How to Use gear motor: Examples, Pinouts, and Specs

Design with gear motor in Cirkit Designer

Design with gear motor in Cirkit DesignerIntroduction

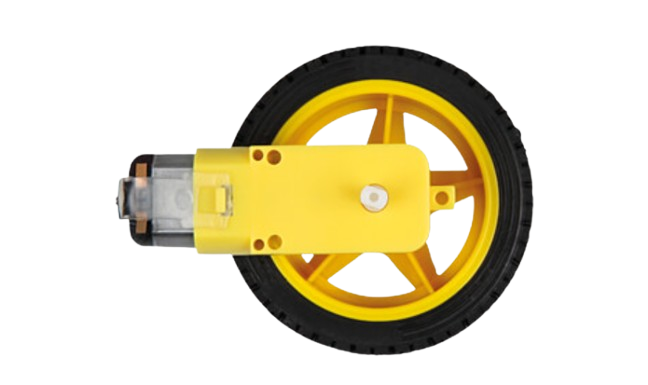

A gear motor is an electric motor integrated with a gear system to reduce speed and increase torque. This combination makes it ideal for applications requiring high torque at low speeds. Gear motors are widely used in robotics, conveyor systems, industrial machinery, and automotive applications. They are particularly valued for their ability to deliver precise motion control and high power efficiency.

Manufacturer: Rajesh Shah

Part ID: motor

Explore Projects Built with gear motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with gear motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the key technical details for the gear motor:

| Parameter | Value |

|---|---|

| Operating Voltage | 6V - 12V |

| Rated Torque | 5 kg·cm - 20 kg·cm |

| No-Load Speed | 30 RPM - 300 RPM |

| Gear Ratio | 10:1 to 100:1 (varies by model) |

| Current Consumption | 100 mA (no load) to 2 A (max load) |

| Shaft Diameter | 6 mm |

| Motor Type | Brushed DC Motor |

| Operating Temperature | -10°C to 50°C |

| Weight | 150 g |

Pin Configuration and Descriptions

The gear motor typically has two terminals for electrical connections. The table below describes the pin configuration:

| Pin | Description |

|---|---|

| Pin 1 | Positive terminal (+) for power input |

| Pin 2 | Negative terminal (-) for power input |

Usage Instructions

How to Use the Gear Motor in a Circuit

- Power Supply: Connect the gear motor to a DC power supply within the specified voltage range (6V - 12V). Ensure the power supply can provide sufficient current for the motor's load requirements.

- Polarity: The direction of rotation depends on the polarity of the power supply. Reversing the polarity will reverse the motor's rotation.

- Motor Driver: For precise control, use a motor driver (e.g., L298N or L293D) to interface the gear motor with a microcontroller like an Arduino UNO.

- Load Considerations: Avoid overloading the motor beyond its rated torque to prevent damage to the motor or gear system.

Important Considerations and Best Practices

- Avoid Stalling: Prolonged stalling can cause overheating and damage the motor.

- Use Proper Mounting: Secure the motor firmly to prevent vibrations or misalignment.

- Add a Flyback Diode: When using a motor driver, include a flyback diode to protect the circuit from voltage spikes caused by the motor's inductive load.

- Lubrication: Periodically check and lubricate the gear system to ensure smooth operation and longevity.

Example: Connecting the Gear Motor to an Arduino UNO

Below is an example of how to control the gear motor using an Arduino UNO and an L298N motor driver:

// Example: Controlling a gear motor with Arduino UNO and L298N motor driver

// Define motor control pins

const int motorPin1 = 9; // IN1 on L298N

const int motorPin2 = 10; // IN2 on L298N

const int enablePin = 11; // ENA on L298N

void setup() {

// Set motor control pins as outputs

pinMode(motorPin1, OUTPUT);

pinMode(motorPin2, OUTPUT);

pinMode(enablePin, OUTPUT);

// Initialize motor in stopped state

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

analogWrite(enablePin, 0); // Set speed to 0

}

void loop() {

// Rotate motor forward at 50% speed

digitalWrite(motorPin1, HIGH);

digitalWrite(motorPin2, LOW);

analogWrite(enablePin, 128); // Speed range: 0 (stopped) to 255 (full speed)

delay(3000); // Run for 3 seconds

// Stop the motor

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

analogWrite(enablePin, 0);

delay(1000); // Pause for 1 second

// Rotate motor backward at 75% speed

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, HIGH);

analogWrite(enablePin, 192); // Speed range: 0 (stopped) to 255 (full speed)

delay(3000); // Run for 3 seconds

// Stop the motor

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

analogWrite(enablePin, 0);

delay(1000); // Pause for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Rotate:

- Cause: Insufficient power supply or incorrect wiring.

- Solution: Verify the power supply voltage and current. Check the wiring connections.

Motor Overheats:

- Cause: Overloading or prolonged stalling.

- Solution: Reduce the load on the motor. Ensure the motor is not stalled for extended periods.

Motor Rotates in the Wrong Direction:

- Cause: Incorrect polarity of the power supply.

- Solution: Reverse the polarity of the power supply or adjust the motor driver control signals.

Noisy Operation:

- Cause: Worn-out gears or lack of lubrication.

- Solution: Inspect the gear system and apply appropriate lubrication.

FAQs

Q: Can I use the gear motor with a 5V power supply?

A: No, the motor requires a minimum of 6V for proper operation. Using a 5V supply may result in insufficient torque or failure to start.Q: How do I calculate the required torque for my application?

A: Determine the load's weight and the distance from the motor's shaft. Use the formula:

Torque (kg·cm) = Load (kg) × Distance (cm).Q: Can I control the speed of the gear motor?

A: Yes, you can control the speed using PWM (Pulse Width Modulation) signals from a motor driver or microcontroller.Q: Is the gear motor waterproof?

A: No, this gear motor is not waterproof. Avoid exposing it to water or moisture.

By following this documentation, you can effectively use and maintain the gear motor for various applications.