps are essential in scenarios where water needs to be transported, pressurized, or circulated efficiently.

Explore Projects Built with Water Pump

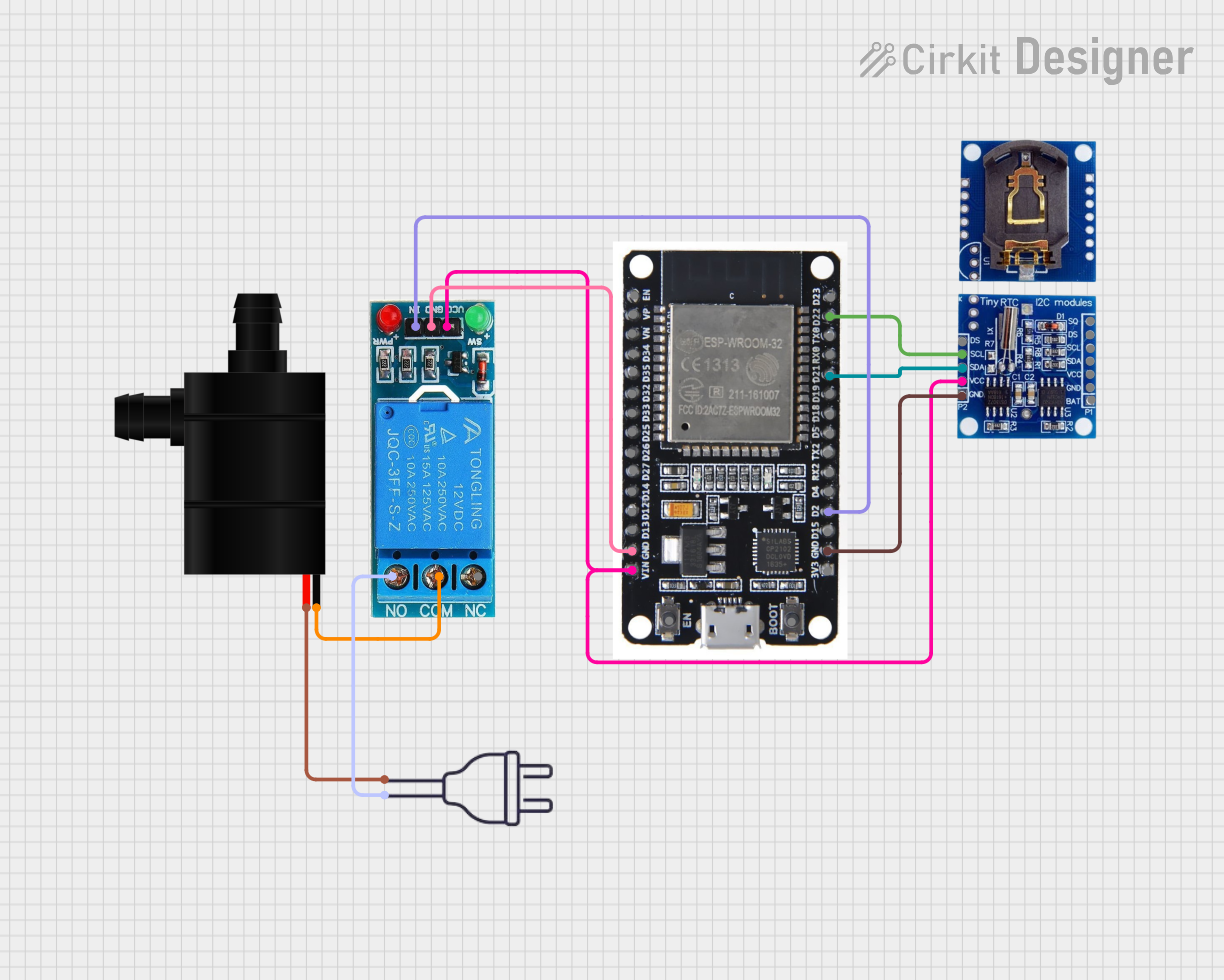

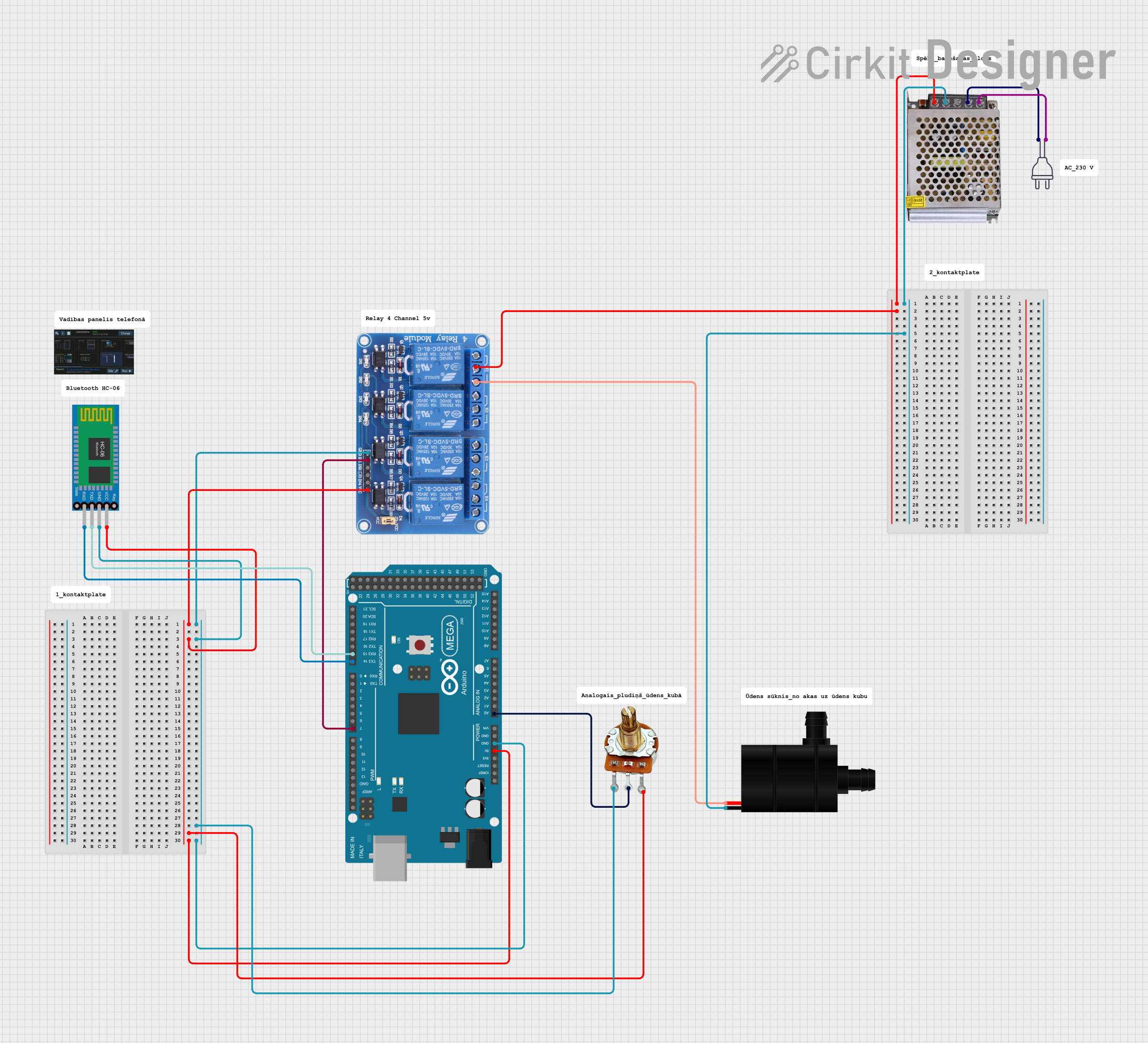

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

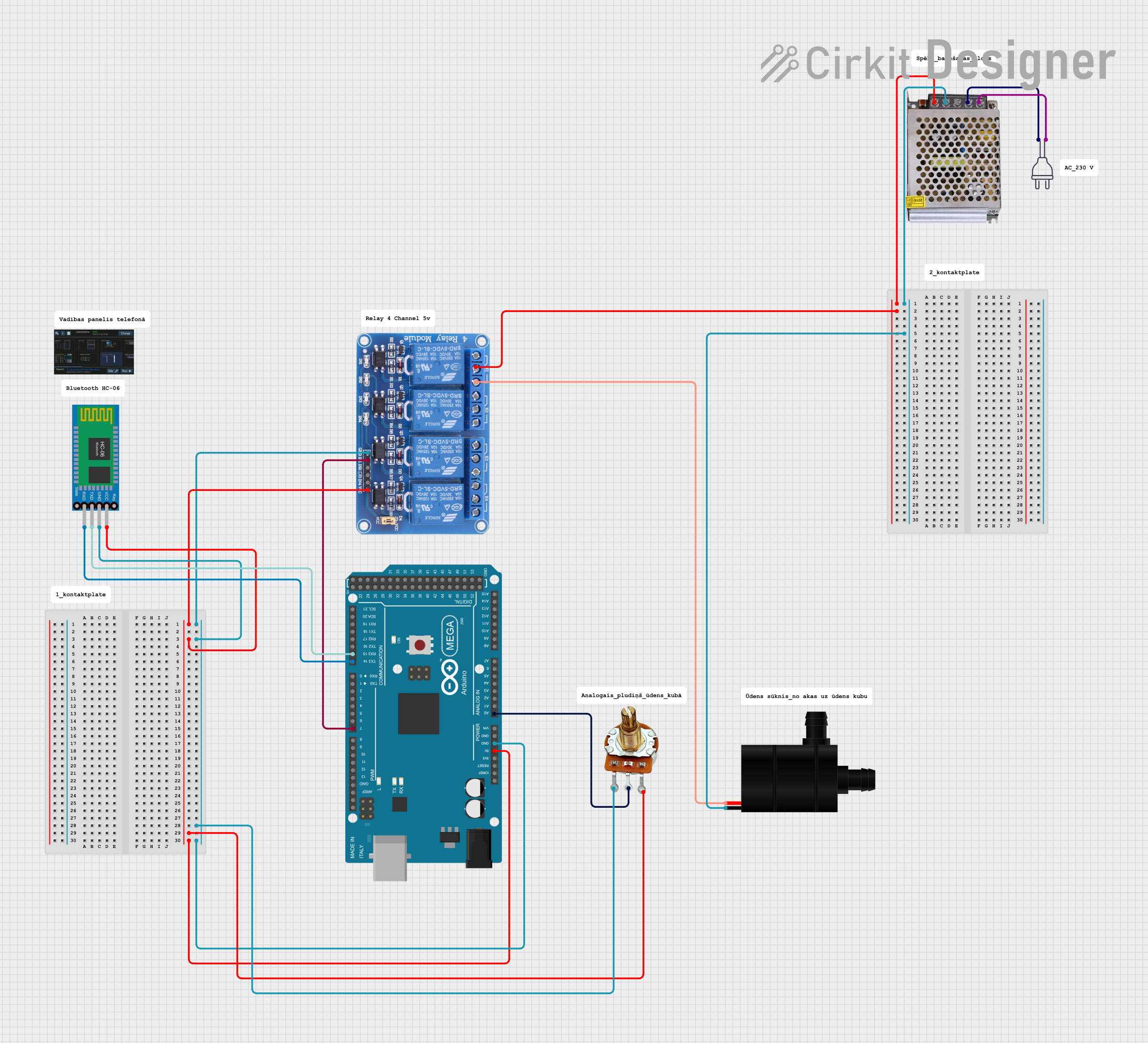

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Water Pump

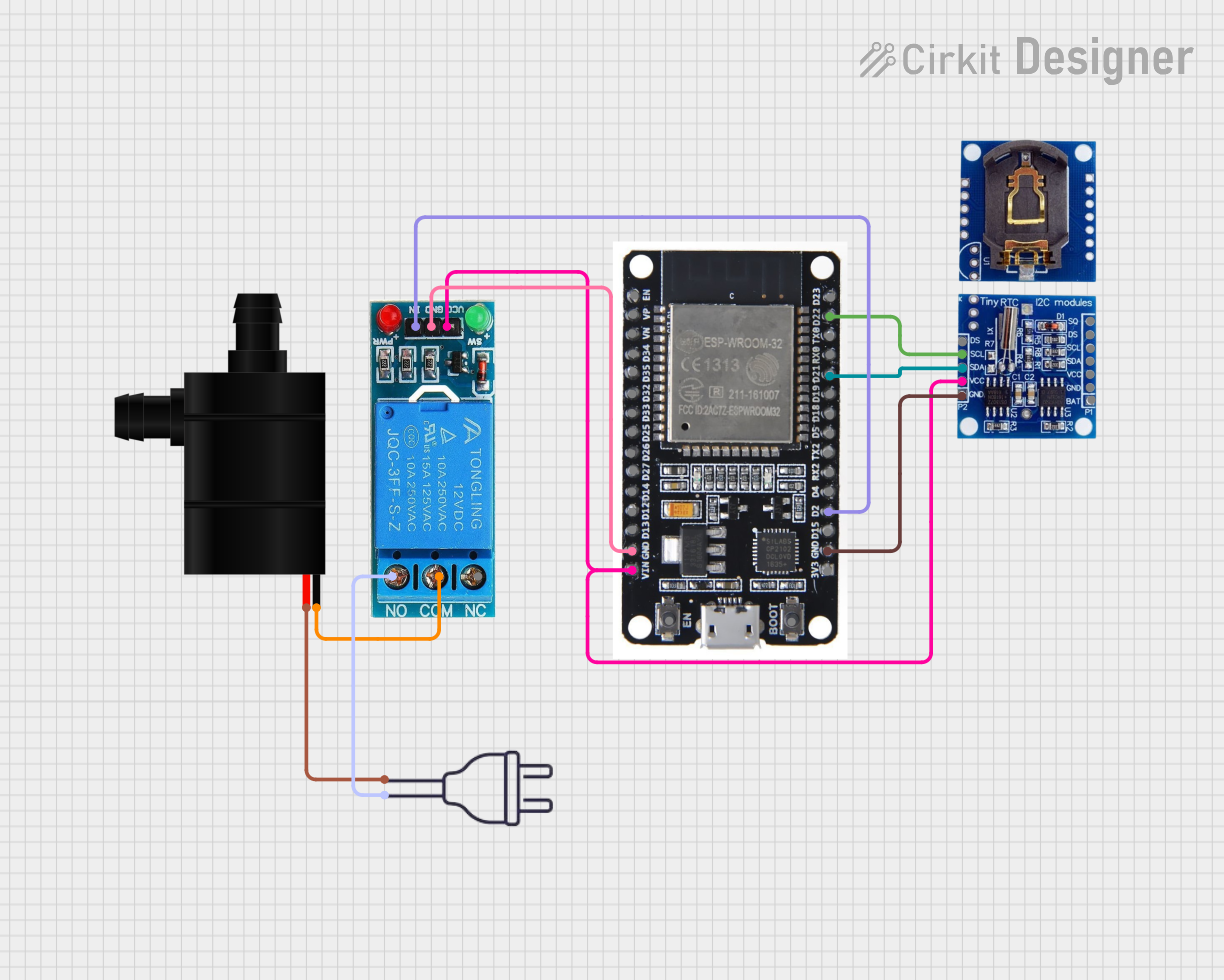

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the general technical specifications for a typical DC-powered water pump:

| Parameter | Value |

|---|---|

| Operating Voltage | 3V - 12V DC |

| Operating Current | 0.1A - 0.5A |

| Power Consumption | 1W - 6W |

| Maximum Flow Rate | 80 - 300 liters per hour (L/h) |

| Maximum Lift Height | 0.5m - 3m |

| Inlet/Outlet Diameter | 4mm - 10mm |

| Material | Plastic (ABS) or Stainless Steel |

| Operating Temperature | 0°C - 50°C |

| Lifespan | 1000 - 3000 hours of operation |

Pin Configuration and Descriptions

For a basic DC water pump, the pin configuration is straightforward:

| Pin Name | Description |

|---|---|

| VCC (+) | Positive terminal for power input (3V-12V DC) |

| GND (-) | Negative terminal for power input (ground) |

Usage Instructions

How to Use the Water Pump in a Circuit

- Power Supply: Connect the VCC pin of the water pump to a DC power source (e.g., a battery or power adapter) within the specified voltage range (3V-12V). Ensure the power source can supply sufficient current for the pump's operation.

- Ground Connection: Connect the GND pin of the water pump to the ground of the power source.

- Water Inlet and Outlet: Attach appropriate tubing to the inlet and outlet ports of the pump. Ensure the tubing is securely fastened to prevent leaks.

- Control (Optional): If you want to control the pump using a microcontroller (e.g., Arduino), connect the pump to a relay module or a transistor circuit to switch it on and off.

Important Considerations and Best Practices

- Voltage Range: Do not exceed the specified voltage range to avoid damaging the pump.

- Dry Run Prevention: Never operate the pump without water, as this can cause overheating and damage the internal components.

- Filtration: Use a filter at the inlet to prevent debris from entering the pump and causing blockages or damage.

- Orientation: Install the pump in the correct orientation as specified by the manufacturer to ensure optimal performance.

- Cooling: Avoid prolonged operation in high-temperature environments to prevent overheating.

Example: Controlling a Water Pump with Arduino UNO

Below is an example of how to control a water pump using an Arduino UNO and a relay module:

// Example: Controlling a water pump with Arduino UNO and a relay module

const int relayPin = 7; // Pin connected to the relay module

void setup() {

pinMode(relayPin, OUTPUT); // Set the relay pin as an output

digitalWrite(relayPin, LOW); // Ensure the pump is off initially

}

void loop() {

// Turn the pump on for 5 seconds

digitalWrite(relayPin, HIGH); // Activate the relay (pump ON)

delay(5000); // Wait for 5 seconds

// Turn the pump off for 5 seconds

digitalWrite(relayPin, LOW); // Deactivate the relay (pump OFF)

delay(5000); // Wait for 5 seconds

}

Note: Ensure the relay module is rated for the pump's voltage and current. Use an external power source for the pump if its power requirements exceed the Arduino's capabilities.

Troubleshooting and FAQs

Common Issues and Solutions

Pump Does Not Start

- Cause: Insufficient power supply or loose connections.

- Solution: Verify the power supply voltage and current. Check all connections for proper contact.

Low Water Flow

- Cause: Blocked inlet or outlet, or insufficient voltage.

- Solution: Clean the inlet and outlet. Ensure the power supply provides the required voltage.

Pump Overheats

- Cause: Dry running or prolonged operation in a high-temperature environment.

- Solution: Ensure the pump is always submerged in water or has water flowing through it. Operate within the recommended temperature range.

Noisy Operation

- Cause: Air trapped in the pump or worn-out components.

- Solution: Remove air bubbles by priming the pump. Replace worn-out parts if necessary.

FAQs

Q: Can I use the water pump with AC power?

A: No, this pump is designed for DC power only. Use a DC power adapter or battery.Q: How do I prevent leaks in the tubing?

A: Use clamps or zip ties to secure the tubing to the pump's inlet and outlet.Q: Can the pump handle hot water?

A: Most pumps are designed for water temperatures up to 50°C. Check the manufacturer's specifications for your specific pump.Q: How do I control the pump speed?

A: Use a PWM (Pulse Width Modulation) signal with a motor driver or a dedicated pump controller to adjust the speed.

This documentation provides a comprehensive guide to understanding, using, and troubleshooting a water pump effectively.