How to Use Vacuum Pump - 12V: Examples, Pinouts, and Specs

Design with Vacuum Pump - 12V in Cirkit Designer

Design with Vacuum Pump - 12V in Cirkit DesignerIntroduction

The Vacuum Pump - 12V (part ID: ROB-10398) is a compact and versatile component designed to create a vacuum by removing air from a specific area or container. This pump operates on a 12V DC supply, making it suitable for a wide range of applications including HVAC systems, laboratory equipment, automotive systems, and robotics. Its portability and ease of use make it a popular choice for hobbyists and professionals alike.

Explore Projects Built with Vacuum Pump - 12V

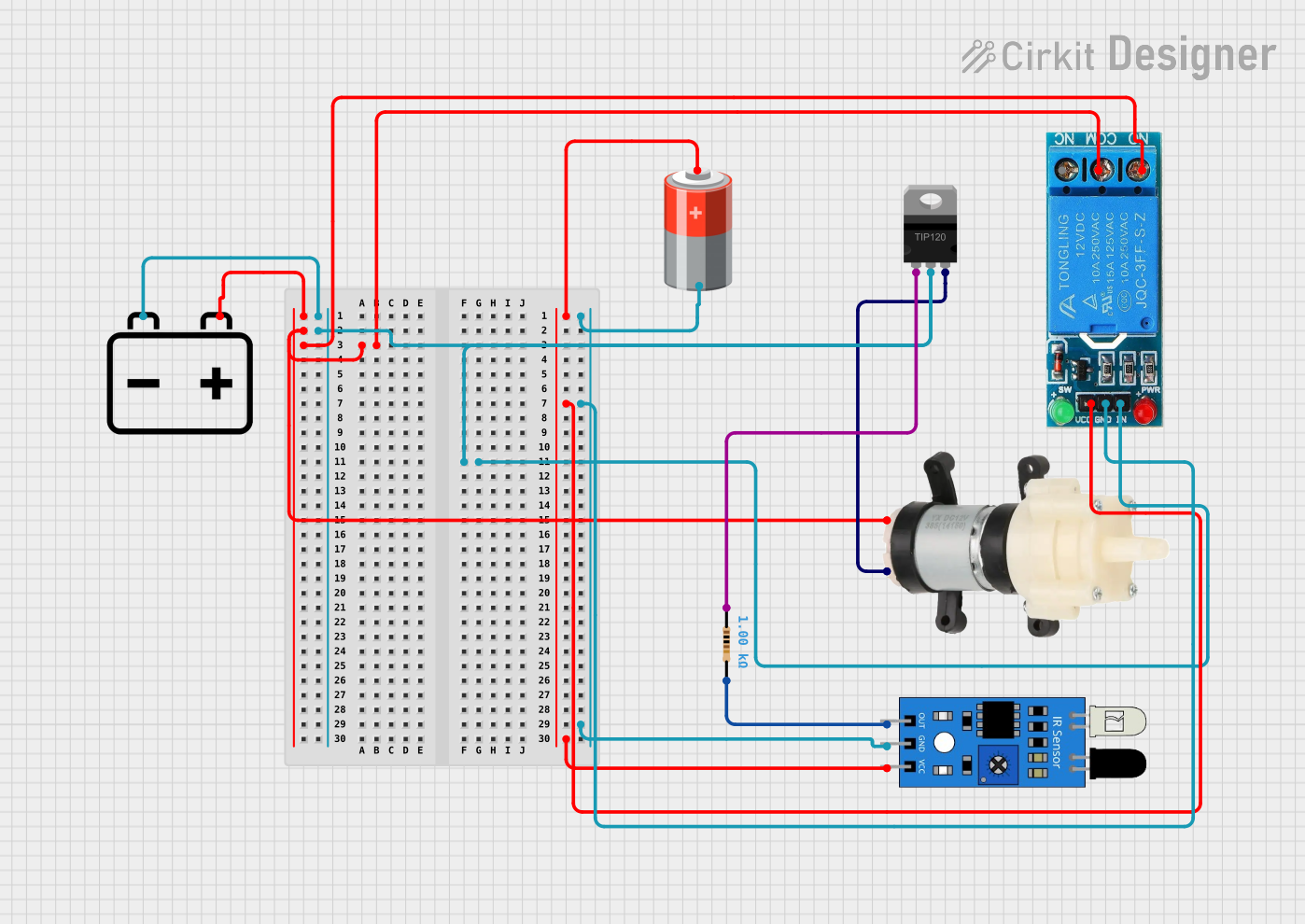

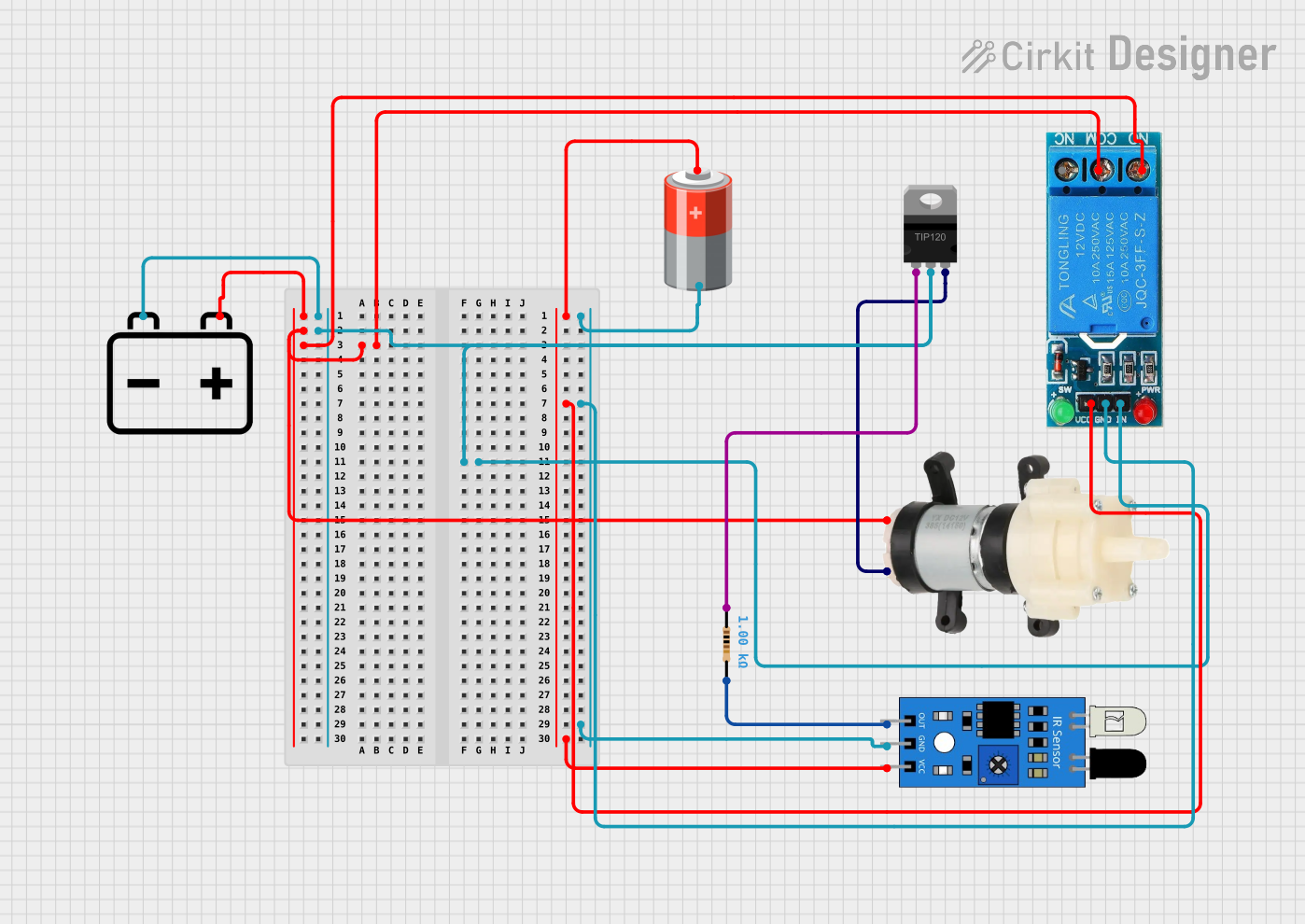

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

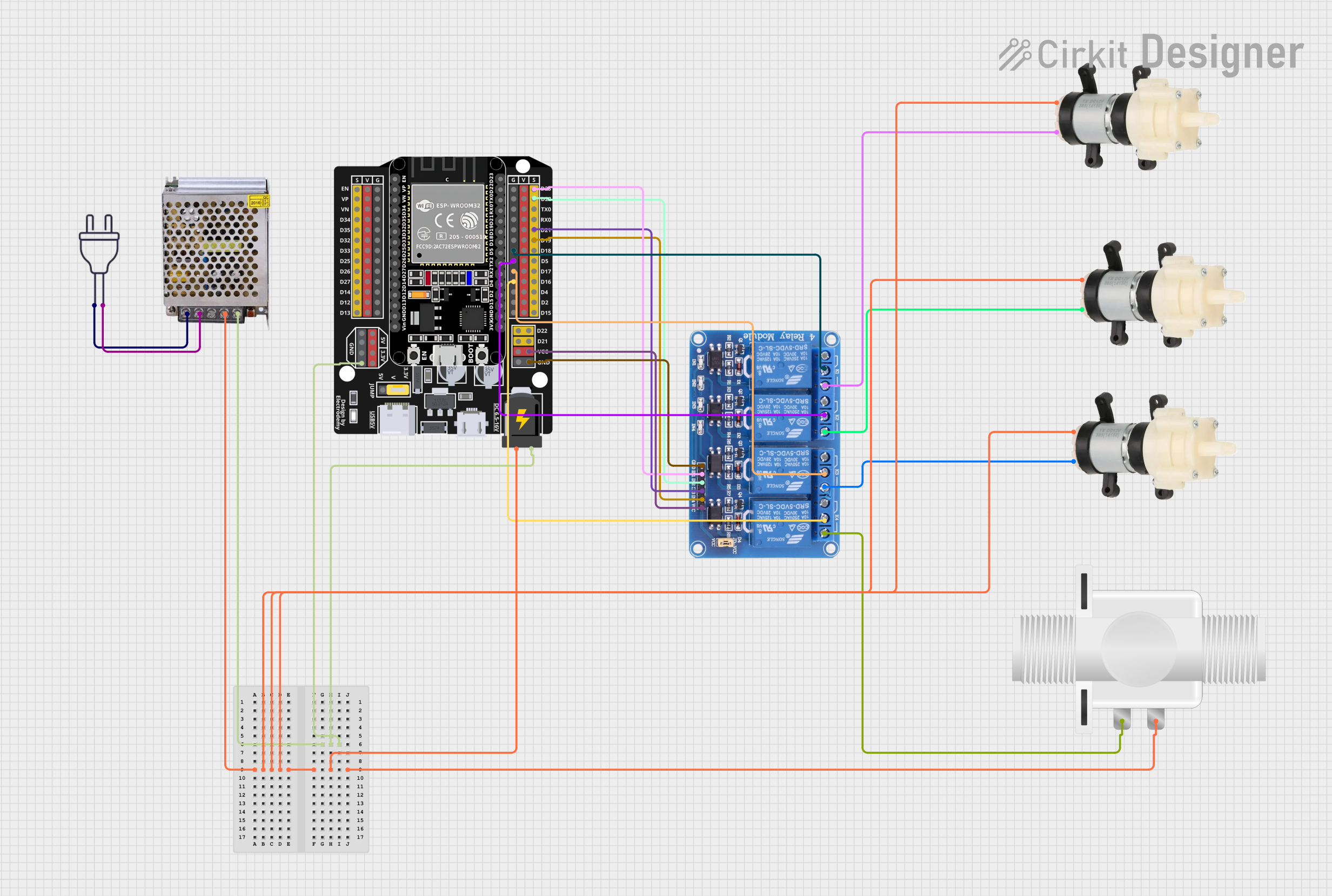

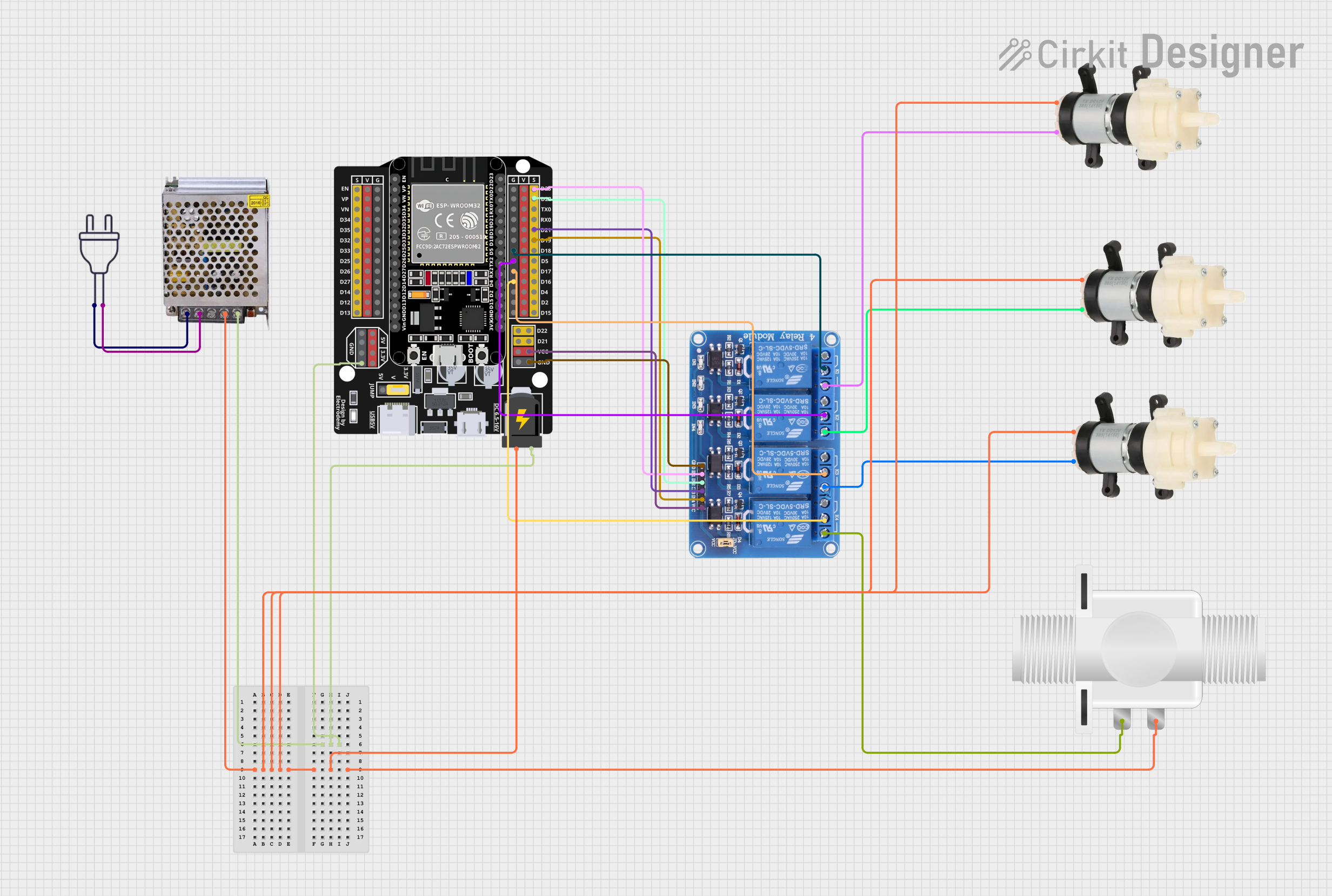

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Vacuum Pump - 12V

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Specifications:

- Operating Voltage: 12V DC

- Current Consumption: 400-600 mA (idle), up to 1A (under load)

- Vacuum Pressure: Up to 15 inHg

- Airflow: 13 L/min

- Operating Temperature: -5°C to 50°C

- Life Expectancy: 500 hours continuous use

Pin Configuration and Descriptions:

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Positive Supply (V+) | Connect to 12V DC power source |

| 2 | Ground (GND) | Connect to system ground |

Usage Instructions

Integration into a Circuit:

- Power Supply: Ensure that the vacuum pump is connected to a 12V DC power supply capable of delivering sufficient current (up to 1A under load).

- Polarity: Observe correct polarity when connecting the pump to the power source. The positive lead should be connected to the V+ pin and the negative lead to the GND pin.

- Switching: Use a relay or an appropriate transistor to switch the pump on and off. This will allow for control via a microcontroller such as an Arduino UNO.

- Protection: Incorporate a diode across the pump terminals to protect against voltage spikes when the pump is turned off (flyback diode).

Best Practices:

- Avoid running the pump continuously at high loads for extended periods to prevent overheating and to prolong its lifespan.

- Ensure that the pump is securely mounted to minimize vibrations and noise.

- Use appropriate tubing and fittings to ensure a good seal and to maintain the vacuum pressure.

Example Arduino Code

// Control a 12V Vacuum Pump with an Arduino UNO

const int pumpRelayPin = 2; // Relay connected to digital pin 2

void setup() {

pinMode(pumpRelayPin, OUTPUT); // Set the relay pin as an output

}

void loop() {

digitalWrite(pumpRelayPin, HIGH); // Turn on the vacuum pump

delay(10000); // Keep the pump on for 10 seconds

digitalWrite(pumpRelayPin, LOW); // Turn off the vacuum pump

delay(20000); // Wait for 20 seconds before the next cycle

}

Troubleshooting and FAQs

Common Issues:

- Pump does not start: Check the power supply and connections. Ensure the pump is receiving 12V and that the current rating is adequate.

- Insufficient vacuum pressure: Verify that all connections are airtight. Check for leaks in the system.

- Pump overheats: Reduce the duty cycle or provide additional cooling.

FAQs:

Q: Can I run the pump continuously? A: The pump is designed for intermittent use. Continuous operation at high loads may reduce its lifespan.

Q: What should I do if the pump is noisy? A: Ensure that the pump is securely mounted. Check for loose parts or obstructions in the pump.

Q: How do I control the vacuum pressure? A: The vacuum pressure can be controlled by modulating the power supply or by using a vacuum regulator in the system.

For further assistance, please refer to the manufacturer's datasheet or contact technical support.