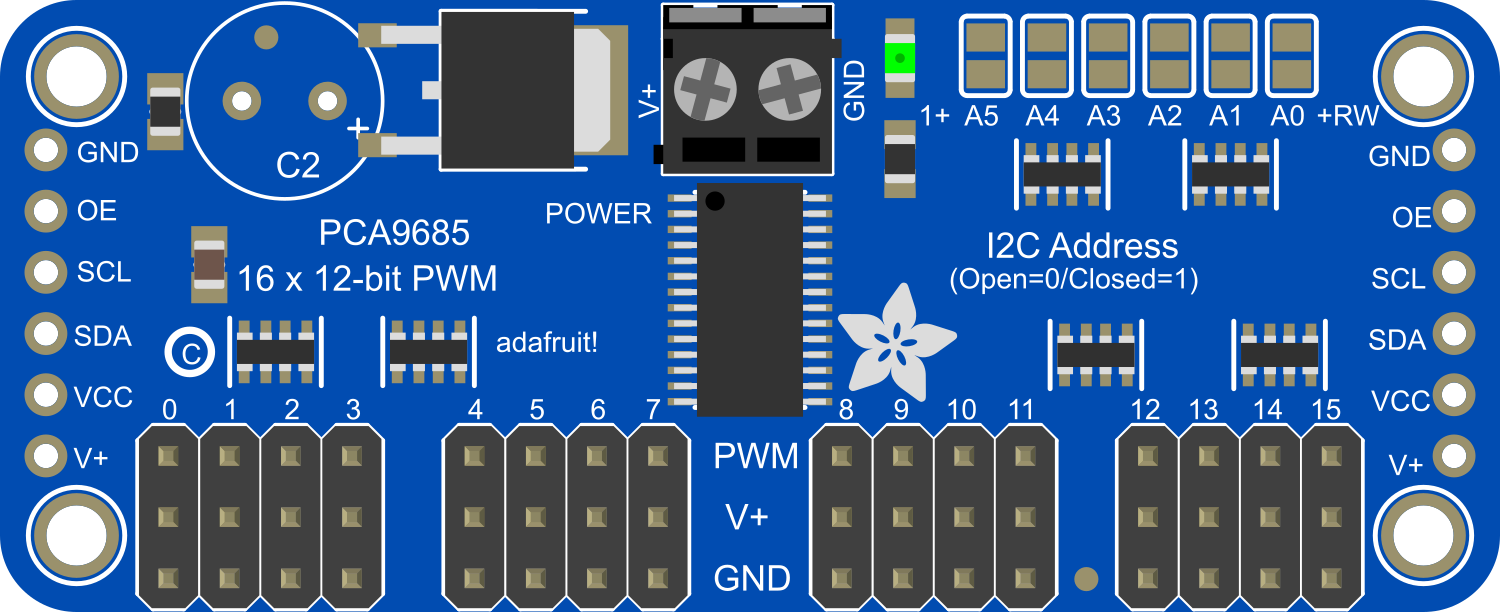

How to Use Adafruit PCA9685 PWM Servo Breakout: Examples, Pinouts, and Specs

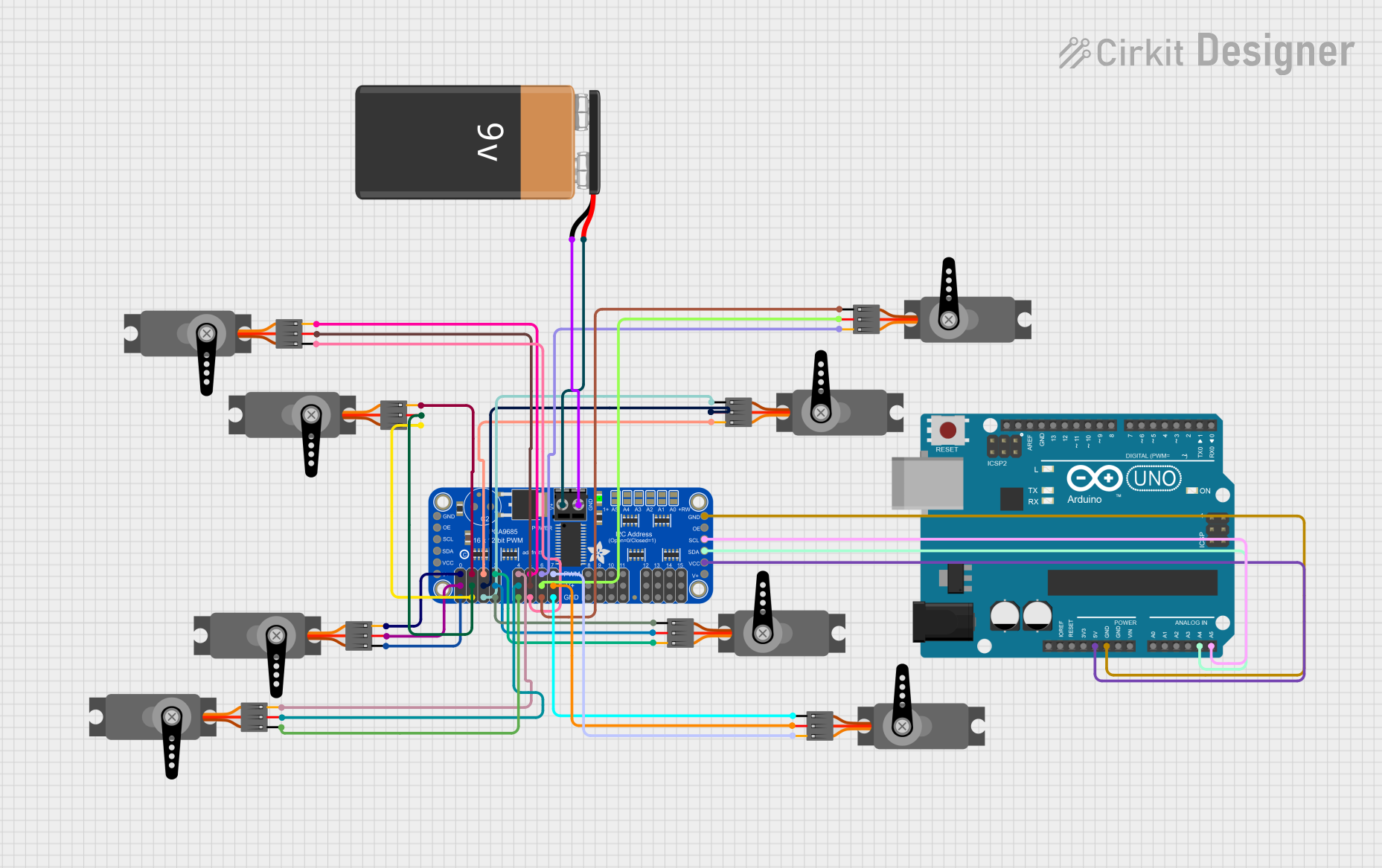

Design with Adafruit PCA9685 PWM Servo Breakout in Cirkit Designer

Design with Adafruit PCA9685 PWM Servo Breakout in Cirkit DesignerIntroduction

The Adafruit PCA9685 PWM Servo Breakout is a versatile and user-friendly breakout board based on the PCA9685 PWM driver IC. It enables the control of up to 16 servos or PWM outputs through just two pins (SDA and SCL) from a microcontroller, such as an Arduino UNO. This component is ideal for robotics, animatronics, lighting control, and any application requiring multiple PWM outputs. It supports both 3.3V and 5V logic levels, making it compatible with a wide range of microcontrollers.

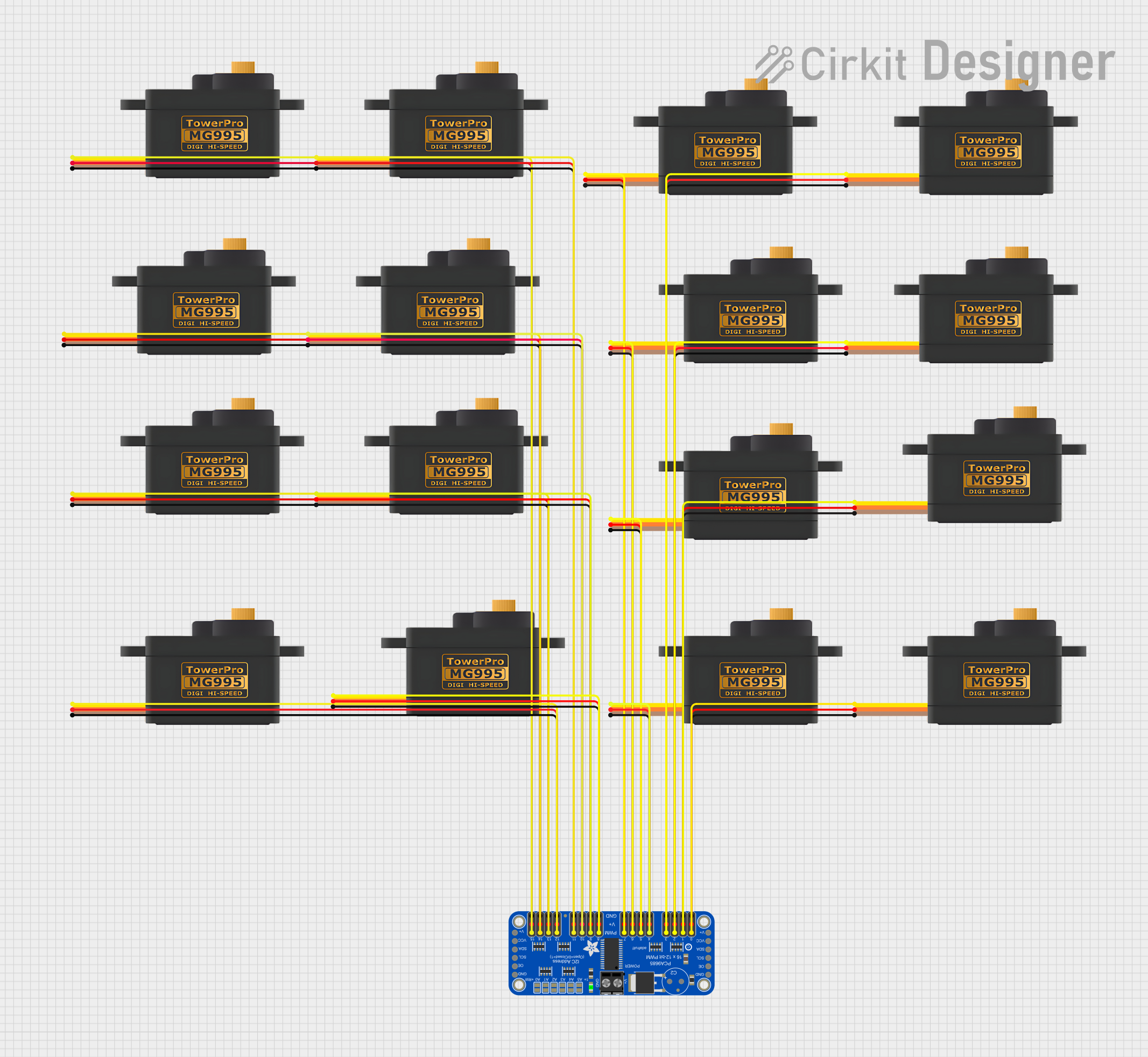

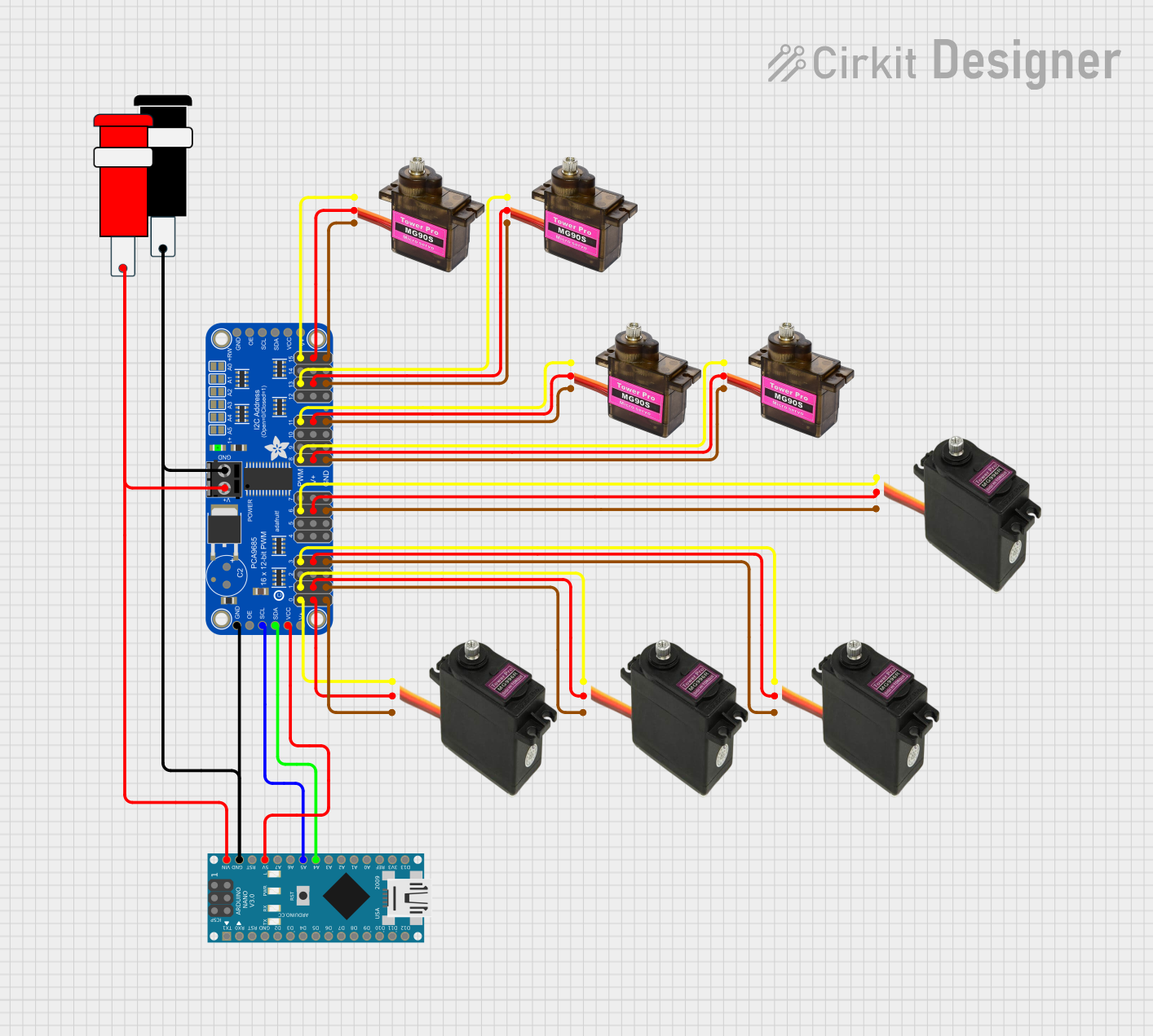

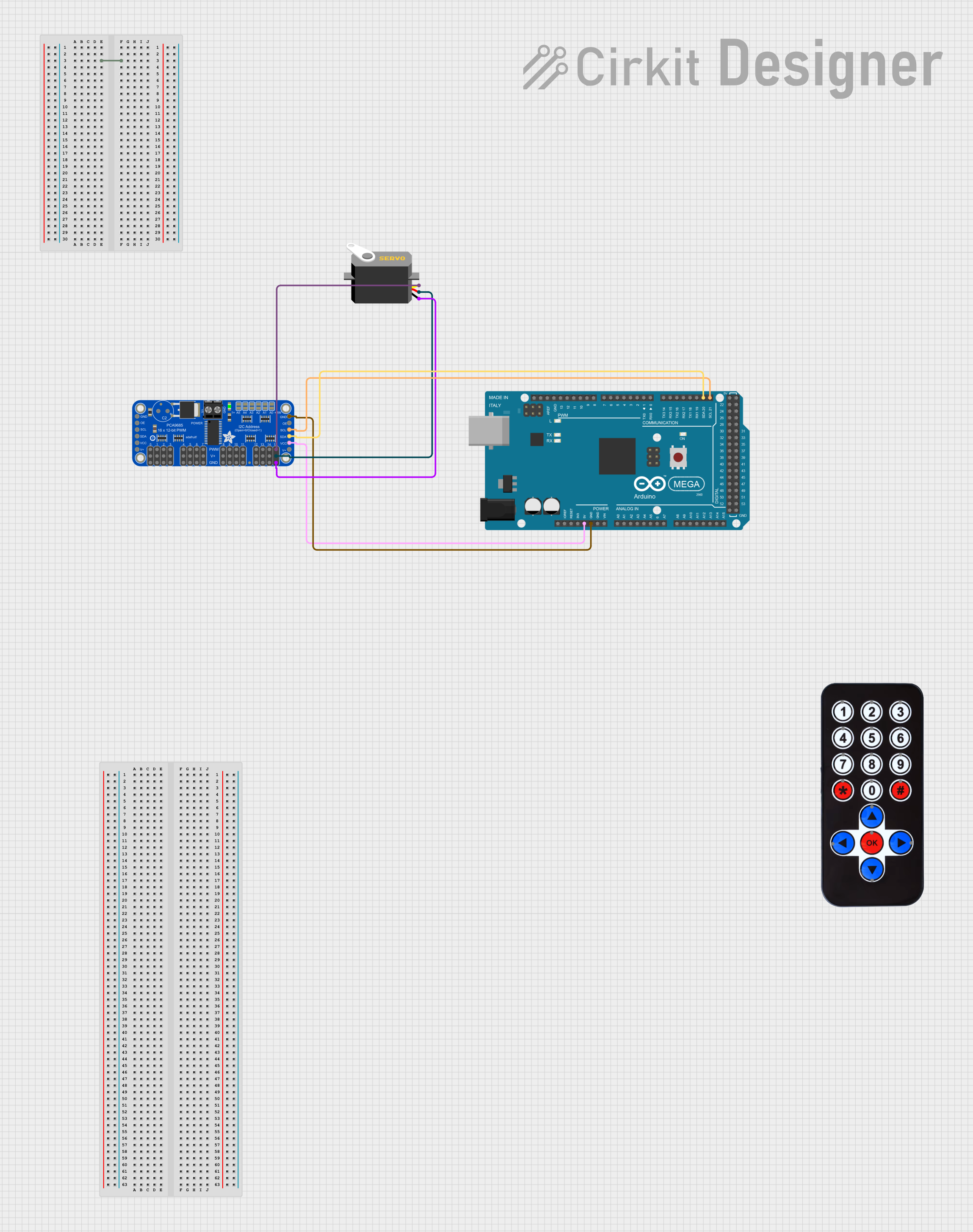

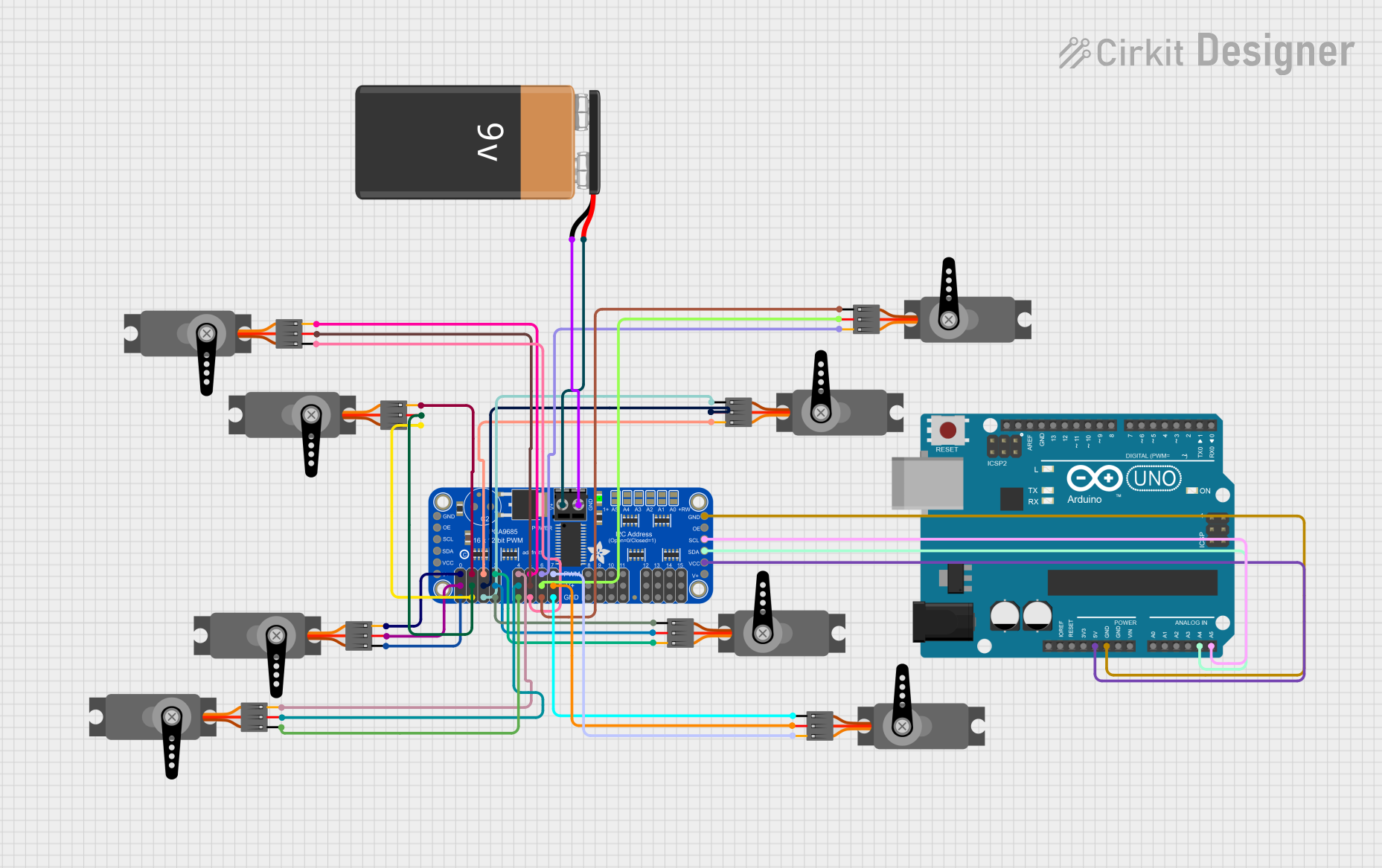

Explore Projects Built with Adafruit PCA9685 PWM Servo Breakout

Open Project in Cirkit Designer

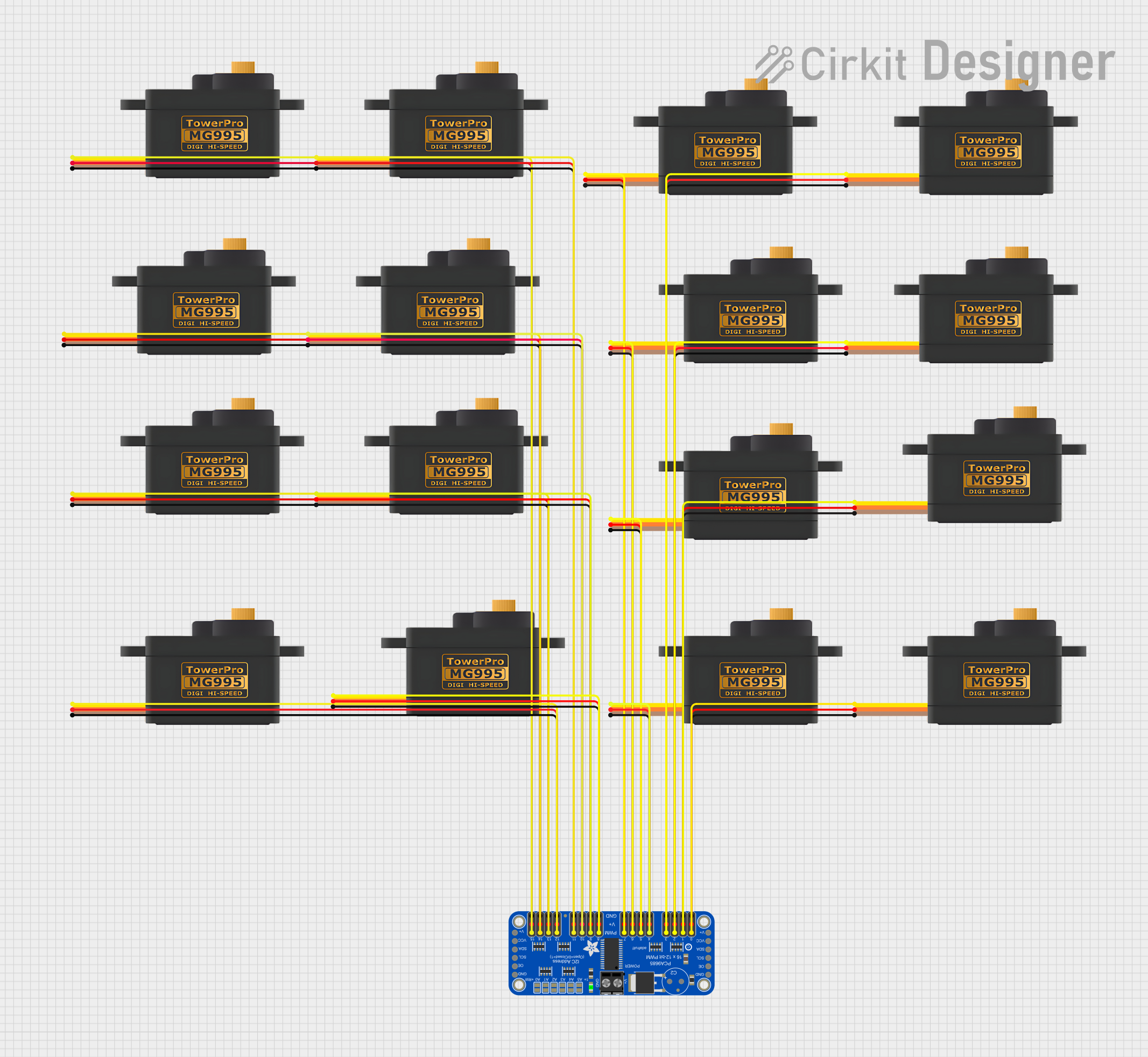

Open Project in Cirkit Designer

Open Project in Cirkit Designer

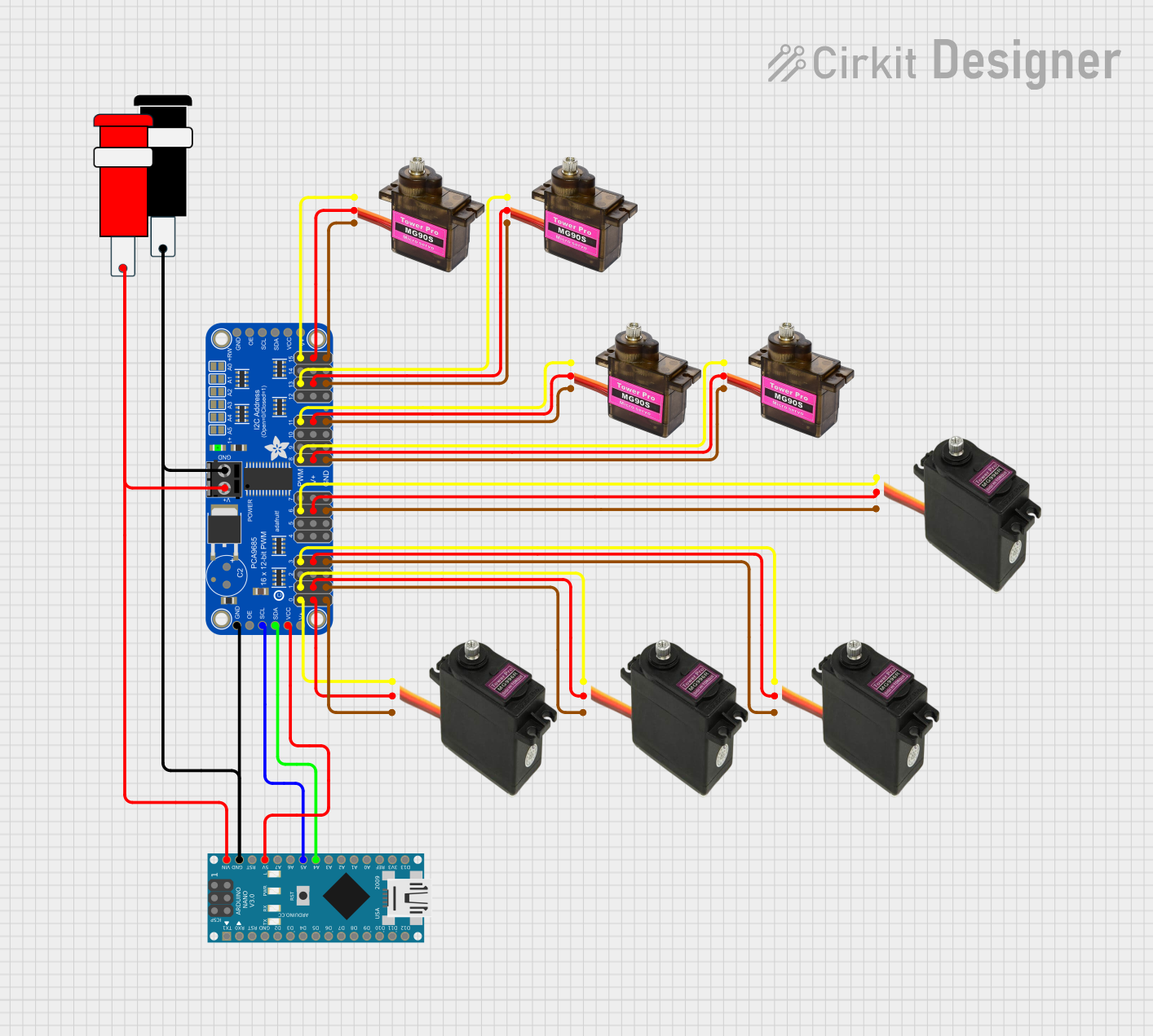

Open Project in Cirkit Designer

Open Project in Cirkit Designer

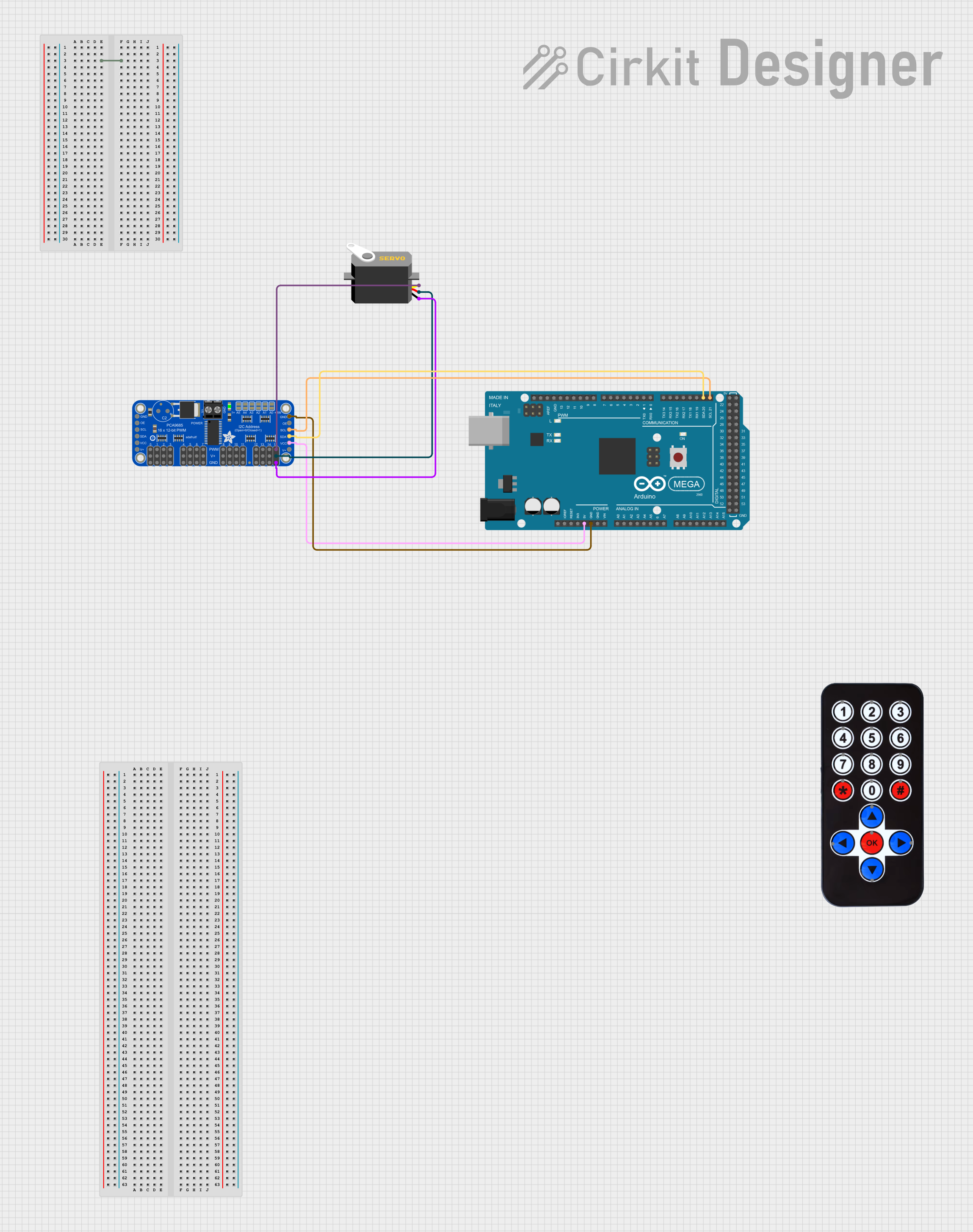

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Adafruit PCA9685 PWM Servo Breakout

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Control multiple servo motors for articulated movement.

- LED lighting: Drive multiple channels of LEDs with dimming control.

- Animatronics: Precise movement control for animatronic figures.

- Drones: Manage multiple motors for flight control systems.

Technical Specifications

Key Technical Details

- Voltage Supply: 5V to 6V (VCC pin)

- Logic Voltage: 3.3V or 5V compatible

- Output Channels: 16 PWM outputs

- Frequency Range: 40Hz to 1000Hz

- Resolution: 12-bit (4096 steps)

- Interface: I2C

- I2C Address: Selectable between 0x40-0x7F (62 addresses)

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply for the PCA9685 and servo motors (5-6V) |

| 2 | GND | Ground connection |

| 3 | SDA | I2C data line |

| 4 | SCL | I2C clock line |

| 5-20 | PWM0-15 | PWM output channels for servos or LEDs |

| 21 | OE | Output enable (active low) |

| 22 | EXTCLK | External clock input (optional) |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect a 5V to 6V power supply to the VCC and GND pins. Ensure that the power supply can handle the current requirements of all connected servos or LEDs.

- I2C Connection: Connect the SDA and SCL pins to the corresponding I2C pins on your microcontroller.

- PWM Outputs: Connect the PWM outputs to your servos or LEDs. Make sure to match the signal, power, and ground wires correctly.

- Address Selection: If using multiple PCA9685 boards, set unique I2C addresses using the address jumpers on the board.

Important Considerations and Best Practices

- Always provide a common ground between the PCA9685 board and the microcontroller.

- Avoid long wires to reduce noise and potential signal degradation.

- When driving a large number of servos, ensure the power supply can handle the peak current.

- Use decoupling capacitors close to the board to stabilize the power supply if necessary.

Example Code for Arduino UNO

#include <Wire.h>

#include <Adafruit_PWMServoDriver.h>

// Called this way, it uses the default address 0x40

Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver();

void setup() {

Serial.begin(9600);

Serial.println("16 channel PWM test!");

pwm.begin();

pwm.setPWMFreq(60); // Analog servos run at ~60 Hz updates

delay(10);

}

void loop() {

// Sweep all servos back and forth

for (uint16_t pulselen = SERVOMIN; pulselen < SERVOMAX; pulselen++) {

for (uint8_t i = 0; i < 16; i++) {

pwm.setPWM(i, 0, pulselen);

}

}

delay(500);

for (uint16_t pulselen = SERVOMAX; pulselen > SERVOMIN; pulselen--) {

for (uint8_t i = 0; i < 16; i++) {

pwm.setPWM(i, 0, pulselen);

}

}

delay(500);

}

Note: Before using the above code, define SERVOMIN and SERVOMAX according to the specifications of the servos you are using.

Troubleshooting and FAQs

Common Issues Users Might Face

- Servos not responding: Check the power supply and wiring. Ensure that the I2C address is correctly set if using multiple PCA9685 boards.

- Inaccurate servo movement: Calibrate

SERVOMINandSERVOMAXvalues to match the servo's specifications. - LEDs not dimming smoothly: Verify the PWM frequency and ensure it is suitable for the LEDs being used.

Solutions and Tips for Troubleshooting

- Double-check all connections and ensure that the power supply is adequate.

- Use the I2C scanner sketch to confirm the PCA9685 is detected on the I2C bus.

- Review the datasheet of the servos or LEDs to ensure compatibility with the PCA9685's voltage and current specifications.

FAQs

Q: Can I chain multiple PCA9685 boards together? A: Yes, you can connect multiple boards to the same I2C bus by setting a unique address for each board using the address jumpers.

Q: What is the maximum number of servos I can control with one PCA9685 board? A: You can control up to 16 servos per board.

Q: Can I use this board with a Raspberry Pi or other single-board computers? A: Yes, the PCA9685 is compatible with any microcontroller or single-board computer that supports I2C communication.

Q: How do I set a specific PWM frequency?

A: Use the setPWMFreq() function in your code to set the desired frequency. The frequency range is 40Hz to 1000Hz.